Associate

- Joined

- 1 Apr 2013

- Posts

- 38

Hey folks,

Started a new build about 3 weeks ago, been slow going and taking my time with it.

Changed over from a Mountain mods UFO case, massive case and took up a lot of room.

Hardware:

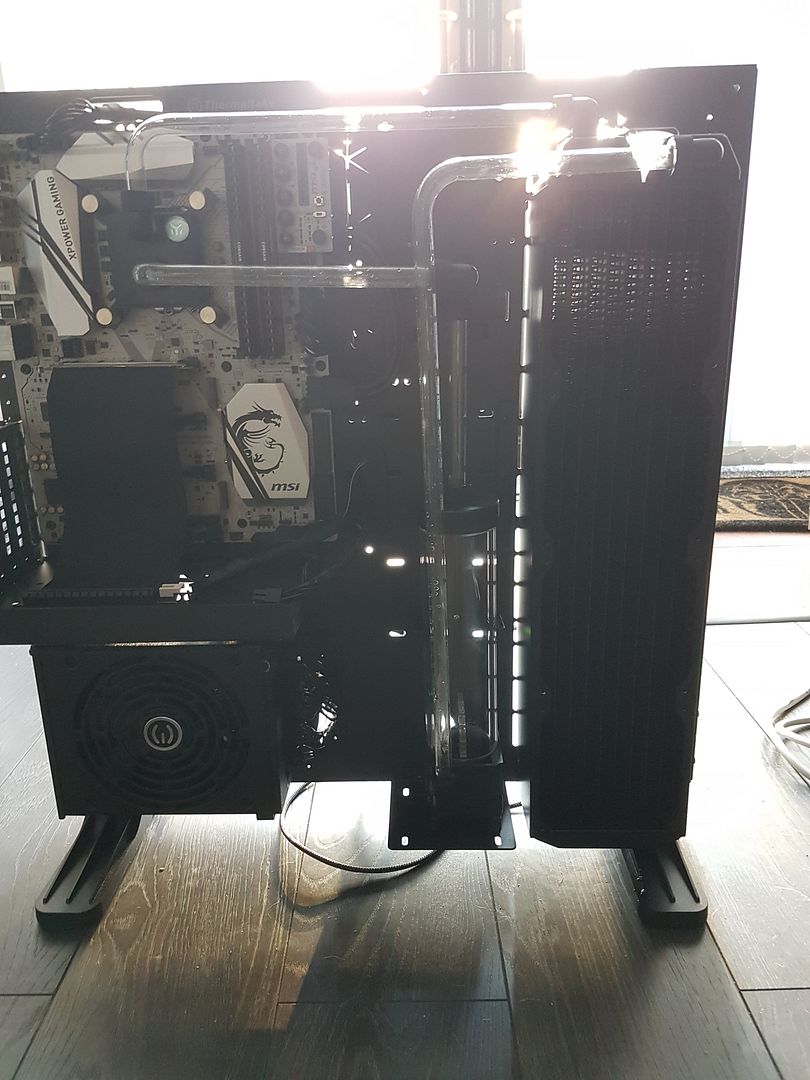

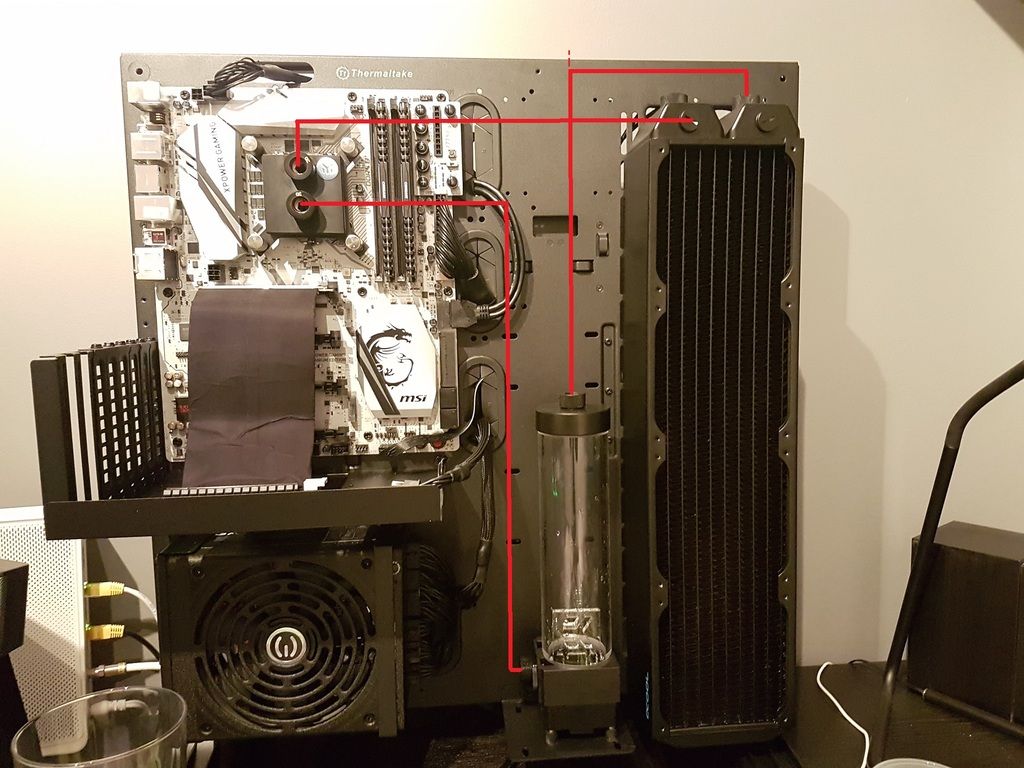

Case: TT Core P5

Mobo: MSI Z170A Titanium

CPU: I7 Skylake 6700k

RAM: Corsair Vengence DDR4 16gb

GPU: (for now) GTX 780Ti

HDD: Samsung Evo 500gb SSD - Seagate 2.0Tb HDD

PSU: EVGA 850 G2 Gold

Watercooling Gear

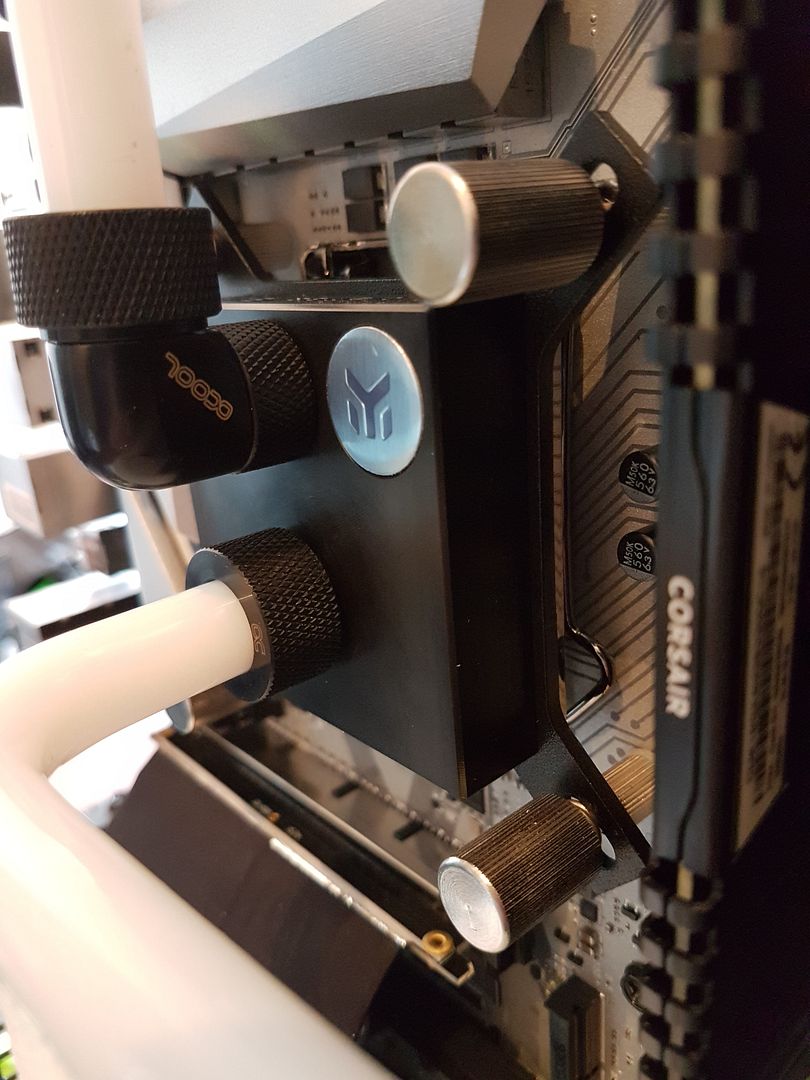

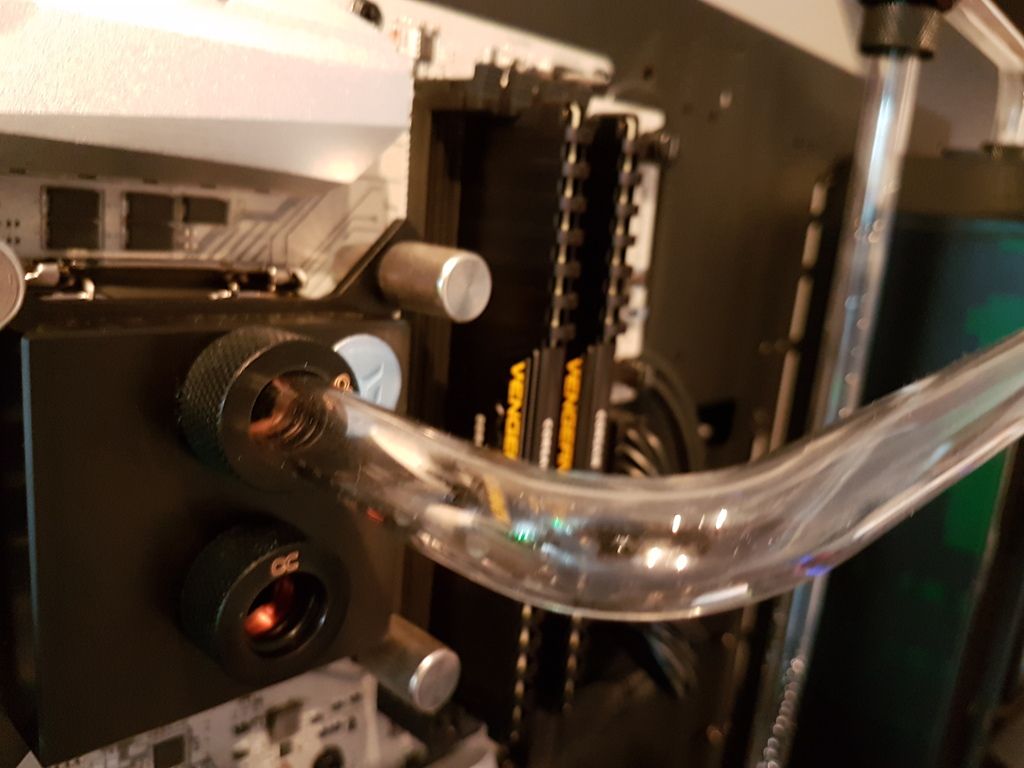

CPU: EK Water Blocks EK-Supremacy EVO - Acetal+Nickel

Rad: Alphacool 480 Monsta

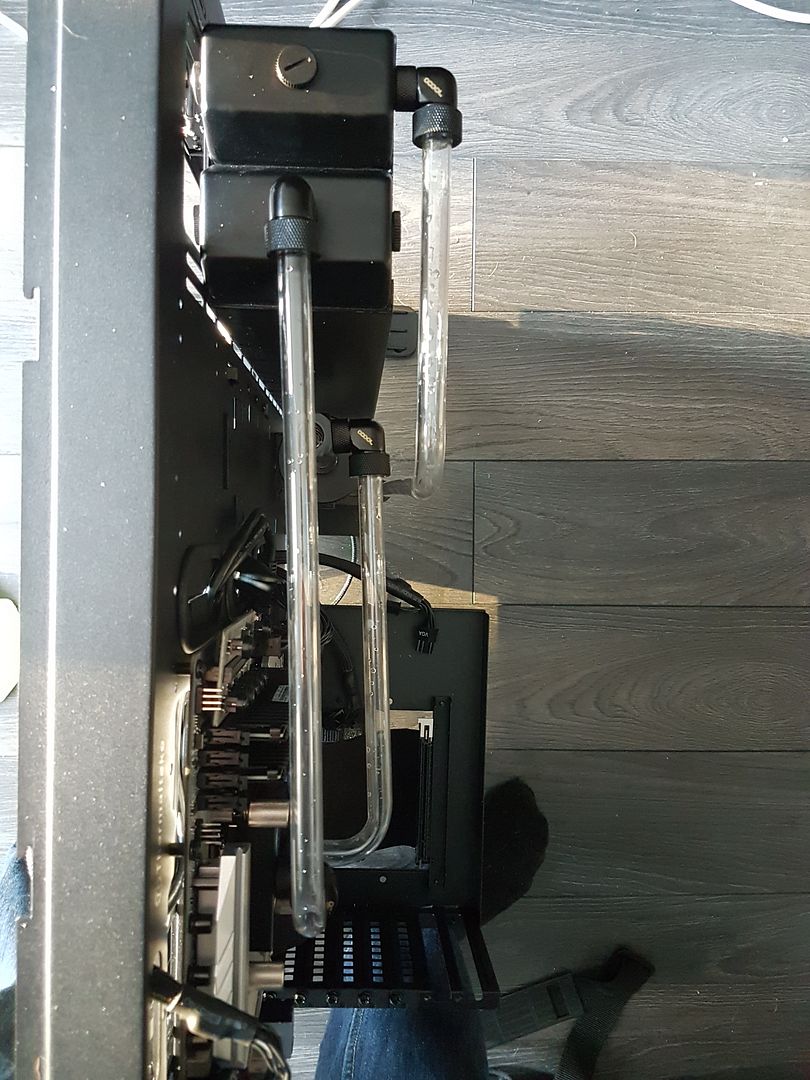

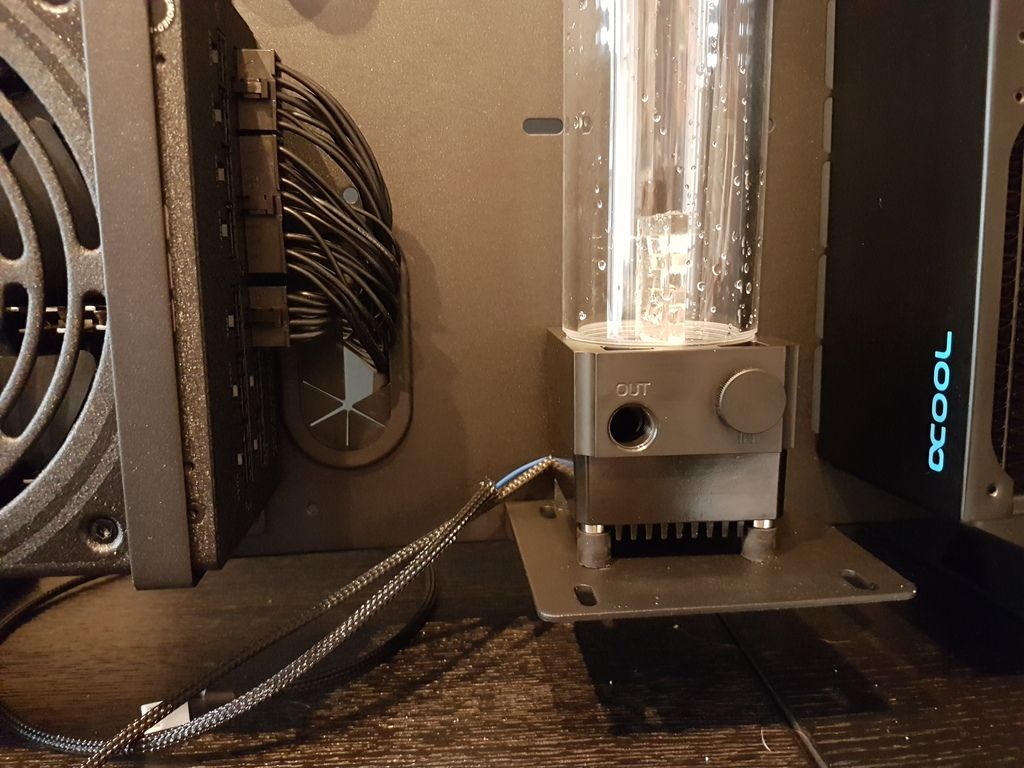

Pump/res: DDC Liang with EK X3 pump 100 res (replaced 100 res with X3 250) EK heatsink for DDC.

Fittings:Alphacool HT 13mm Compression Fitting G1/4 For Plexi/Brass

Tubing:Alphacool HardTube 13/10mm Plexi Clear.

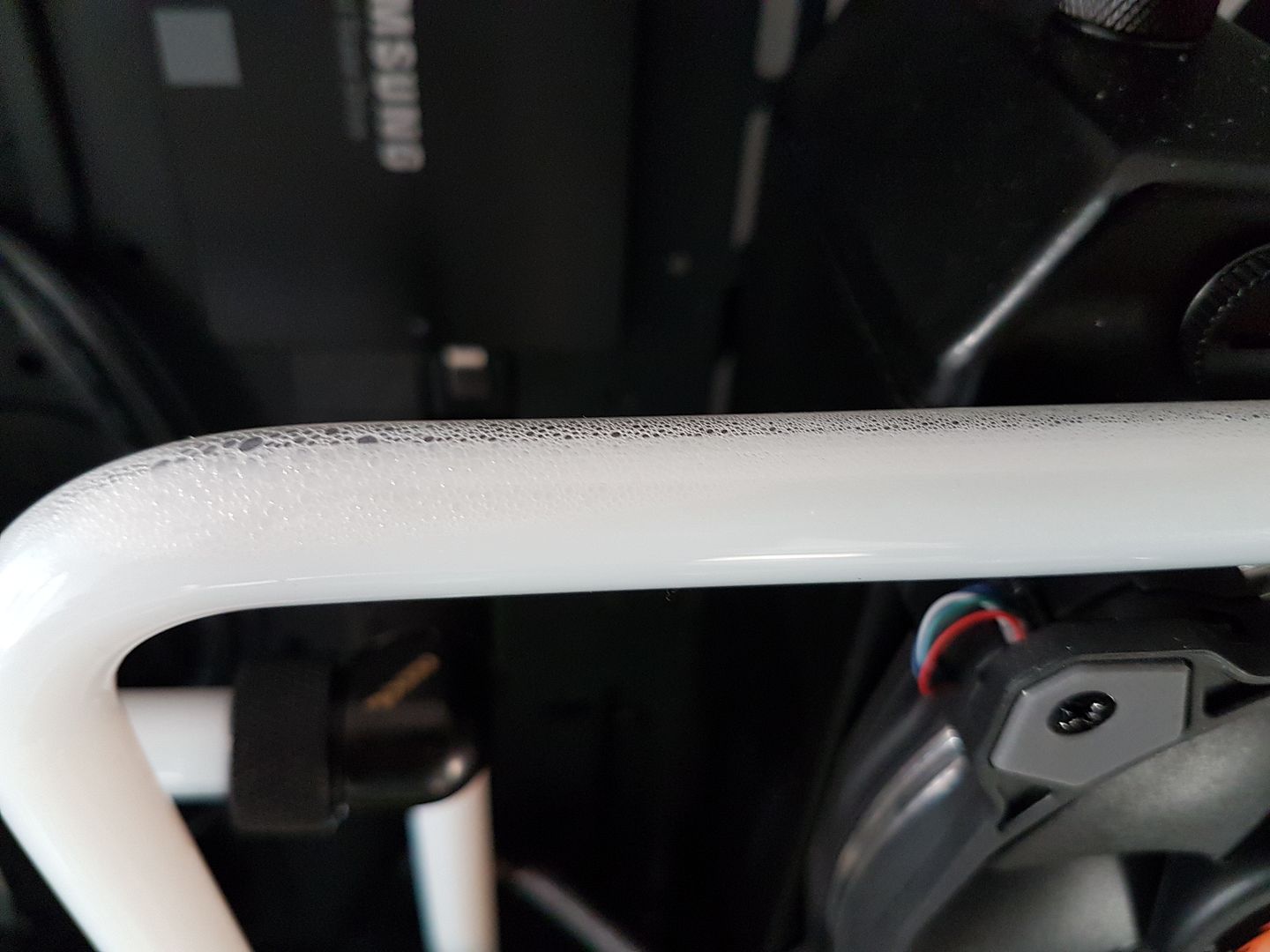

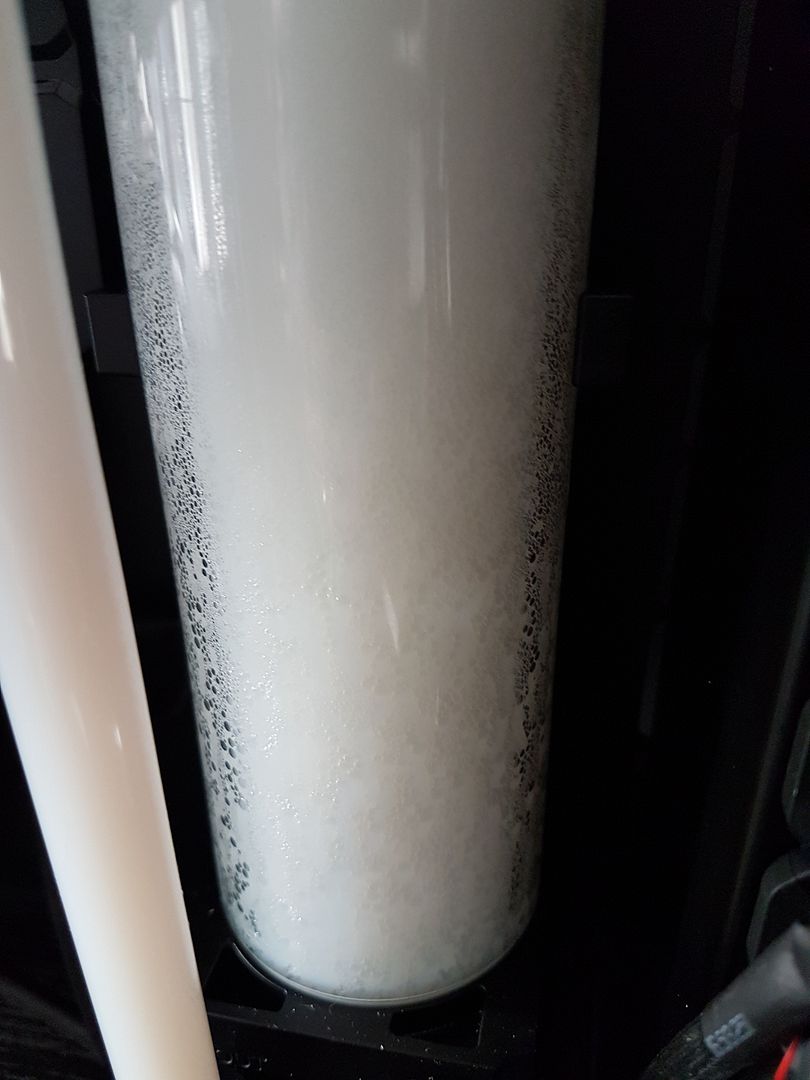

Coolant: Mayhems Pastel Ice white.

As it comes.

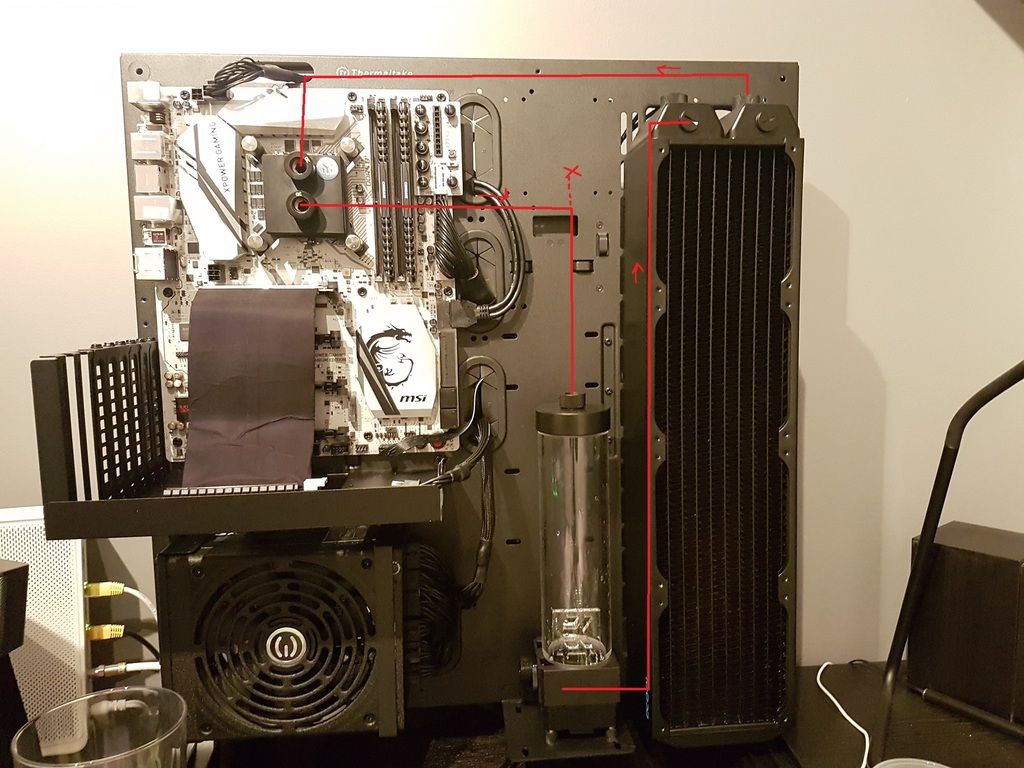

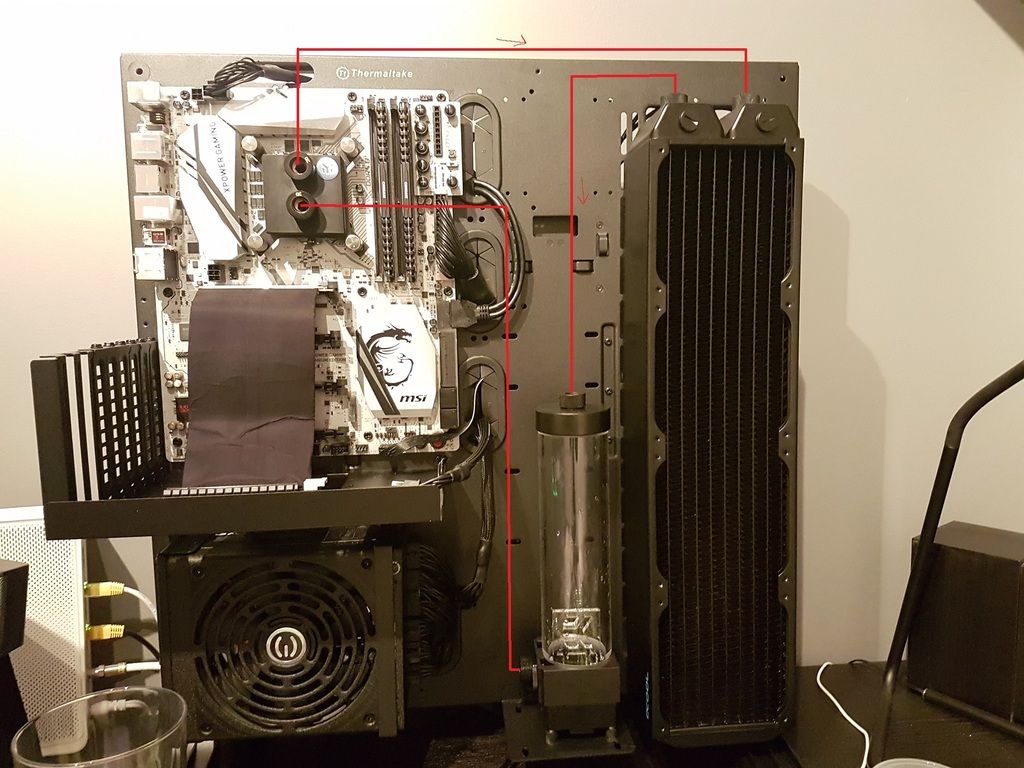

Heres a few pics of progress so far:

Started a new build about 3 weeks ago, been slow going and taking my time with it.

Changed over from a Mountain mods UFO case, massive case and took up a lot of room.

Hardware:

Case: TT Core P5

Mobo: MSI Z170A Titanium

CPU: I7 Skylake 6700k

RAM: Corsair Vengence DDR4 16gb

GPU: (for now) GTX 780Ti

HDD: Samsung Evo 500gb SSD - Seagate 2.0Tb HDD

PSU: EVGA 850 G2 Gold

Watercooling Gear

CPU: EK Water Blocks EK-Supremacy EVO - Acetal+Nickel

Rad: Alphacool 480 Monsta

Pump/res: DDC Liang with EK X3 pump 100 res (replaced 100 res with X3 250) EK heatsink for DDC.

Fittings:Alphacool HT 13mm Compression Fitting G1/4 For Plexi/Brass

Tubing:Alphacool HardTube 13/10mm Plexi Clear.

Coolant: Mayhems Pastel Ice white.

As it comes.

Heres a few pics of progress so far:

)

)

You could put T piece directly onto the top of the res though - and then fill with a funnel and a piece of tubing. Optionally with a fitting on the end if you have one spare. You can either split the rising tube and have the T some way up it but that would need two fittings. You could also get a male to male connection and screw it directly onto the top. A rotary male to male would let you choose which direction the T port faces.

You could put T piece directly onto the top of the res though - and then fill with a funnel and a piece of tubing. Optionally with a fitting on the end if you have one spare. You can either split the rising tube and have the T some way up it but that would need two fittings. You could also get a male to male connection and screw it directly onto the top. A rotary male to male would let you choose which direction the T port faces.