Deleted User 298457

Deleted User 298457

Hi folk,

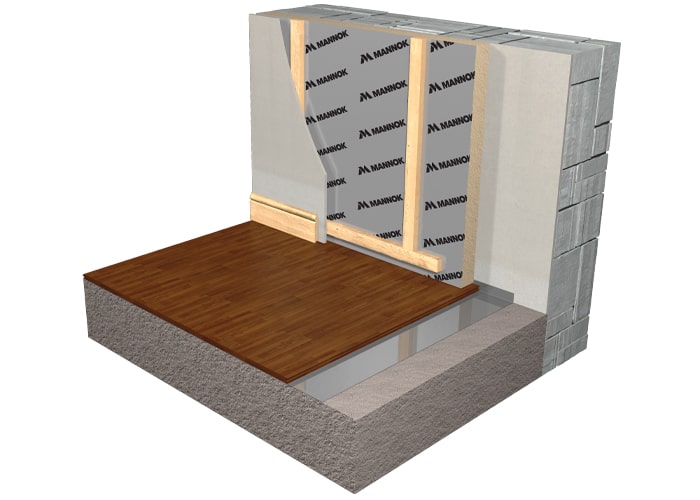

I have a 1930s semi as some of you are aware. To get to the end-state I have in mind, I need to lift a lot of floorboards and remove pretty much all of the skirting - upstairs, and down stairs. I am placing PIR board between the joists.

Givens:

* Air bricks will be cleaned thoroughly and ducts put in place where they are ineffective (I have some that are at skirting board level, so barely get "under the floor")

My questions relate to therefore...

* Q1 How "sealed" should the 'surface floor' (i.e. the boards I will place the proper hardwood floor on top of) be to the surrounding walls?

--- I get loads of draughts from the edges, and the current carpet is black around the perimeter due to draught (...and being 30 years old).

--- Can I butt the floor right up to the wall, or is this a problem?

--- Related to Q2 as well, but can I plaster "down to the surface" floor, or should there be a gap behind the skirting where it touches the floor?

* Q2 Plaster needs replacing -- I am reading conflicting things on how important it is for these 1930s solid walls to breath, and what types of plaster to use - as it could have been a lime+gypsum blend anyway. The walls are currently plastered in a mix of stuff, pics below.

The walls are mostly papered, but as you can see from picture 3 - the wall paper pretty much pulled away with limited effort.

Floor pics: https://i.imgur.com/IF9zZWz.jpg

* Q3 When I do the PIR I have some areas where it just isn't practical to cut a piece of PIR and slot it in (or maybe I just need to perservere?) E.g. in this pciture the joist by the radiator is about 3cm from the wall. Can I fill this gap with expanding foam?

* Q4 I also bought silver tape --- is there any merit in taping over the top of the joists/from PIR board to PIR board? This means only "foil" would be in contact with the floor above it?

* Q5 Some of the boards are battered due to how dry they were when they came up --- I can either drill down what is left of them, replace with chipboard (like I was forced to do in the hall), or get replacement boards from Wickes (need to price up). I guess if I am doing a hardwood floor I may want to throw some giant sheets of Plywood down anyway to get a perfect surface?

Thank you!

I have a 1930s semi as some of you are aware. To get to the end-state I have in mind, I need to lift a lot of floorboards and remove pretty much all of the skirting - upstairs, and down stairs. I am placing PIR board between the joists.

Givens:

* Air bricks will be cleaned thoroughly and ducts put in place where they are ineffective (I have some that are at skirting board level, so barely get "under the floor")

My questions relate to therefore...

* Q1 How "sealed" should the 'surface floor' (i.e. the boards I will place the proper hardwood floor on top of) be to the surrounding walls?

--- I get loads of draughts from the edges, and the current carpet is black around the perimeter due to draught (...and being 30 years old).

--- Can I butt the floor right up to the wall, or is this a problem?

--- Related to Q2 as well, but can I plaster "down to the surface" floor, or should there be a gap behind the skirting where it touches the floor?

* Q2 Plaster needs replacing -- I am reading conflicting things on how important it is for these 1930s solid walls to breath, and what types of plaster to use - as it could have been a lime+gypsum blend anyway. The walls are currently plastered in a mix of stuff, pics below.

The walls are mostly papered, but as you can see from picture 3 - the wall paper pretty much pulled away with limited effort.

Floor pics: https://i.imgur.com/IF9zZWz.jpg

* Q3 When I do the PIR I have some areas where it just isn't practical to cut a piece of PIR and slot it in (or maybe I just need to perservere?) E.g. in this pciture the joist by the radiator is about 3cm from the wall. Can I fill this gap with expanding foam?

* Q4 I also bought silver tape --- is there any merit in taping over the top of the joists/from PIR board to PIR board? This means only "foil" would be in contact with the floor above it?

* Q5 Some of the boards are battered due to how dry they were when they came up --- I can either drill down what is left of them, replace with chipboard (like I was forced to do in the hall), or get replacement boards from Wickes (need to price up). I guess if I am doing a hardwood floor I may want to throw some giant sheets of Plywood down anyway to get a perfect surface?

Thank you!

Last edited by a moderator: