Hi all, I have a little update for you.

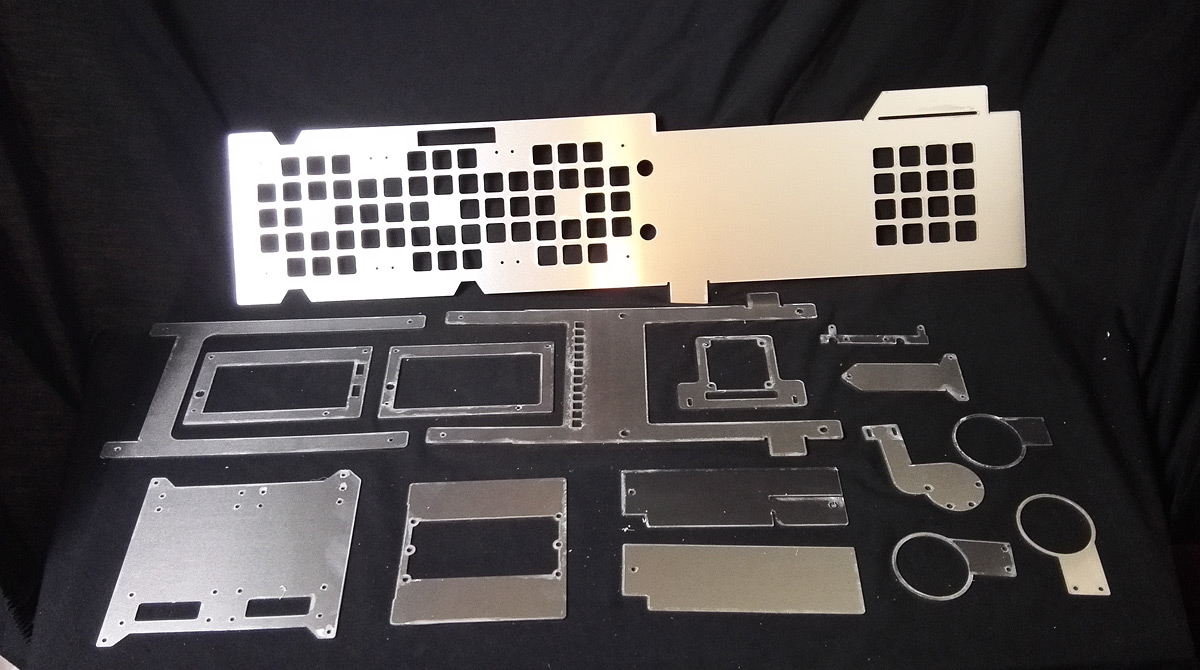

It took a while to get the sheet bender repeatedly accurate and get the bend radius of my aluminium work down to where it should be, but now it's good to go!

So I've folded some plastic instead

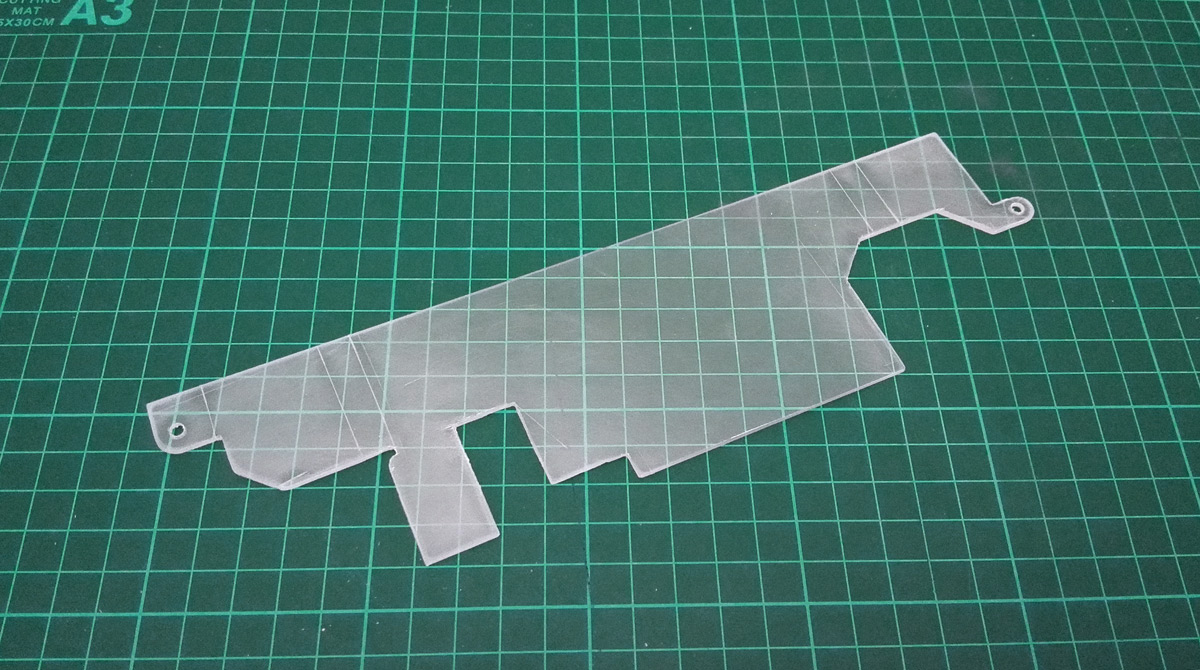

I/O shroud shape, cut by hand in 1.5mm PETG sheet

Took a while to get that I will admit. Looks like my wrist is still a bit wonky to get accurate cuts with a coping saw, so I went for neverending score, cut and snap with a sharp knife. Got there in the end though.

After a bit of cleanup, I did a quick frosting job on a portion of what will be the top face for an experiment I'll mention shortly

It's not perfect, but will only have tiny amount of it showing so should be fine. Circular motions with 100 grit paper for a few minutes on both sides of the piece, then another couple of minutes with 400 grit to smooth it up. Didn't bother to wet sand this as it's only small.

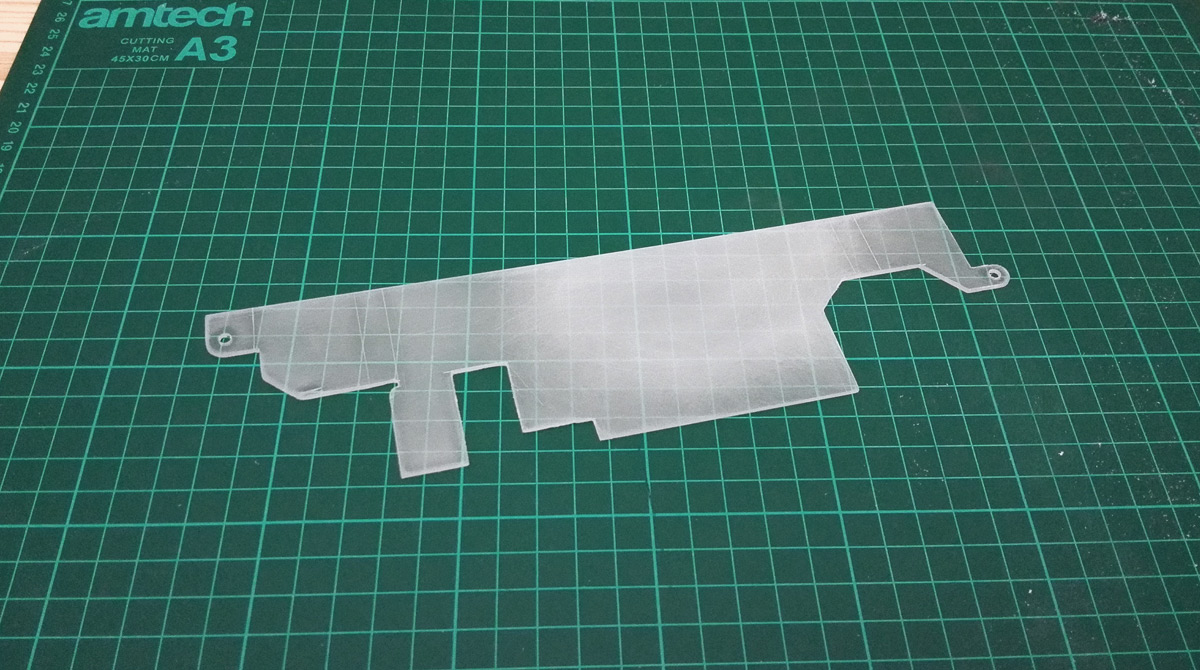

Then got the heat gun out and folded it all up. The front face was put into my sheet bender for a nice, tight edge, and the curved ends were done over the handle of an exacto knife for a 5mm radius, or thereabouts.

Took a few attempts to get it all correct and relatively straight, but I got so excited at finishing it I didn't take a picture of the untreated item and went straight into a quick test wrap.

Brushed black aluminium effect. I wanted to replicate the hairline brushing on EVGA's shrouds, but wasn't sure if it'd be too much against the matte black I've used on the motherboard...

Now THAT is a Black Edition motherboard. Excuse the wonky placement and the dodgy Alphacool M3 copper screws!

It's not perfect but the wrap covers a multitude of sins, plus it'll be painted to cover any exposed PETG when the wrap is done properly.

Hopefully my little enhancement will pan out: backlit logo

Thanks for looking!

had a hold up on building the material bender I need so things stalled a bit, and then I smashed my wrist up.

had a hold up on building the material bender I need so things stalled a bit, and then I smashed my wrist up. )

)