Application Notes -Amount of Applied Compound

There is always some debate on the amount of applied compound to use, our approach is based on a best to worst case scenario with a one size fits all so the user can experience best odds of a successful mount out of the gate without having to redo his mount.

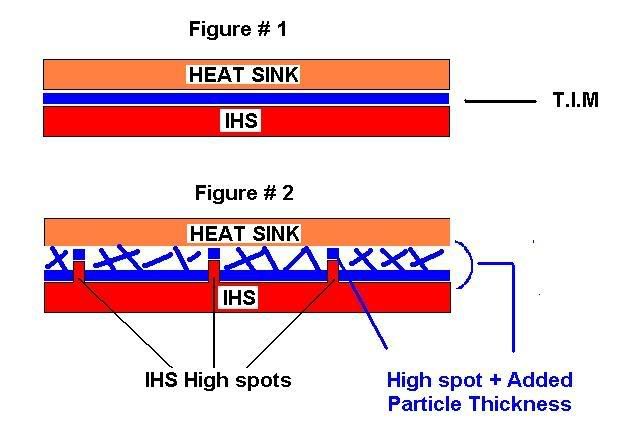

Say that Intel has a spec of Flat and parallel // to .002. - At the extreme end you get something like the 2 images of the candidate below, to fill that gap/volume you need .05 ml volume of compound for a 30mm X 30mm area about the

size of a grain of rice.

At Innovation we view the rice method differently. We understand that while many heat sink bases are good some can be off as much as the IHS and to cover the contingency of irregular contour on both sink & IHS and since as few as 5% of users lap to correct irregular contour problems and fewer still lap to perfection, IC Diamond adds another .05 ml to compensate for a total of 0.1 ml.

Another factor associated with irregular contours is another mil or two layer of compound is added on the high spots depending on the pressure applied. To fill that gap we add another .05 ml for a total recommended amount of 1.5 ml which approx. equals our 5-5.5mm size bead on center.

Thermal compound is a volume application to fill gaps, not one of weight, liquid spread-ability etc. and our opinion is that whatever the compound, you still need the equivalent volume to close that gap.

Additionally, it is important to apply enough compound, because as the paste thins as it spreads it reaches a maximum zone where air is reformed into the paste application between the sink and his leading to decreased performance and early compound failure

http://innovationcooling.com/applicationinstructions.htm

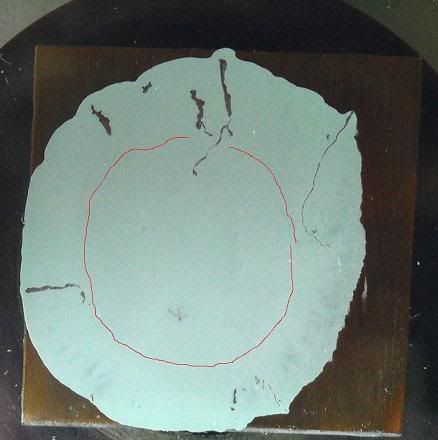

This is one our competitors compounds - high liquid, low viscosity with the recommended rice size

This is the same application under a glass slide and you can see where air has been introduced into the joint.

Note the darkened halo/spots from about 3 o' clock to 8 o'clock, those are air bubbles obscured with a thin coat of paste.

Under heat and pressure the air expands displacing the compound leading to early compound failure and looks something like this...