Fans

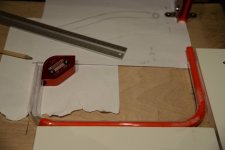

Remember the "interesting" design of the radiator/fan mounting plates, where there are bars going across that don't match the spacing of either 120mm or 140mm fans?

As predicted, when I mounted the fans and a radiator on these as a test there was awful fan noise even at fairly low speeds. It was a buzzy, chopping sound and my guess is that it was caused by the fans blades rotating so close the the bars. My solution was to get the Dremel out.

A quick test on the rough result was much quieter. I need to finish off the Dremel cuts with a file in places to neaten things up.

Three fans back in, and it's not looking too bad.

I'm using an EK-WB Splitty so that I only have to have one fan cable going from each radiator to the Aquaero. Slightly overkill as it can run accommodate 9 fans but I guess it gives me expansion room if I want to go to push-pull in the future.

I trimmed the fan cables and crimped new terminals on to neaten up the cables.

Remember the "interesting" design of the radiator/fan mounting plates, where there are bars going across that don't match the spacing of either 120mm or 140mm fans?

As predicted, when I mounted the fans and a radiator on these as a test there was awful fan noise even at fairly low speeds. It was a buzzy, chopping sound and my guess is that it was caused by the fans blades rotating so close the the bars. My solution was to get the Dremel out.

A quick test on the rough result was much quieter. I need to finish off the Dremel cuts with a file in places to neaten things up.

Three fans back in, and it's not looking too bad.

I'm using an EK-WB Splitty so that I only have to have one fan cable going from each radiator to the Aquaero. Slightly overkill as it can run accommodate 9 fans but I guess it gives me expansion room if I want to go to push-pull in the future.

I trimmed the fan cables and crimped new terminals on to neaten up the cables.