Cheers for the feed back guys and I appreciate your honesty.

I've decided to leave it as is and not to paint it. Having seen the mock up I did I was convinced it was just too much going on.

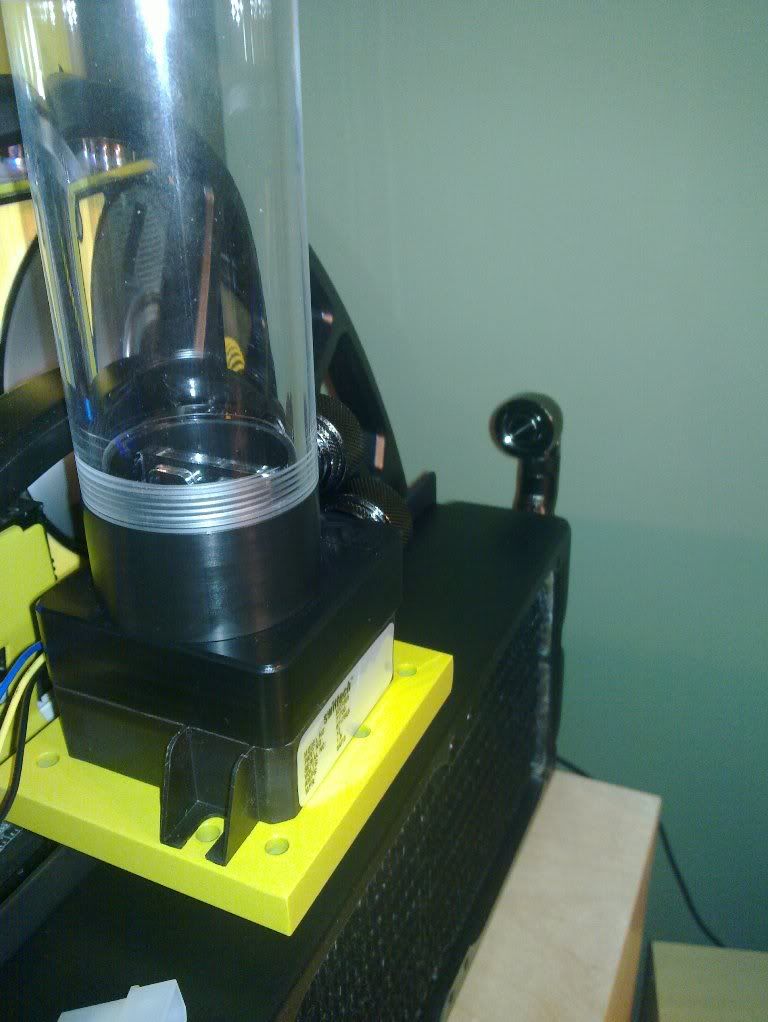

Still waiting on my fittings, won't be in untill end of month but plenty for me to do in the mean time.

I've decided to leave it as is and not to paint it. Having seen the mock up I did I was convinced it was just too much going on.

Still waiting on my fittings, won't be in untill end of month but plenty for me to do in the mean time.

(Where's the thumbs up smiley?)

(Where's the thumbs up smiley?)