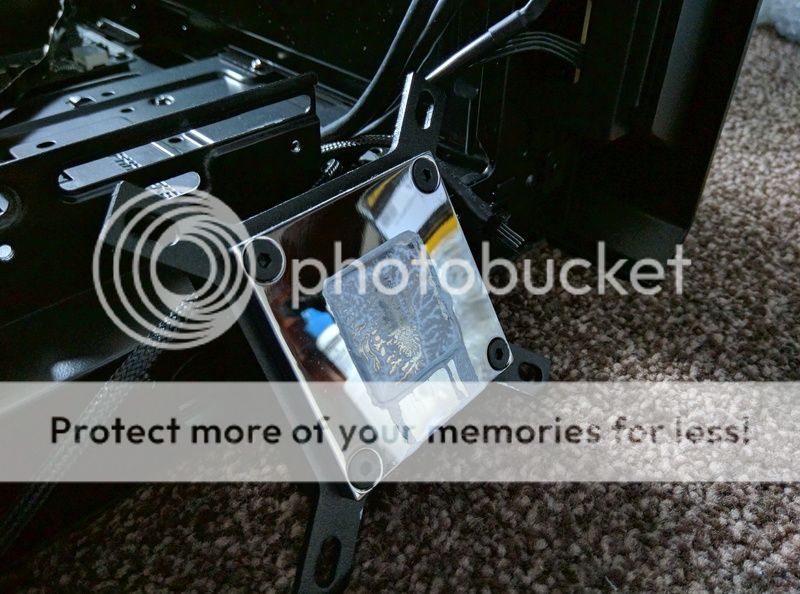

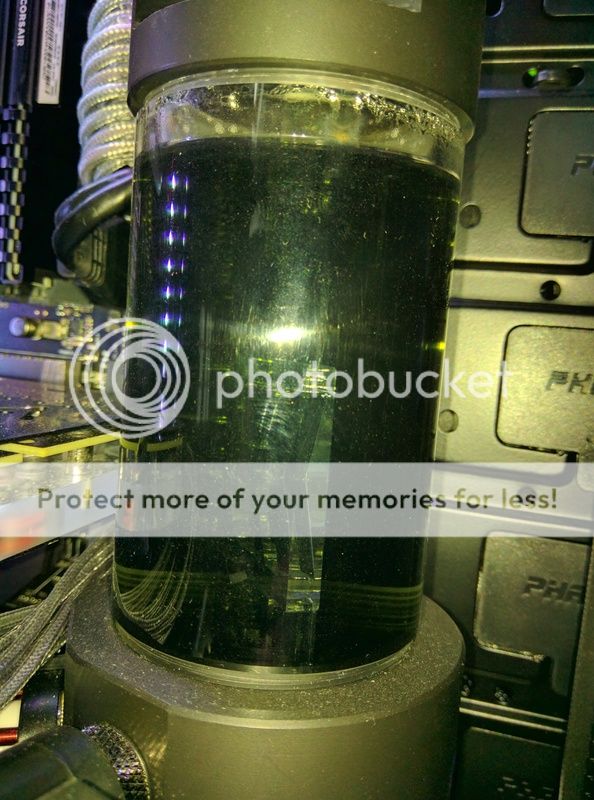

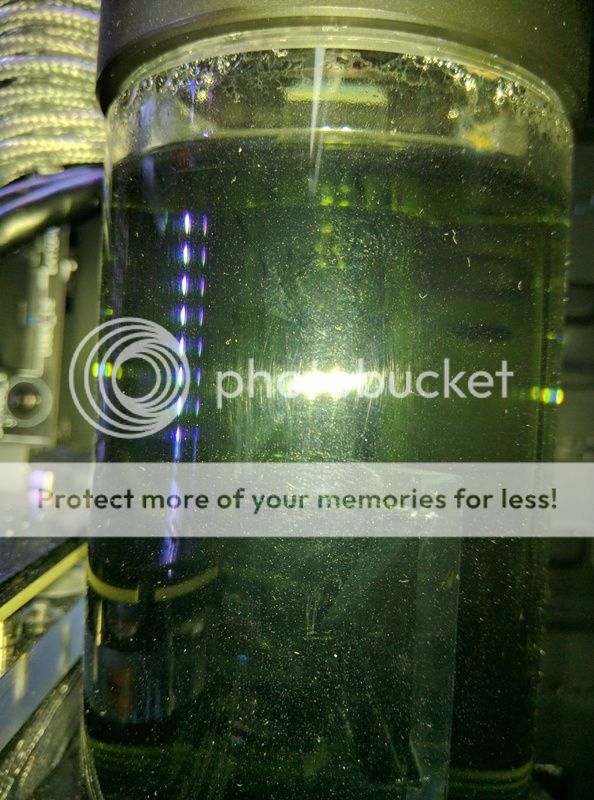

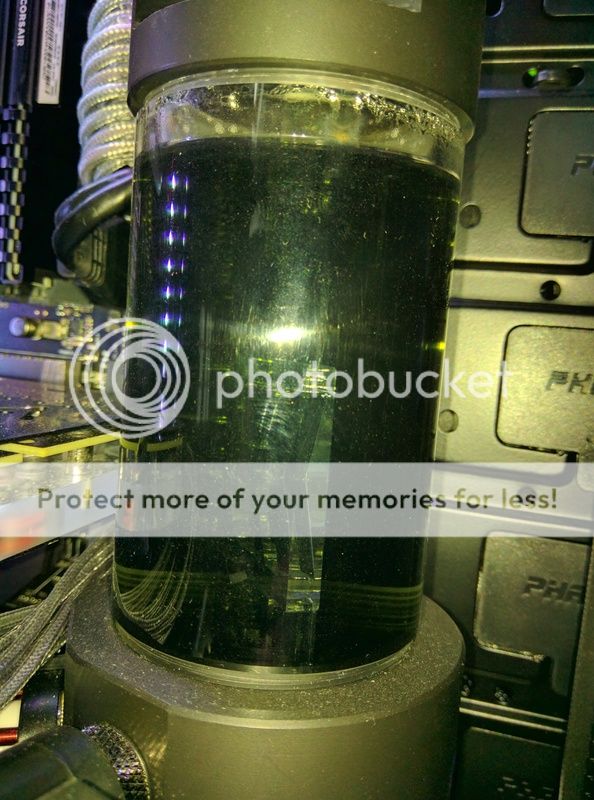

Before all of my brainpower gets used up on the new build I thought I'd best check the current one over as it hasn't been used a lot recently, and I hadn't given it the once over for leaks in months.

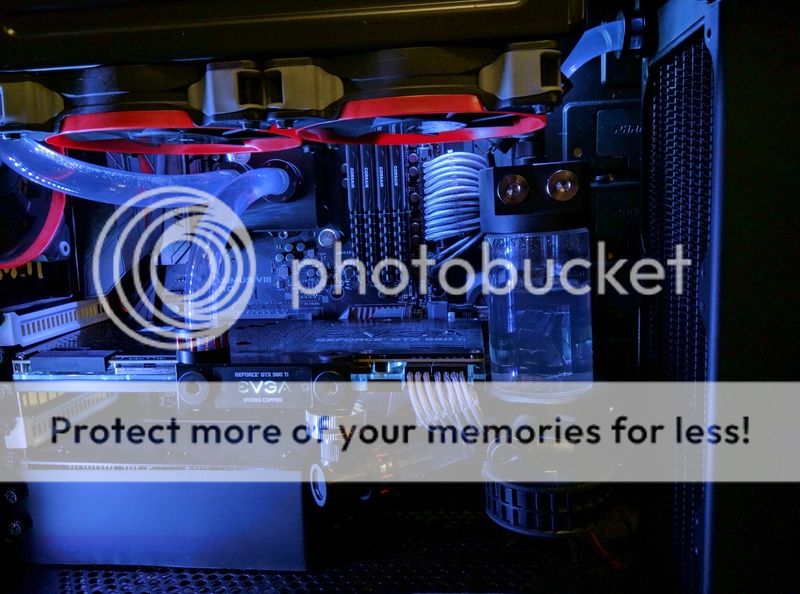

Well there weren't any leaks... But... Erm...

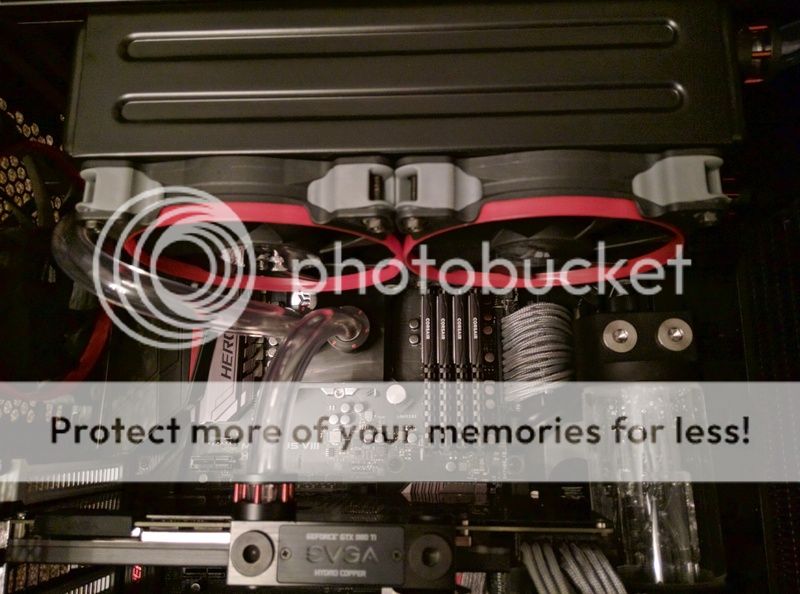

Still working faultlessly and the temperatures are still absolutely brilliant, but think I might just have to strip this one down, give it a quick flush and install some new tubing before the current / future build starts

It's tempting to use this as a trial run with the PETG, but not sure I could justify all the extra expense on new fittings when there's nothing wrong with the current setup. Oh well, time to order some more Mayhems

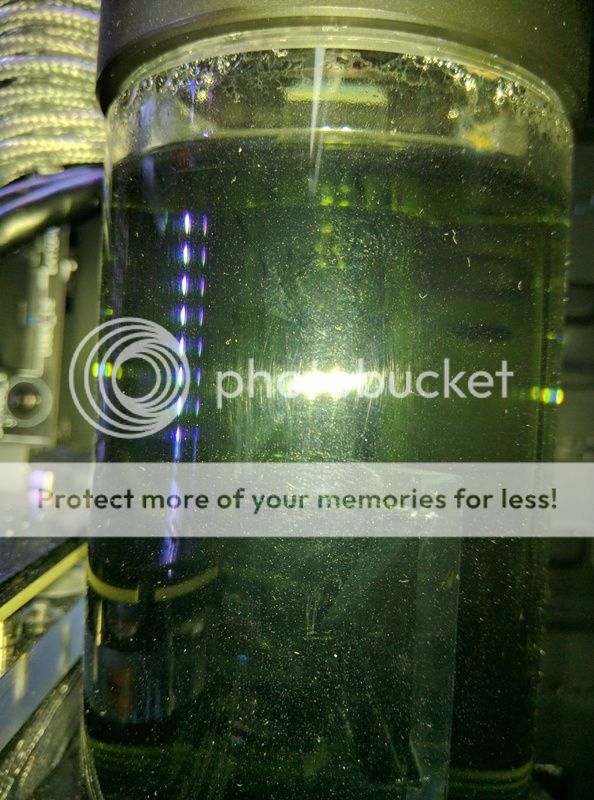

Well there weren't any leaks... But... Erm...

I don't recall the water being that colour!!

It's tempting to use this as a trial run with the PETG, but not sure I could justify all the extra expense on new fittings when there's nothing wrong with the current setup. Oh well, time to order some more Mayhems