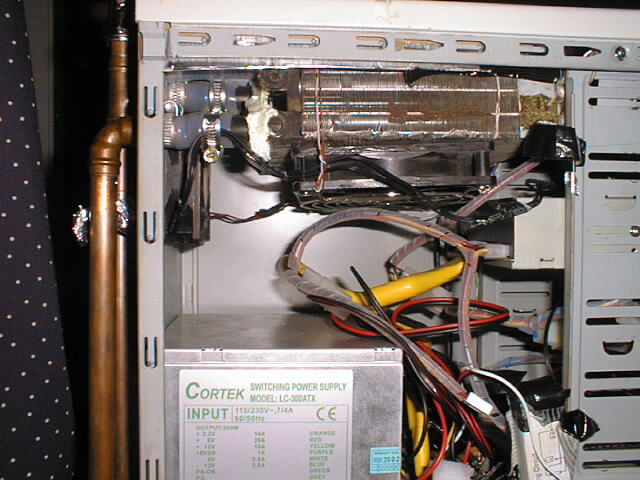

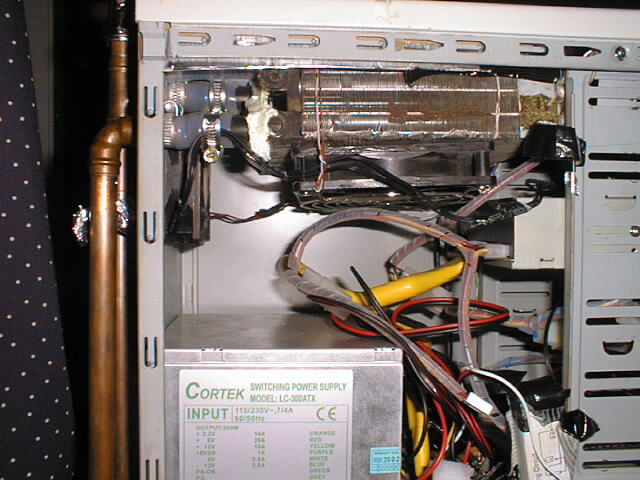

So, the last watercooled PC I built was this one;

Things have certainly come on from heater matrixes and pond pumps, and I want to build a nice looking custom looped system.

Parts I have;

Asrock X670E (white PCB, ATX)

Ryzen 7950X

64GB RGB DDR5

Seasonic 1000W fully modular PSU

MSI 4080 Suprimx

Thinks I like;

www.overclockers.co.uk

www.overclockers.co.uk

What I've done so far;

The case can support 280mm radiators though.

Things I don't know;

Is the reason behind using a res so that the system can bleed itself?

Should I do a single loop and pass through each rad one after another?

How do people do the nice neat bends?

What about fittings - are they universal?

Things have certainly come on from heater matrixes and pond pumps, and I want to build a nice looking custom looped system.

Parts I have;

Asrock X670E (white PCB, ATX)

Ryzen 7950X

64GB RGB DDR5

Seasonic 1000W fully modular PSU

MSI 4080 Suprimx

Thinks I like;

Lian Li O11 Air Mini, Midi-Tower, Tempered Glass - White

Order Lian Li O11 Air Mini, Midi-Tower, Tempered Glass - White now online and benefit from fast delivery.

What I've done so far;

Based on your choices we estimate the heat load (of the liquid cooled components) to be 830W.

Therefore we recommend the use of EK-CoolStream SE 240 (Slim Dual) on pedestal right and EK-CoolStream SE 240 (Slim Dual) on Position front and EK-CoolStream SE 240 (Slim Dual) on Position bottom of your computer case.

The case can support 280mm radiators though.

Things I don't know;

Is the reason behind using a res so that the system can bleed itself?

Should I do a single loop and pass through each rad one after another?

How do people do the nice neat bends?

What about fittings - are they universal?