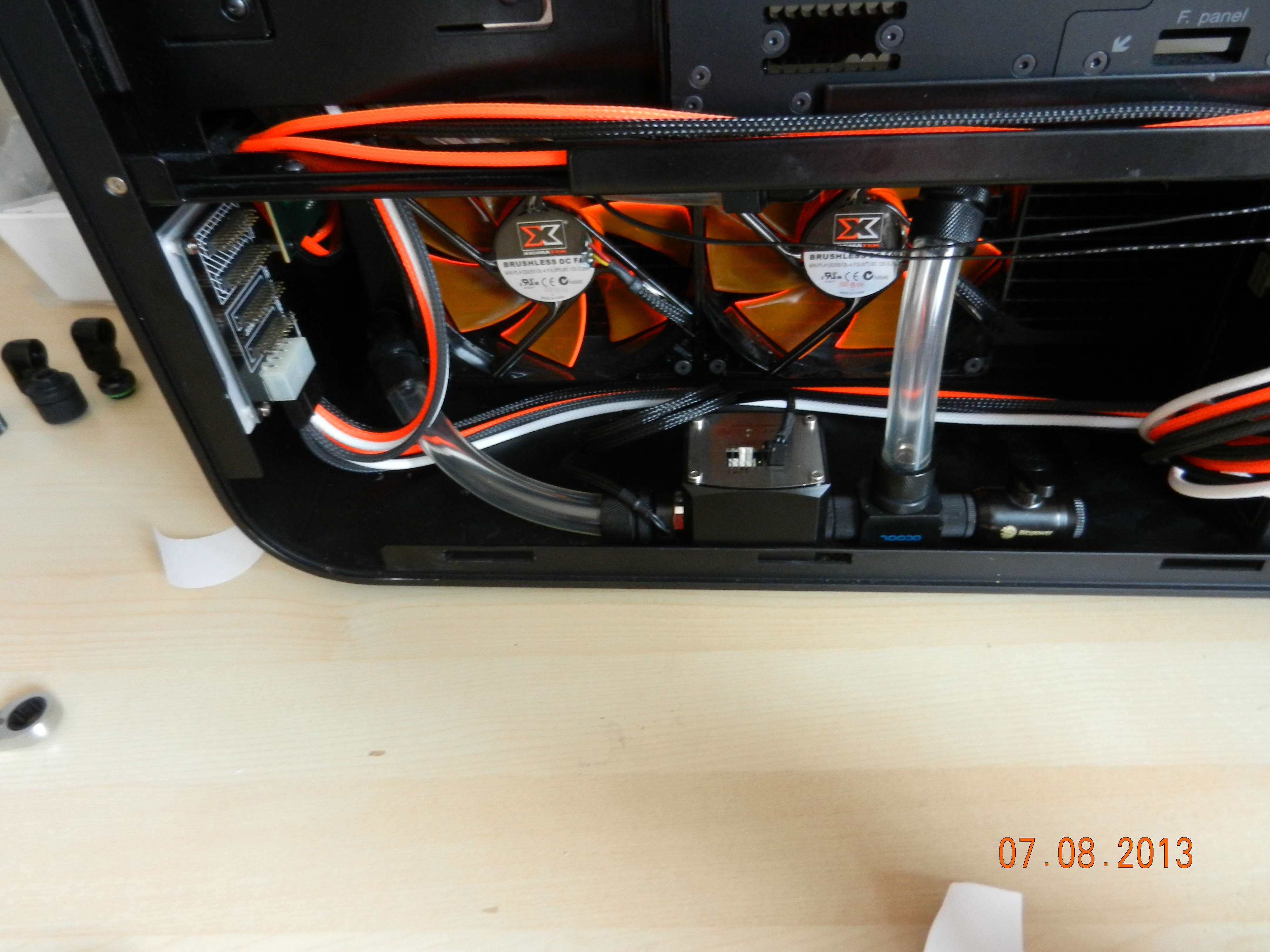

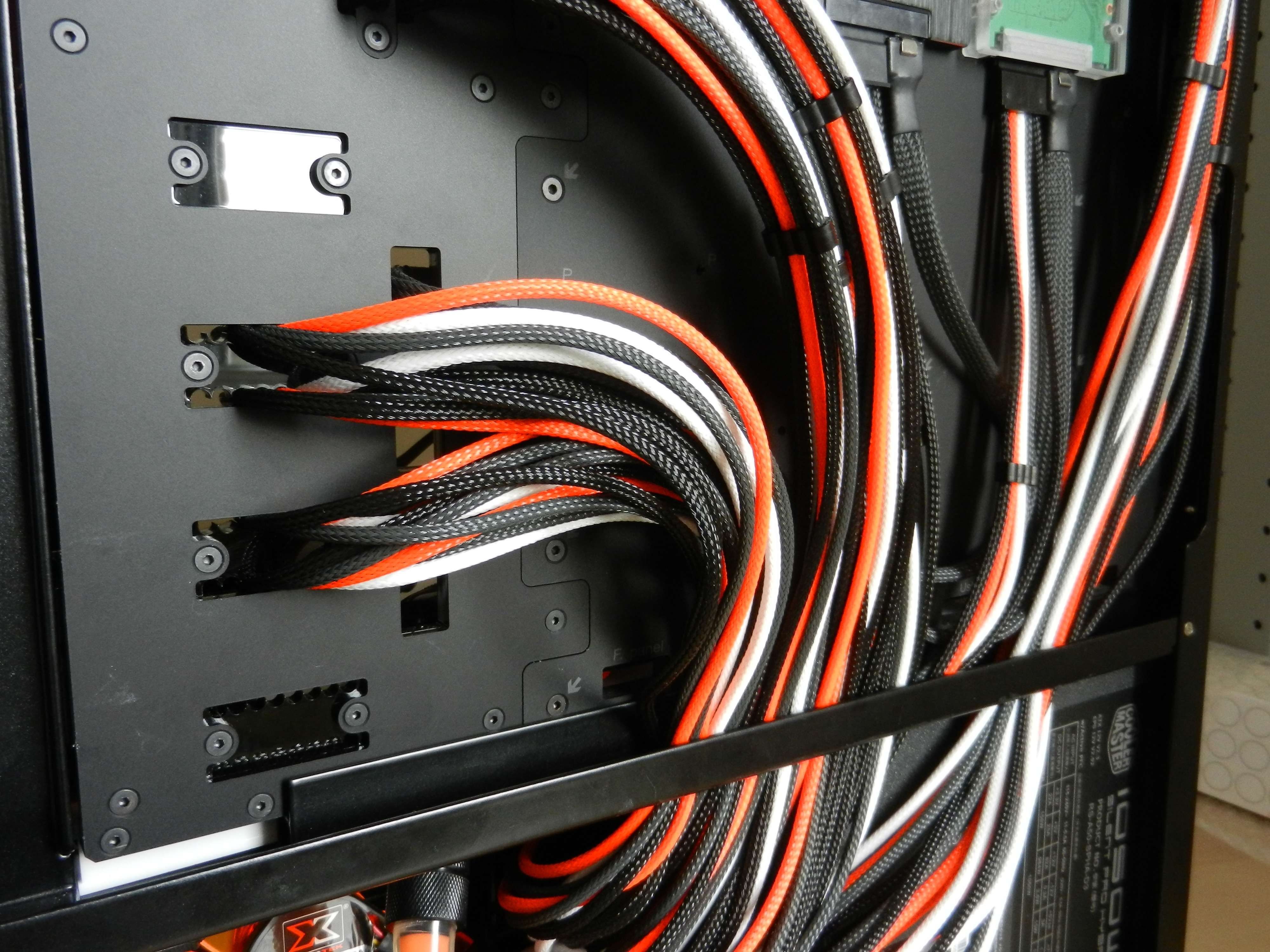

Small update. I finally came around to make all my fan extension cables tonight. 9 pieces in various lengths I believe. I measures how long every fan extension needed to be. Wrote it down and took a seat

I will sleeve them tomorrow I think. They will be all black. They just need to look clean not be noticed a lot

It just needs to look tidy.

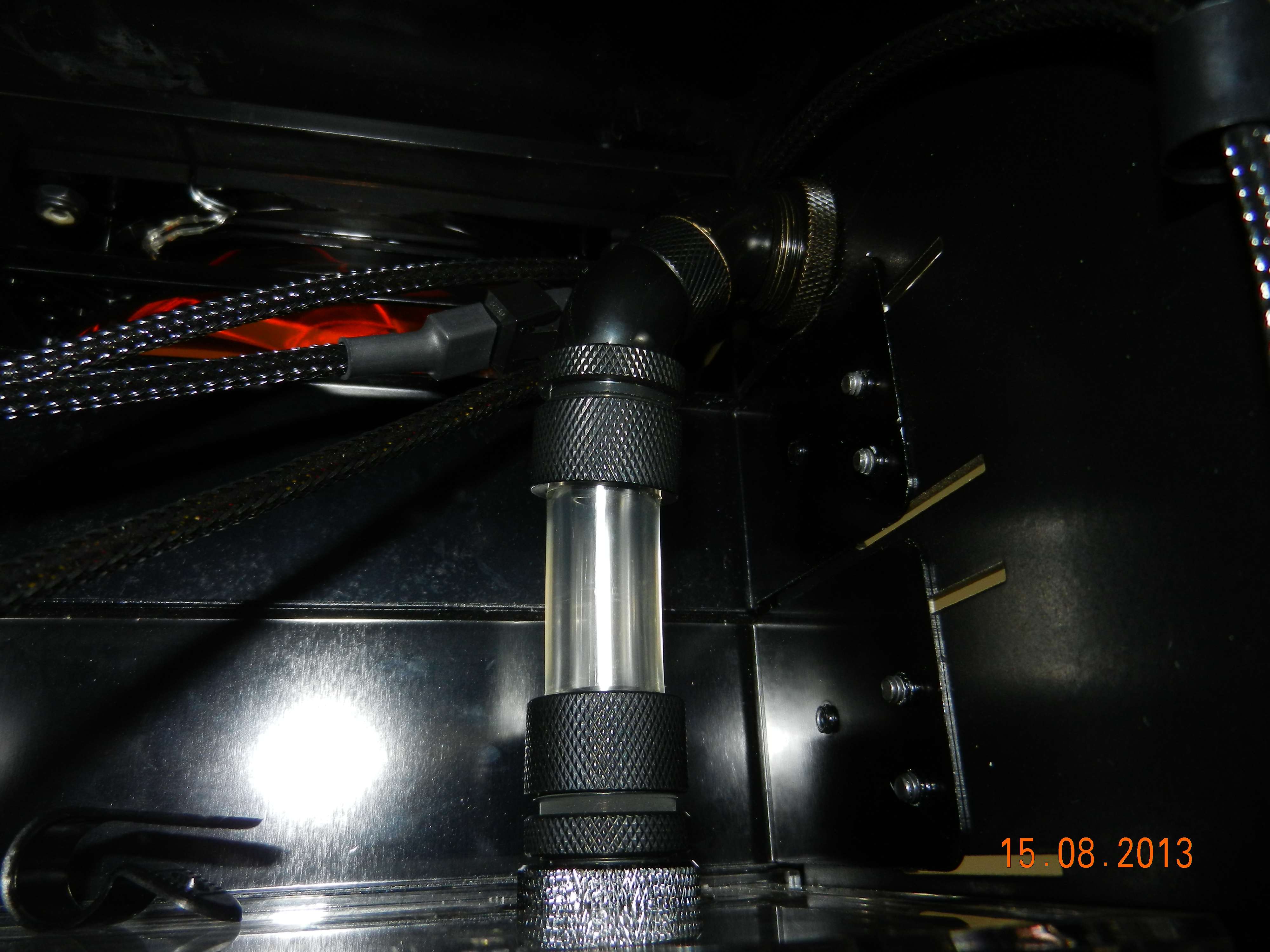

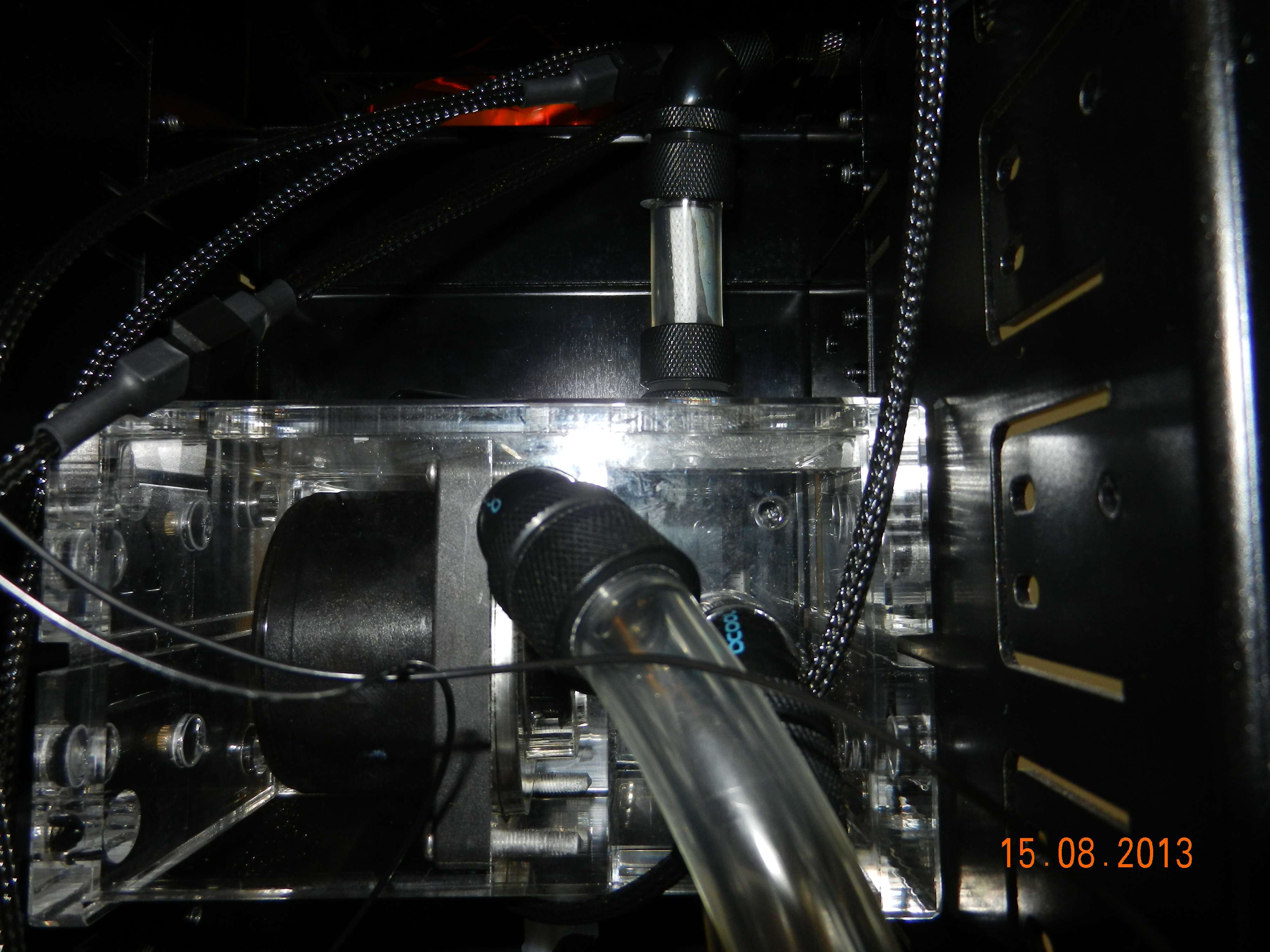

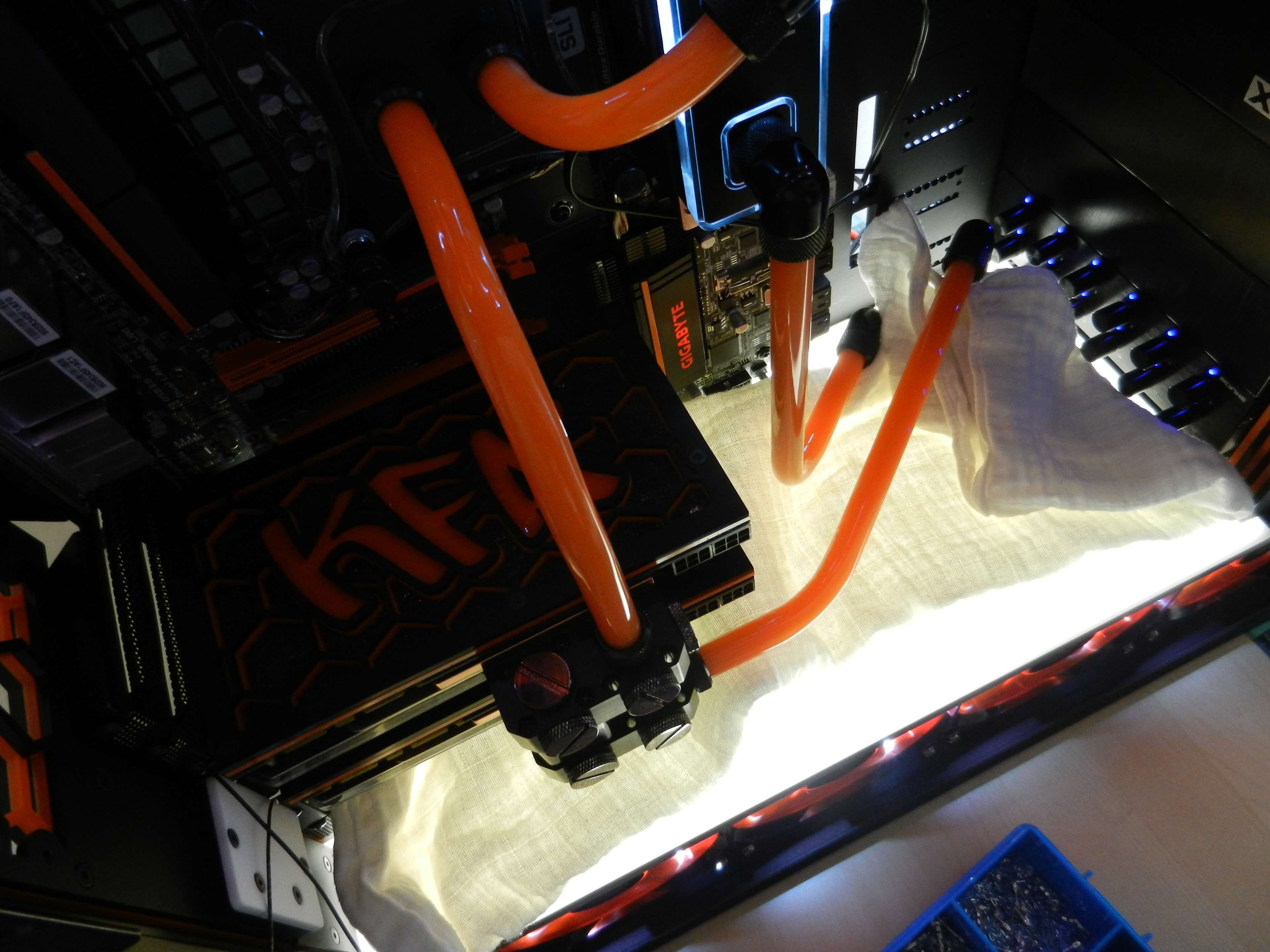

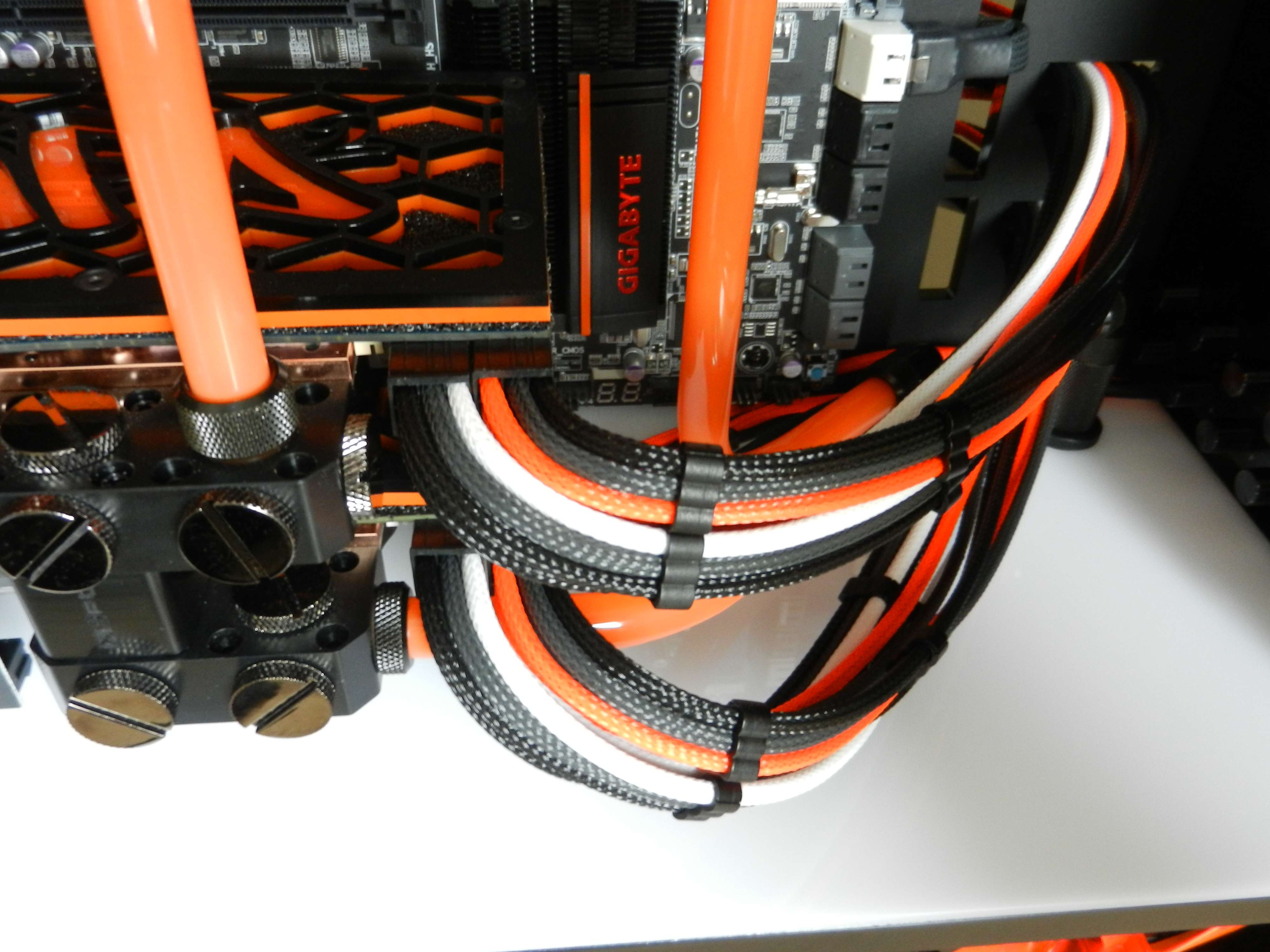

I also received a small package from an UK watercooling shop. I wanted to try out a few shops just to see how fast they ship and how good their prices are and also very important how good their stock is. I hate it when shops need to order stuff themselves and it takes weeks or longer for it to arrive to them. I don't have tie for that. Anyway, bought me two 90 degree EKWB adapters (who needs Bitspower with these looks and prices), an XSPC SLI connector to connect two pci slots that are directly next to eachother, a very heave Alphacool T-section. I will use this to fit the tab for the loop at the lowest point. And a male-male Alphacool connector to be able to fit that tab to the T-piece

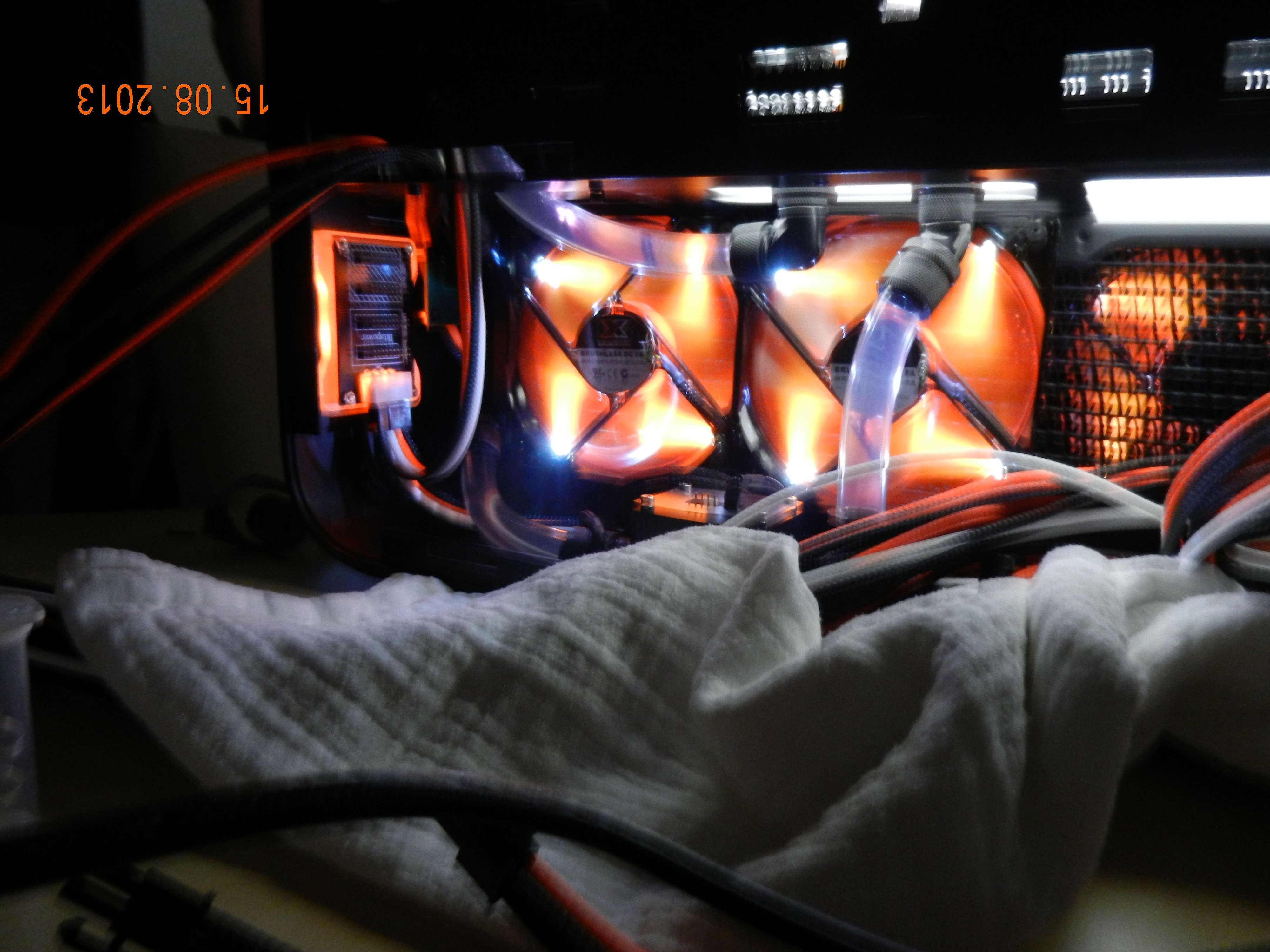

Hopefully I can mount some stuff tomorrow or sunday. I still need to also sleeve the pump wiring (and shorten the 4 pin on that a lot. It is now almost all wiring, cablemanagement and hoses/pipes. After that the LEDs and their LED board. And after that.....leaktesting.

I will sleeve them tomorrow I think. They will be all black. They just need to look clean not be noticed a lot

It just needs to look tidy.

I also received a small package from an UK watercooling shop. I wanted to try out a few shops just to see how fast they ship and how good their prices are and also very important how good their stock is. I hate it when shops need to order stuff themselves and it takes weeks or longer for it to arrive to them. I don't have tie for that. Anyway, bought me two 90 degree EKWB adapters (who needs Bitspower with these looks and prices), an XSPC SLI connector to connect two pci slots that are directly next to eachother, a very heave Alphacool T-section. I will use this to fit the tab for the loop at the lowest point. And a male-male Alphacool connector to be able to fit that tab to the T-piece

Hopefully I can mount some stuff tomorrow or sunday. I still need to also sleeve the pump wiring (and shorten the 4 pin on that a lot. It is now almost all wiring, cablemanagement and hoses/pipes. After that the LEDs and their LED board. And after that.....leaktesting.