Soldato

- Joined

- 2 May 2011

- Posts

- 12,336

- Location

- Woking

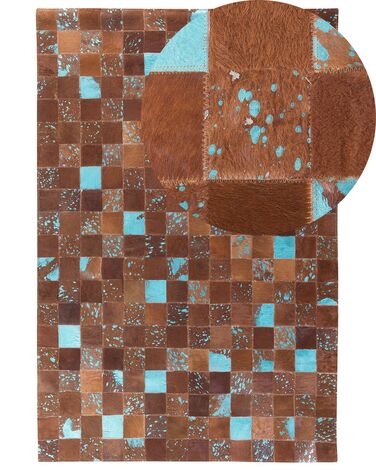

What is this rug? Got to say man, it doesn't go with the table!

Rug weaving is his next project...What is this rug? Got to say man, it doesn't go with the table!

Table isn't going there, so it's OKWhat is this rug? Got to say man, it doesn't go with the table!

I will have black, brown and blue running through the place, but lounge area where this coffee table will be actually has a cow hide rug. Will show you when it's together. I'm not wed to it but it'll do for now.

I will have black, brown and blue running through the place, but lounge area where this coffee table will be actually has a cow hide rug. Will show you when it's together. I'm not wed to it but it'll do for now.

Well, I was kept up until about 3am this morning because I really want rid of this bookcase and I now have a really cool idea for a bookcase, but it's pretty mega... I'll need to design it on paper, then solidworks, then 3d print a test scaled piece to make sure it'll work. It'll be concrete, metal and woodRug weaving is his next project...

my head is such a dick

my head is such a dick

Say whaaaat? I did not know this was a thing!! Damn. Ordered some for future jobs!!anti spatter spray

I preferred the IKEA crap TBH

You just gotta do whatever makes you happy!

You just gotta do whatever makes you happy!I won't list all of the projects in various states...Well done. I’m impressed that you finish it. I normally give up at about 75%

I was determined to see it through and will finish that stuff off tomorrow. As soon as I get the bits I'll finish the coffee table too. The stain arrived for it today, just need the router bit now. I will make it all how I want!!

I was determined to see it through and will finish that stuff off tomorrow. As soon as I get the bits I'll finish the coffee table too. The stain arrived for it today, just need the router bit now. I will make it all how I want!!  Another thing I can tick off

Another thing I can tick off

Yea, I totallllllly thought this half way through. I also then thought I should have one of those saws that does it for you and you can set the angle? Like a mitre saw but for metal? Either way, I think I still need oneJust a suggestion but next time you weld box section, mitre the ends so you don't need blanking caps. Also if you chamfer the edges that are going to be welded so that you are welding in a "V" it saves a lot of grinding to neaten the weld.

And a table saw... all of the tools!

And a table saw... all of the tools!Yeah a mitre saw... Just a mitre saw! Mine came with a wood and metal blade.Yea, I totallllllly thought this half way through. I also then thought I should have one of those saws that does it for you and you can set the angle? Like a mitre saw but for metal? Either way, I think I still need oneAnd a table saw... all of the tools!

*adds to the amazon basketYeah a mitre saw... Just a mitre saw! Mine came with a wood and metal blade.

*

*