Soldato

- Joined

- 31 May 2006

- Posts

- 7,564

- Location

- West London

Project log: Out of Reach

Reason: Primarily to move pc ‘out of reach’ of my little boy and secondary to provide an area that I can actually work at home from

(cutting down my office hours and getting home for my sons bedtime)

To cut a long story short the PC is now in our bedroom with a bungee HDD mod and a passive watercooling loop to remove almost all the fans and noise from the system. I’ll give you all the pre-mod guided tour later so you can see what I’m working with. It on 24/7 working on a DC project called Folding@Home and runs so quietly that I can hear my son breathing in the room next door at night.

To stop my little one ‘playing’ with the buttons (especially the power one) a barricade has been setup at the foot of our bed so he can’t walk round. He also knows that he’s not allowed to climb off that side of the bed, and thankfully rarely does.

Current setup technically works reasonable well considering is going something akin to prime 24/7 at 42c (with a 7300 in the loop). The passive rad could be moved further away from the central heating radiator. But it only comes on when very cold outside so not a major problem day to day. The major issue is comfort, as sitting on the bed is the only way to use the PC – fine for surfing for up to 30 minutes but not great for work.

Original starting point:

The corner of my bedroom, with pc occupying/surrounding an old TV bench.

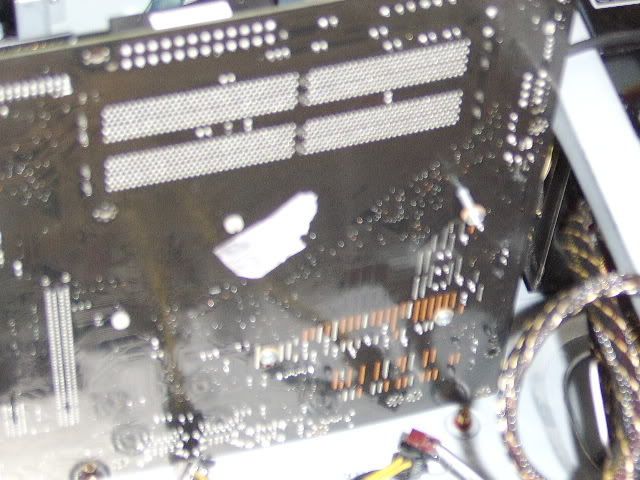

Revenge of the spaghetti monster, well if it’s out of sight…

Not the neatest case in the world I’m sure you’ll all agree

but since I removed the fans I’ve been a bit slack.

Full specification:

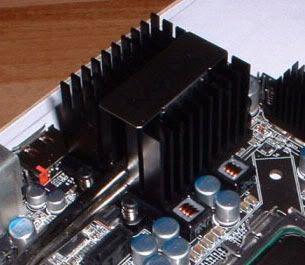

Case: Silverstone TJ05 with thermal controller (windowed side panel still boxed)

Mobo: Abit AW9D-Max running at FSB360

CPU: Intel [email protected]

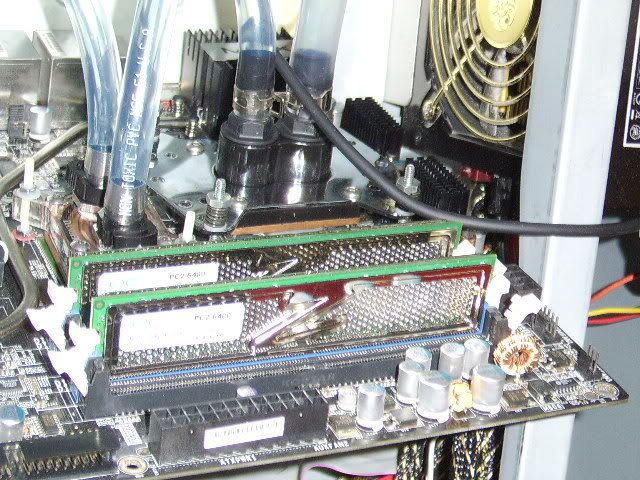

Ram: OCZ PC2-6400C4 Dual Channel Platinum Revision 2 XTC 1:1@760 (4,4,4,16)

VGA: Geforce 7300 SE passive

PSU: Enermax Liberty 400w

HDD: Western Digital raptor 36Gb

HDD: Seagate 300Gb

Drive: Pionoieer DVD-RW.

CPU Block: Zalman ZM-WB4 Gold

VGA Block: Zalman ZM-GWB3

Reservoir: Reserator2 body

Radiator: Reserator2 body

Pump: 3w DC12v 150L/sec (Lift 1m) inc in Reserator2 body

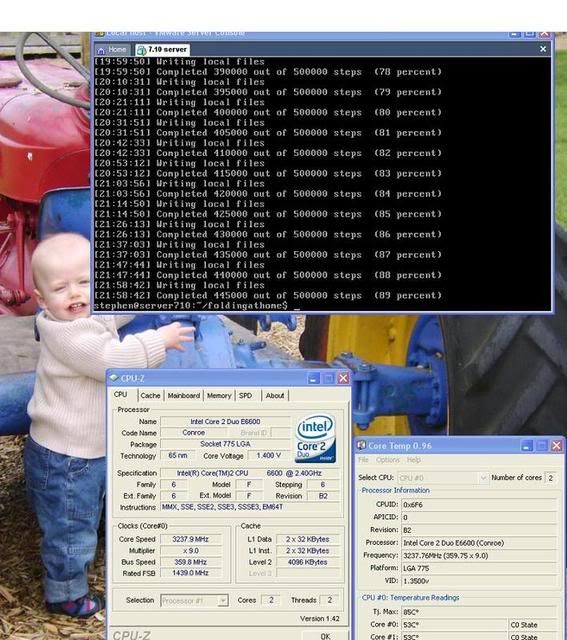

Even with what many consider a weedie pump this loop keeps both my CPU cores at or below 42c (coretemp)

at full load with the 7300 on the same loop. None to shabbly I’m sure you’ll agree for a system that relies on

natural convection in a house at 20c.

For comparison here's a few coretemps values for the chips I've had cooled by the Reverator in the last month or so.

[email protected]@100%@42c - Thermalright xp120 and Amber at 7v’s (plus 2 case fans)

[email protected]@100%@52c - Zalman Reserator2

[email protected]@100%@43c - Zalman Reserator2

[email protected]@ 75%@70c - Zalman Reserator2

[email protected]@100%@42c - Zalman Reserator2

[email protected]@100%@54c - Zalman Reserator2 with 7800GT OC installed

Screenshot of F@H coretemp and CPU-z, wallpaper is the little one in question

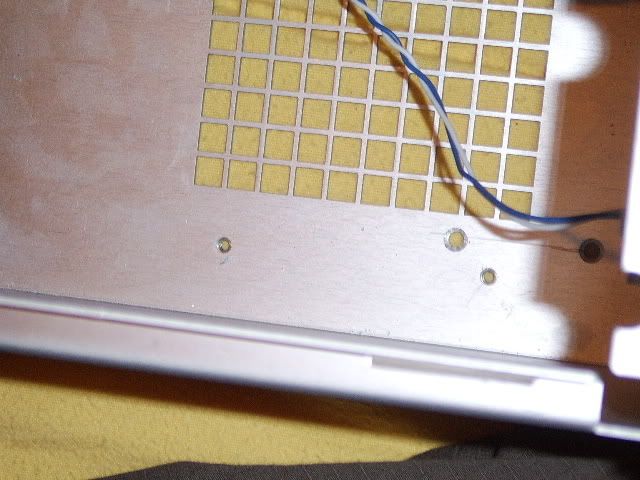

Ok that’s where I was, now for a sneek peak as some of the parts for the build.

There's a few missing but I'll intro them later as I progress.

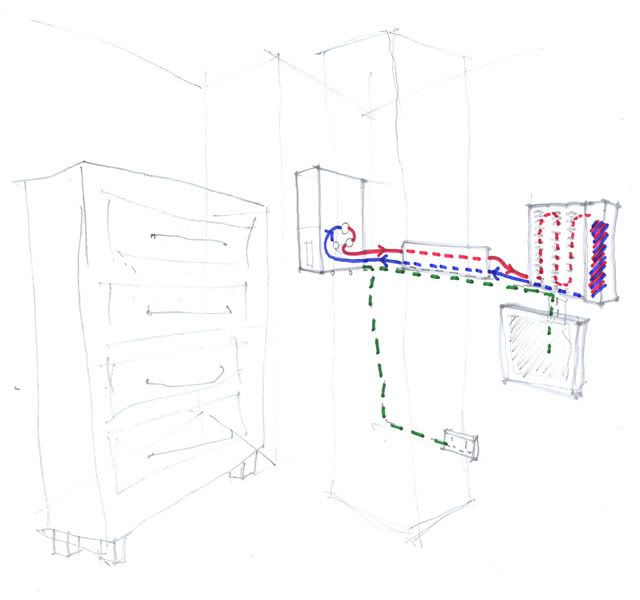

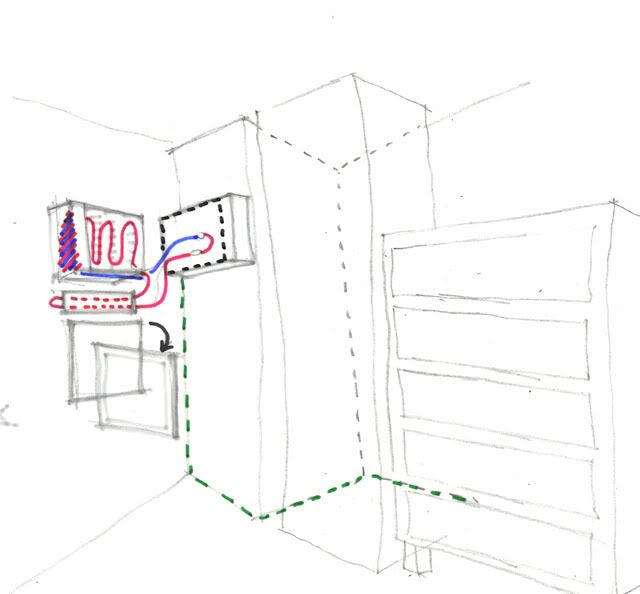

Edit: OK I know I haven't even started yet - but had a major re-design last weekend that resulted in me needed a different shaped case.

But have no fear I'm collecting it Wednesday and the grand plan will be revealed.

Prior to that I'll show all my ‘Plan A’ and the major flaw that my wife spotted

(I was to pre-occupied with aesthetic to notice I removed maintenance access Doh!)

Reason: Primarily to move pc ‘out of reach’ of my little boy and secondary to provide an area that I can actually work at home from

(cutting down my office hours and getting home for my sons bedtime)

To cut a long story short the PC is now in our bedroom with a bungee HDD mod and a passive watercooling loop to remove almost all the fans and noise from the system. I’ll give you all the pre-mod guided tour later so you can see what I’m working with. It on 24/7 working on a DC project called Folding@Home and runs so quietly that I can hear my son breathing in the room next door at night.

To stop my little one ‘playing’ with the buttons (especially the power one) a barricade has been setup at the foot of our bed so he can’t walk round. He also knows that he’s not allowed to climb off that side of the bed, and thankfully rarely does.

Current setup technically works reasonable well considering is going something akin to prime 24/7 at 42c (with a 7300 in the loop). The passive rad could be moved further away from the central heating radiator. But it only comes on when very cold outside so not a major problem day to day. The major issue is comfort, as sitting on the bed is the only way to use the PC – fine for surfing for up to 30 minutes but not great for work.

Original starting point:

The corner of my bedroom, with pc occupying/surrounding an old TV bench.

Revenge of the spaghetti monster, well if it’s out of sight…

Not the neatest case in the world I’m sure you’ll all agree

but since I removed the fans I’ve been a bit slack.

Full specification:

Case: Silverstone TJ05 with thermal controller (windowed side panel still boxed)

Mobo: Abit AW9D-Max running at FSB360

CPU: Intel [email protected]

Ram: OCZ PC2-6400C4 Dual Channel Platinum Revision 2 XTC 1:1@760 (4,4,4,16)

VGA: Geforce 7300 SE passive

PSU: Enermax Liberty 400w

HDD: Western Digital raptor 36Gb

HDD: Seagate 300Gb

Drive: Pionoieer DVD-RW.

CPU Block: Zalman ZM-WB4 Gold

VGA Block: Zalman ZM-GWB3

Reservoir: Reserator2 body

Radiator: Reserator2 body

Pump: 3w DC12v 150L/sec (Lift 1m) inc in Reserator2 body

Even with what many consider a weedie pump this loop keeps both my CPU cores at or below 42c (coretemp)

at full load with the 7300 on the same loop. None to shabbly I’m sure you’ll agree for a system that relies on

natural convection in a house at 20c.

For comparison here's a few coretemps values for the chips I've had cooled by the Reverator in the last month or so.

[email protected]@100%@42c - Thermalright xp120 and Amber at 7v’s (plus 2 case fans)

[email protected]@100%@52c - Zalman Reserator2

[email protected]@100%@43c - Zalman Reserator2

[email protected]@ 75%@70c - Zalman Reserator2

[email protected]@100%@42c - Zalman Reserator2

[email protected]@100%@54c - Zalman Reserator2 with 7800GT OC installed

Screenshot of F@H coretemp and CPU-z, wallpaper is the little one in question

Ok that’s where I was, now for a sneek peak as some of the parts for the build.

There's a few missing but I'll intro them later as I progress.

Edit: OK I know I haven't even started yet - but had a major re-design last weekend that resulted in me needed a different shaped case.

But have no fear I'm collecting it Wednesday and the grand plan will be revealed.

Prior to that I'll show all my ‘Plan A’ and the major flaw that my wife spotted

(I was to pre-occupied with aesthetic to notice I removed maintenance access Doh!)

Last edited:

- but it still has buttons on case / keyboard / monitor and mouse

- but it still has buttons on case / keyboard / monitor and mouse