Hello! This is my first thread here. I would like to show what I have been developing recently.

FINAL PHOTOS ADDED (28-12-2015)

----------------

It started with Hadron Air, small stylish and no airflow at all. Took me some time to mod it as I decided to fit ATX power supply inside. Things were so crammed, temps were going crazy.

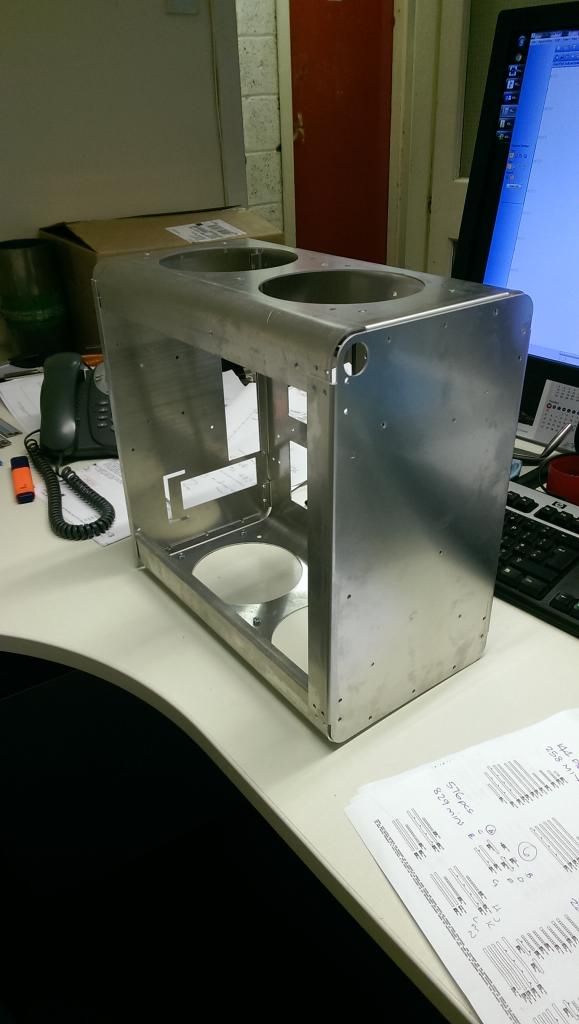

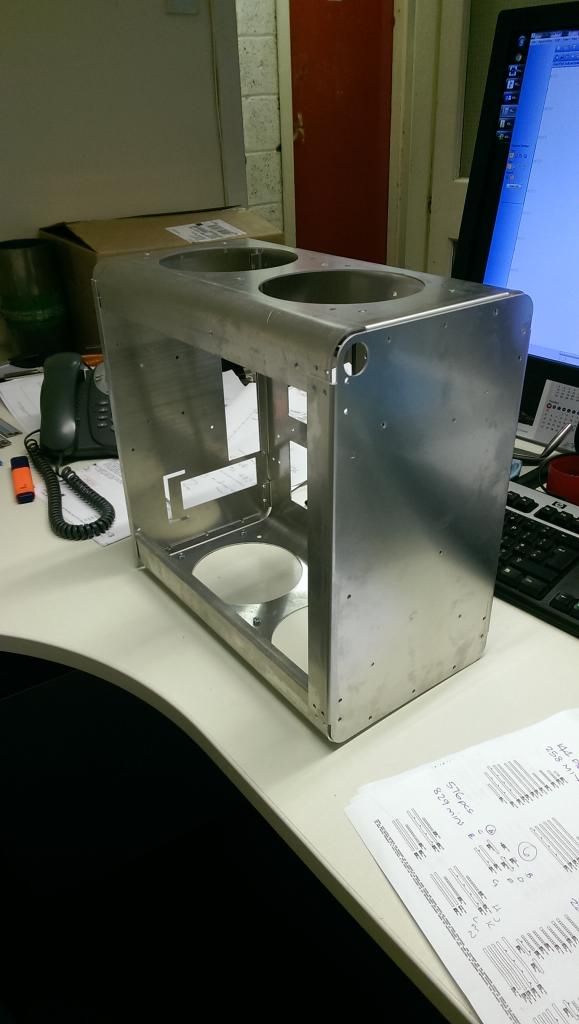

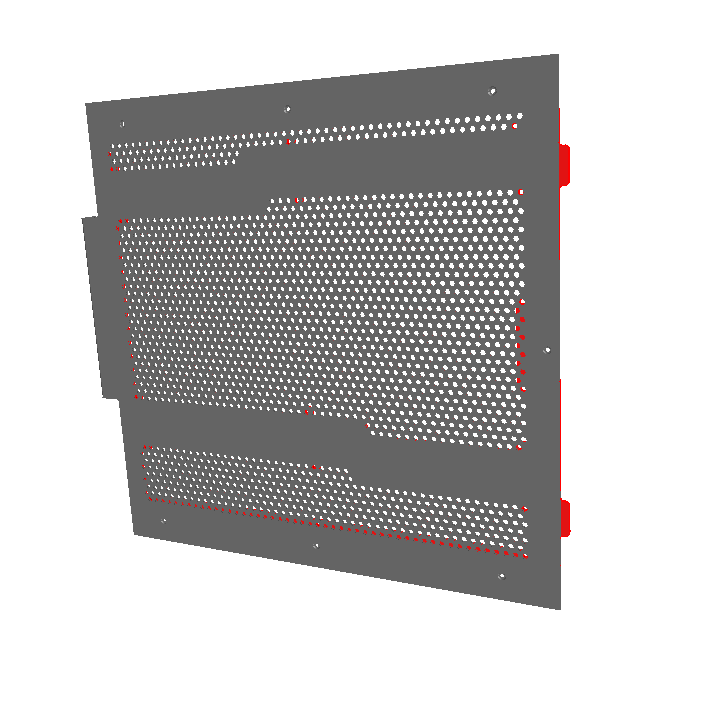

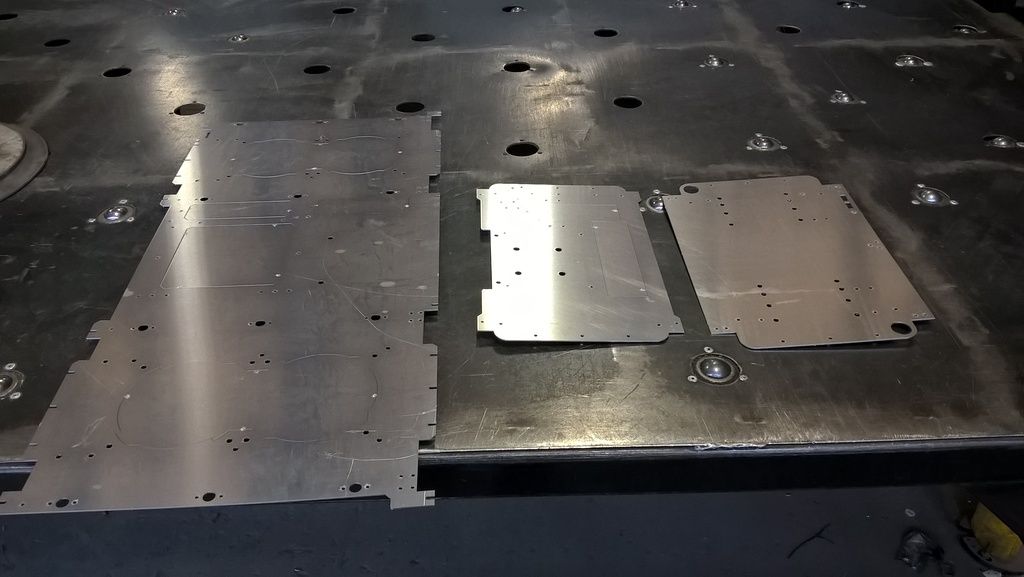

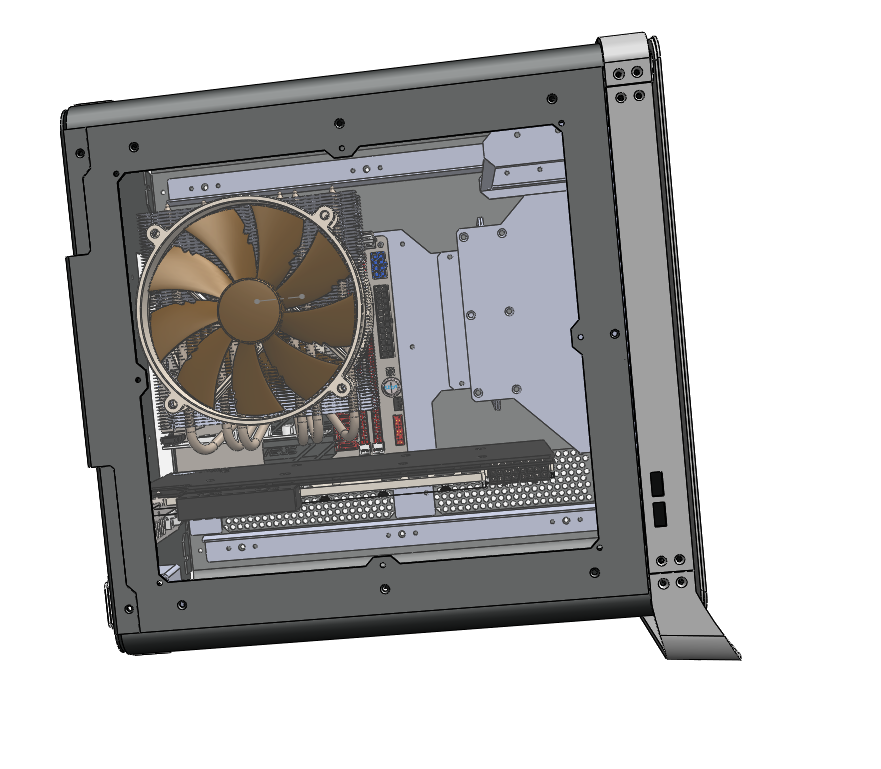

I thought to myself - how hard can it be to make my own case? Since I have access to machinery I decided to have a go, then this came up.

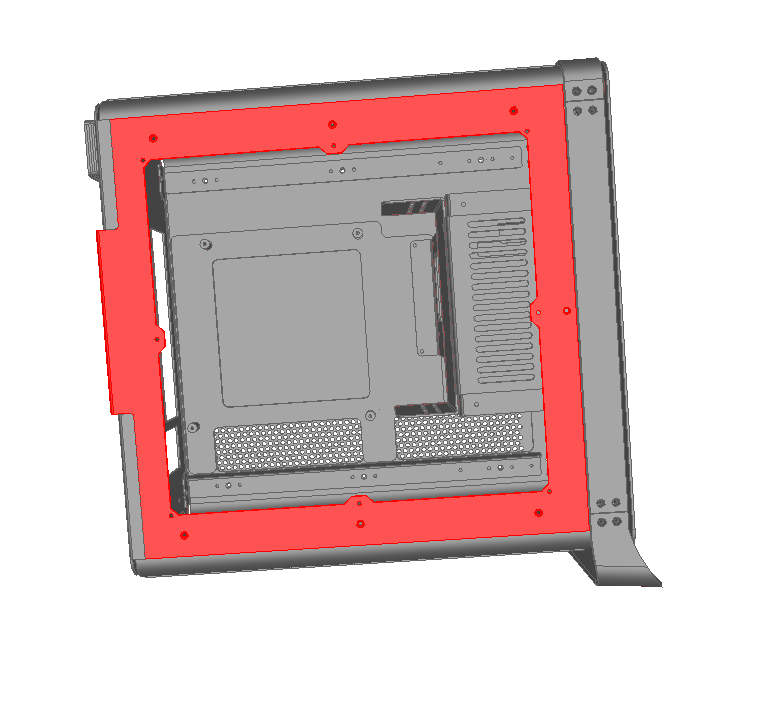

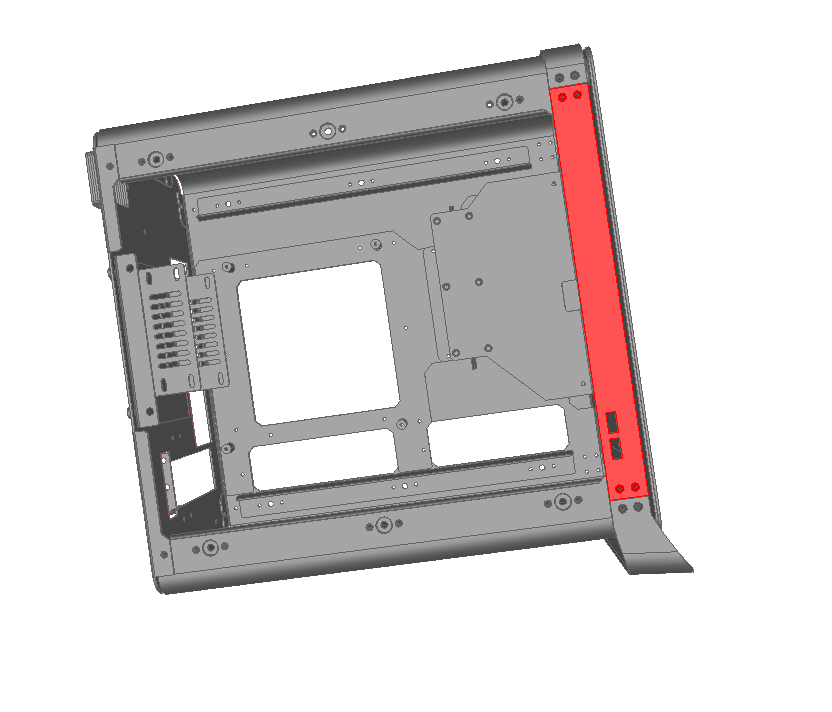

Basic frame worked fine for me so I started to add more things to it.

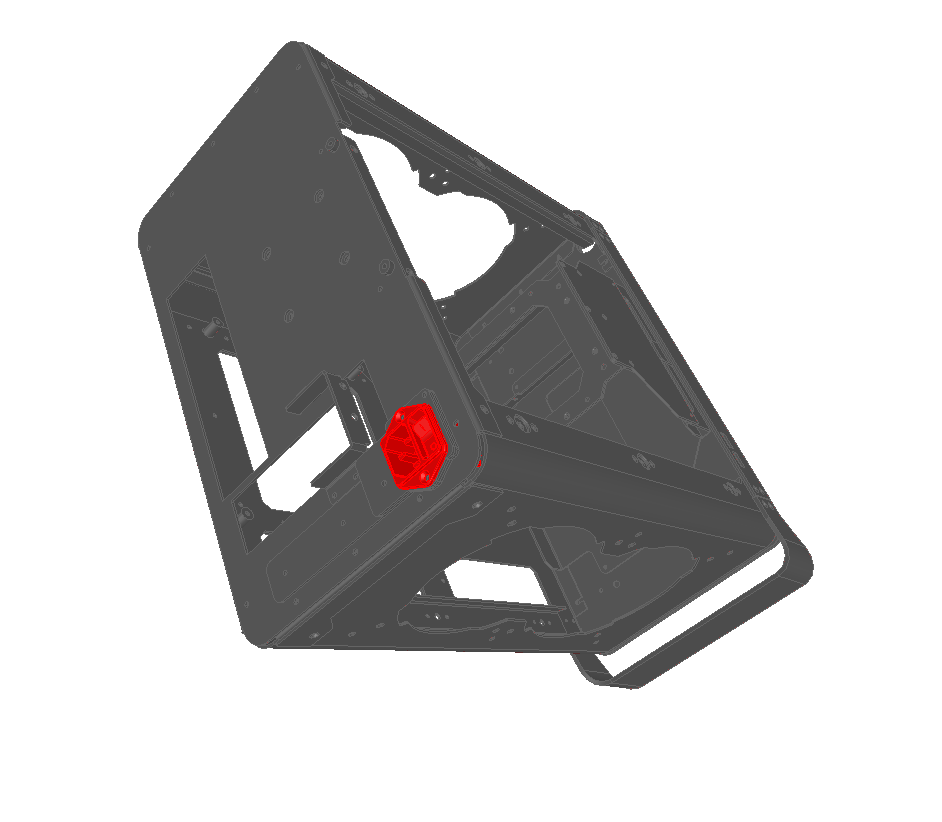

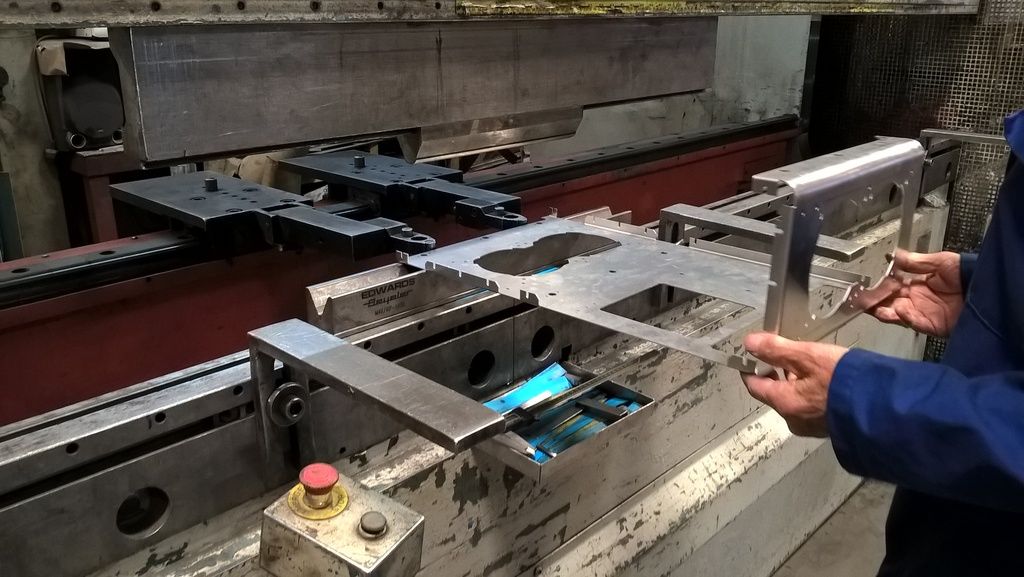

I was quite happy with everything so far, apart from the front foot, which wasn't bent quite as expected. I had to change that and come up with some fan covers.

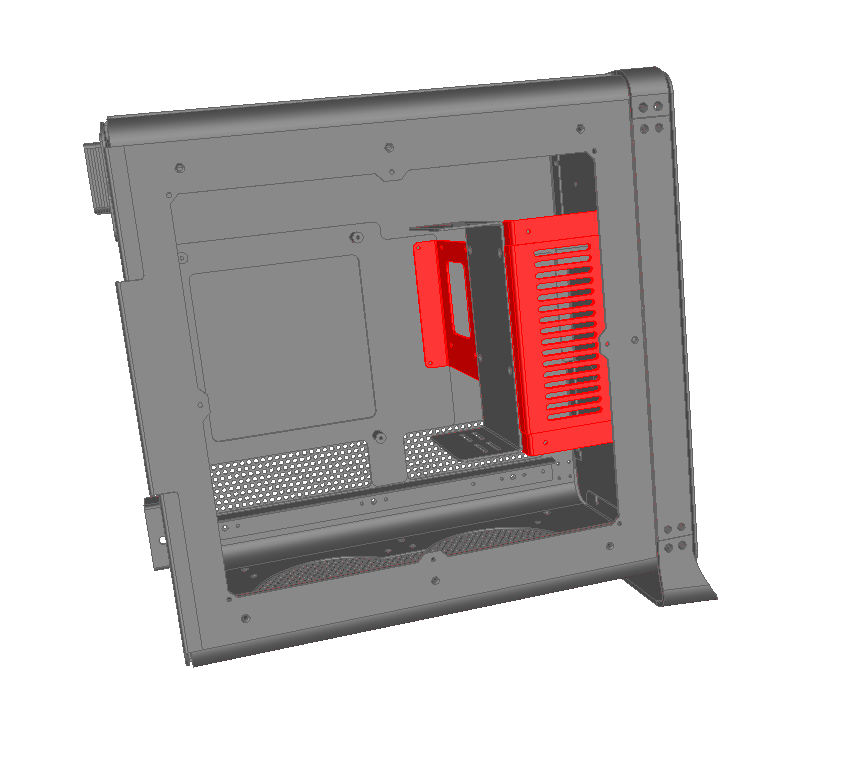

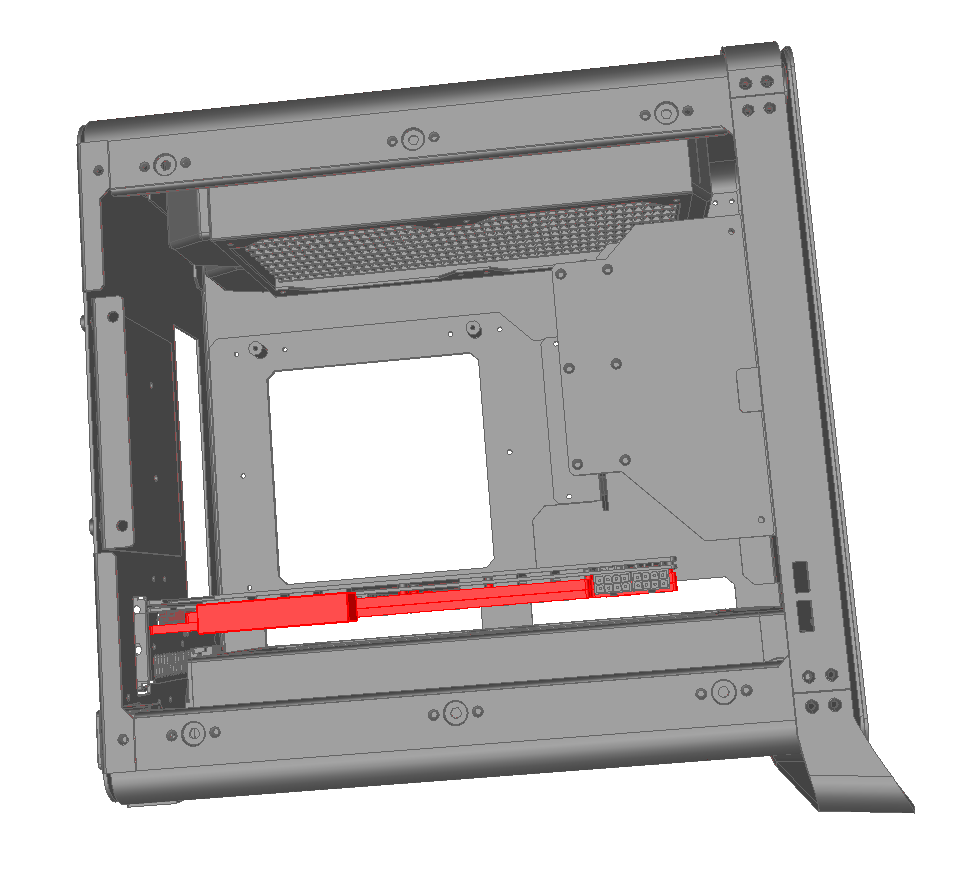

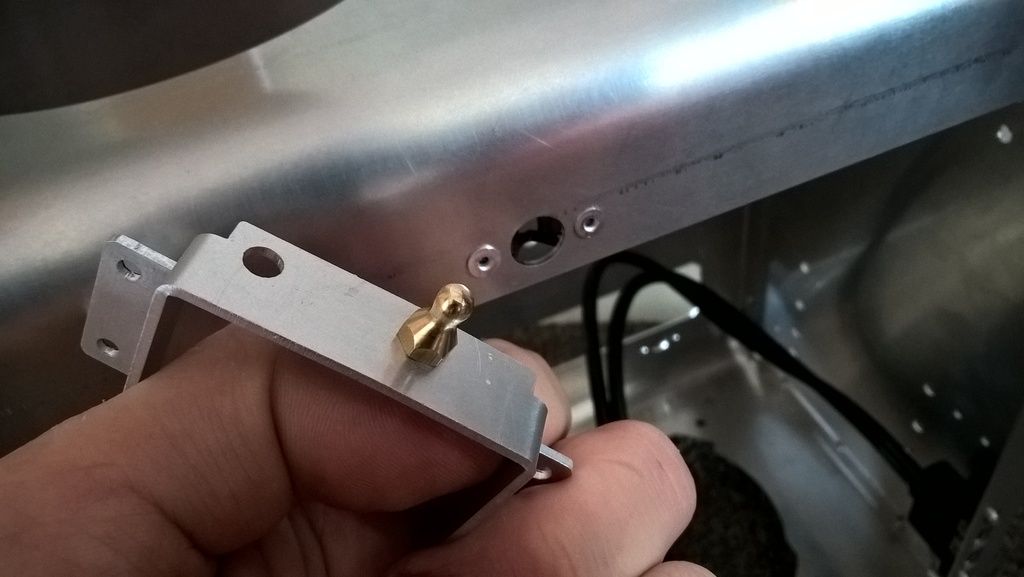

Came up with the idea to mount power supply at 90 degree angle, so new bracket made:

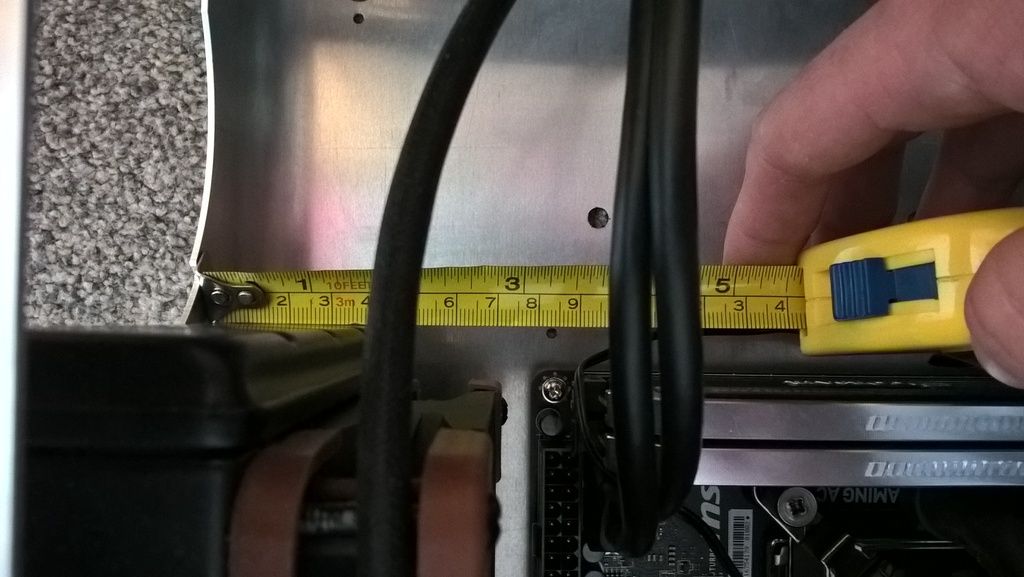

I was also testing my old gtx 770 lightning. Much cooler than kingpin:

Finally after some time:

And some better photos with dslr:

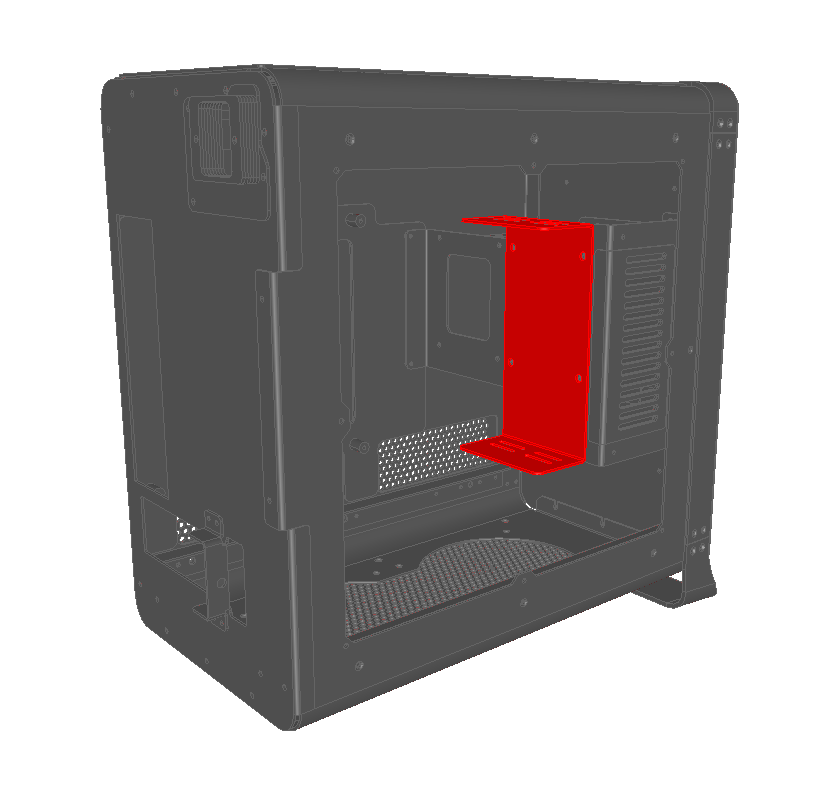

I have also decided to have my H80i on the side, new bracket to fit:

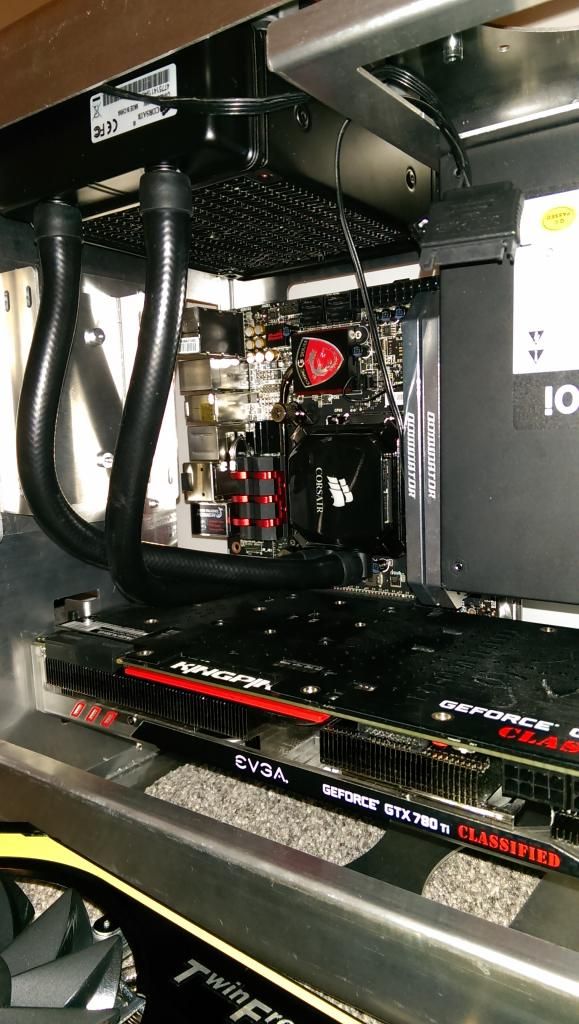

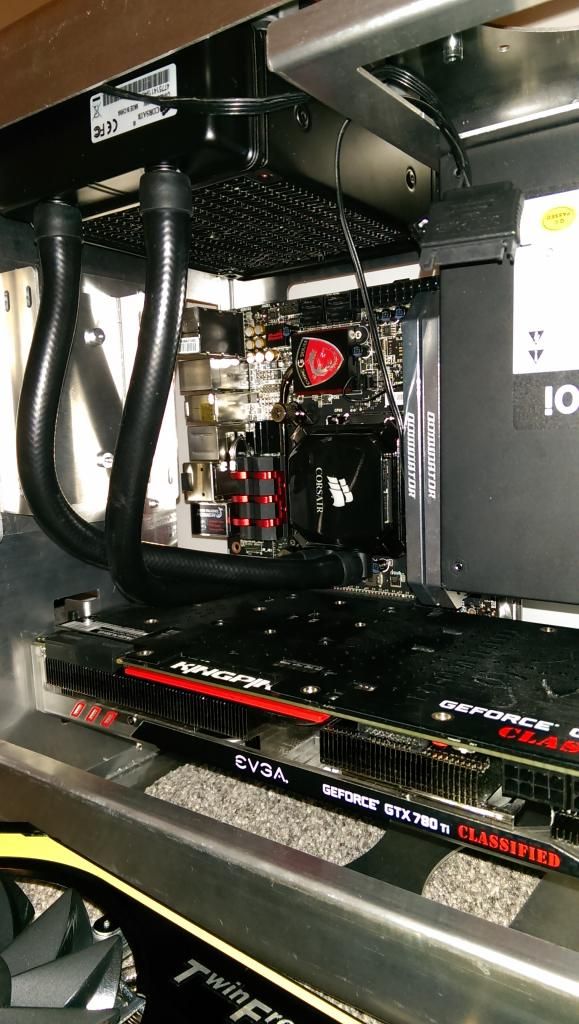

Stuff inside:

i7 4790K

Z97i Gaming AC

2 x 4GB Dominator Platinum 2133

850 Pro SSD

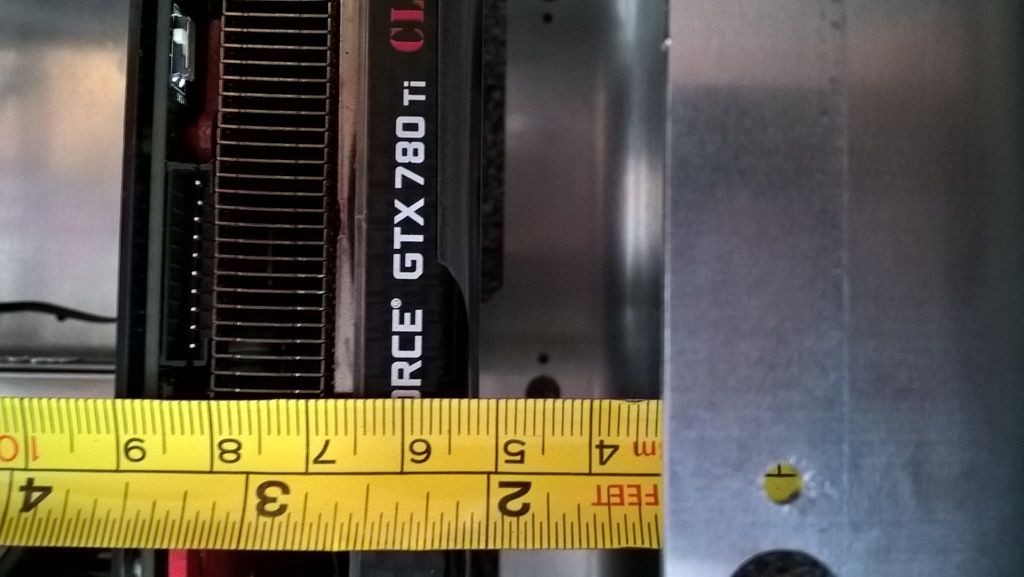

780ti Kingpin

H80i+Noctua NF-F12 2000RPM PWM

4 x Noctua NF-S12B Redux 1200 RPM PWM

In Battlefield 4 (no OC) with room temp @ 22.5 deg C:

CPU @ 66 deg. C (fan at 90%)

GPU @ 74 deg. C (fan at 70%)

Firestrike - 12049 points:

-CPU @ 4.7 GHz

-MEM @ 2133MHz

-GPU core @ 1270MHz

-GPU mem @ 3542MHz

Max registered temp during benchmark:

-CPU = 67 deg. C

-GPU = 79 deg. C (with custom fan curve in Afterburner with speed @ 80%)

I'm currently working to support water cooling, relocate SSD mounting bracket, some other tweaks.

Let me know what you guys think

FINAL PHOTOS ADDED (28-12-2015)

----------------

It started with Hadron Air, small stylish and no airflow at all. Took me some time to mod it as I decided to fit ATX power supply inside. Things were so crammed, temps were going crazy.

I thought to myself - how hard can it be to make my own case? Since I have access to machinery I decided to have a go, then this came up.

Basic frame worked fine for me so I started to add more things to it.

I was quite happy with everything so far, apart from the front foot, which wasn't bent quite as expected. I had to change that and come up with some fan covers.

Came up with the idea to mount power supply at 90 degree angle, so new bracket made:

I was also testing my old gtx 770 lightning. Much cooler than kingpin:

Finally after some time:

And some better photos with dslr:

I have also decided to have my H80i on the side, new bracket to fit:

Stuff inside:

i7 4790K

Z97i Gaming AC

2 x 4GB Dominator Platinum 2133

850 Pro SSD

780ti Kingpin

H80i+Noctua NF-F12 2000RPM PWM

4 x Noctua NF-S12B Redux 1200 RPM PWM

In Battlefield 4 (no OC) with room temp @ 22.5 deg C:

CPU @ 66 deg. C (fan at 90%)

GPU @ 74 deg. C (fan at 70%)

Firestrike - 12049 points:

-CPU @ 4.7 GHz

-MEM @ 2133MHz

-GPU core @ 1270MHz

-GPU mem @ 3542MHz

Max registered temp during benchmark:

-CPU = 67 deg. C

-GPU = 79 deg. C (with custom fan curve in Afterburner with speed @ 80%)

I'm currently working to support water cooling, relocate SSD mounting bracket, some other tweaks.

Let me know what you guys think

Last edited:

I'd even go as far to say 2.3kg of force could be too much!

I'd even go as far to say 2.3kg of force could be too much!