What you need is some nice easy soft tube! ....is what I kept telling myself when I was cutting the glass tubes. Hey, on the bright side, yours don't break or give off a nice abrasive dust that you want to avoid breathing in when you cut them!

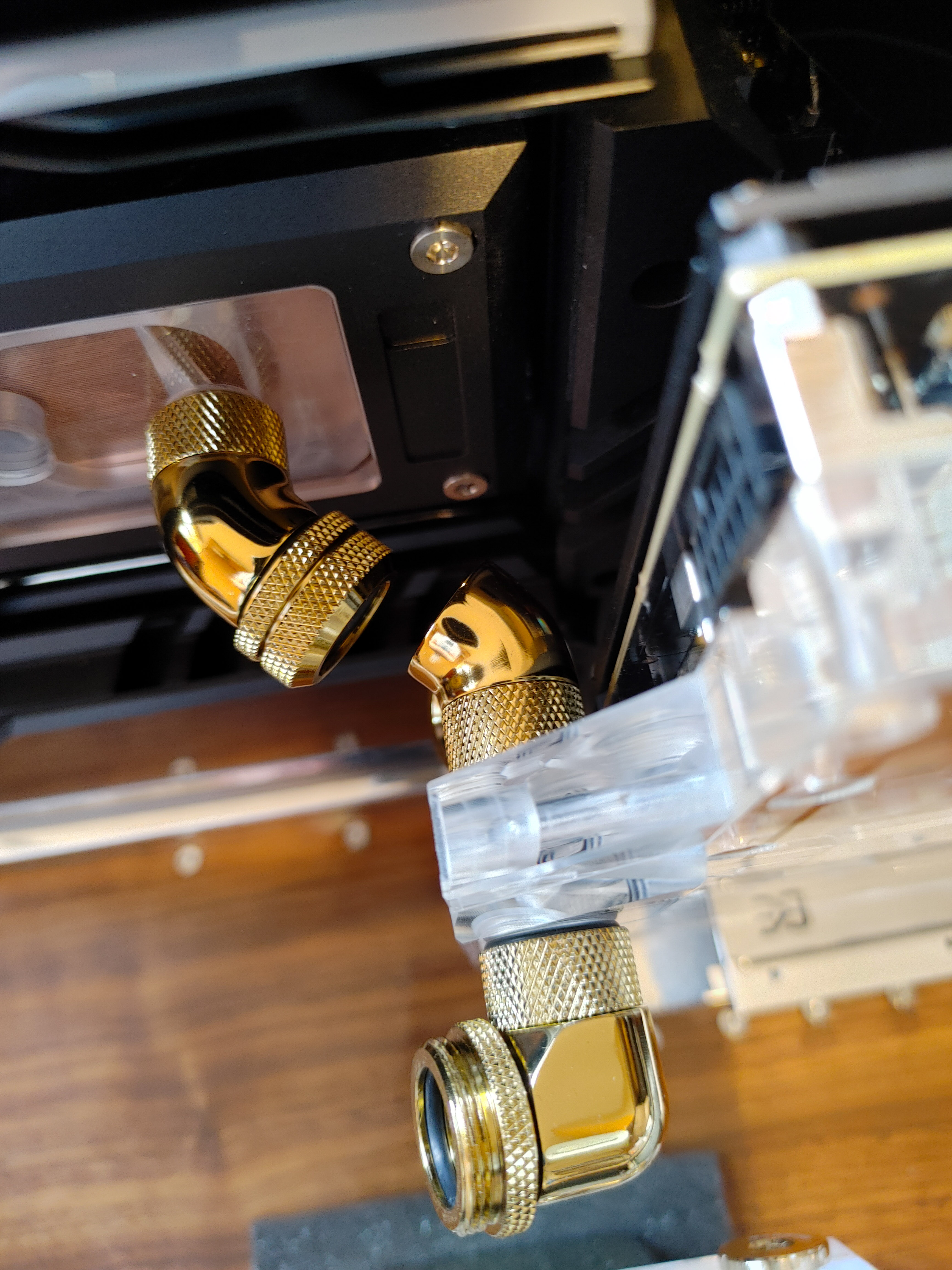

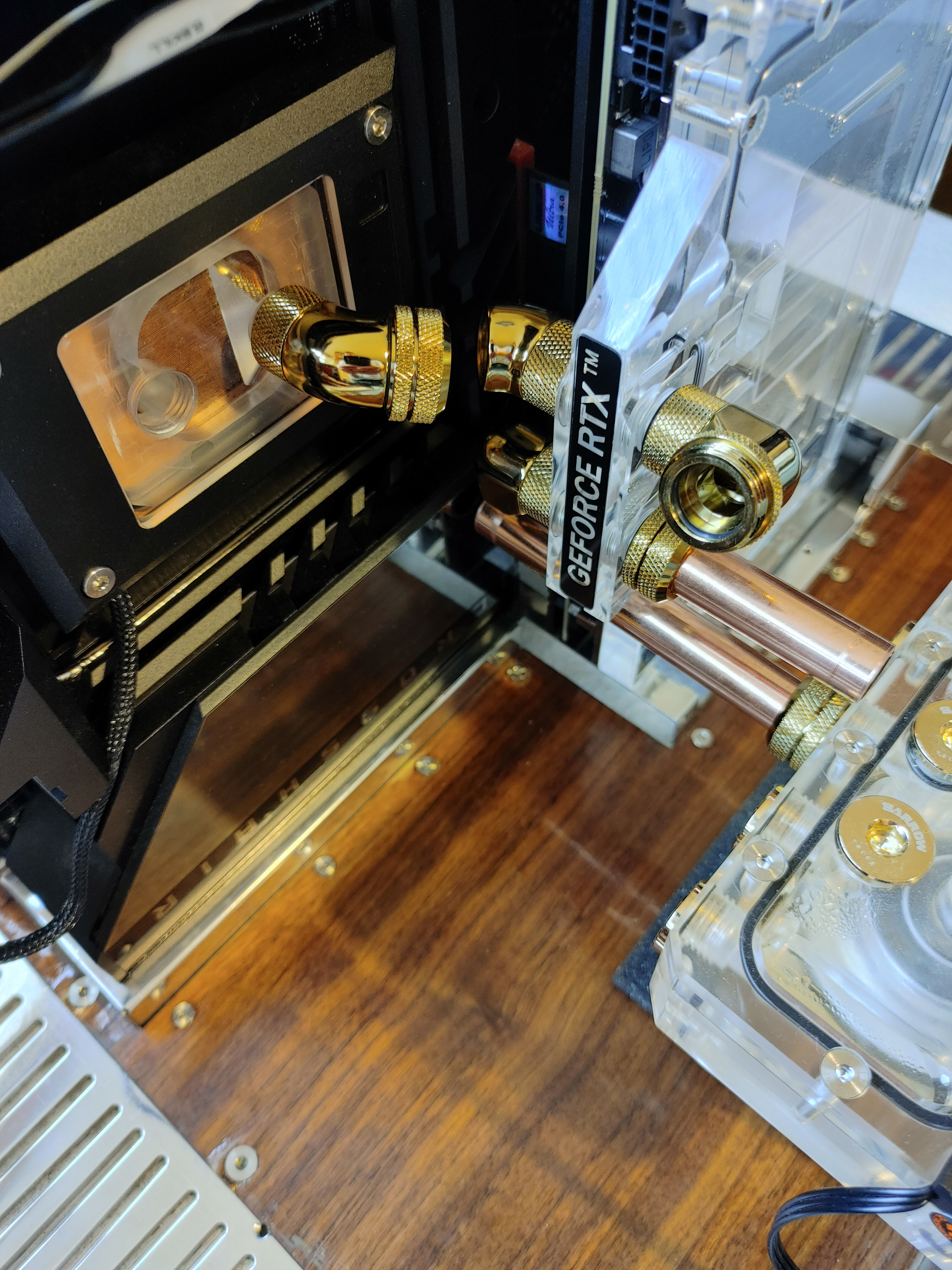

That CPU-GPU link is awkward. Too close in one dimension for either of those ports. A few suggestions

* Could you swap GPU ports and go in where you have the temp sensor? Direction of flow supposedly doesn't matter on some blocks.

* If you went for the first port you've shown, your 45's are too tall and it's never going to meet. You might strike lucky on some non-rotary 45's or even just one of them. Not as tall so might get you the line-up....but could also point in entirely the wrong direction. You've got two ports so two threads to play with so you're doubling the chance of one of them pointing in the right direction. You may also find that some fittings are 'clocked' differently - ie the thread starts in a different position so they'll end up pointing in different directions when tightened. Barrow also do a 1.5mm 'extension' or spacer. Essentially a washer with an O-ring in the back. Given the G1/4 pitch, that ought to (at least in theory) get you 44° CCW rotation of the fitting.

* Would a double or triple snake fitting work and not look too horible?

* Is there enough room to put 90° fittings on both ports and then your line-up is adjustable by adding height to one or both with small spacers/extensions.

* Are you in range of an offset fitting? Some go quite a distance now - EK do one up to 28mm offset

EK: 3, 7, 14, 21, 28mm

Alphacool: 8,16mm

Barrow: 14mm

You'll definitely get a tighter bend by bending the tube long (more leverage for a start) and then cutting the end back. Measure once, cut twice, swear many times

You could always anneal the tube with a blow torch (heat to a dull glow and then let cool naturally) as that will make it softer and 'bendable' without snapping. Copper will work-harden too so it'll get harder as you're bending. It may require re-annealing half-way if you're having that much trouble with it.

Last idea would be a block of acrylic/delrin, steel even - copper's too pricey and you don't want aluminium in your loop. Brass maybe? A square prism (square bar) with a hole most of the way down the middle, tapped G1/4 at one end for a stop-plug. Then a G1/4 hole tapped in the right place for straight m/m rotary fittings (if enough room!) to connect to your ports.

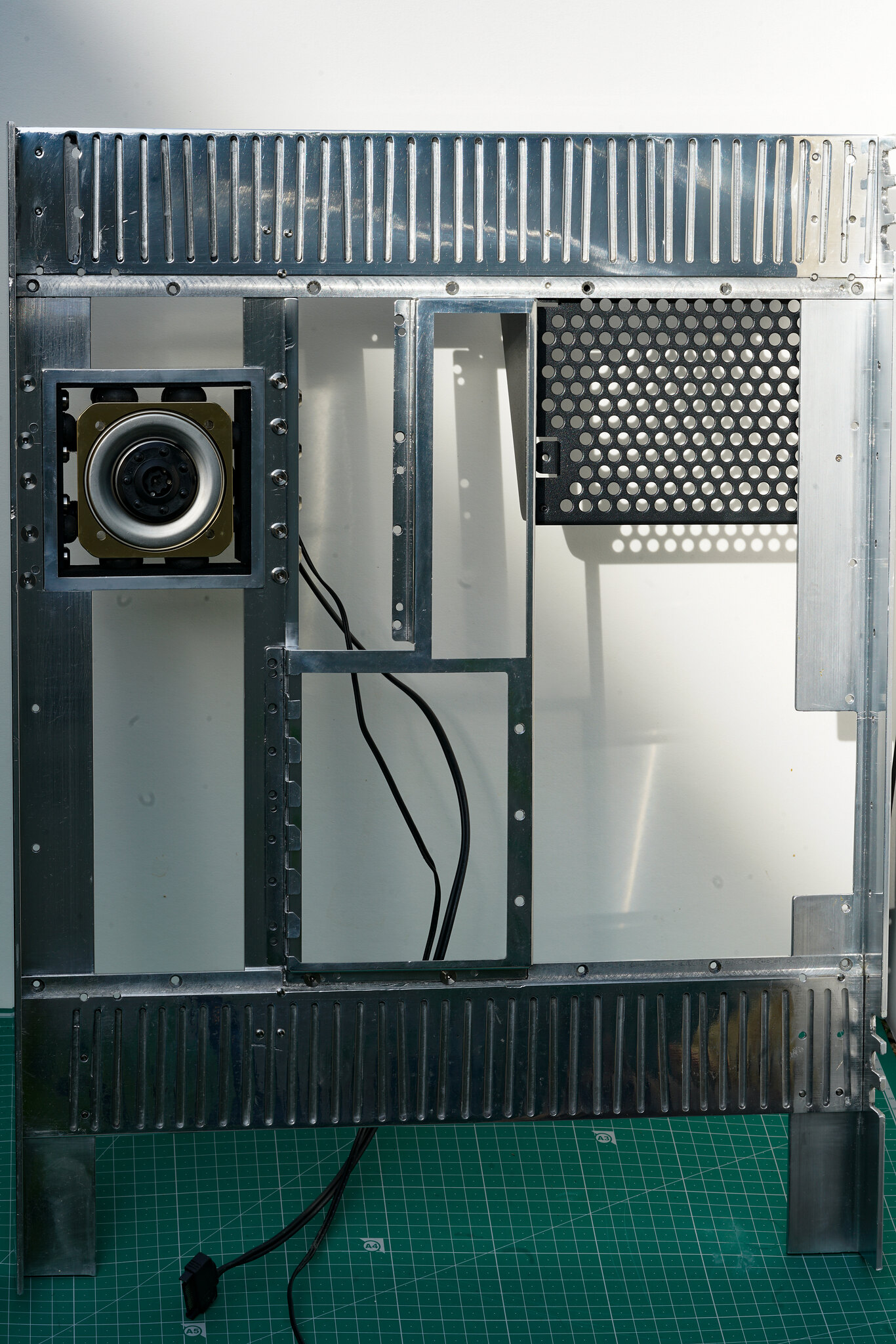

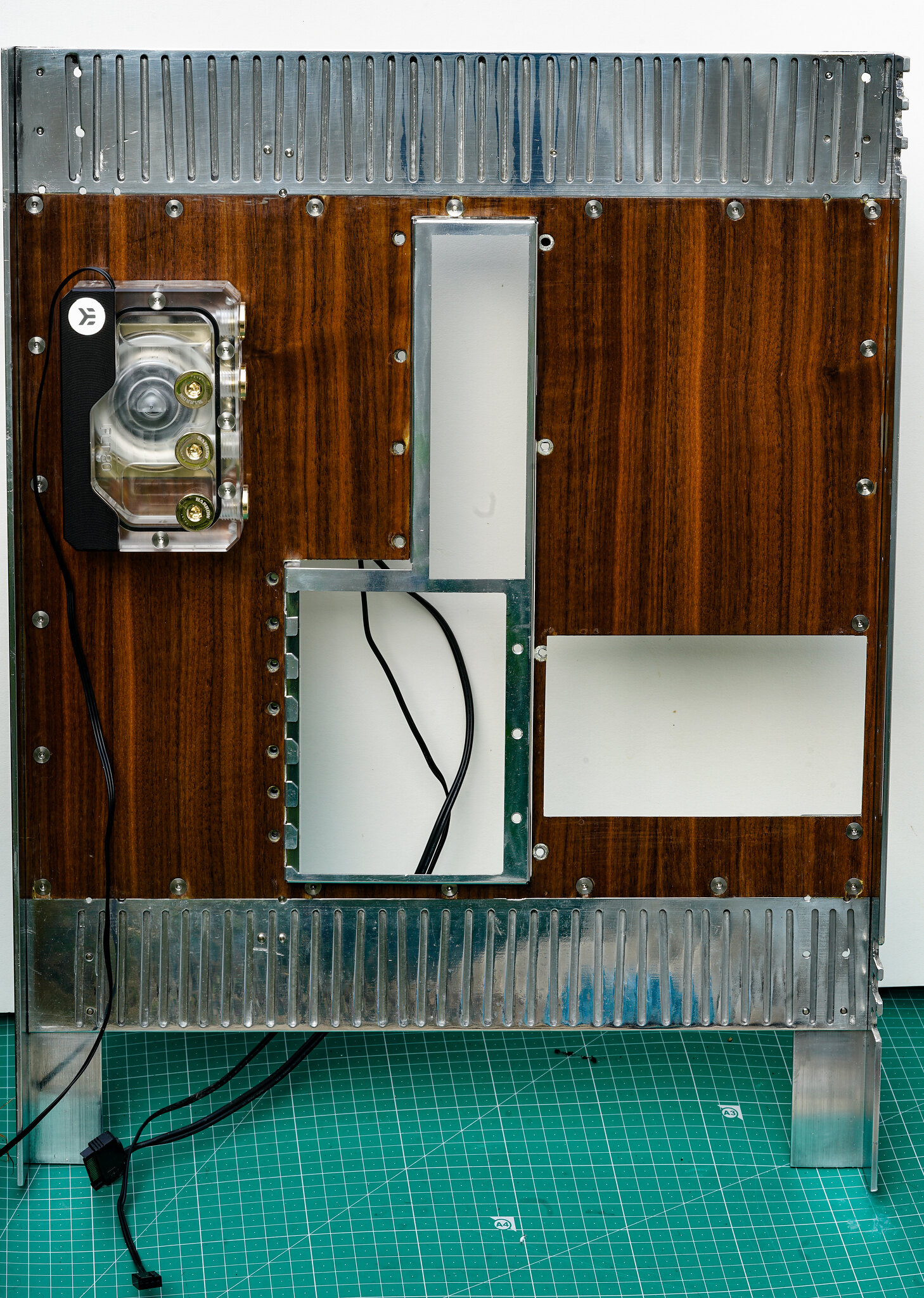

PSX_20230429_181207

PSX_20230429_181207 20230429_152606~2

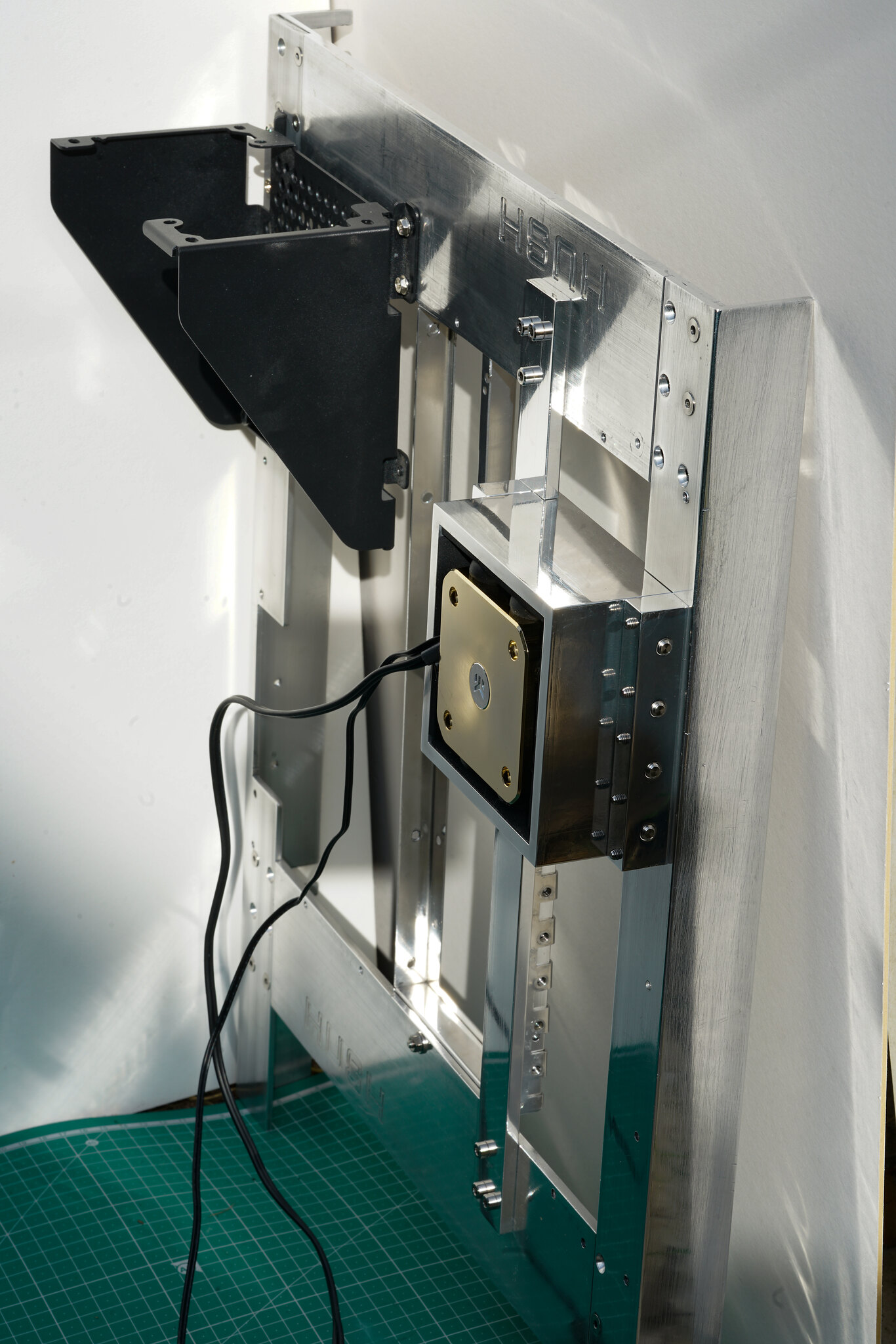

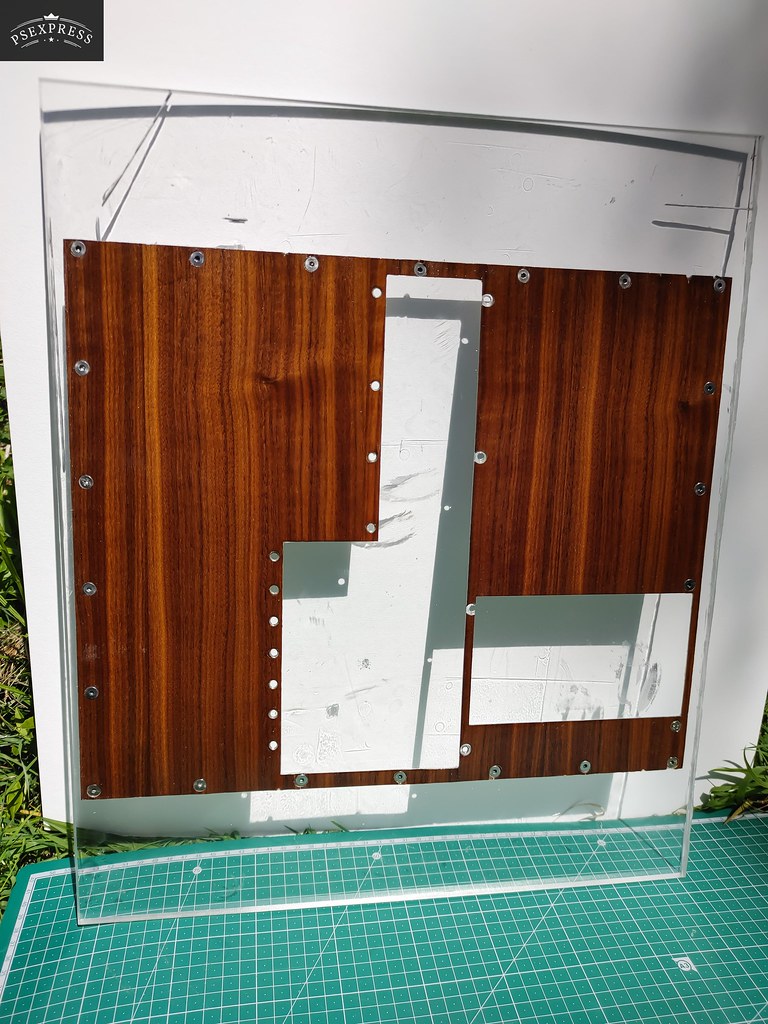

20230429_152606~2 PSX_20230429_174845

PSX_20230429_174845 PSX_20230429_175205

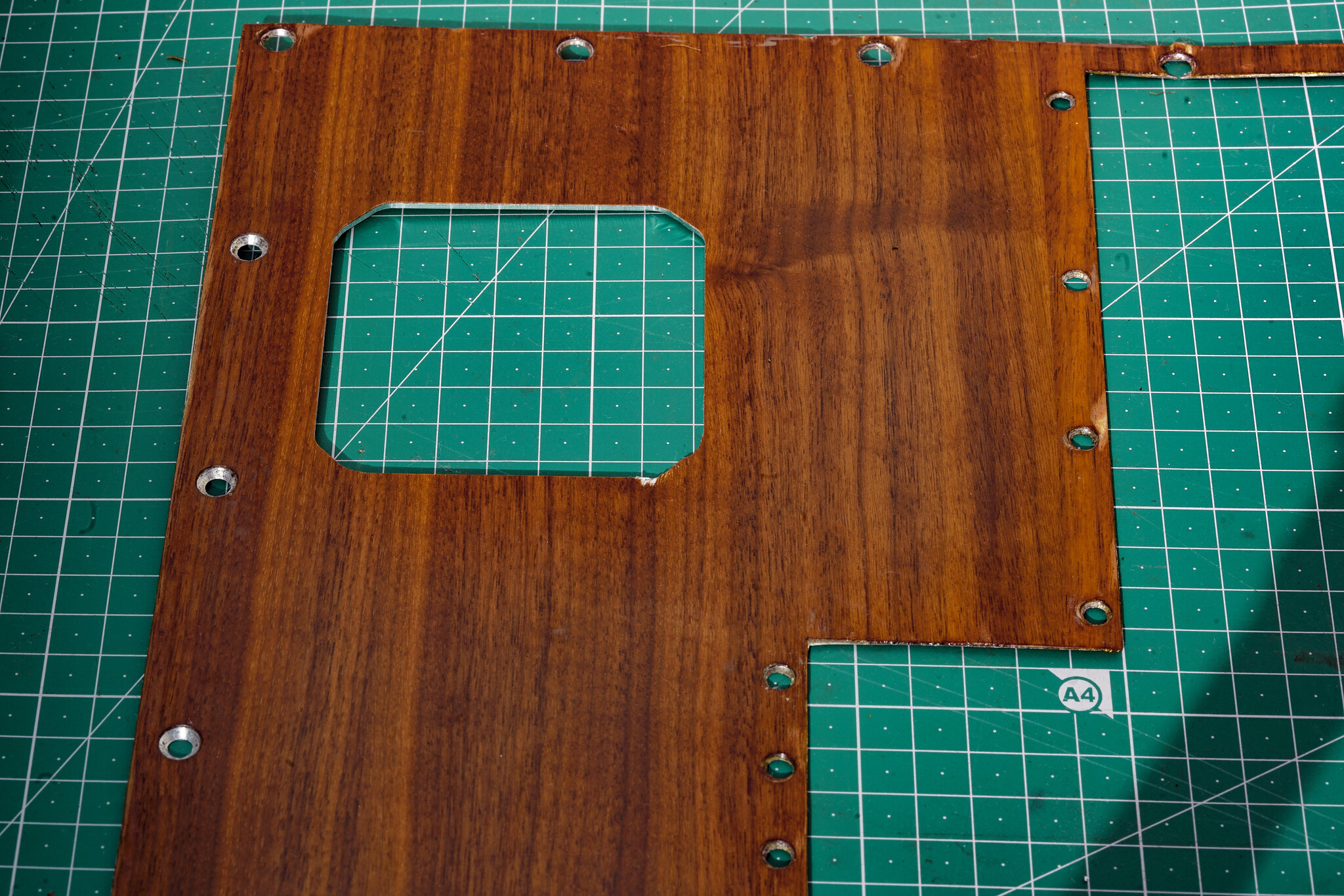

PSX_20230429_175205 PSX_20230429_180058

PSX_20230429_180058 PSX_20230429_175608

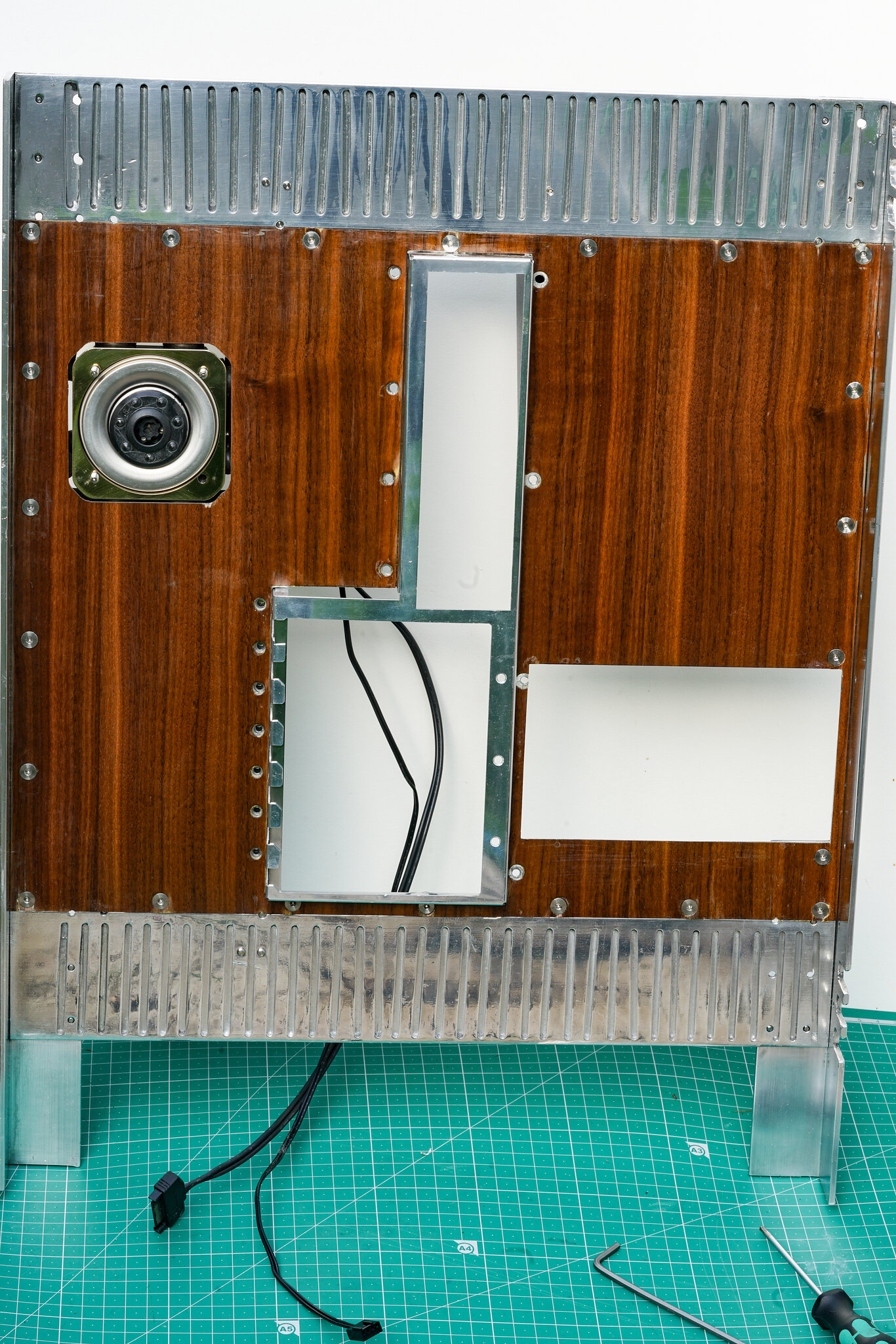

PSX_20230429_175608 :

: PSX_20230503_132224

PSX_20230503_132224 PSX_20230503_132414

PSX_20230503_132414 PSX_20230510_134520

PSX_20230510_134520 PSX_20230510_135355

PSX_20230510_135355 20230508_125244_HDR

20230508_125244_HDR 20230510_015804_HDR

20230510_015804_HDR PSX_20230510_140954

PSX_20230510_140954 PSX_20230510_141209

PSX_20230510_141209 20230510_015915_HDR

20230510_015915_HDR 20230510_015729_HDR

20230510_015729_HDR

PSX_20230606_094101

PSX_20230606_094101 PSX_20230529_032227

PSX_20230529_032227 PSX_20230528_013800

PSX_20230528_013800 20230611_142816_HDR

20230611_142816_HDR 20230611_143008_HDR

20230611_143008_HDR 20230611_193756_HDR

20230611_193756_HDR 20230610_195019_HDR

20230610_195019_HDR 20230611_024732_HDR

20230611_024732_HDR 20230611_132132_HDR

20230611_132132_HDR PSX_20230828_203027

PSX_20230828_203027 PSX_20230828_200029

PSX_20230828_200029 PSX_20230828_200655

PSX_20230828_200655 PSX_20230828_201535

PSX_20230828_201535 PSX_20230828_194725

PSX_20230828_194725 PSX_20230828_201906

PSX_20230828_201906 PSX_20230828_202517

PSX_20230828_202517 PSX_20230828_203545

PSX_20230828_203545