cheers for the great comment man.

the the bulgin switch would you say its about 2 mill overhang on its widest part?

looks that way so about 23/24mill at its thickest

and thats a really good shot of the switch in action they really are a sleak bit of kit

the the bulgin switch would you say its about 2 mill overhang on its widest part?

looks that way so about 23/24mill at its thickest

and thats a really good shot of the switch in action they really are a sleak bit of kit

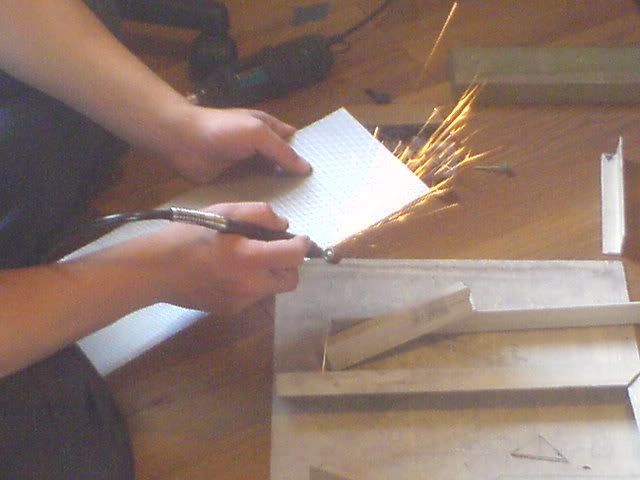

and bent it till it snapped but it was nothing a quick go over with the sand wheel on the old rotary tool didn't solve

and bent it till it snapped but it was nothing a quick go over with the sand wheel on the old rotary tool didn't solve