Well, another year gone - hmmm, that brings this PC to nearly 6 years old already. Must be time to put a new head on Trigger's broom!

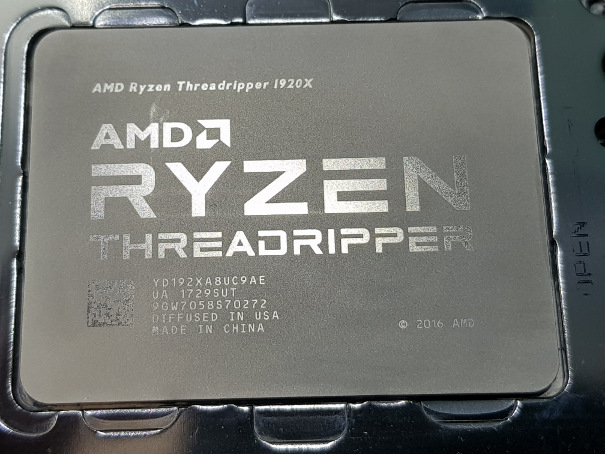

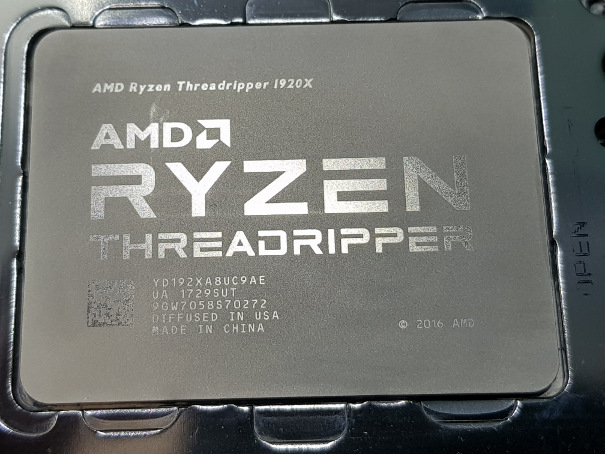

So, I have sitting here - courtesy of

@ALXAndy - a Threadripper 1920x on an MSI X399 Godlike with a Bykski water block. It'd be rude not to put it to good use!

Glad I ordered another gramme of Kryonaut as that's the ENTIRE tube right there!

I'd not heard of Bykski but you can't argue with the surface finish of that cold plate

Incidentally, I cleaned the inside of the block (previously had black coolant in it) and pressure tested it for paranoia's sake.

And all together:

That's a pair of 1TB Black Friday special M.2 SSDs under those heatsinks. Probably overthinking it but the M.2 Shield (one on the far right) didn't seem to offer much in the way of heat dissipation so I replaced the two that have actual disks under them. Yeah, I'm surprised I didn't populate all three too!

The sharper eyed of you might have noticed TWO EPS power connectors in the bottom left and also a PCIE power connector by the PCIE slots. From what I can find, the PCIE power is only really required if you're going to be doing excessive things to the GPU or running several of them. As I'm not, I'm going to plan to leave that unused. The second EPS connections seems to be one that's recommended.....and guess what my PSU doesn't have! Can't have the PC down (used for both work and recreation) for too long....and so begins Project Procrastination!

My PSU does have many spare PCIE power sockets which are

almost identical to an EPS connection - in fact it actually uses the EPS connector but the wiring is PCIE stlye - ie 3x12V and 5xGround when EPS is four of each. I should be able to make up a secondary EPS connector and run it off that by just forking one of the 12V lines. All I need are some ATX crimp pins....which I can't find. Ordered some more....and forgot the shells they go in. Ordered those....and failed to get one for each end of the cable. Yeah, I'm on a multi-day roll! Where's the facepalm smiley when you need one?! *facepalm*

It would mean flipping the res, all the drain ports in the wrong place. No, not enough spare sanity....or enough to realise it's a bad idea, depending on your take on it!

It would mean flipping the res, all the drain ports in the wrong place. No, not enough spare sanity....or enough to realise it's a bad idea, depending on your take on it!