Associate

- Joined

- 16 May 2011

- Posts

- 1,308

- Location

- Staffordshire

Okay, so i'm a year 12 student studying engineering at a new-ish school with a large association with a certain reputable digger company.

As part of year long design-make-review project i am planning to design-make-and review a custom computer case. I chose this is its what i'm interested in and find it easy to talk about. So i'm hoping more experienced people here will assist me in this project.

At my school i have access to a huge array of machinery in our workshops and pretty good at using the majority of it and if i cant i have people who will.

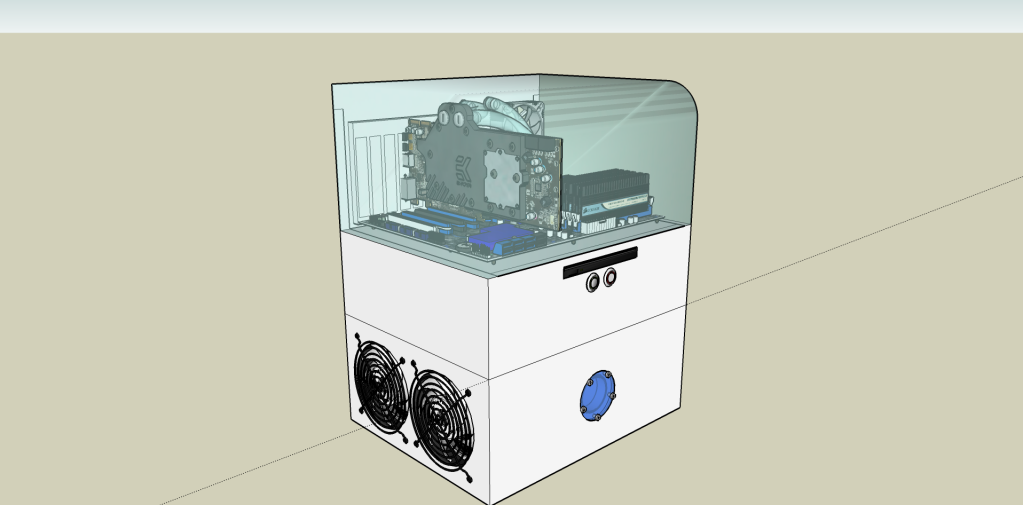

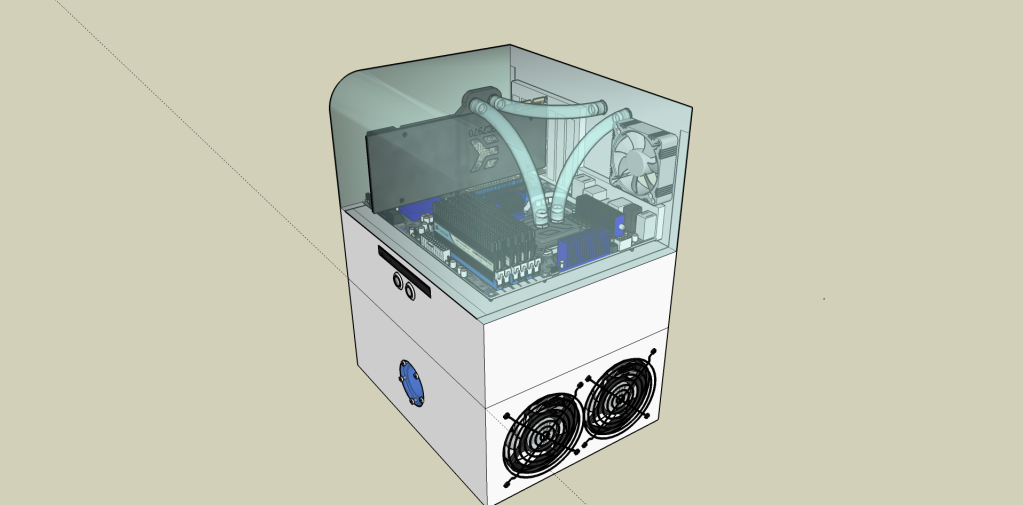

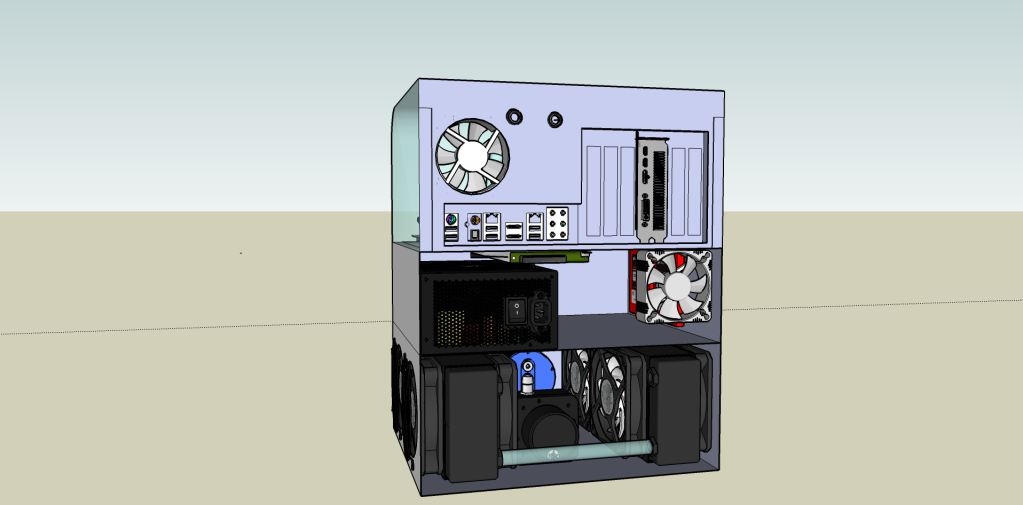

I'm thinking a white windowed case, but i want it to be different to all the other white windows cases out there. So i'm thinking along the lines of curves, maybe inverted motherboard tray, and some distinguishing lets say 'ornate' features, either 3d printed or vacuum formed. I think my obsessive attention to detail will come in very handy with this too

First will be concepting of ideas, which will then move on to CAD drawings, manufacture and the evaluation with a full report as i go along.

If you could make any suggestions i could add to my concepts these will also be greatly appreciated.

I was also thinking (but not getting my hopes up) that i may be able to get sponsorship to kit the thing out. After all what would a custom case be without some water and some power hungry components inside. I would be happy to write a full project log once i get going with the build. If you happen to have any experience with obtaining sponsorship or perhaps would be interesting in sponsoring me with this project then please message me. If all goes well then i hope to have some initial plans and ideas soon and i will certainly be keeping people updated with my progress.

Thanks

As part of year long design-make-review project i am planning to design-make-and review a custom computer case. I chose this is its what i'm interested in and find it easy to talk about. So i'm hoping more experienced people here will assist me in this project.

At my school i have access to a huge array of machinery in our workshops and pretty good at using the majority of it and if i cant i have people who will.

I'm thinking a white windowed case, but i want it to be different to all the other white windows cases out there. So i'm thinking along the lines of curves, maybe inverted motherboard tray, and some distinguishing lets say 'ornate' features, either 3d printed or vacuum formed. I think my obsessive attention to detail will come in very handy with this too

First will be concepting of ideas, which will then move on to CAD drawings, manufacture and the evaluation with a full report as i go along.

If you could make any suggestions i could add to my concepts these will also be greatly appreciated.

I was also thinking (but not getting my hopes up) that i may be able to get sponsorship to kit the thing out. After all what would a custom case be without some water and some power hungry components inside. I would be happy to write a full project log once i get going with the build. If you happen to have any experience with obtaining sponsorship or perhaps would be interesting in sponsoring me with this project then please message me. If all goes well then i hope to have some initial plans and ideas soon and i will certainly be keeping people updated with my progress.

Thanks