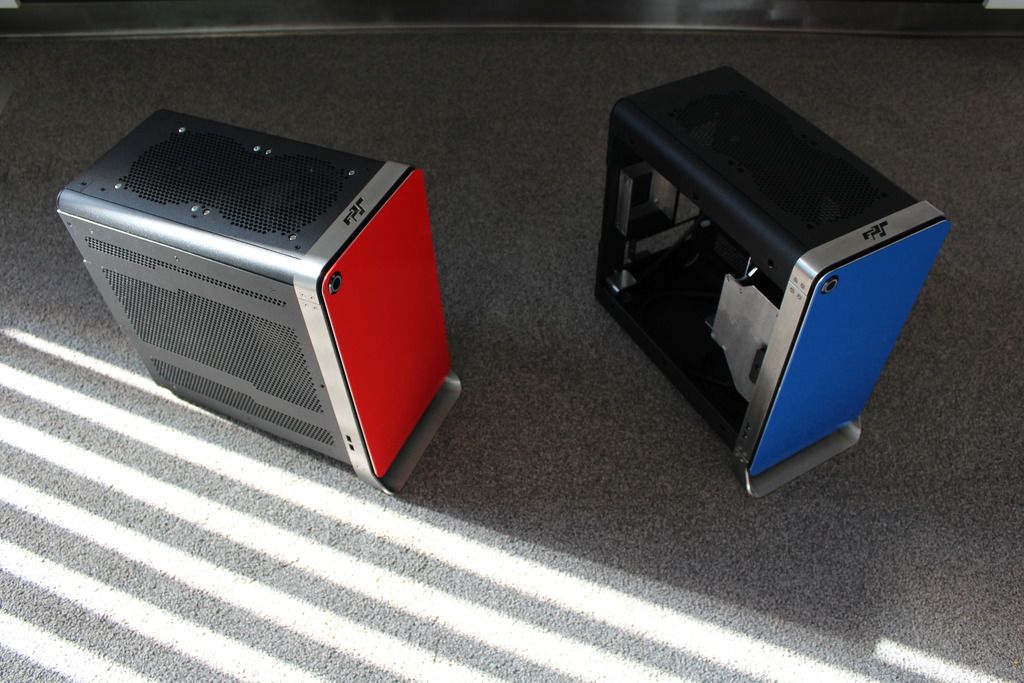

Right, so I tested it. I came across few issues.

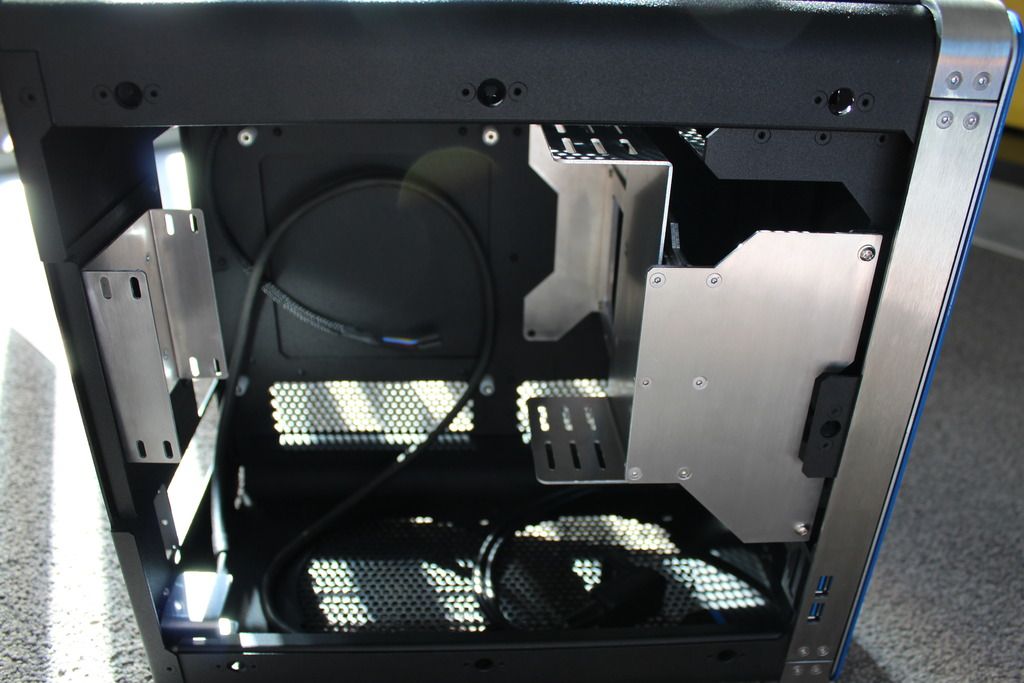

1) SFX power supply - cables are way too short for clean install. There are extensions available, which I will be trying in future, but even with these cables I wasn't able to plug my 780ti card as I was short of 1 x 6 pin connector and I didn't have any sort of SATA>PCIE adapter. I had to try my AX760i psu.

2) New PSU mount restricts some cable routing behind power supply, The shroud will have to be slightly redesigned so I can hide all cables behind it.

3) To put everything right I had to follow this fitting sequence: mount psu to bracket, mount psu in with bracket in place, plug extension cable, mount fan over psu, mount fan next to it. Nothing really wrong, but If you have to take something out, it may be a pain.

4) PCIE power cable could be A LOT shorter, like 1/4 of the length. I had to cram them behind GPU

5) As I lowered the PSU mount by literally 3mm down, it got really tight at the bottom and big cards like this kingpin struggle slightly for clearance, cables had to be bent.

Apart from these, I'm overall quite happy with how all of it went in. I will be looking out for even shorter PSU, like 150mm long for extra 10mm clearance which will help a lot. If I had thinner fans I could lift this PSU up by extra 10mm which would help - mounting points are there already.

Front USB ports work like a charm, VERY handy to have it

Performance wise - I have started this with 4 fans in total. I was expecting temps on GPU to be higher, but they weren't. Maxed Kingpin out at 74 degrees C in Valley. which isn't bad. I have noticed that it just takes longer to cool down. I also noticed that with Window panel, there is a lot more hot air coming through the top.

Checked Heaven benchmark and BF4 as well, Couldn't get GPU or CPU over 74 deg C.

While GPU maintains steady temp with window panel, CPU is higher than previously. Must me less cold air entering the case.

OK guys, I hope you enjoy couple of shots. I have to tidy up a bit in my room now.