It's good. Big, but that is sort of the point. I tend to run mine passively most of the time and a Aquaero kicks the fans in for a bit when the coolant gets up to near 40°C and stops once it's cooled a few degrees. The one thing I'd say is that the grill is a necessity - if it's on the floor, at some point you're going to kick it. Maybe they've changed the design slightly since I bought it but the gap between the rad and the grill is quite slim. This means there aren't many 200mm fans that will fit in the gap - hence why my 200mm fans are off most of the time. They're not loud exactly but louder than a decent fan would be at that speed but all the decent ones are too thick. You could, of course, mount the grill on washers or pieces of tube to space it off the rad a bit. That would let you put thicker fans in but leave a gap between the rad and grill that I didn't want. If you're looking at 200mm fans (4x200 fans are cheaper than 9x120) let me know and I'll measure the clearance between grill and rad for you.

The other thing to note is that you'll need a bit more coolant than a small rad. Mine takes slightly more than 2 litres from a casual drain (not trying to get all of it dry) and the res is 880ml if 100% full.

Cheers for the information, I have just looked on their site and they do a high rise one, takes up to 38mm fans.

I do have 2x480 rads, I might strap them together in the same style and mount the res and pump on the side.

Then at a later date buy the mora 420 and 9x 140mm fans.

Passively sounds ace for reading and watching iplayer etc. Been a bit obsessed with having a silent pc since i got into watercooling 5 years ago

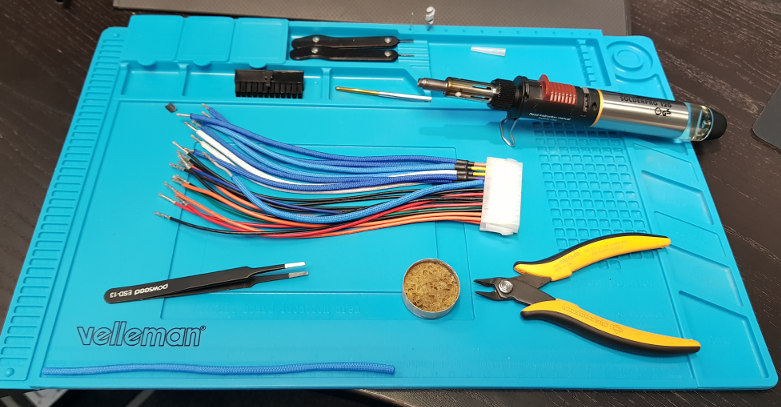

I got a load of black from China and it does annoying things. Stretch it off the bundle to wire length and it will shrink 4% once the cord is removed. Stretch it again when the wire is in and it's only 3% too short, but too short nonetheless. Compensate with 3% extra when the cord is still in and the uncorded length stretched over the wire is now 5% too long!

I got a load of black from China and it does annoying things. Stretch it off the bundle to wire length and it will shrink 4% once the cord is removed. Stretch it again when the wire is in and it's only 3% too short, but too short nonetheless. Compensate with 3% extra when the cord is still in and the uncorded length stretched over the wire is now 5% too long!