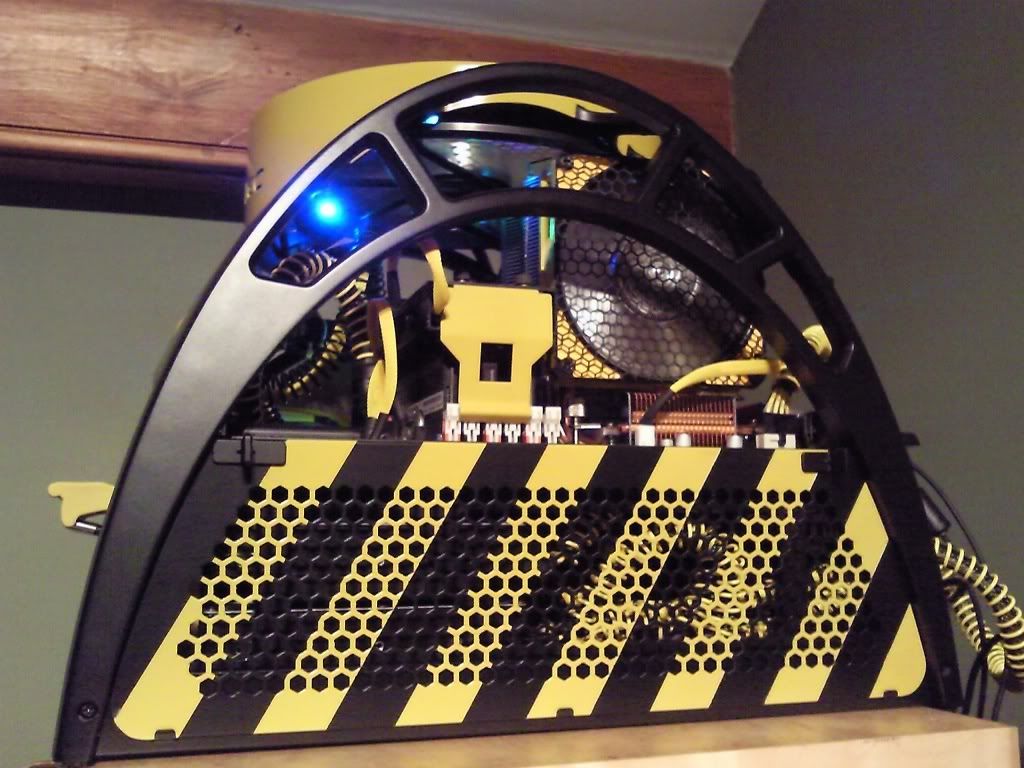

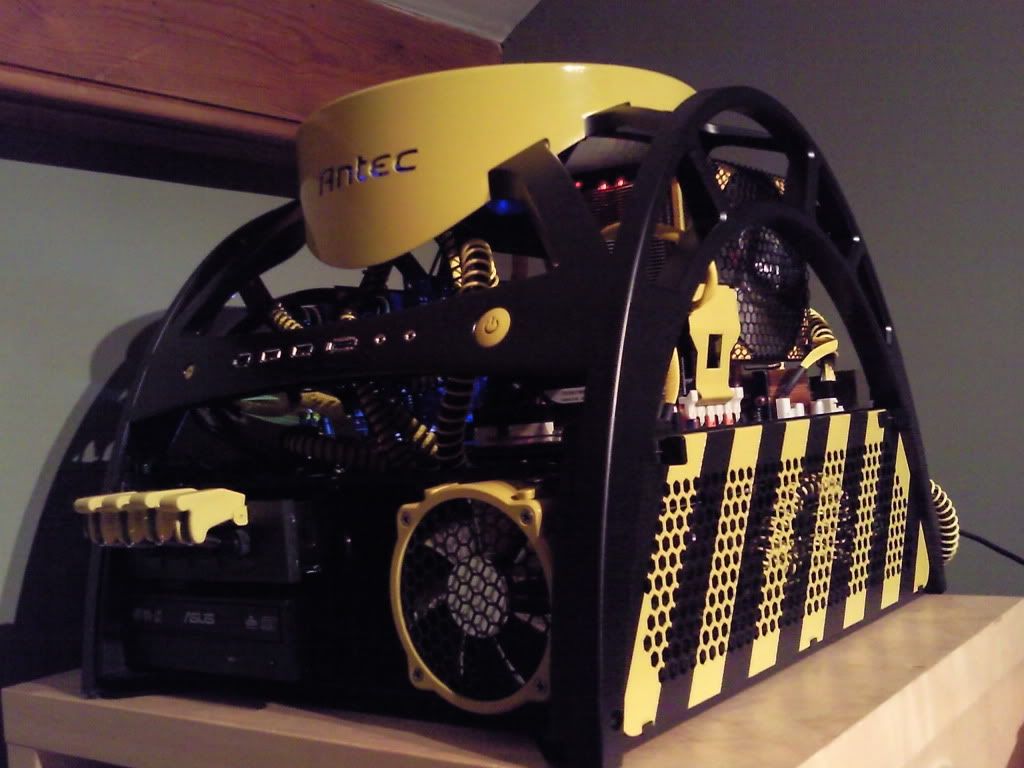

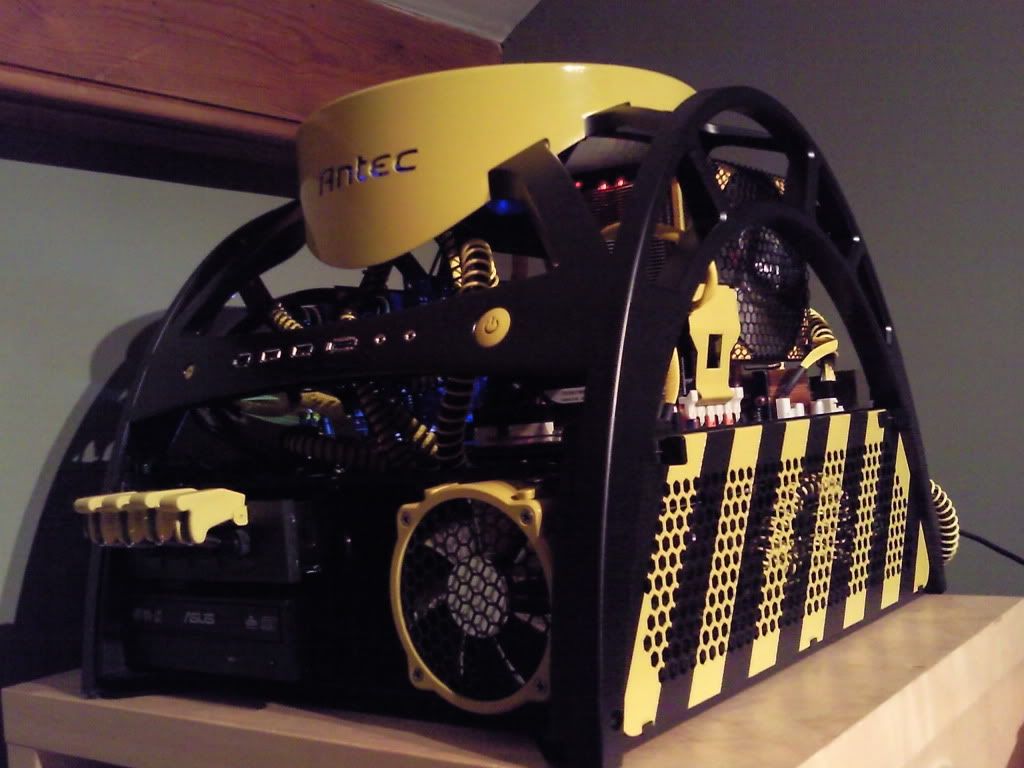

I've been a huge fan of this case since it first came out, and have modded a few in the last year or so.

I was origianlly going to carry this project on as an extension of my previous thread

http://forums.overclockers.co.uk/showthread.php?t=18059119

But have decided that as it is essentially a whole new project I would start a new thread. (aside from the fact I might actually use a fresh Skeleton, haven't decided yet)

So the other mods, incase you missed em.

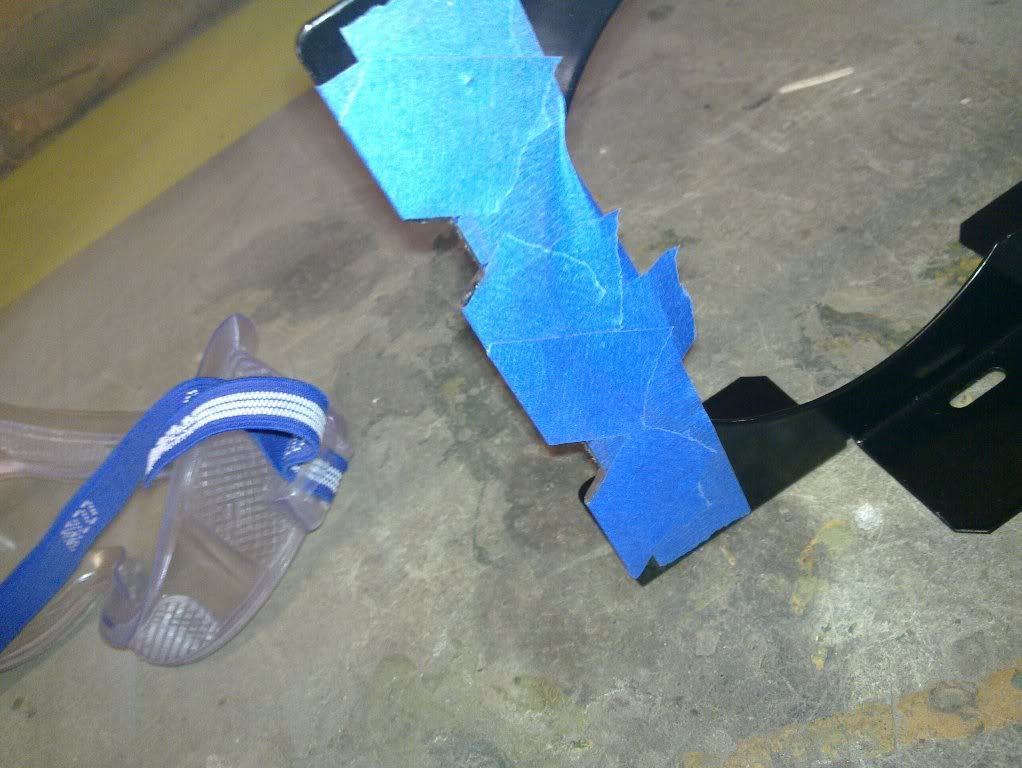

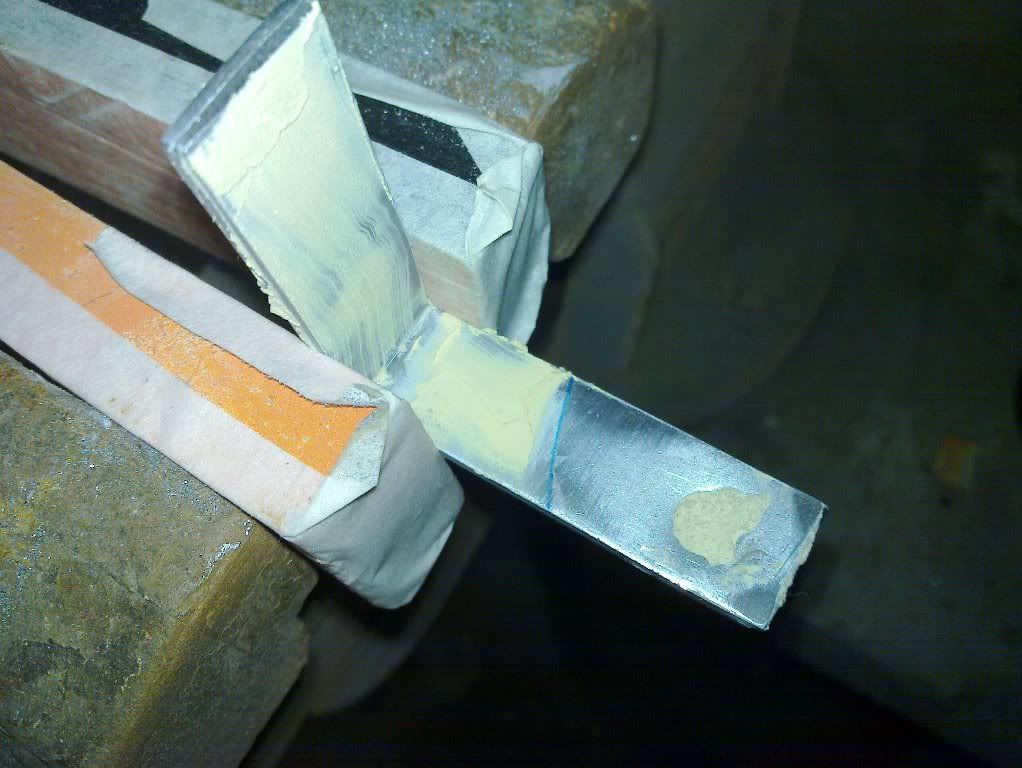

Having completed these two mods I decided I wanted to see what could be done with Water cooling.

With regards to installing the kit, unlike other cases there is no well trodden path (Pump goes down here, res over there. pump up there etc)

So a bit of a challenge, but also a blank canvas to work with.

Most parts have been ordered and have arrived, so should be able to get underway fairly soon.

So to the goodies.

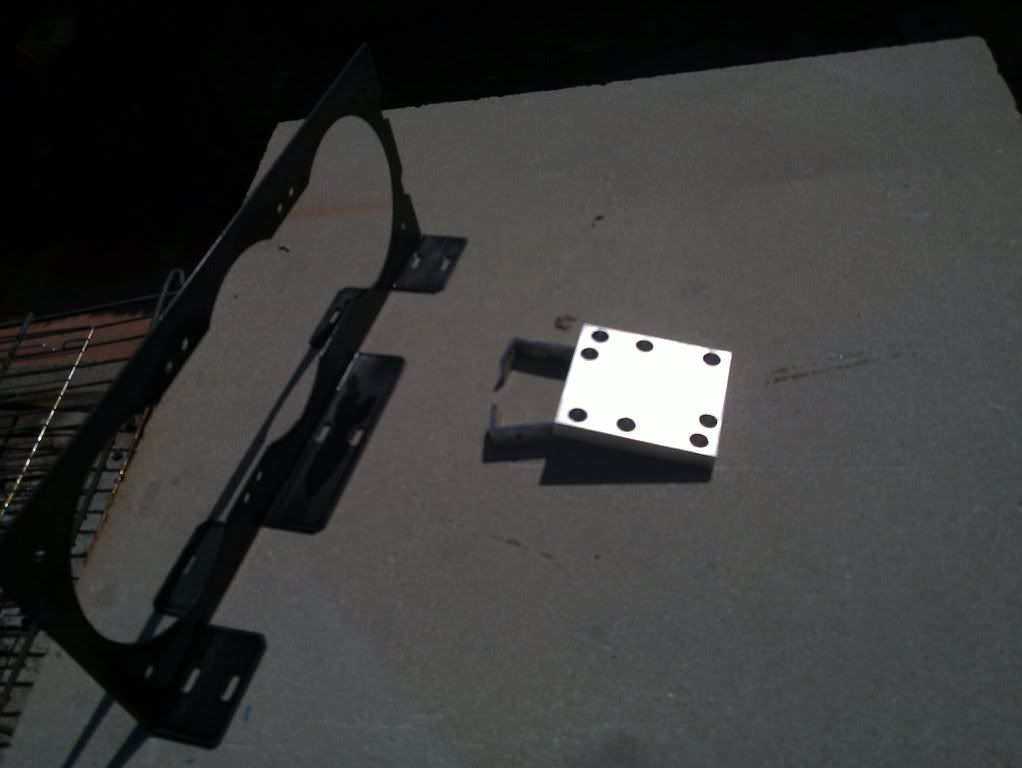

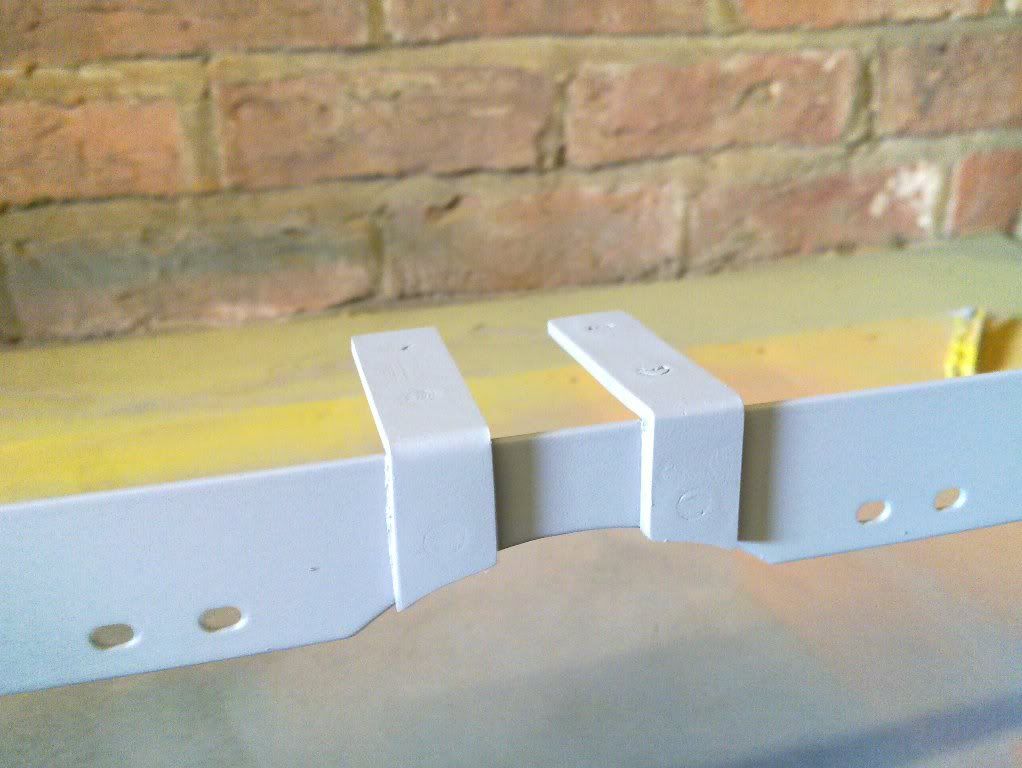

Going to be using the Phobya G-Changer 360mm Radiator Rev 1.2 as my Rad Got a few ideas of how to mount this monster of a Rad. In hind sight maybe should have gone for a 240 but hey size matters right guys!!!

Watercool HeatKiller CPU Water Block LGA1366 Rev. 3 Copper

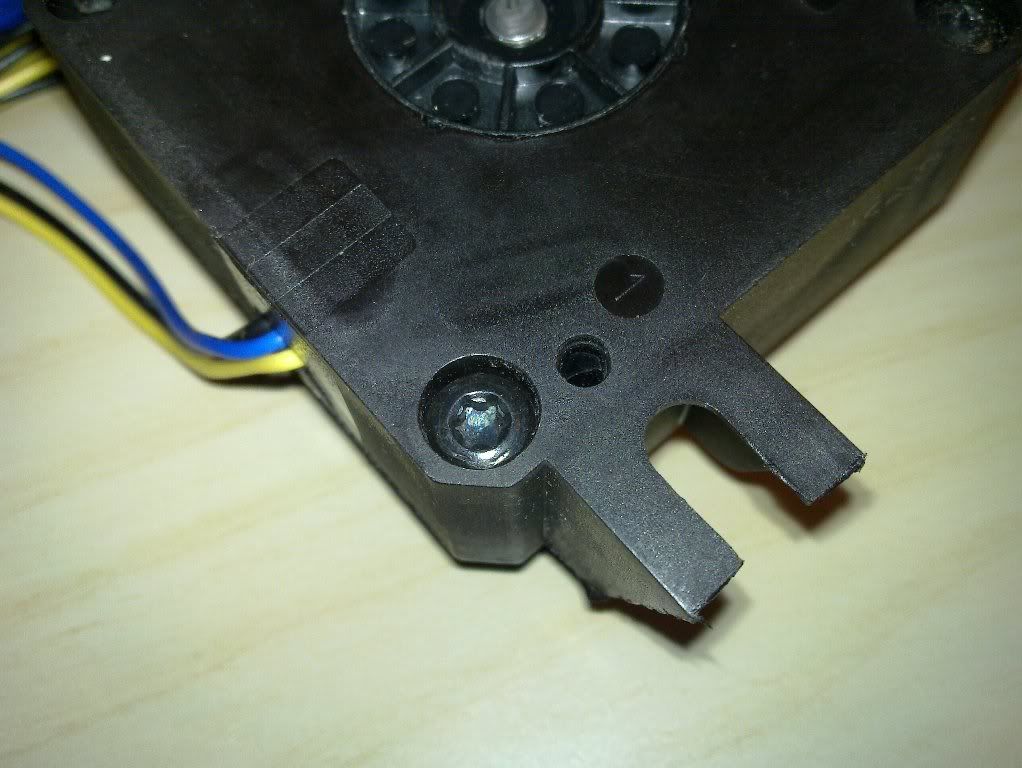

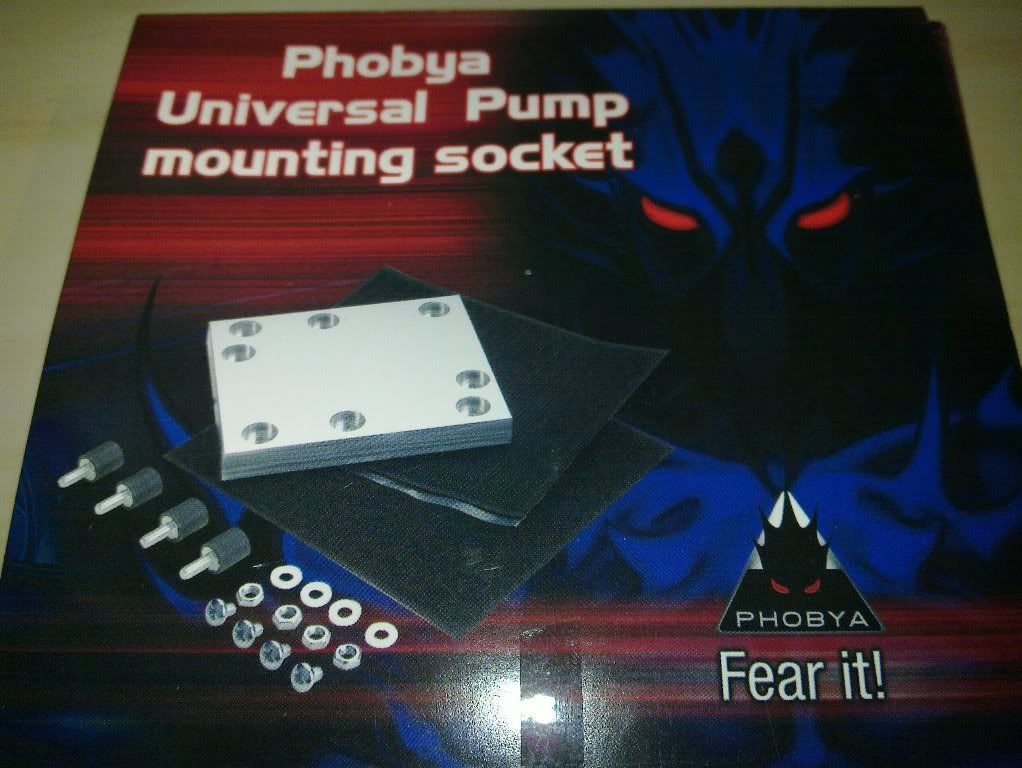

Swiftech MCP355 Laing DDC-Pump 12V DDC-1Plus 18W Ultra

EK-DDC X-RES 140

Primochill PrimoFlex Pro LRT Clear Tubing

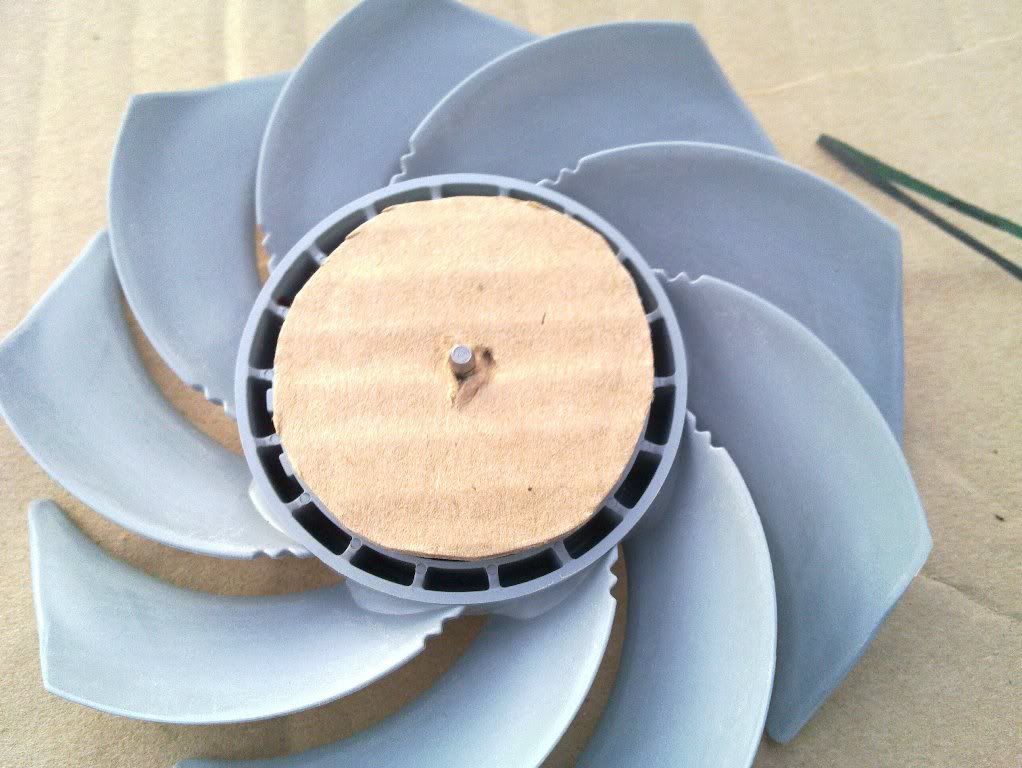

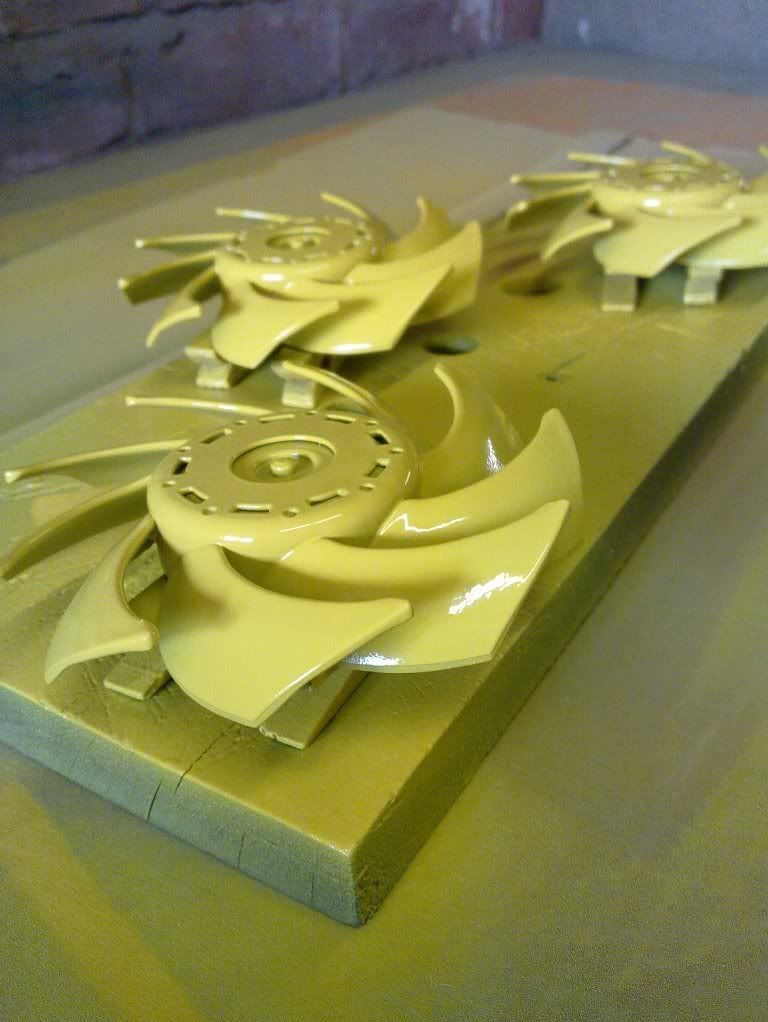

Scythe Gentle Typhoon 120mm Case Fan - 1850 RPMx3

A few more bits and bobs to come, But i've got enough toys here to be going on with.

I was origianlly going to carry this project on as an extension of my previous thread

http://forums.overclockers.co.uk/showthread.php?t=18059119

But have decided that as it is essentially a whole new project I would start a new thread. (aside from the fact I might actually use a fresh Skeleton, haven't decided yet)

So the other mods, incase you missed em.

Having completed these two mods I decided I wanted to see what could be done with Water cooling.

With regards to installing the kit, unlike other cases there is no well trodden path (Pump goes down here, res over there. pump up there etc)

So a bit of a challenge, but also a blank canvas to work with.

Most parts have been ordered and have arrived, so should be able to get underway fairly soon.

So to the goodies.

Going to be using the Phobya G-Changer 360mm Radiator Rev 1.2 as my Rad Got a few ideas of how to mount this monster of a Rad. In hind sight maybe should have gone for a 240 but hey size matters right guys!!!

Watercool HeatKiller CPU Water Block LGA1366 Rev. 3 Copper

Swiftech MCP355 Laing DDC-Pump 12V DDC-1Plus 18W Ultra

EK-DDC X-RES 140

Primochill PrimoFlex Pro LRT Clear Tubing

Scythe Gentle Typhoon 120mm Case Fan - 1850 RPMx3

A few more bits and bobs to come, But i've got enough toys here to be going on with.