Associate

- Joined

- 23 Aug 2007

- Posts

- 1,699

- Location

- Rothesay

Ok im currently running a Zalman Reserator V1 to cool my aging Amd X2 4400+ 939 socket. Now with it coming slowly into summer and the temps slowly rising current idle temps around 32c.

I knew when i bought the cooling system from MM that it would not drastically lower my CPU temps but it would lower the amout of noise my system makes, which it has done.

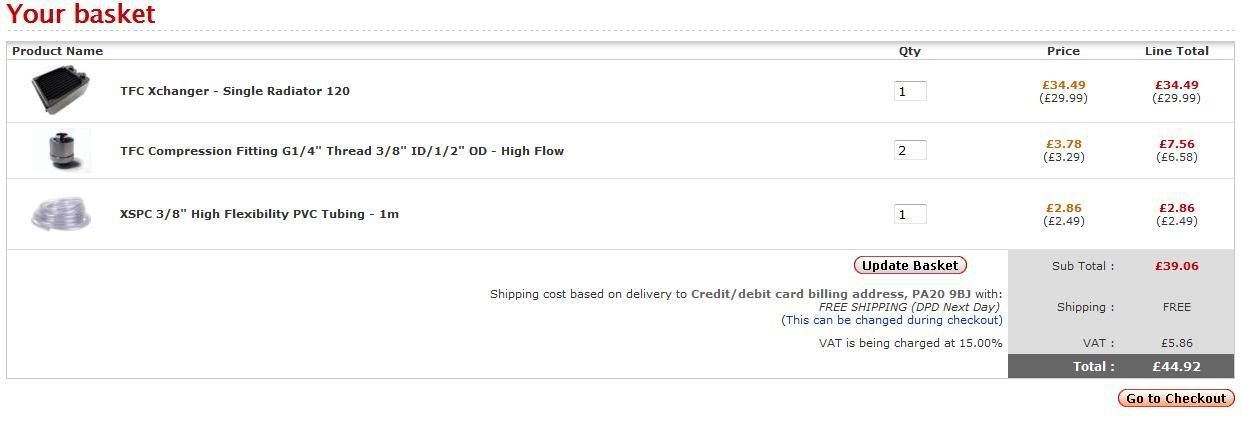

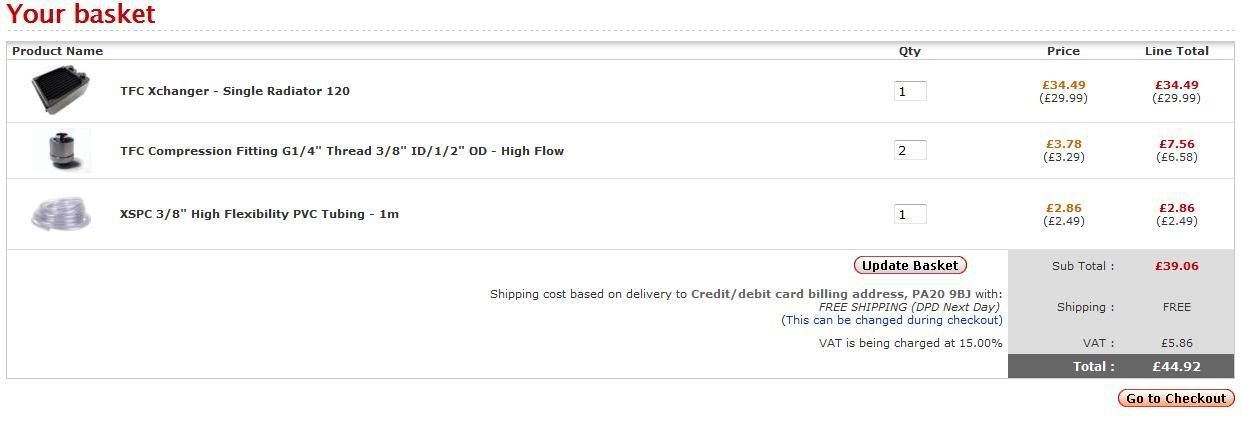

So ive decided to add a 120.1 rad to the loop and make use of the rear case fan that is already running to help reduce my temps whilst still enjoying the silence i currently have.

To this end i have put together a shopping list and am just looking for a couple of opinions as to the merit of its current content.

I know the Thermochill PA120.1 rad would be better but my budget cant quite strech that far at present.

I also know that a fully active internal system would be a lot better but im not ready to go the full custom internal WC system yet but slowly working towards it.

I knew when i bought the cooling system from MM that it would not drastically lower my CPU temps but it would lower the amout of noise my system makes, which it has done.

So ive decided to add a 120.1 rad to the loop and make use of the rear case fan that is already running to help reduce my temps whilst still enjoying the silence i currently have.

To this end i have put together a shopping list and am just looking for a couple of opinions as to the merit of its current content.

I know the Thermochill PA120.1 rad would be better but my budget cant quite strech that far at present.

I also know that a fully active internal system would be a lot better but im not ready to go the full custom internal WC system yet but slowly working towards it.