Associate

- Joined

- 25 Apr 2010

- Posts

- 183

- Location

- Bristol

Hey,

Thought I might as well document what might well be a tremendous **** up and make a log of my first watercooling attempt.

I have been researching this since before Christmas and have been buying bits and pieces for it since may.

After spending days reading through forums and reviews I finally decided what to buy with the last parts arriving this week.

I am planning on upgrading my graphics card later on in the year to a 400 series which will either be added to the loop or on a another loop.

Its to cool a i7 920 @ 4.0Ghz on a Gigabyte EX58-UD5. The reason I want to go water is that I render videos for 3D walkthroughs which can be 30+ hours to render at 100% load. Although temps are fine at the moment it gets pretty noisy and I keep thinking it cant be good for it to be like that all the time so here we are.

My Spec for my CPU only loop

Case: Cosmos S

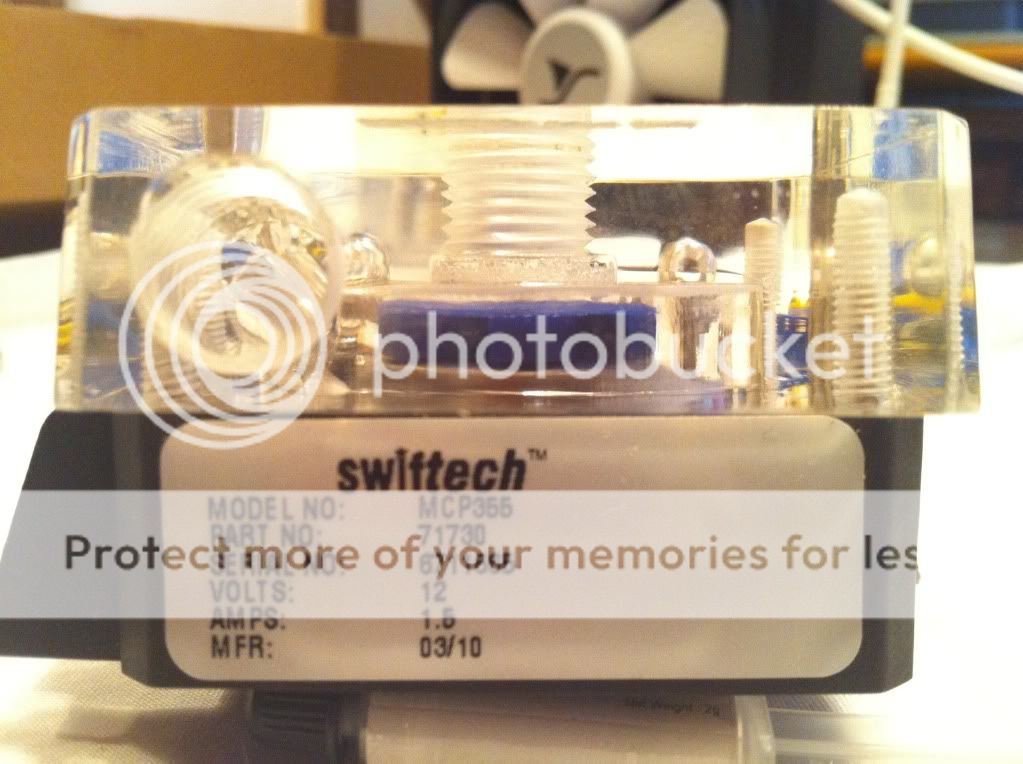

Pump: Laing DDC Ultra 18W with XSPC Laing DDC Pump Top V3

Res: EK Multioption Reservoir X2 250 Advanced

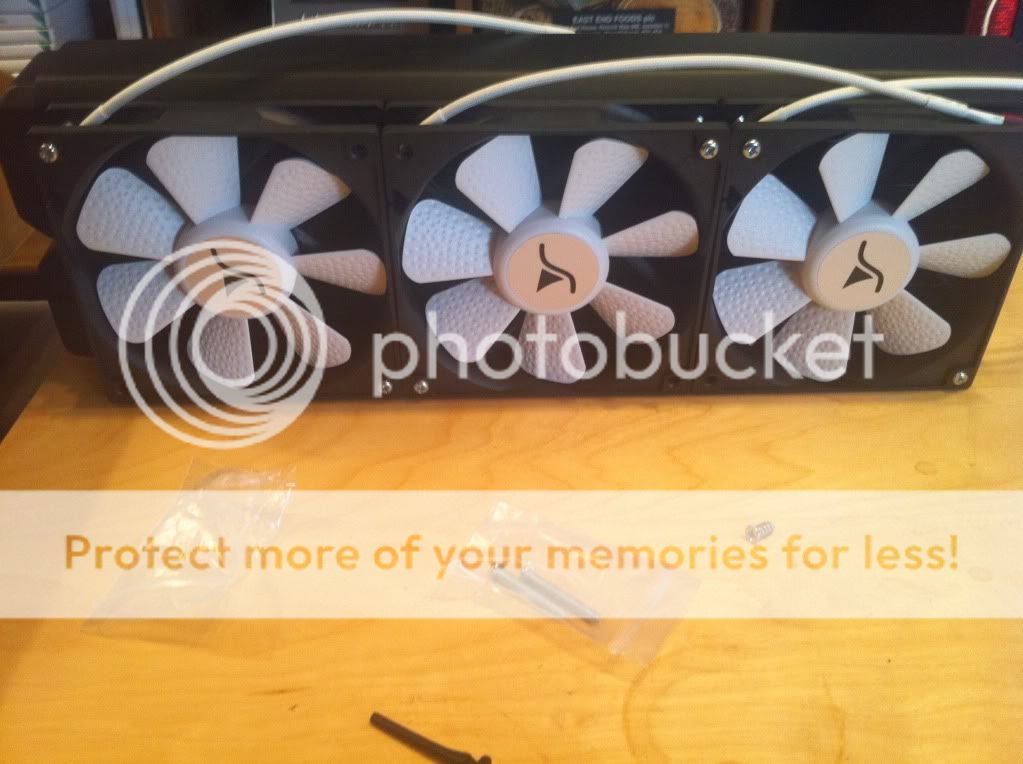

Rad: Black Ice SR1 360

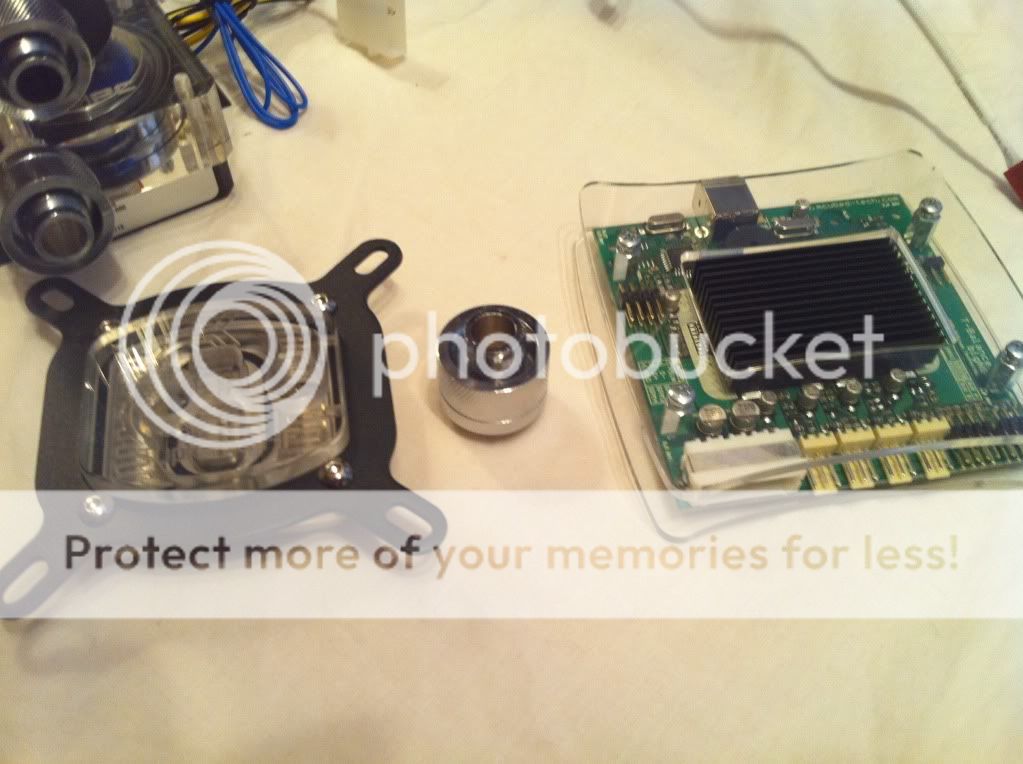

Block: EK Water Blocks EK-Supreme HF Nickel Universal

Fans: Sharkoon Silent Eagle 2000 120mm

Fan Controller: mCubed HFX 113 T-Balancer BigNG Cooling Controller

Fittings: TFC Compression Fitting G1/4" Thread 1/2" ID/3/4" OD - High Flow and OcUK Value Double Nipple G1/4" to G1/4" with O-Ring

Hose: XSPC white ID 1/2 OD 3/4

Fluid: Distilled water with PT Nuke

So the build starts tomorrow

(Pics to come soon)

The only problem so far is that the BigNG uses an internal USB but the case has 4 usb's on the front using both the internal headers of the UD5 so I have to lose on side of USB's which is annoying.

Anyway if anyone has any advice please let me know

Cheers

Thought I might as well document what might well be a tremendous **** up and make a log of my first watercooling attempt.

I have been researching this since before Christmas and have been buying bits and pieces for it since may.

After spending days reading through forums and reviews I finally decided what to buy with the last parts arriving this week.

I am planning on upgrading my graphics card later on in the year to a 400 series which will either be added to the loop or on a another loop.

Its to cool a i7 920 @ 4.0Ghz on a Gigabyte EX58-UD5. The reason I want to go water is that I render videos for 3D walkthroughs which can be 30+ hours to render at 100% load. Although temps are fine at the moment it gets pretty noisy and I keep thinking it cant be good for it to be like that all the time so here we are.

My Spec for my CPU only loop

Case: Cosmos S

Pump: Laing DDC Ultra 18W with XSPC Laing DDC Pump Top V3

Res: EK Multioption Reservoir X2 250 Advanced

Rad: Black Ice SR1 360

Block: EK Water Blocks EK-Supreme HF Nickel Universal

Fans: Sharkoon Silent Eagle 2000 120mm

Fan Controller: mCubed HFX 113 T-Balancer BigNG Cooling Controller

Fittings: TFC Compression Fitting G1/4" Thread 1/2" ID/3/4" OD - High Flow and OcUK Value Double Nipple G1/4" to G1/4" with O-Ring

Hose: XSPC white ID 1/2 OD 3/4

Fluid: Distilled water with PT Nuke

So the build starts tomorrow

(Pics to come soon)

The only problem so far is that the BigNG uses an internal USB but the case has 4 usb's on the front using both the internal headers of the UD5 so I have to lose on side of USB's which is annoying.

Anyway if anyone has any advice please let me know

Cheers

Last edited: