Associate

- Joined

- 5 Feb 2009

- Posts

- 405

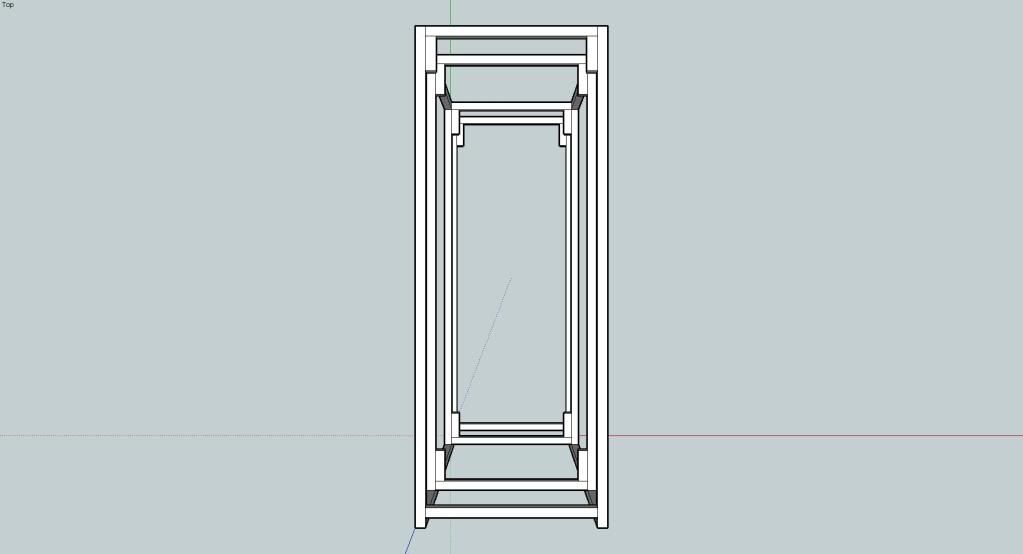

Computer Build-log – “Great Heights”

Background History

Been thinking about getting a new case for a while just never found “The One” that appealed to me with lots of room, correct price, style and management. Well In essence I need more room as my TT Armour is full up and no more room for expansion in any direction. I would need it to house all of my stuff internally with ease and maybe add another loop into it.

Current Rig:

Core 2 Duo E8400 (775s) @ 4.0 GHz

Evga 780i 3way-Sli motherboard

Evga 9800GTX+ SSC edition

Creative X-Fi Platinum Fatality + Front Bay

Zalman ZM850-HP Modular

3x 320GB WD (Raid 0 & Storage)

4 GB Kingston Ram (5-7-7-20)

Hauppauge WinTv 1100-HVR

Thermaltake Armour (Silver)

2 Water cooling loops

Loop 1 (CPU) – Pump -> CPU Block -> 120Rad -> 240Rad -> Res

Loop 2 (GFX) – Pump -> GFX Block -> 240(external)Rad -> Res

Samsung 2433WB Monitor 1920*1200

Phillips 200WB Monitor 1600*1050

Prologue:

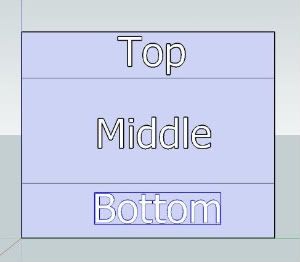

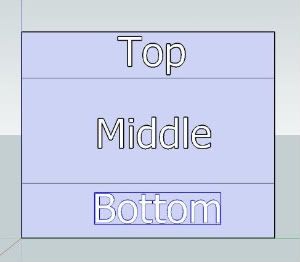

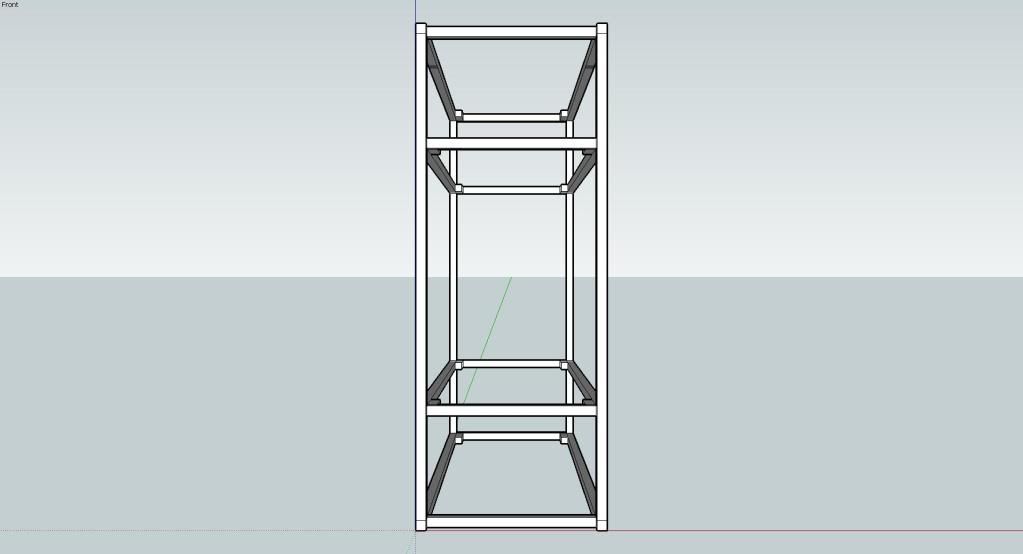

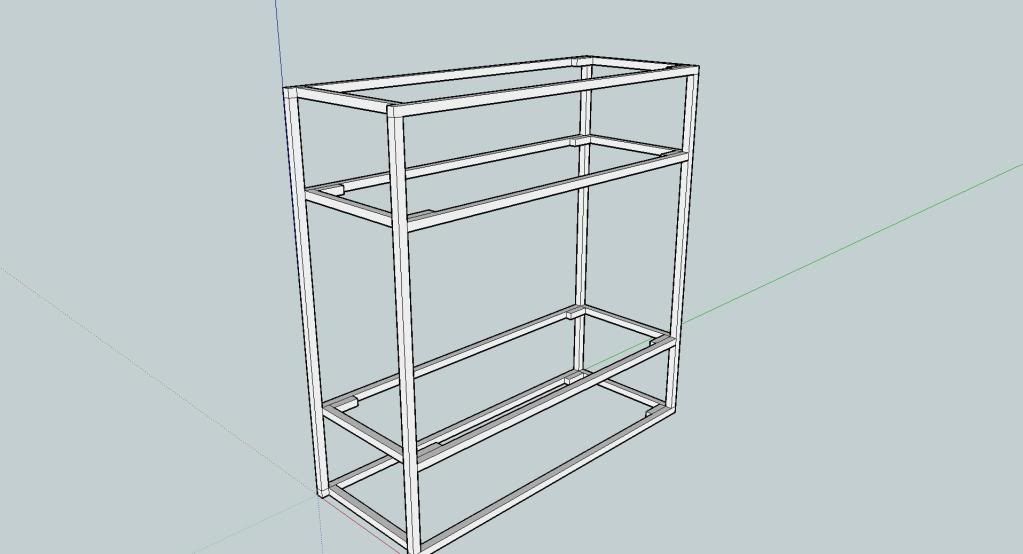

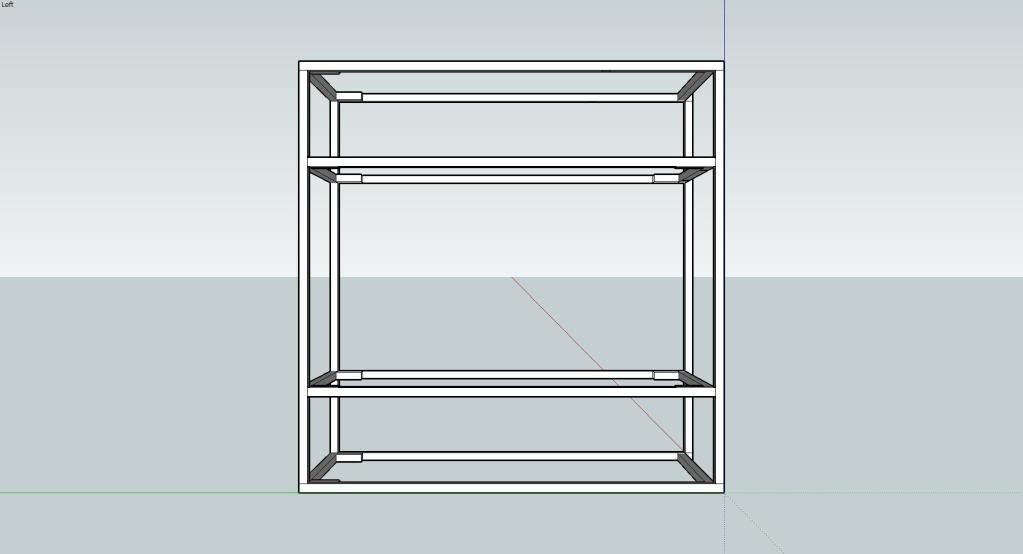

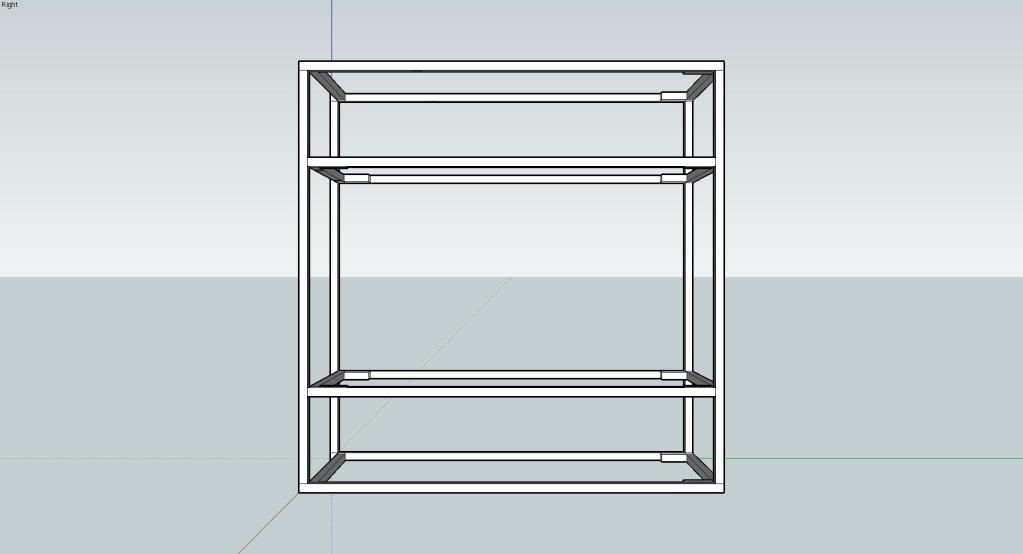

With this in mind I thought up some concepts that I like/would like to create. This was to have sections within the main case. My main though is to have 3 sections all lying parallel in the case:

Bottom:

Watercooling Rads/Pumps/Etc.

Middle:

Motherboard/DVD Bays/Etc.

Top:

HDDs/PSU/Control Box

My aim is to stick to this and house all of my Rig + Extra Room for expansion in the future.

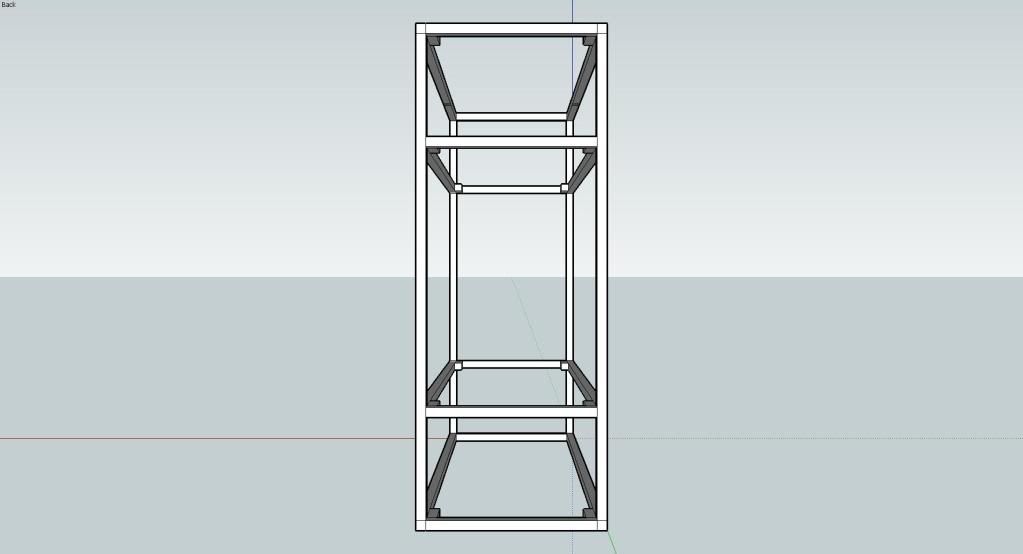

This led me to do some concept art (Mainly during lessons at school). I love the look of the Tenjim TJ-07 how the Rad sections is situated and separated from the rest of the Case, this was my main theme and I decided to mirror this by having same design for the top section as bottom.

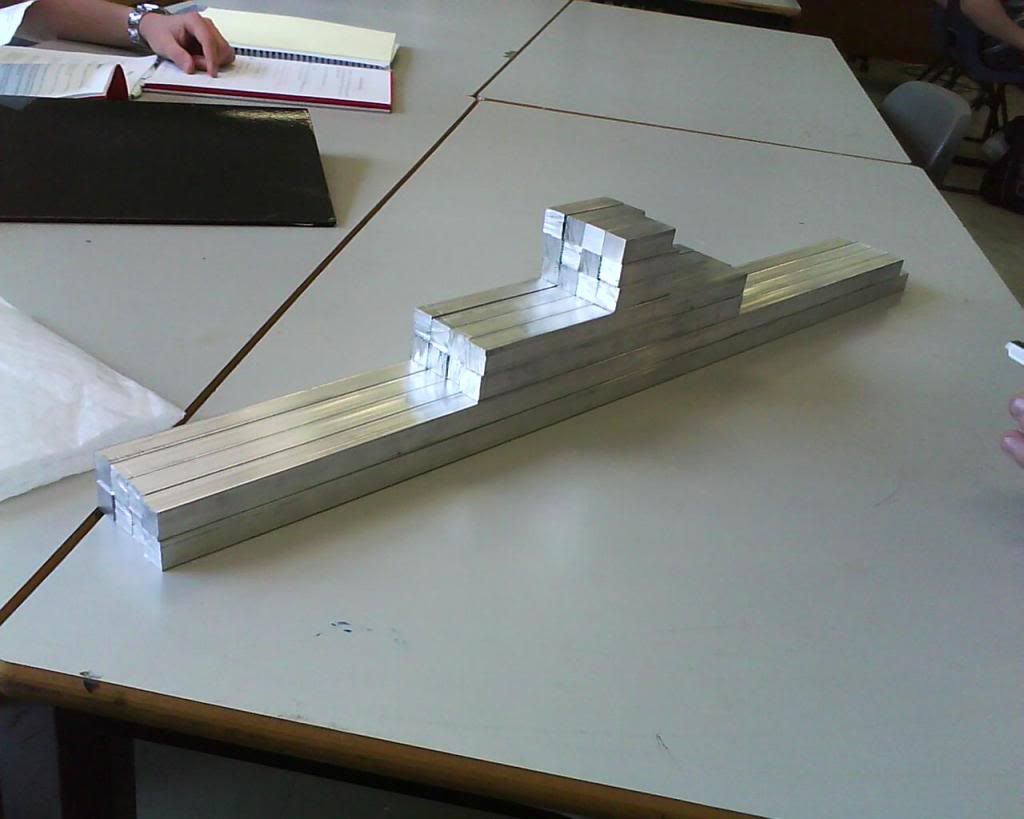

As I knew there wasn’t a case in production that was like this, I will haft to go it alone and build a case from scratch, this required a lot of thinking and research and skills which I will need to pick up.

Also took me on a trip to my design teacher to actually see if it was physically possible, all good talked him through what I wanted to do and he gave me the all clear and the facilities of whole design block to use (inc. Laser CNC, Milling machine, Pillar Drills, Most tools). This should make my life easier with all these at my disposal.

More later

Ninja

Background History

Been thinking about getting a new case for a while just never found “The One” that appealed to me with lots of room, correct price, style and management. Well In essence I need more room as my TT Armour is full up and no more room for expansion in any direction. I would need it to house all of my stuff internally with ease and maybe add another loop into it.

Current Rig:

Core 2 Duo E8400 (775s) @ 4.0 GHz

Evga 780i 3way-Sli motherboard

Evga 9800GTX+ SSC edition

Creative X-Fi Platinum Fatality + Front Bay

Zalman ZM850-HP Modular

3x 320GB WD (Raid 0 & Storage)

4 GB Kingston Ram (5-7-7-20)

Hauppauge WinTv 1100-HVR

Thermaltake Armour (Silver)

2 Water cooling loops

Loop 1 (CPU) – Pump -> CPU Block -> 120Rad -> 240Rad -> Res

Loop 2 (GFX) – Pump -> GFX Block -> 240(external)Rad -> Res

Samsung 2433WB Monitor 1920*1200

Phillips 200WB Monitor 1600*1050

Prologue:

With this in mind I thought up some concepts that I like/would like to create. This was to have sections within the main case. My main though is to have 3 sections all lying parallel in the case:

Bottom:

Watercooling Rads/Pumps/Etc.

Middle:

Motherboard/DVD Bays/Etc.

Top:

HDDs/PSU/Control Box

My aim is to stick to this and house all of my Rig + Extra Room for expansion in the future.

This led me to do some concept art (Mainly during lessons at school). I love the look of the Tenjim TJ-07 how the Rad sections is situated and separated from the rest of the Case, this was my main theme and I decided to mirror this by having same design for the top section as bottom.

As I knew there wasn’t a case in production that was like this, I will haft to go it alone and build a case from scratch, this required a lot of thinking and research and skills which I will need to pick up.

Also took me on a trip to my design teacher to actually see if it was physically possible, all good talked him through what I wanted to do and he gave me the all clear and the facilities of whole design block to use (inc. Laser CNC, Milling machine, Pillar Drills, Most tools). This should make my life easier with all these at my disposal.

More later

Ninja

)

)

when I have though how to word it, without giving to much away

when I have though how to word it, without giving to much away

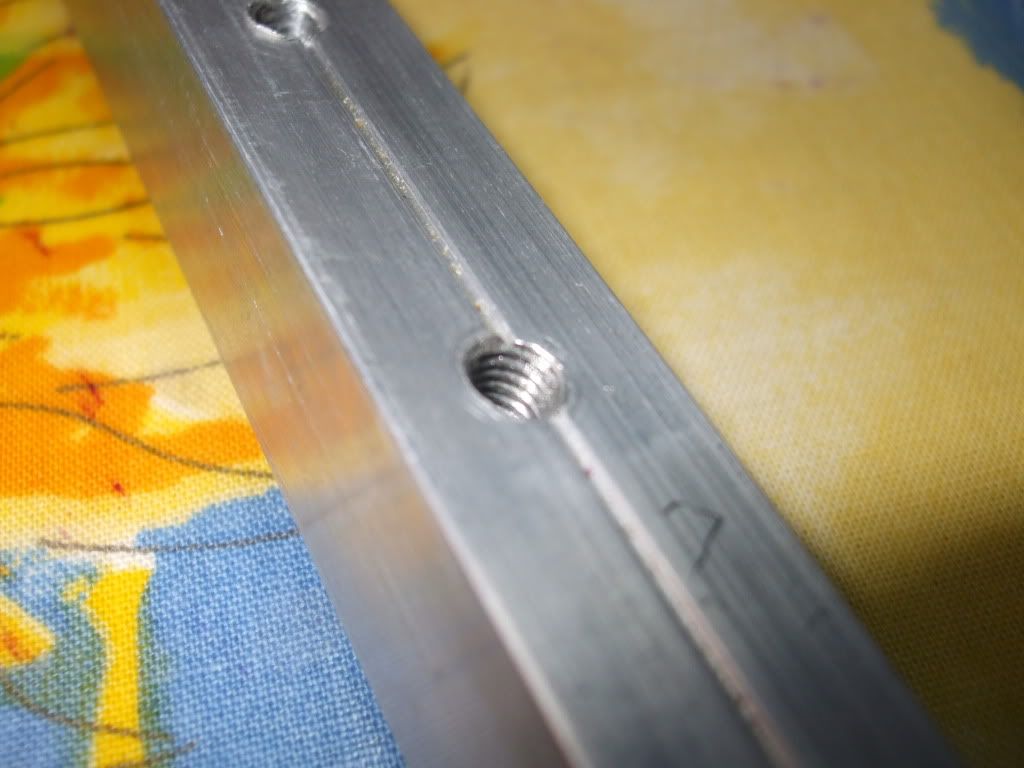

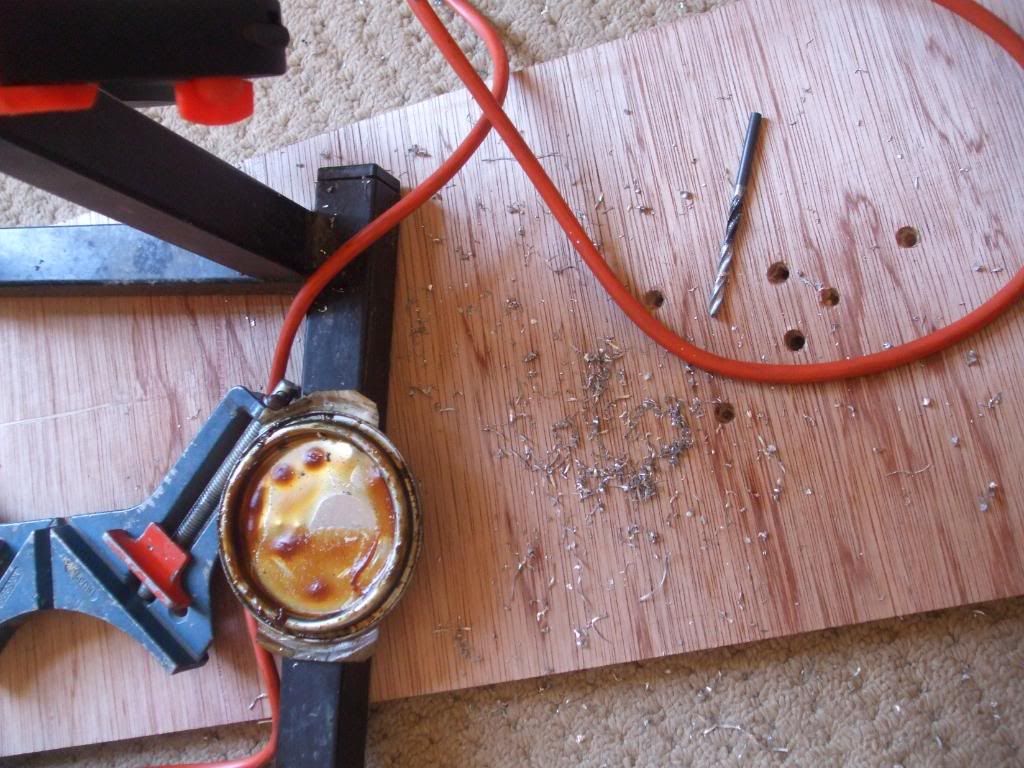

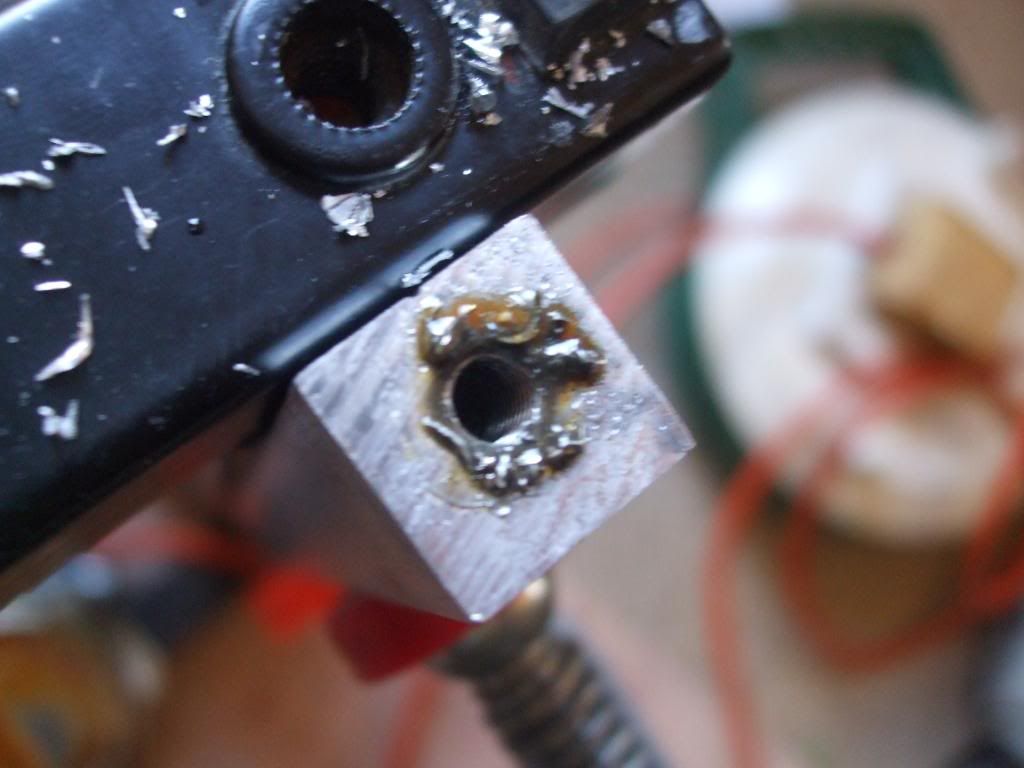

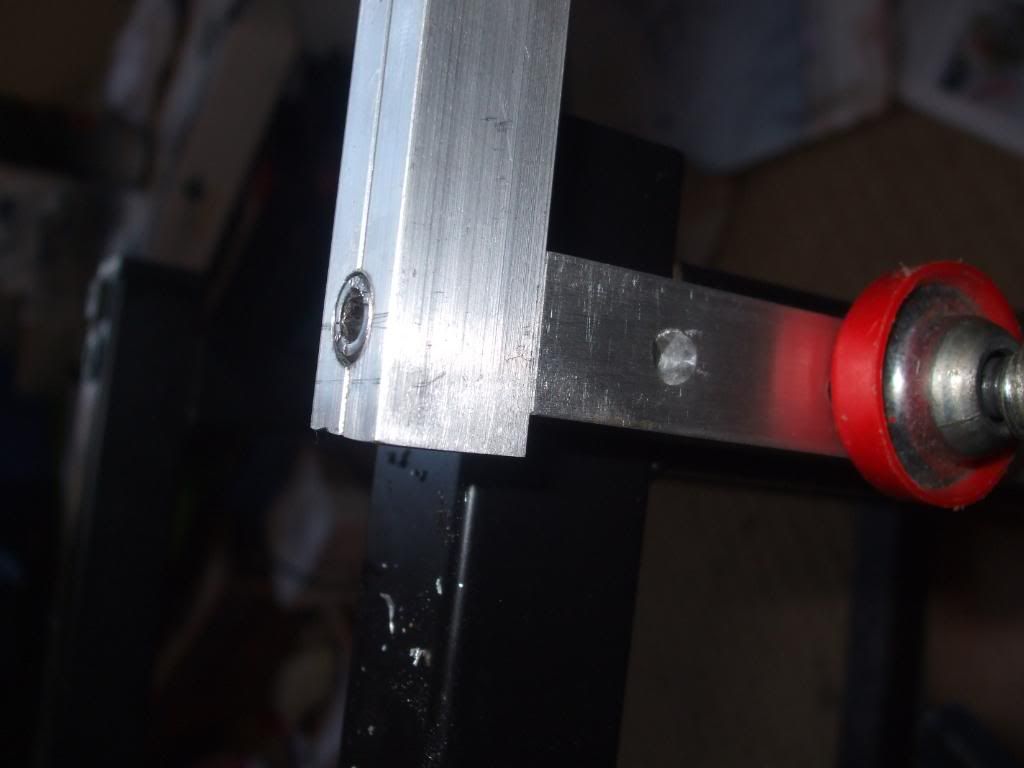

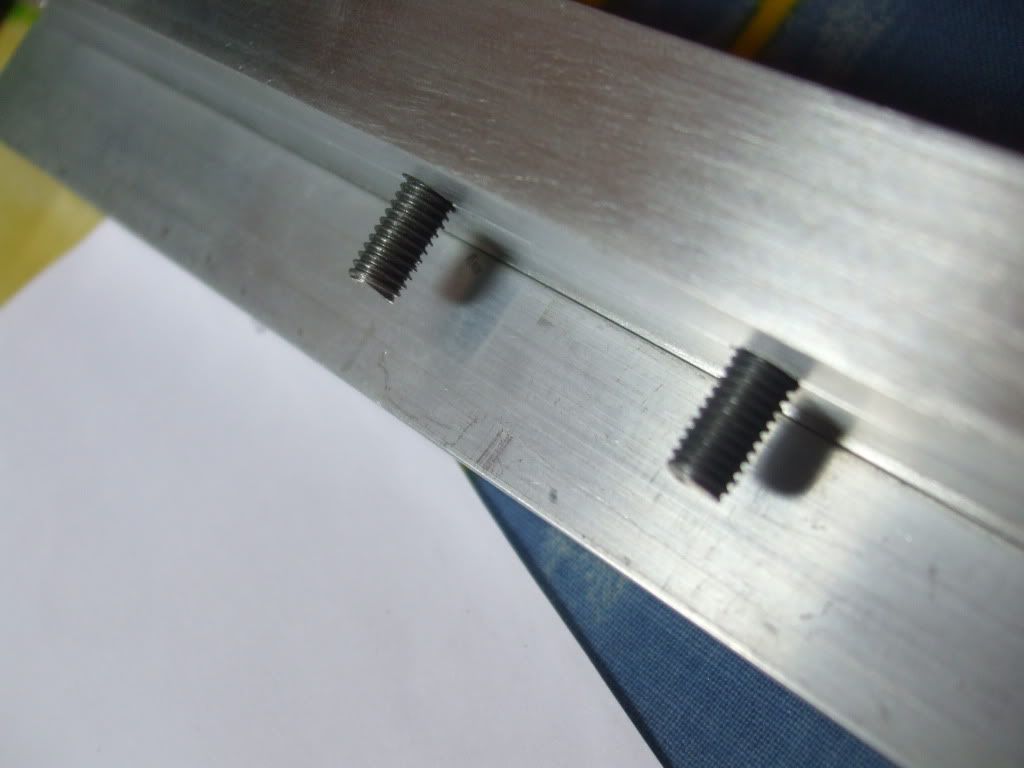

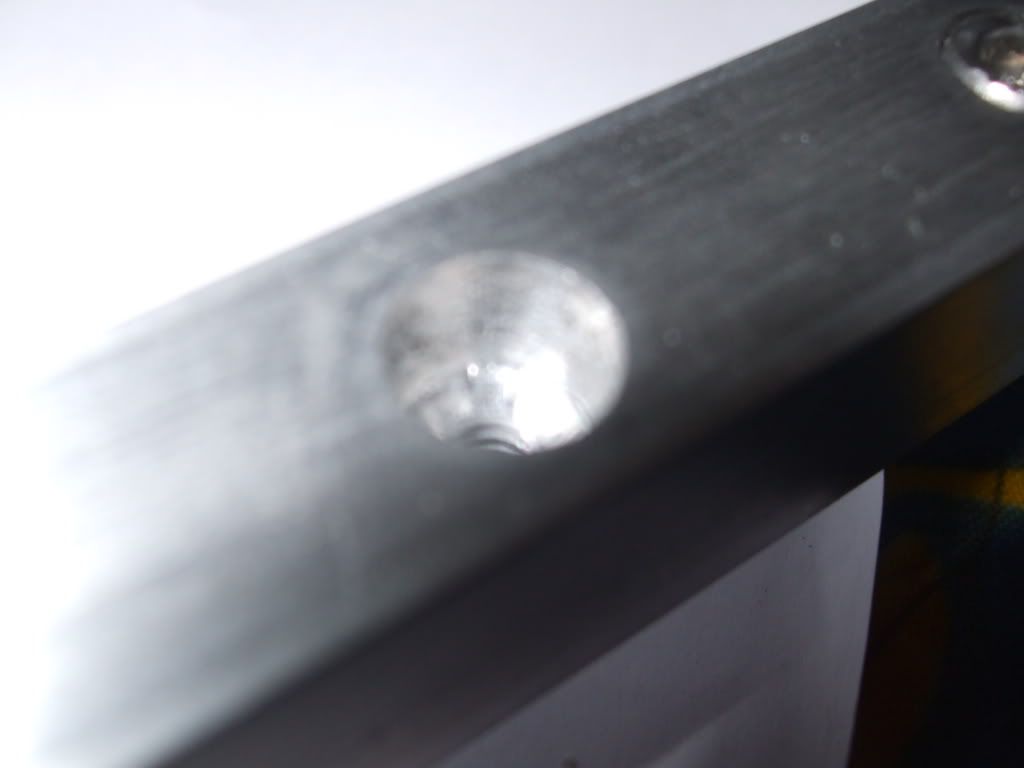

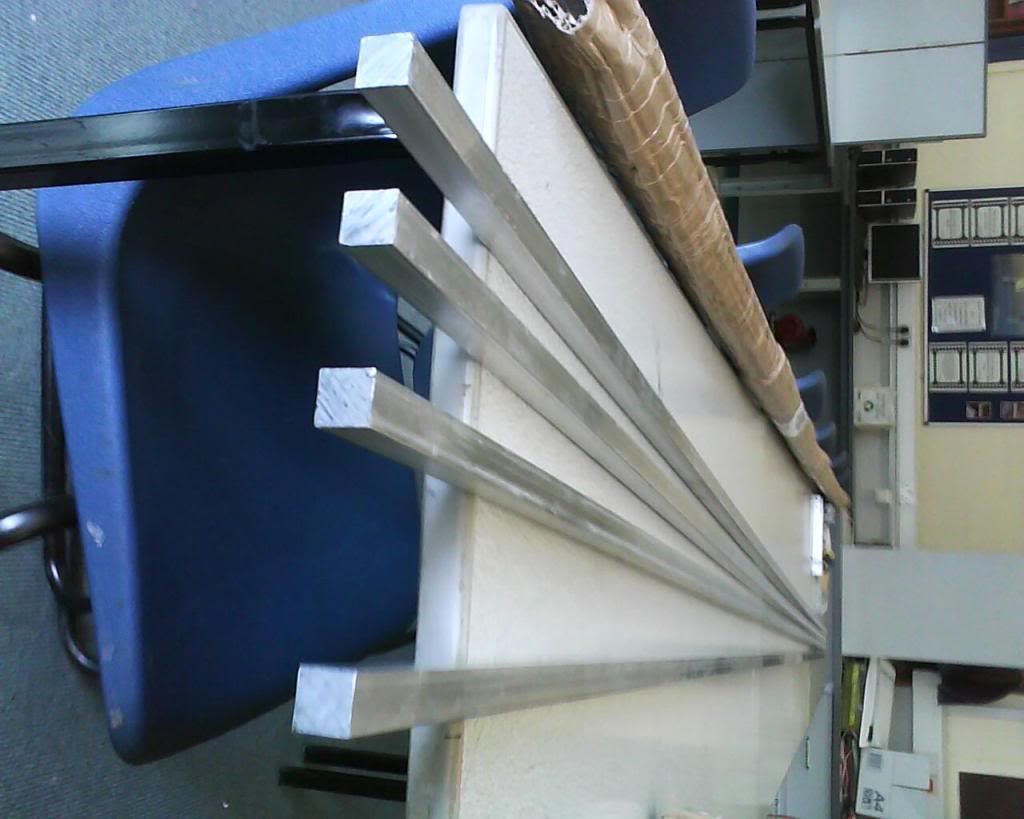

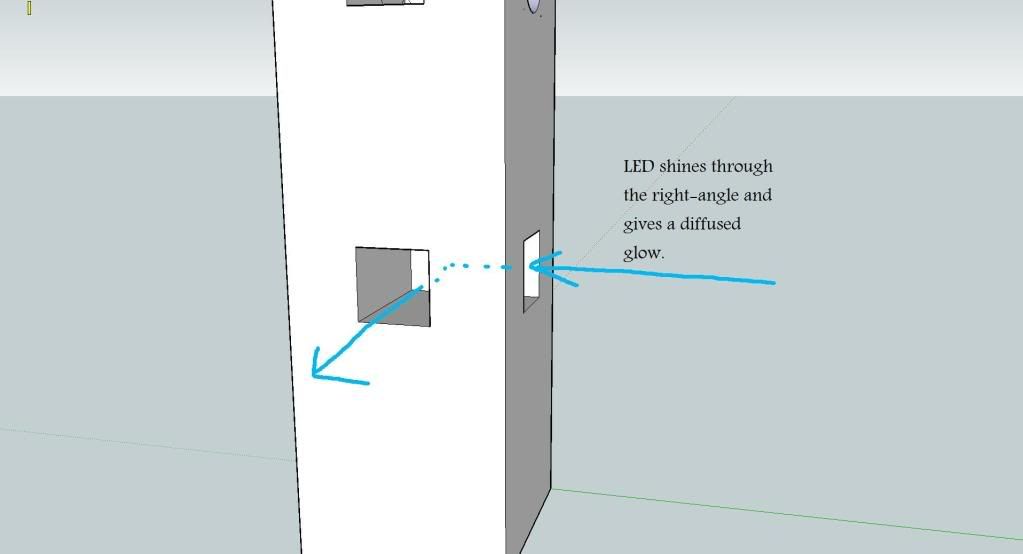

4, that I will cut later on:

4, that I will cut later on: