Soldato

In the 20+ years I've been building PCs, it was always either an air cooled setup or balls deep in phase change cooling (some of you will remember those glory days), or more recently air + AIO. I had never ventured into custom water loops... until now

Anyways, this time I thought I'd try and attack it head on and do it all, went straight for hard lines as my first go, and also thought I'd have a crack at making my own custom PSU cables.

Had a few hiccups along the way but overall very happy with the end result.

Final Specs:

Probably worth saying I started with a fairly bog standard air+AIO build, same hardware apart from the GPU which was a 6900 XT Red Devil Limited Edition:

Removed the AIO (sold off), got the side fans out then put the distro plate in immediately:

Behind the scenes bits:

Rads flushed out and installed with the Corsair fans. Also close up of the "hot & cold" fittings:

CPU Block in (had to reorientate it to 'goofy' to align to the distro holes to the right:

Lots of reading up on parts and inserts on the Molex website and prayed I ordered the right parts (shipped from the USA):

Decided to not bother cutting out the tubing until my PrimoChill RFB Bit arrived (who the hell wants to use sandpaper on tube ends? not me that's who ), so I got cracking with the PSU cabling in the meantime.

), so I got cracking with the PSU cabling in the meantime.

Rather than trust the internet I got out the multimeter and tested every pin myself to ensure I got it right. The Nvidia 12-pin micro molex was horrendous to do, probably didn't help that I was using 18 AWG wire that barely fit into the terminal ends, and my cheap crimping tool sucked... a lot.

Had to make a "funnel" out of heat shrink tubing in order to fit the braided sleeves into the comb holes. Otherwise it's like threading a needle with a thread that frayed out even if you just looked at it funny:

Starting to question my sanity during all this, especially knowing that I still had to work out the other ends and crimp those too... as well as still having to make the CPU EPS cables next.

"Please kill me, why didn't I just buy these online"...

The RFB bit arrived just before I lost my mind crimping wires. Very much welcome break to try out bending out some hard lines:

Looks like watching all them youtube vids for tips paid off

Carefully transferring the 3090 FE to the new EK waterblock was interesting... couldn't believe how chunky and heavy it is though!

Pressure testing the loop (soft tube bypassing the CPU terminals because I ran out of hard tube due to wasting over a metre learning how to do it right, more en route over the bank holiday weekend):

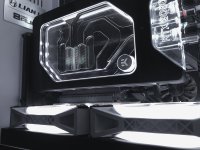

The plan is starting to come together:

Done as much as I could whilst waiting for the additional tube. 2 power cables done and neatly in, just the CPU EPS ones to go:

A couple of days later, CPU tubes are done and in. Fill her up and let the pump run whilst I finish up making the 8+4 EPS cable

Anyways, this time I thought I'd try and attack it head on and do it all, went straight for hard lines as my first go, and also thought I'd have a crack at making my own custom PSU cables.

Had a few hiccups along the way but overall very happy with the end result.

Final Specs:

- Lian-Li O11D White (Not XL!)

- AMD Ryzen 9 5950X

- Nvidia RTX 3090 FE

- MSI MAG X570 Tomahawk WiFi Motherboard

- 32GB (2x16) Samsung B-Die DDR4 Memory

- LINKUP Ultra PCIE 4.0 Riser Cable + Casemod Vertical GPU Bracked (Modified)

- EK-Quantum Velocity D-RGB Nickel + Plexi CPU Block

- EK-Quantum Vector FE Black Special Edition Water Block

- EK Lian-Li O11D Distro Plate G1

- EK Twin 360mm Radiator Setup - EK Coolstream PE top, SE bottom

- EK-Quantum Torque Fittings (Black Nickle) + Hot/Cold coloured inserts

- EK-Quantum Torque Drain Valve (Black Nickle)

- 14mm PETG Hard Tubing

- 6x Corsair QL120 RGB Fans

- Corsair iCUE Commander PRO + 2x Corsair Fan Hub Controllers

Probably worth saying I started with a fairly bog standard air+AIO build, same hardware apart from the GPU which was a 6900 XT Red Devil Limited Edition:

Removed the AIO (sold off), got the side fans out then put the distro plate in immediately:

Behind the scenes bits:

Rads flushed out and installed with the Corsair fans. Also close up of the "hot & cold" fittings:

CPU Block in (had to reorientate it to 'goofy' to align to the distro holes to the right:

Lots of reading up on parts and inserts on the Molex website and prayed I ordered the right parts (shipped from the USA):

Decided to not bother cutting out the tubing until my PrimoChill RFB Bit arrived (who the hell wants to use sandpaper on tube ends? not me that's who

), so I got cracking with the PSU cabling in the meantime.

), so I got cracking with the PSU cabling in the meantime.Rather than trust the internet I got out the multimeter and tested every pin myself to ensure I got it right. The Nvidia 12-pin micro molex was horrendous to do, probably didn't help that I was using 18 AWG wire that barely fit into the terminal ends, and my cheap crimping tool sucked... a lot.

Had to make a "funnel" out of heat shrink tubing in order to fit the braided sleeves into the comb holes. Otherwise it's like threading a needle with a thread that frayed out even if you just looked at it funny:

Starting to question my sanity during all this, especially knowing that I still had to work out the other ends and crimp those too... as well as still having to make the CPU EPS cables next.

"Please kill me, why didn't I just buy these online"...

The RFB bit arrived just before I lost my mind crimping wires. Very much welcome break to try out bending out some hard lines:

Looks like watching all them youtube vids for tips paid off

Carefully transferring the 3090 FE to the new EK waterblock was interesting... couldn't believe how chunky and heavy it is though!

Pressure testing the loop (soft tube bypassing the CPU terminals because I ran out of hard tube due to wasting over a metre learning how to do it right, more en route over the bank holiday weekend):

The plan is starting to come together:

Done as much as I could whilst waiting for the additional tube. 2 power cables done and neatly in, just the CPU EPS ones to go:

A couple of days later, CPU tubes are done and in. Fill her up and let the pump run whilst I finish up making the 8+4 EPS cable