Soldato

Right, as a chronic tinkerer and DIYer I have a new conundrum and I need YOUR help to scratch the itch.

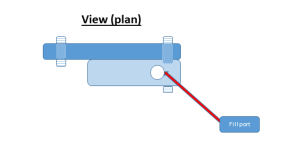

I really think I need to develop and make a custom distribution plate. I love the idea of putting my fittings exactly where they're needed. It opens up options like fill and drain ports, parallel routes (if wanted), and can just tidy up the entire case.

I have access to a laser cutter. I'm familiar with working with acrylic, mechanical assembly etc. Here are my expected challenges:

- I need to make sure it's watertight. This is easy if I glue the parts together, but will be visible if using clear acrylic. I'd love to find a good adhesive process that can look OK. If not...

- I'll need to make rubber gasket seals. This will involve cutting a channel in the acrylic and using gasket strip. I'll experiment with this in the near future to see if a decent channel can be made using the tools I have.

- It needs to be useful! No point making a plain old reservoir unless it looks awesome, so I want to design something that serves a need in a particular case or project.

I'm open to input from everyone as to what I need to consider and how to go about it. If you have a build coming up and you'd like to collaborate, and test my prototypes, even better. I won't be happy until I've given this a go and I intend to learn a lot through the process. I'm ordering clear perspex in 6mm and 10mm thicknesses, let me know if you think I ought to order black or some other solid/transparent colours!

So what do you think? Am I barking up the wrong tree, or are you excited to see the results?

N.B. Mods, if this would be better suited to the Project Logs forum please go ahead and move it

I really think I need to develop and make a custom distribution plate. I love the idea of putting my fittings exactly where they're needed. It opens up options like fill and drain ports, parallel routes (if wanted), and can just tidy up the entire case.

I have access to a laser cutter. I'm familiar with working with acrylic, mechanical assembly etc. Here are my expected challenges:

- I need to make sure it's watertight. This is easy if I glue the parts together, but will be visible if using clear acrylic. I'd love to find a good adhesive process that can look OK. If not...

- I'll need to make rubber gasket seals. This will involve cutting a channel in the acrylic and using gasket strip. I'll experiment with this in the near future to see if a decent channel can be made using the tools I have.

- It needs to be useful! No point making a plain old reservoir unless it looks awesome, so I want to design something that serves a need in a particular case or project.

I'm open to input from everyone as to what I need to consider and how to go about it. If you have a build coming up and you'd like to collaborate, and test my prototypes, even better. I won't be happy until I've given this a go and I intend to learn a lot through the process. I'm ordering clear perspex in 6mm and 10mm thicknesses, let me know if you think I ought to order black or some other solid/transparent colours!

So what do you think? Am I barking up the wrong tree, or are you excited to see the results?

N.B. Mods, if this would be better suited to the Project Logs forum please go ahead and move it

Cut a few spares out of proper clear for the second stage of testing, in the second picture. Excuse potato photos, my phone died on 26% battery as I sat down at the laser.

Cut a few spares out of proper clear for the second stage of testing, in the second picture. Excuse potato photos, my phone died on 26% battery as I sat down at the laser.