Hello Everyone

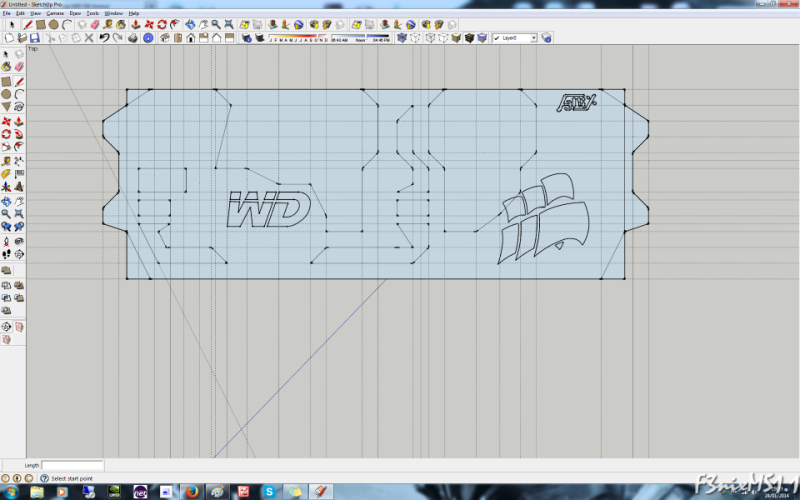

I have been building my custom desk for a while now and it has reached that stage where I feel that it's time to share with this great community.

Would like to thank the likes of Peter Brands and Pascal de Greef who have inspired and motivated me to attempt something of this scale, there has been stages where I just thought that it was turning out to be a bit too much but with a bit of research I have come to learn that everything is possible. I have also learned along this journey that there is some really good people out their who are willing to give up their own time to assist and help a total stranger in all ways that they can. There's still hope for humanity after all :thumb: lol

I have picked up a few sponsors along the way which I will be introducing as I progress through this build log, I would like to take this opportunity to once more thank them for their help and belief, this project would have been completely different without their help :dremel:

But let's get this build log going, I will try and keep it as short as possible but have well over 1000 pictures on my facebook page, which by the way is FenixMS1.1. Just in case anyone is interested to have a look.

Mod to live or live to mod???

Thank you everyone. Hope you enjoy the ride

**************************************************

I would like to take the chance to send a huge thank you to all the companies that have believed and decided to support this build. I surely wouldn't have been able to do it the same way without their amazing help. Thank you All

Power and Reset Switches

PSU and Fans

LED Lighting and Custom Cables

Fans

Partial Sponsor of a 360 Admiral Radiator

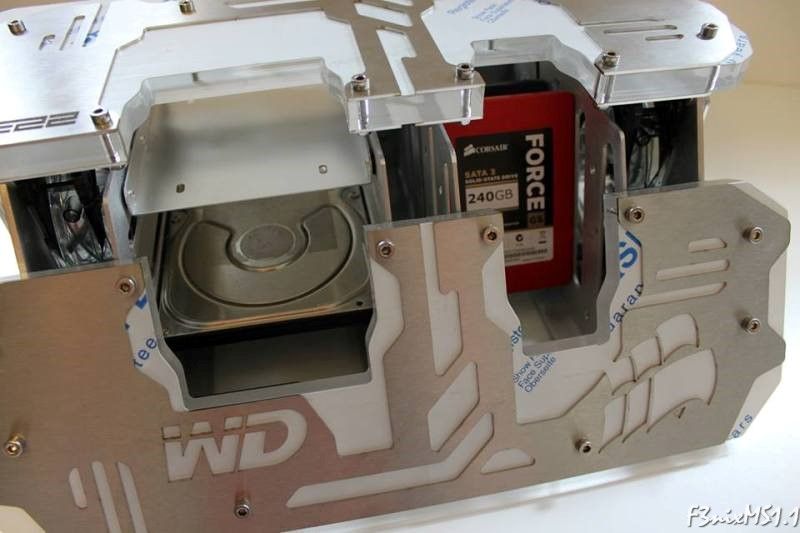

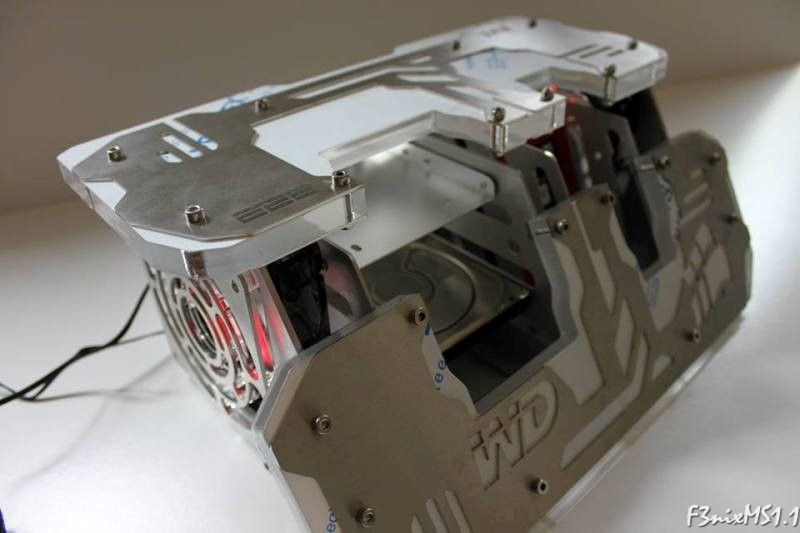

4TB Hard Drive

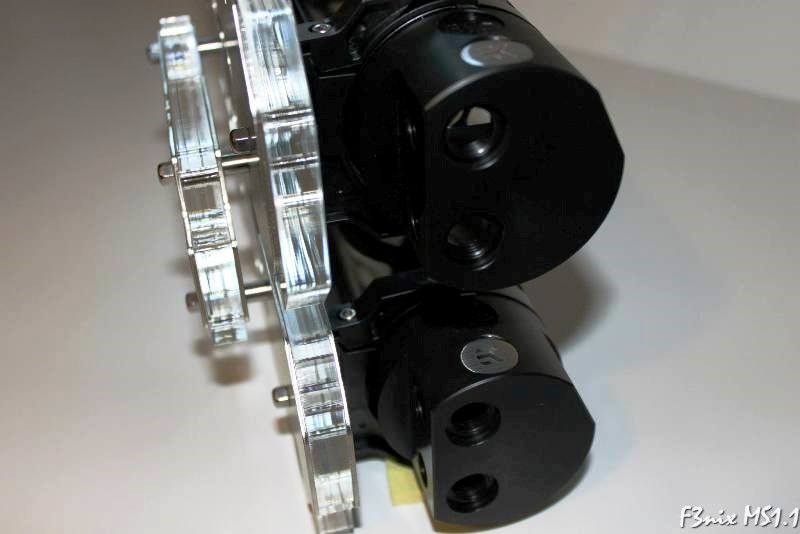

Water Cooling Parts

PSU and Fans

Slim Optical Disc Drives, 5.25" Aluminium Cover Bay and Fan Filters

16GB (4096MB 512M x 64-Bit x 4 pcs.) DDR4-2666MHz

2 Huge Custom Sized Filters

And some more which unfortunately I cannot mention as they are direct competitors of Overclockers UK

I have been building my custom desk for a while now and it has reached that stage where I feel that it's time to share with this great community.

Would like to thank the likes of Peter Brands and Pascal de Greef who have inspired and motivated me to attempt something of this scale, there has been stages where I just thought that it was turning out to be a bit too much but with a bit of research I have come to learn that everything is possible. I have also learned along this journey that there is some really good people out their who are willing to give up their own time to assist and help a total stranger in all ways that they can. There's still hope for humanity after all :thumb: lol

I have picked up a few sponsors along the way which I will be introducing as I progress through this build log, I would like to take this opportunity to once more thank them for their help and belief, this project would have been completely different without their help :dremel:

But let's get this build log going, I will try and keep it as short as possible but have well over 1000 pictures on my facebook page, which by the way is FenixMS1.1. Just in case anyone is interested to have a look.

Mod to live or live to mod???

Thank you everyone. Hope you enjoy the ride

**************************************************

I would like to take the chance to send a huge thank you to all the companies that have believed and decided to support this build. I surely wouldn't have been able to do it the same way without their amazing help. Thank you All

Power and Reset Switches

PSU and Fans

LED Lighting and Custom Cables

Fans

Partial Sponsor of a 360 Admiral Radiator

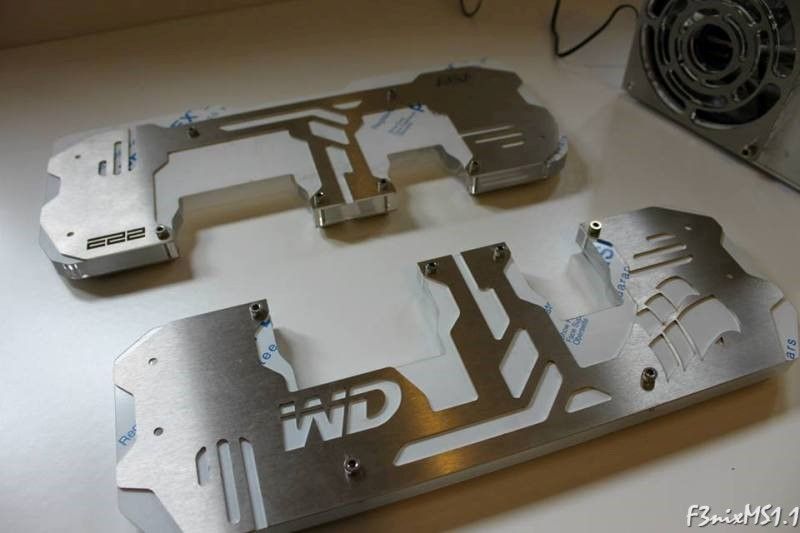

4TB Hard Drive

Water Cooling Parts

PSU and Fans

Slim Optical Disc Drives, 5.25" Aluminium Cover Bay and Fan Filters

16GB (4096MB 512M x 64-Bit x 4 pcs.) DDR4-2666MHz

2 Huge Custom Sized Filters

And some more which unfortunately I cannot mention as they are direct competitors of Overclockers UK

Last edited: