Hello OCUK! I'm extremely excited to be starting another personal project, as most of you will know since Chocolate Box I have been collaborating with Parvum Sytems on their rig building exploits. Over that time I've developed a wide array of new techniques and gained a huge insight into how Parvum design and manufacture their cases. Consequently rather than being a descendant of an existing case this will be a scratch build designed specifically to accommodate the hardware being used, while no doubt elegantly incorporating some custom watercooling epicness.

Case - Custom Parvum JR1.0

Motherboard - MSI X99A XPOWER AC

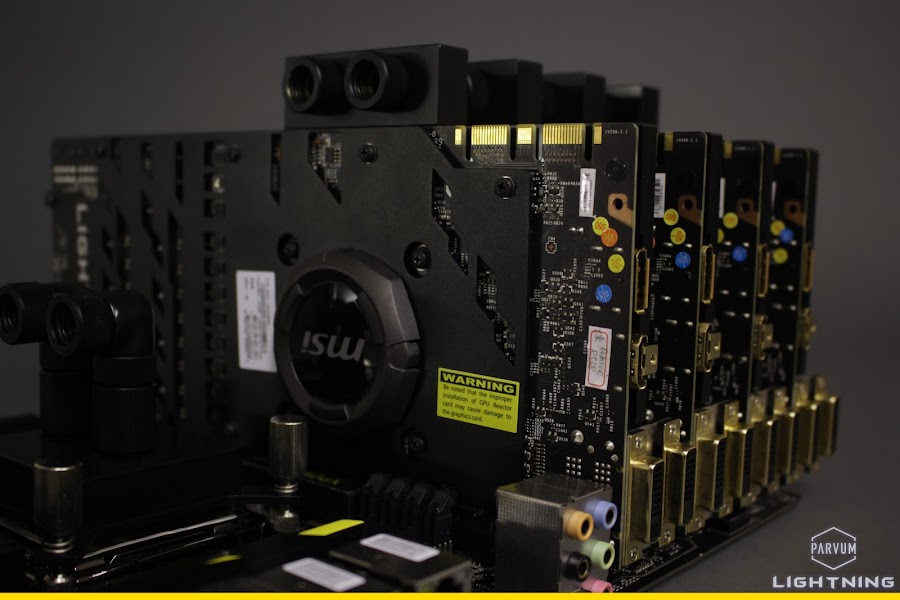

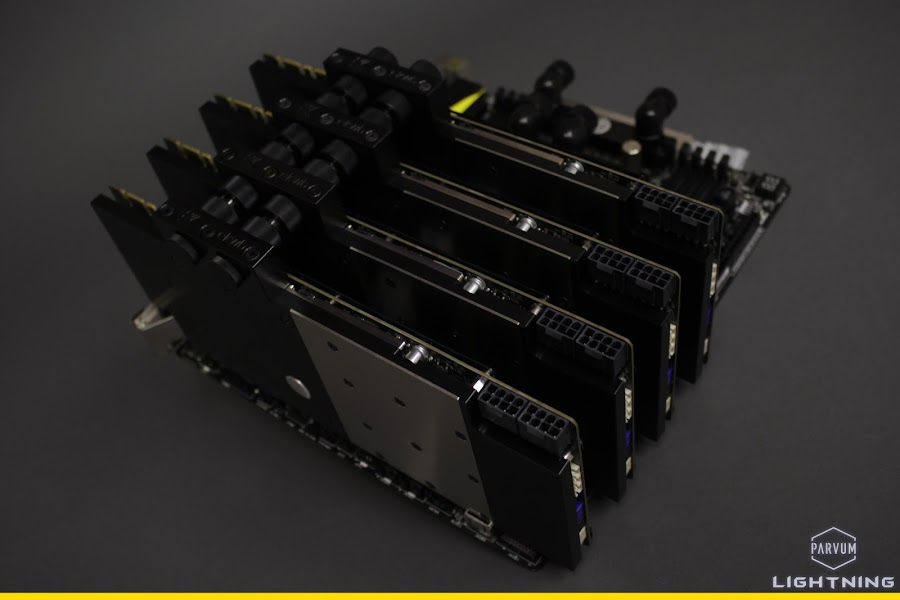

GPU - MSI GTX 780Ti LIGHTNING x4

CPU - Intel Haswell-E i7-5960X

RAM - HyperX Predator 3000MHz 8x4GB

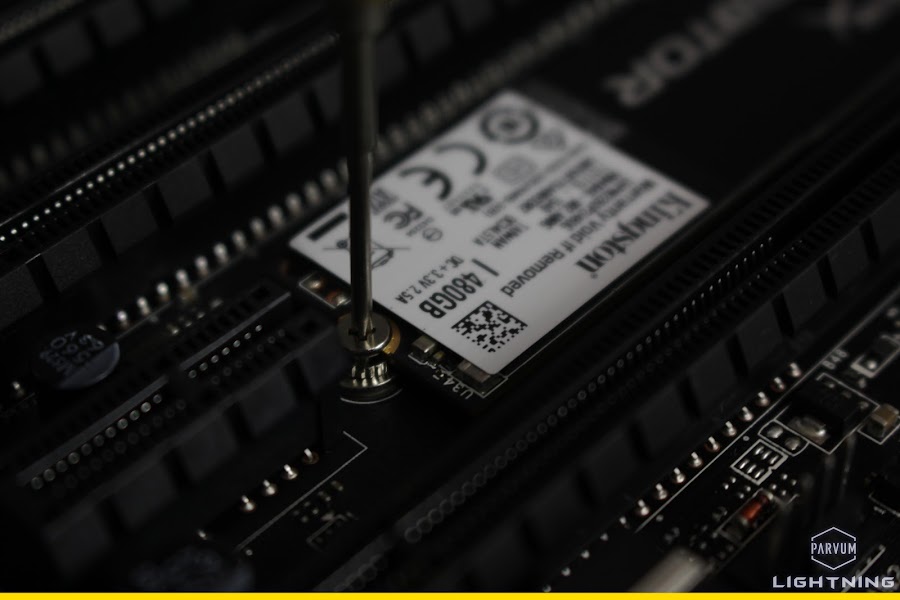

SSD - HyperX Predator M.2 480GB

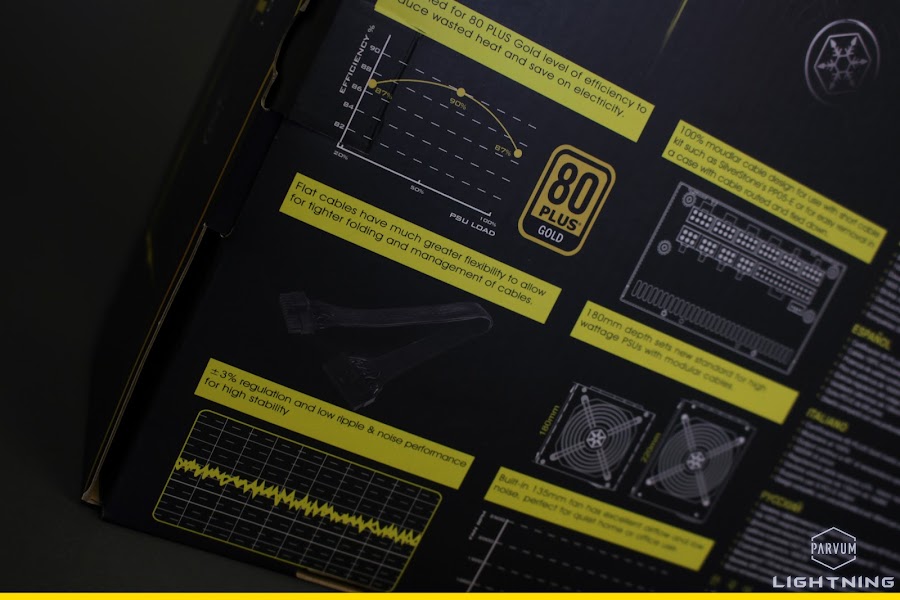

PSU - Silverstone Strider ST1500-GS x2

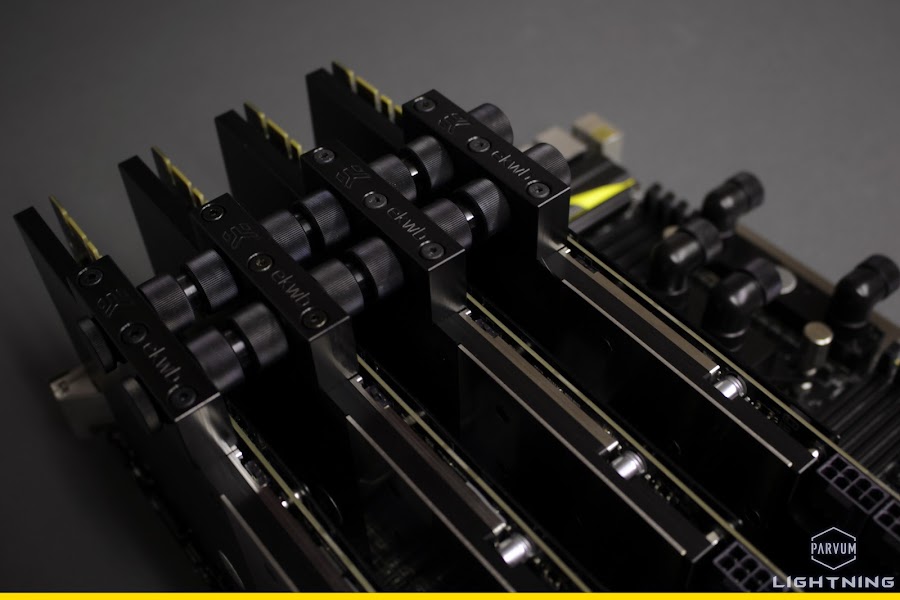

GPU Block - EK-FC780 GTX Lightning - Acetal+Nickel x4

CPU Block - EK-Supremacy EVO - Acetal+Nickel

VRM Block - EK-MOSFET MSI X99 XPower - Acetal+Nickel

Pump - EK-XTOP D5 Vario - Acetal (incl. pump) x2

Reservoir - EK-RES X3 250 x2

Radiator - EK-CoolStream XE 480 (Quad) x3

Fittings - EK-HD Adapter 10/12mm - Black x54

Rotaries - EK-AF Angled 90° G1/4 Black x2

Tubing - Shakmods Crystal Clear rigid acrylic

Sleeving - Telios Yellow, Dark Grey and Black

Fan Controller - Aqua Computer Aquaero 6LT

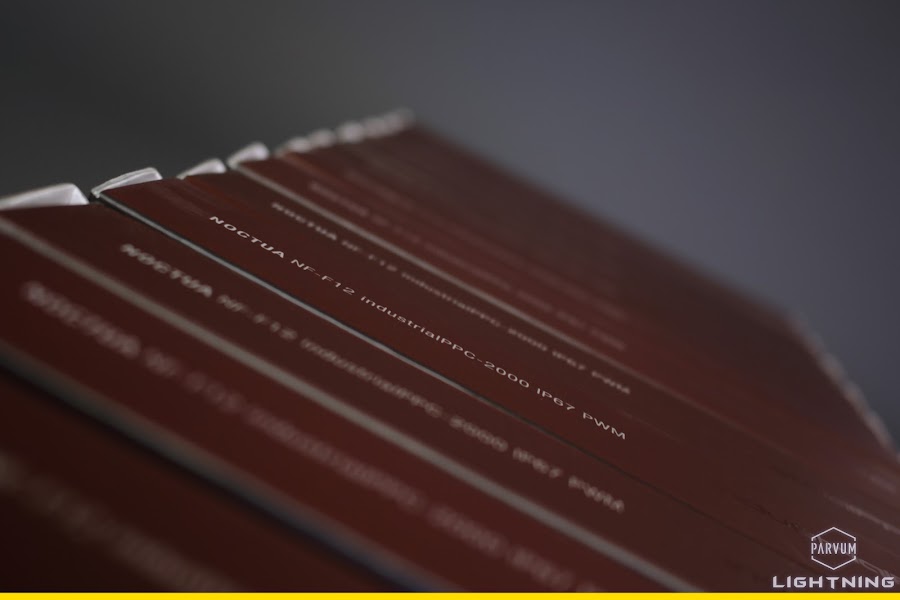

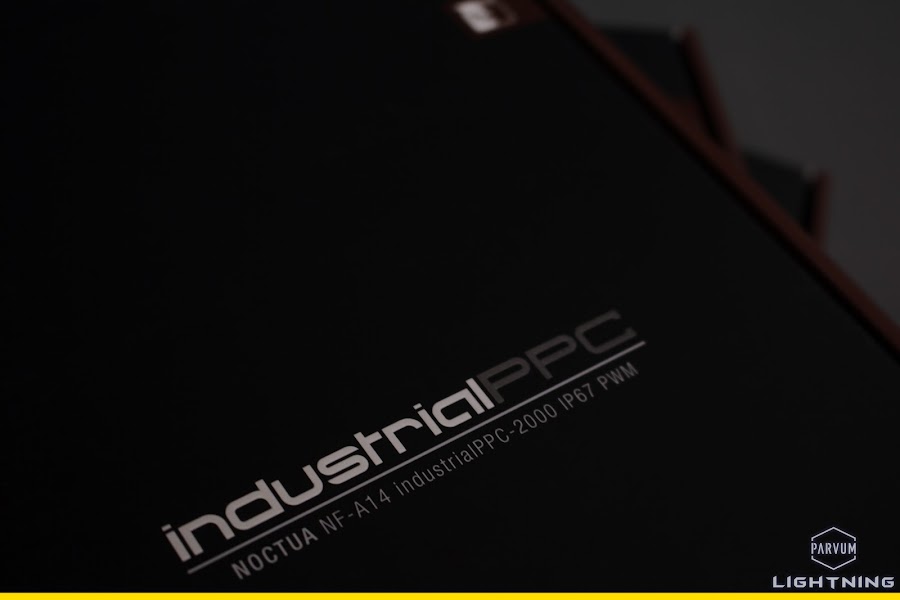

Fans - Noctua iPPC 2000 PWM IP67 NF-A14 x3 and NF-F12 x12

I think the theme has probably been given away by the title at this point so I will leave the specs until a little later in the project. This is something i've been planning for quite a while now, long before I started working at Parvum. After expressing my love for MSI's Lightning series it has quickly snowballed into reality, I suppose we better take a look at what arrived in the mail last week...

As those of your familiar with Lightnings will know the packaging and accessories are on another level to just about every GPU in existence. It's great to see an extended LN2 heatsink for the power circuitry and a slick black SLI bridge although I doubt that I will be needing either of those.

Here comes the main event...

...the classic Lightning Tri-Frozr

But wait, wots that m9's...

...lets take a closer look

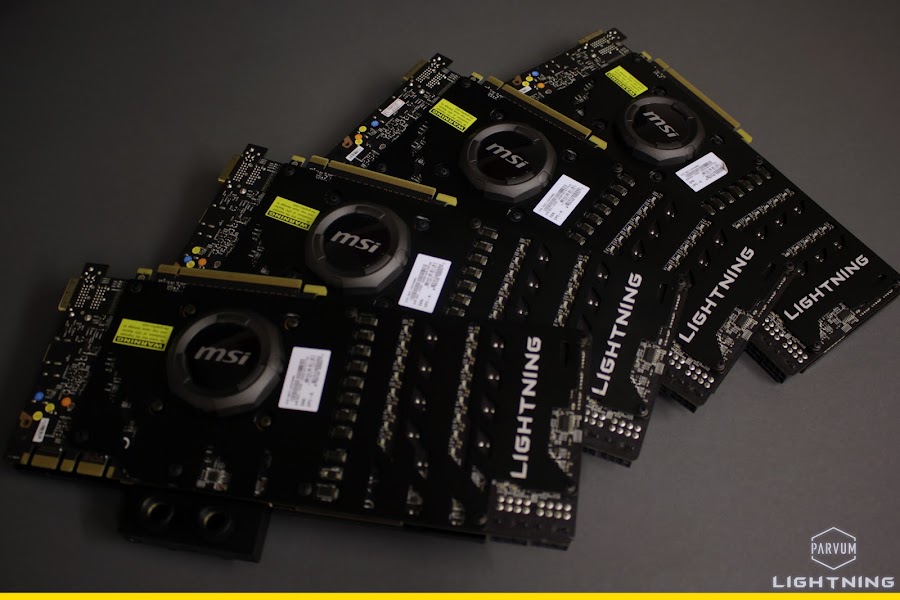

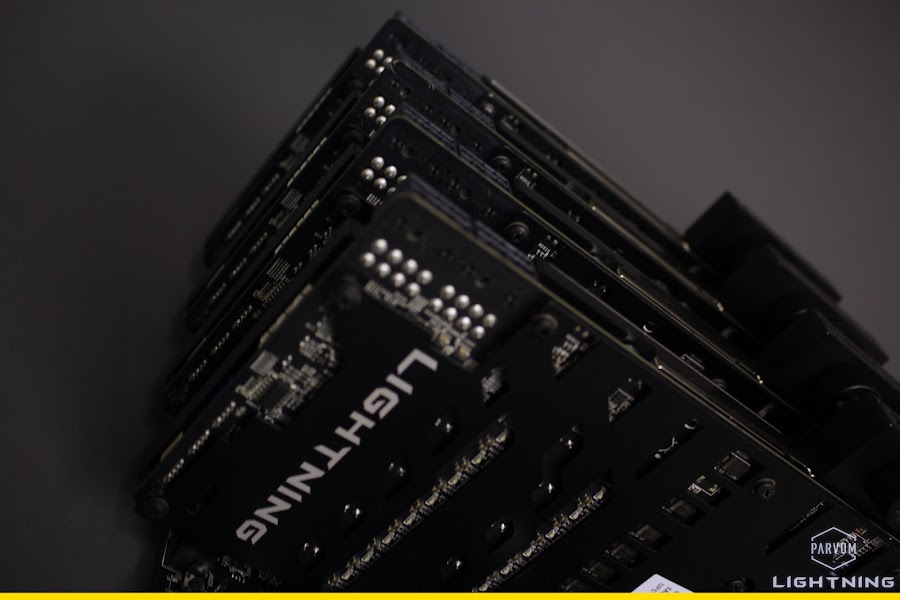

GTX 780Ti LIGHTNING confirmed. One of only 12 engineering samples produced before MSI cancelled their plans to retail the card.

But as they say Lightning doesn't strike twice...

...it hits 4 times!

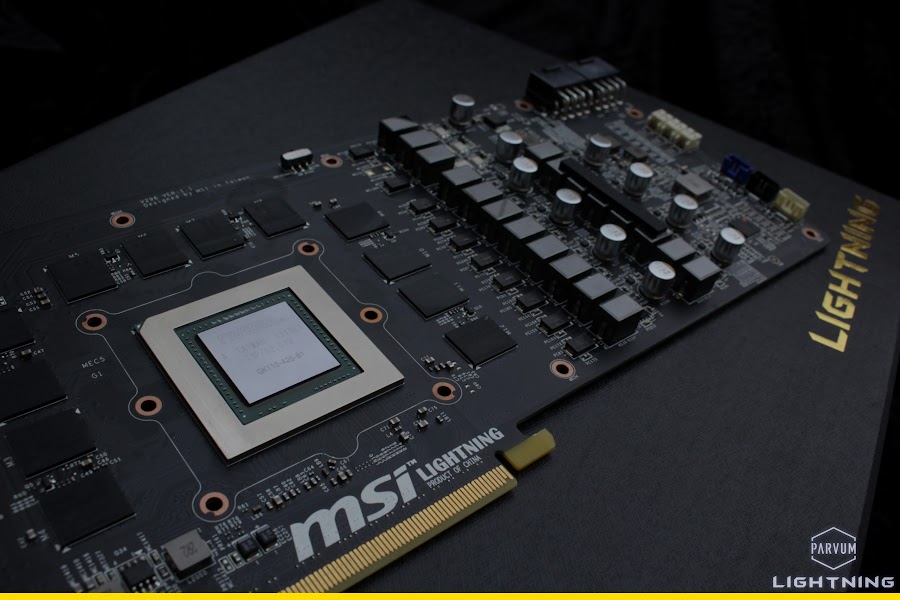

So much Power circuitry, (14+3)x4.

What else could follow up that monumental show of prowess from MSI, nothing less their flagship overclocking board the X99A XPOWER AC.

Tease much?

The shear amount of accessories was overwhelming, even a pen drive in there somewhere.

I suppose we ought to take a look at the board then.

Should be plenty of PCIe to go around.

MSI's 2011-3 socket, now with added pins.

Black and yellow, black and yellow, black and yellow...

Massive thanks to MSI for making this happen and releasing some of the coolest Lightning cards ever built into the wild, let alone 1/3 of them.

Perhaps its now obvious why I will be designing a case from scratch, as a Parvum of the required magnitude doesn't yet exist. A substantial amount of progress has already been made on that front and i'm looking forward to presenting some renders very soon.

JR

Last edited:

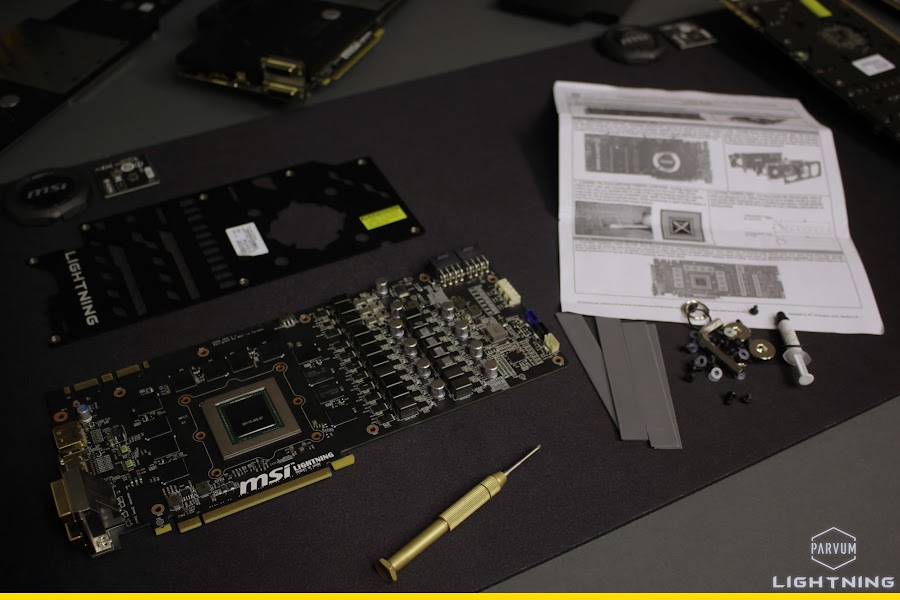

I was impatient and already blocked one card which is just as well as they are enormous.

I was impatient and already blocked one card which is just as well as they are enormous.