You mean the MSI X99S?

It was shipped free, by DPD, but that's because of the forum posts etc.

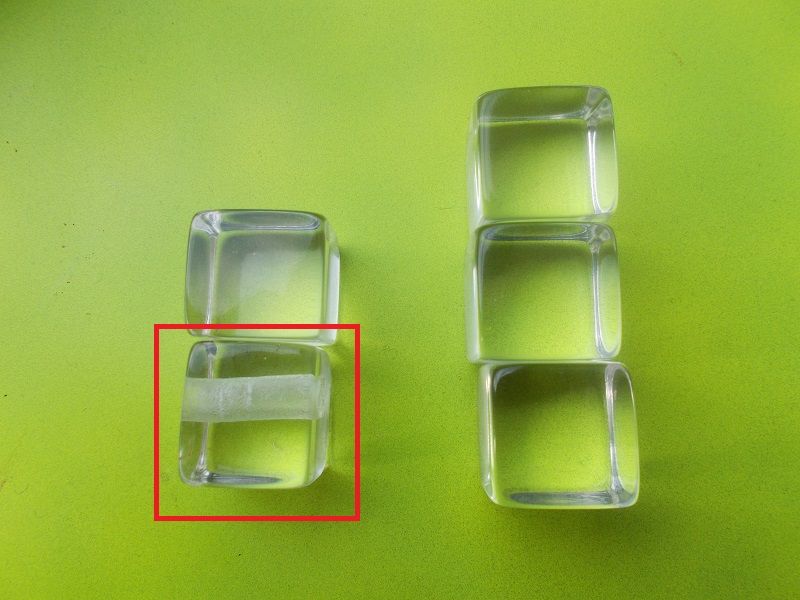

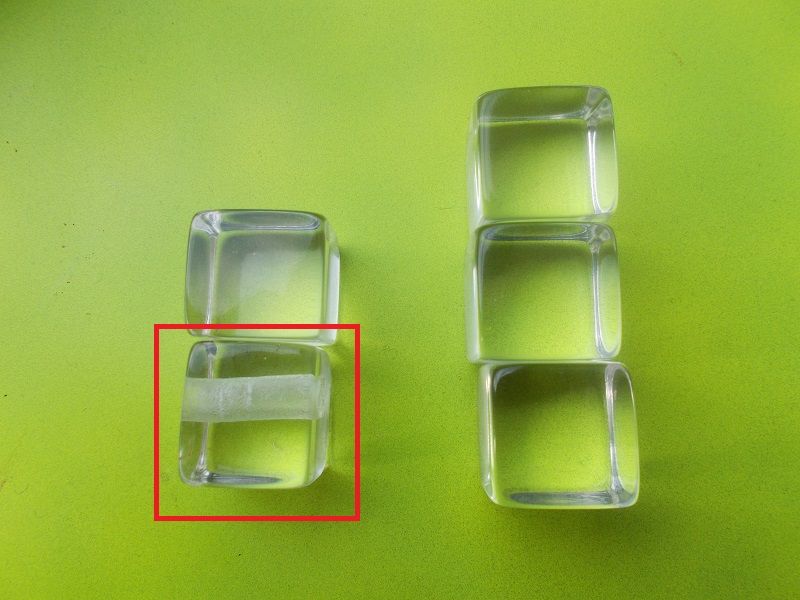

All cubes have rounded edges, maybe that's why they look different thickness, but it looks like between 0.5 and 1 mm.

The exact size advertised was 25.4mm each edge so I guess it's because of the manufacturing process (cast).

I will have to polish the wall which are going to be attached permanently with the walls anyway, so it won't matter. I will be have to be very careful and precise with the drilling and triple check everything.

Edit: Here is a photo of few cubes. I used one to test the drills I had and it was nice and easy. But it's also the one which is different size.

Edit2: I checked rest of the cubes and apparently more than one is slightly different size.

This pose a problem, so I had to modify the project a little. Cubes and round rods will still be used for minor skeleton parts, like to strengthen some construction i.e. PSU cover, however main skeleton will be made with square rod. I ordered 6 meters of 10x10 mm square rod and should receive it next week, at same time as acrylic glue and drill bits, so you can expect an update soon

It was shipped free, by DPD, but that's because of the forum posts etc.

All cubes have rounded edges, maybe that's why they look different thickness, but it looks like between 0.5 and 1 mm.

The exact size advertised was 25.4mm each edge so I guess it's because of the manufacturing process (cast).

I will have to polish the wall which are going to be attached permanently with the walls anyway, so it won't matter. I will be have to be very careful and precise with the drilling and triple check everything.

Edit: Here is a photo of few cubes. I used one to test the drills I had and it was nice and easy. But it's also the one which is different size.

Edit2: I checked rest of the cubes and apparently more than one is slightly different size.

This pose a problem, so I had to modify the project a little. Cubes and round rods will still be used for minor skeleton parts, like to strengthen some construction i.e. PSU cover, however main skeleton will be made with square rod. I ordered 6 meters of 10x10 mm square rod and should receive it next week, at same time as acrylic glue and drill bits, so you can expect an update soon

Last edited: