Soldato

- Joined

- 6 Jan 2013

- Posts

- 22,177

- Location

- Rollergirl

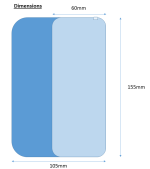

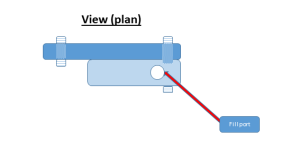

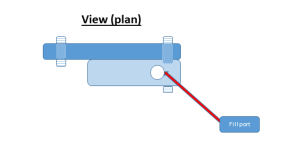

I think maybe we could simplify the reservoir first as it consumes a lot of the space. Here's a wee idea:

Remove the reservoir and affix a plate to the inside rear. Could this plate be used as a reservoir too? You'll see that I would need 2 off G1/4 ports on the rear that would cater for the external loop. One of the rear ports would connect to the reservoir and the other would connect to a port on the inside that the GPU outlet would connect to. Another port on the inside would connect to the reservoir and the pump inlet would screw into that one.

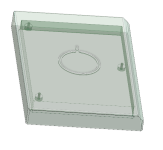

Does that make sense? By the way, here's some current photographs.

Remove the reservoir and affix a plate to the inside rear. Could this plate be used as a reservoir too? You'll see that I would need 2 off G1/4 ports on the rear that would cater for the external loop. One of the rear ports would connect to the reservoir and the other would connect to a port on the inside that the GPU outlet would connect to. Another port on the inside would connect to the reservoir and the pump inlet would screw into that one.

Does that make sense? By the way, here's some current photographs.

4D Model Shop and Cut Laser Cut are zone 1 but services rather than workshops. Yep, like a vinyl type thing but obviously needs to look good.

4D Model Shop and Cut Laser Cut are zone 1 but services rather than workshops. Yep, like a vinyl type thing but obviously needs to look good.