Hi folks,

Me again - given the turn in weather, the boiler man being booked for early November, and a Christmas visit from my mum planned - I am thinking I may hold off on any major progress on the bathroom until the new year. Cue the perfect opportunity for a low effort (lol), high impact (lol) job - loft insulation.

At the moment I have a lath and plaster ceiling, and about 60% of the loft boarded. The roof is the original 1930s clay tiles on wood (no felt). It is cold up there, and I think the lathe and plaster ceilings offer little to nothing in terms of insulation. There is some fibreglass looking stuff up there in places at the moment, but not very much and clearly a half job (maybe just for one of the bedrooms).

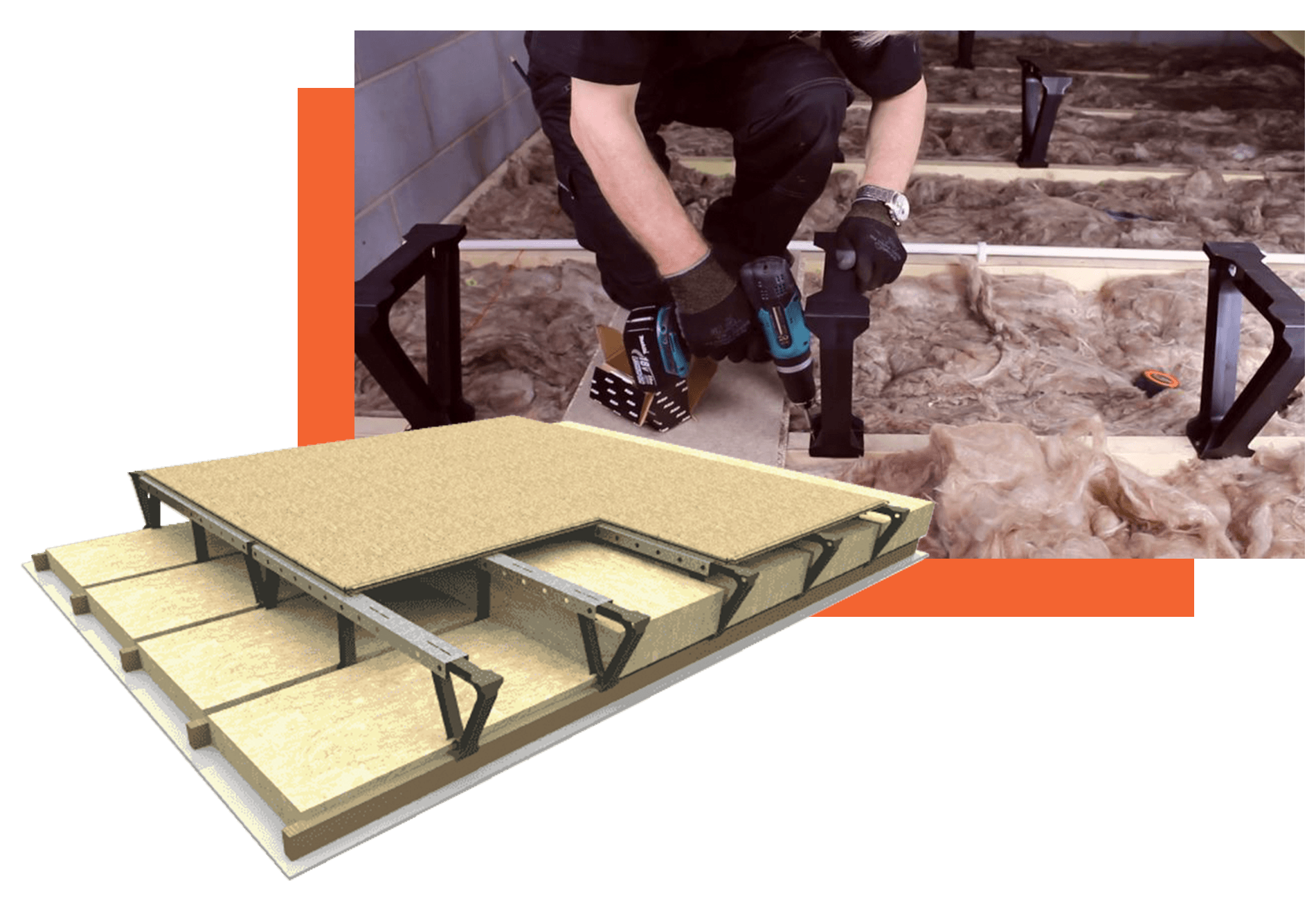

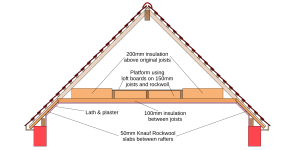

I have seen a few products that suggest raising the joists to pack in (but not squash) rockwool type stuff, and silver barriers stapled to the roof interior. I also found this chap who goes into detail on the theory and provides some tips, so this'll be my default guide.

What's the general craic on doing this job? Where do I begin? What systems have you used and is there a way to do this inexpensively?

Thanks!

Me again - given the turn in weather, the boiler man being booked for early November, and a Christmas visit from my mum planned - I am thinking I may hold off on any major progress on the bathroom until the new year. Cue the perfect opportunity for a low effort (lol), high impact (lol) job - loft insulation.

At the moment I have a lath and plaster ceiling, and about 60% of the loft boarded. The roof is the original 1930s clay tiles on wood (no felt). It is cold up there, and I think the lathe and plaster ceilings offer little to nothing in terms of insulation. There is some fibreglass looking stuff up there in places at the moment, but not very much and clearly a half job (maybe just for one of the bedrooms).

I have seen a few products that suggest raising the joists to pack in (but not squash) rockwool type stuff, and silver barriers stapled to the roof interior. I also found this chap who goes into detail on the theory and provides some tips, so this'll be my default guide.

What's the general craic on doing this job? Where do I begin? What systems have you used and is there a way to do this inexpensively?

Thanks!

! I guess with the 300sqft workshop it was low down the priority list.

! I guess with the 300sqft workshop it was low down the priority list.

. I'm a brute force and ignorance lad so I'm sure I'll suss out a means to get them up there, so yes entirely solo on this job.

. I'm a brute force and ignorance lad so I'm sure I'll suss out a means to get them up there, so yes entirely solo on this job.