Associate

Been ages since i last took a look in here, nice to see the rig more complete.

Awesome job

Awesome job

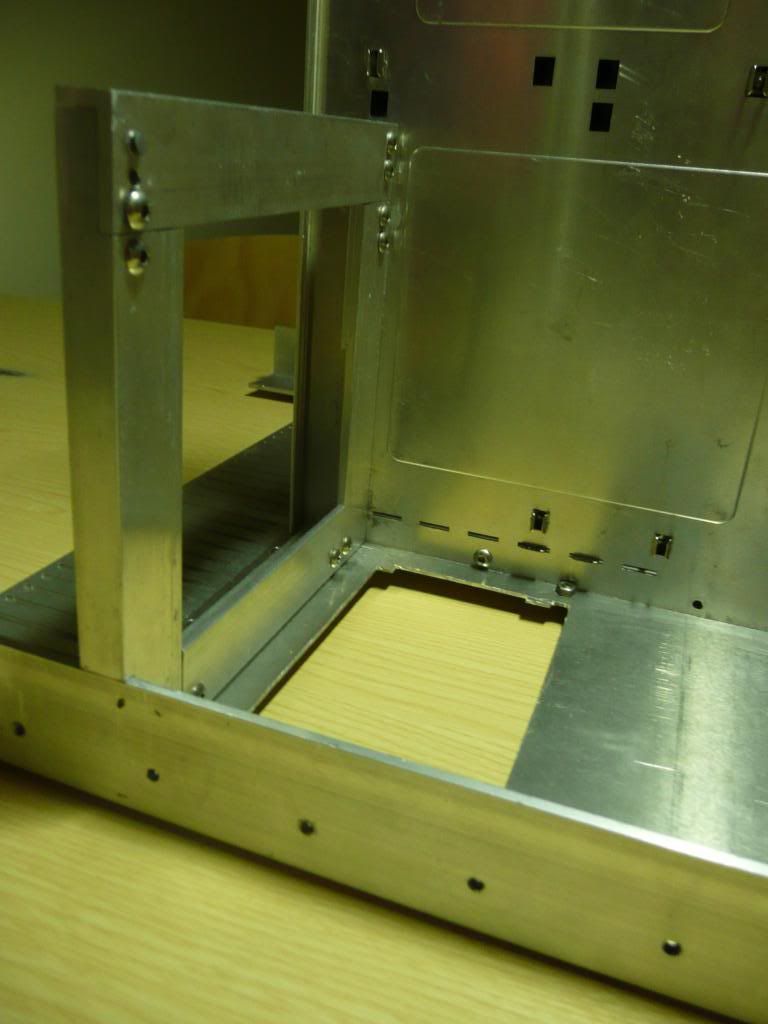

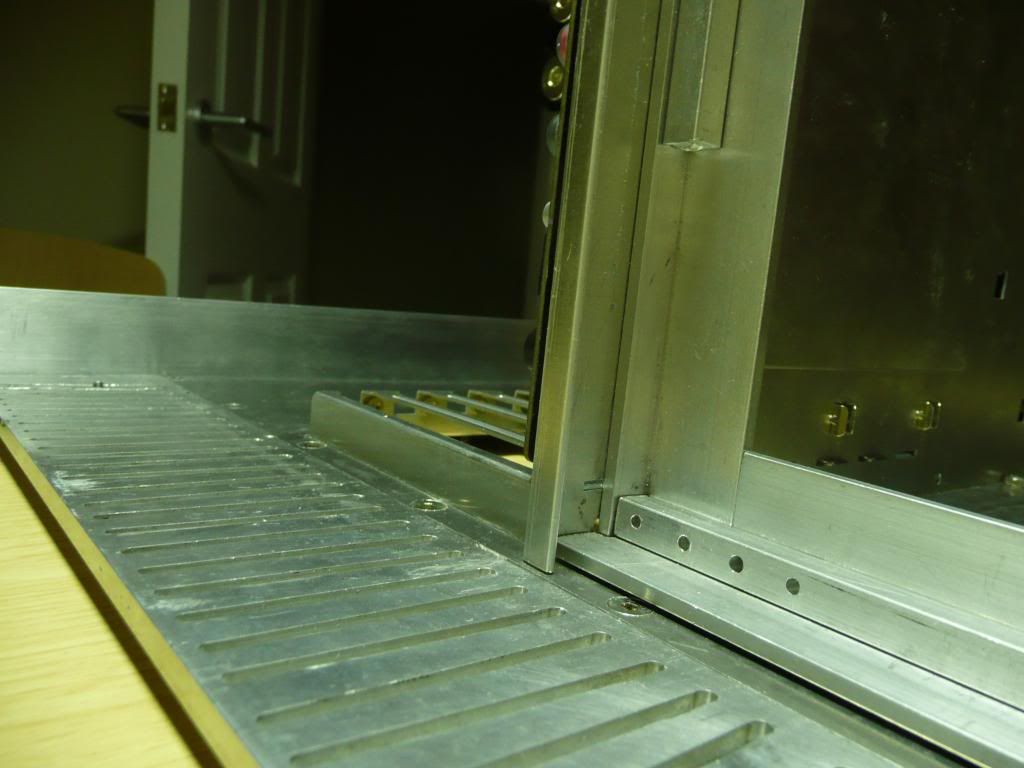

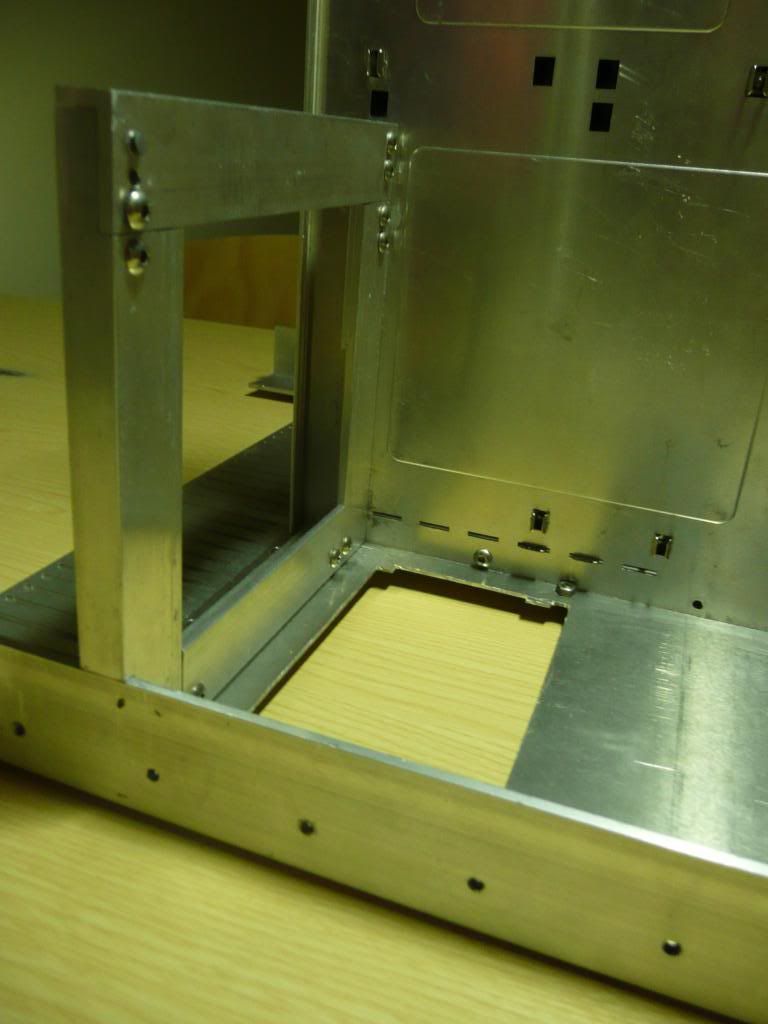

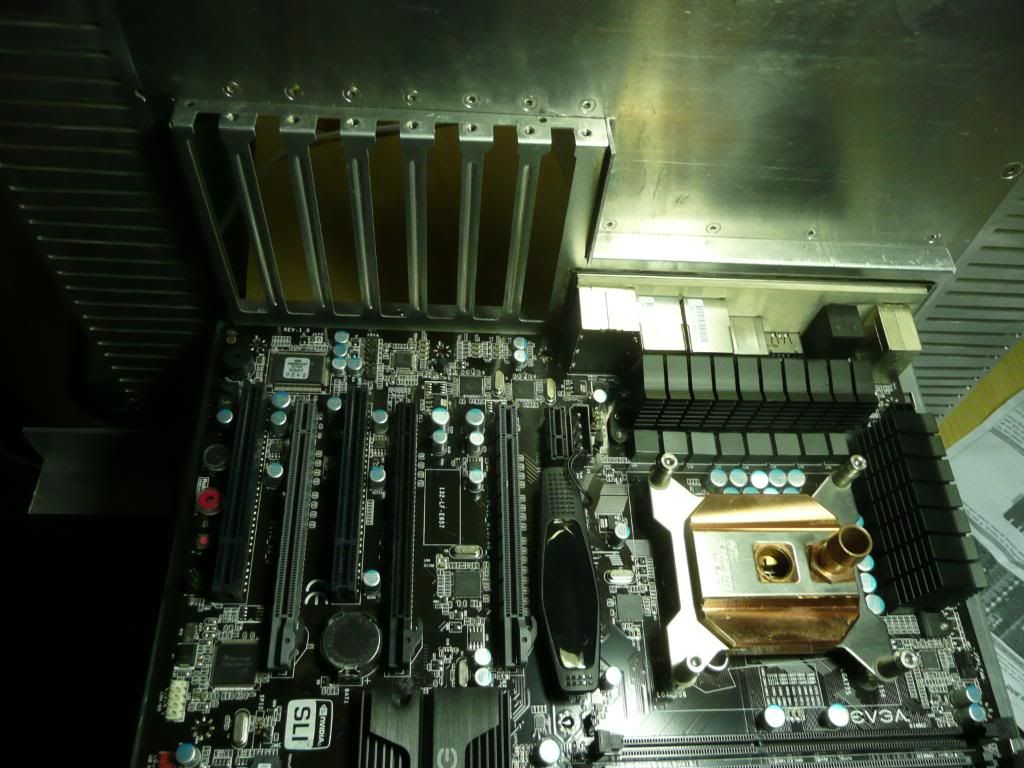

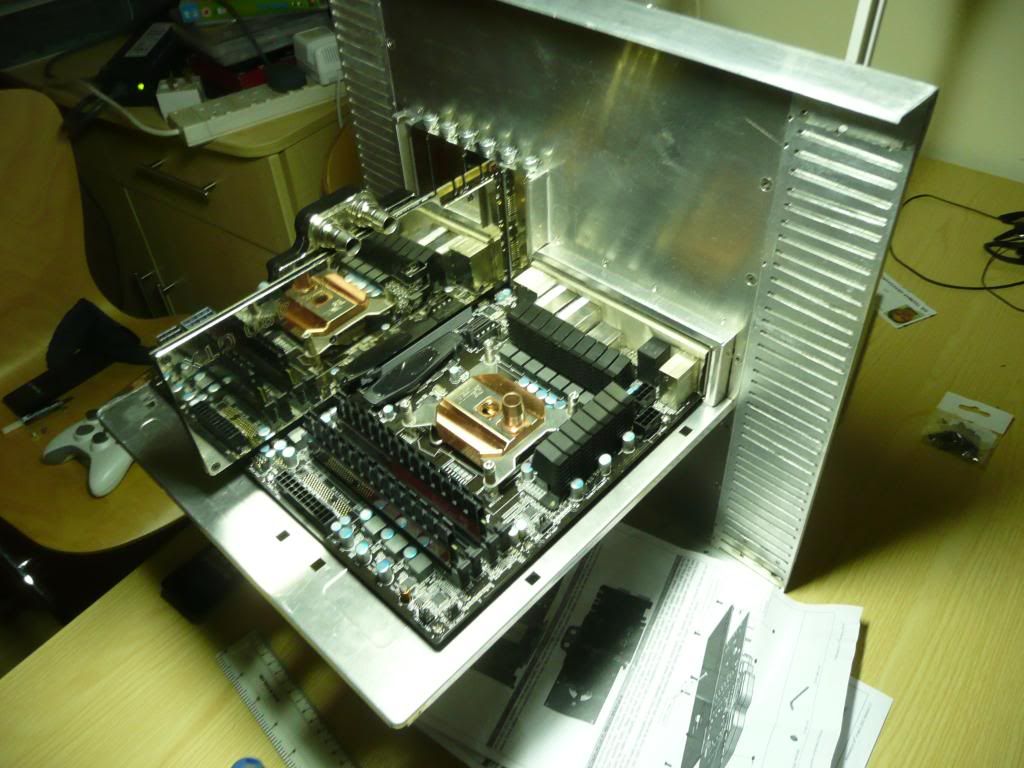

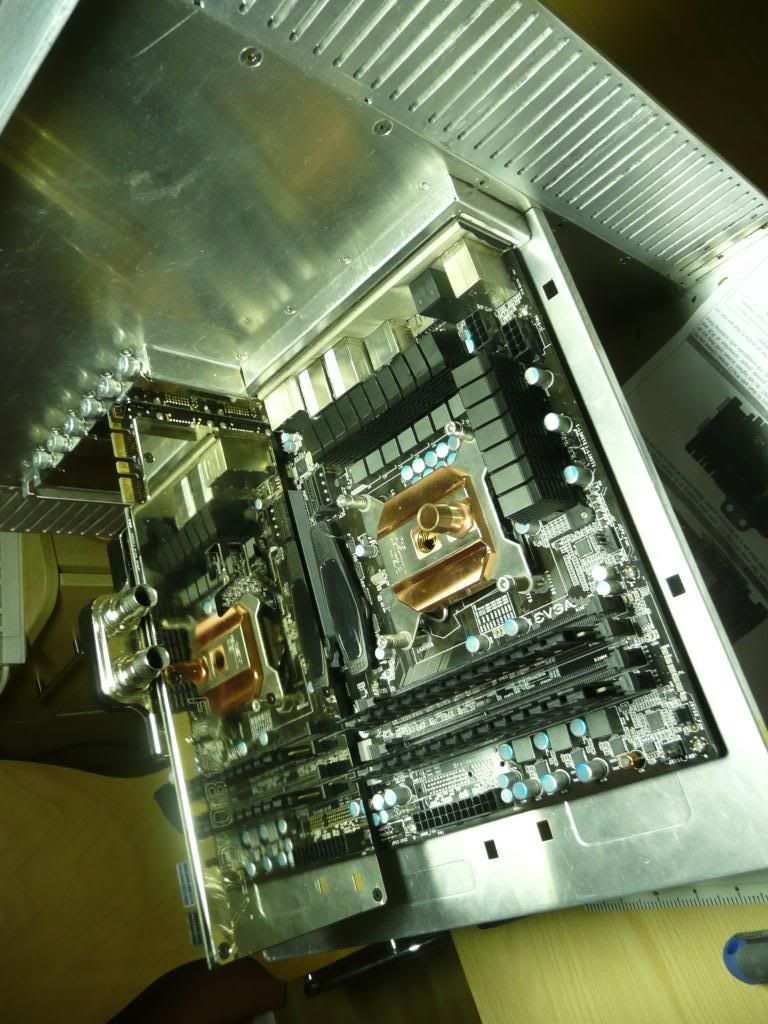

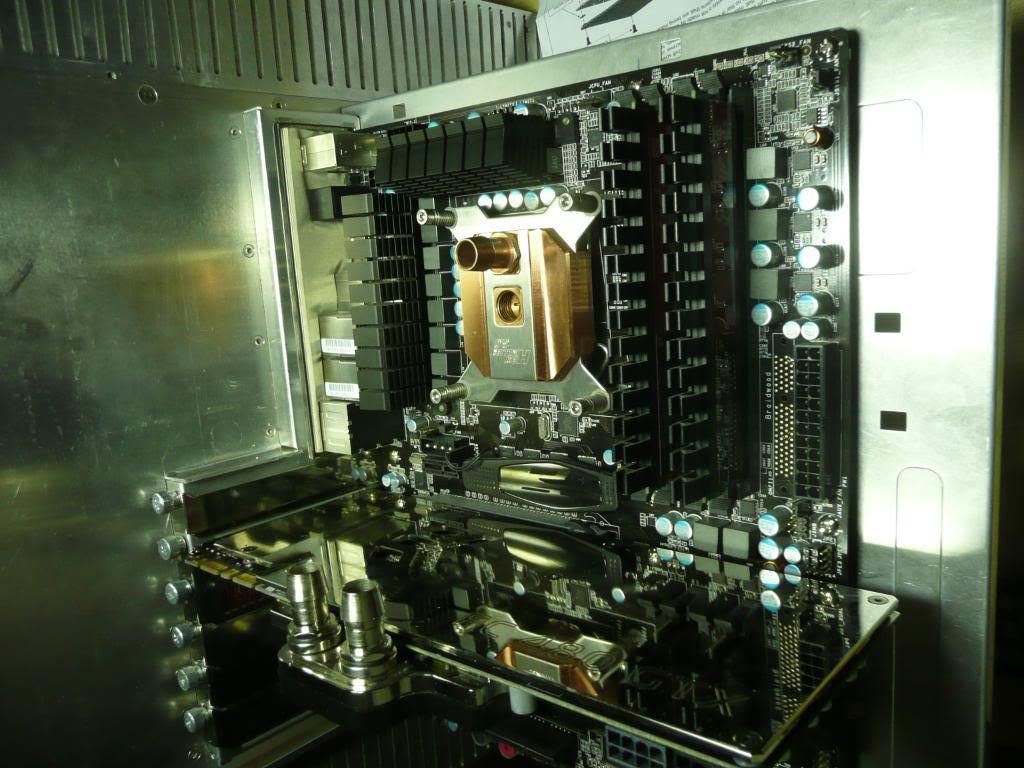

Here's the back of the case - Using countersunk screws inside means I need to have nuts on this side.

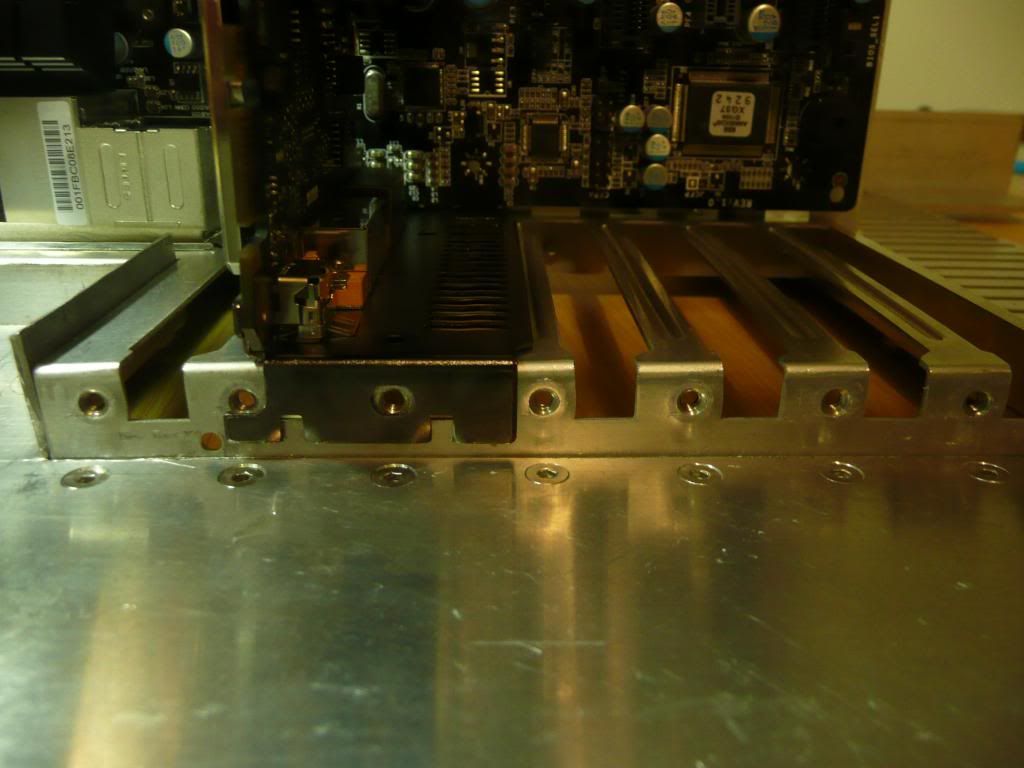

IC cooling are kind enough to send out free samples of their Thermal interface material if you agree to test it against your previous paste and send them the results.

So after sorting out the kink in the watercooling loop and testing my previous paste, MX-3, using Intel Burn Test, and using InterBurnTest and MSI Kombustor/Furmark simultaneously (to produce as much heat as possible - around 550W!) I swapped out the TIM and remounted the blocks.

Those rivet nuts aren't bad - bit big though, and I'd like to still be able to take the panels off in the future should I need to.

20210719_175552_HDR

20210719_175552_HDR 20210719_175559_HDR

20210719_175559_HDR 20210720_210723

20210720_210723 Screenshots_2022-05-11-22-50-04

Screenshots_2022-05-11-22-50-04 20211031_211556_HDR

20211031_211556_HDR 20211123_005727

20211123_005727 20211123_005636

20211123_005636 20211124_232137

20211124_232137 20211121_154135

20211121_154135 20211124_232152

20211124_232152 20211219_054205

20211219_054205 20211125_205916

20211125_205916 20210822_175028_Edited

20210822_175028_Edited![[IMG] [IMG]](https://live.staticflickr.com/65535/52067401169_1e327c3eea_b.jpg) 20211101_101436

20211101_101436![[IMG] [IMG]](https://live.staticflickr.com/65535/52067169951_dbfb1981db_b.jpg) 20211031_211803_HDR

20211031_211803_HDR![[IMG] [IMG]](https://live.staticflickr.com/65535/52067657420_7213c11ac8_b.jpg) 20211101_130618

20211101_130618 20220124_125827

20220124_125827 20220124_141258

20220124_141258 YouCut_20220512_013031616

YouCut_20220512_013031616 20220404_181116_HDR

20220404_181116_HDR 20220327_165039

20220327_165039 20220122_161833

20220122_161833 20220122_161934

20220122_161934 20211031_224433

20211031_224433 20211112_162027

20211112_162027 20220130_190612_HDR

20220130_190612_HDR 20211112_161905

20211112_161905 20211112_161916

20211112_161916 20220210_155437_HDR

20220210_155437_HDR 20220210_155125

20220210_155125 20220228_134132

20220228_134132 20220216_015928 Video - excuse the extractor fan noise!

20220216_015928 Video - excuse the extractor fan noise! 20220217_224259

20220217_224259 20220217_225553 (shiny, noisy video!)

20220217_225553 (shiny, noisy video!)

20220124_125808

20220124_125808 20220217_152030_HDR

20220217_152030_HDR 20220404_181116_HDR

20220404_181116_HDR 20220317_112454_HDR

20220317_112454_HDR 20220317_112518_HDR

20220317_112518_HDR 20220317_112522_HDR

20220317_112522_HDR 20220319_162236_HDR

20220319_162236_HDR 20220319_161132_HDR

20220319_161132_HDR 20220317_112647

20220317_112647 20220503_182206

20220503_182206 20220319_162630

20220319_162630