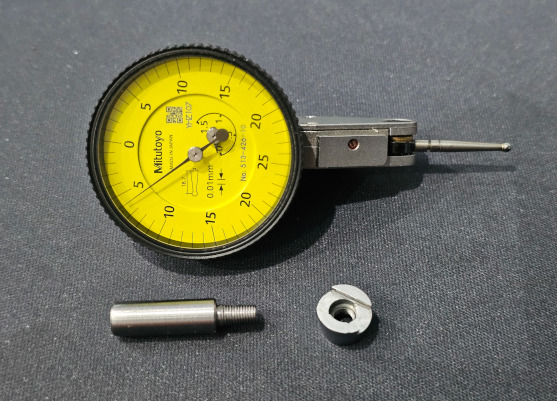

Ok, I'll cave. I was hoping to get things assembled before pics. It's not difficult to assemble but I will need to set up a DTI and sweep that across to make sure it's aligned when I tighten the bolts - otherwise I'll be cutting wedges instead of flat plates. Same thing with tramming the spindle. I think partly I'm finding it very difficult to actually do anything at the moment - even though I'm keen to 'play' with my new 'toy'. May be just burned out - hopefully the Christmas break will help. I suspect there's also a certain amount of Schroedinger's Cat at play: it can't be disappointing if I haven't tested it

Yeah, I know; I hear it too.

'Mounted' on the floor. Trip hazard? Dunno what you mean guv'!

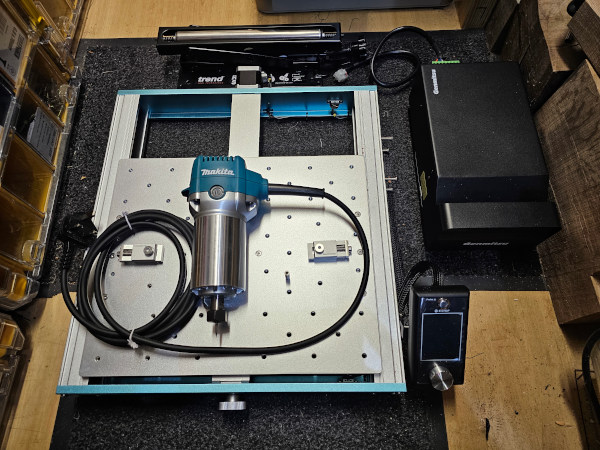

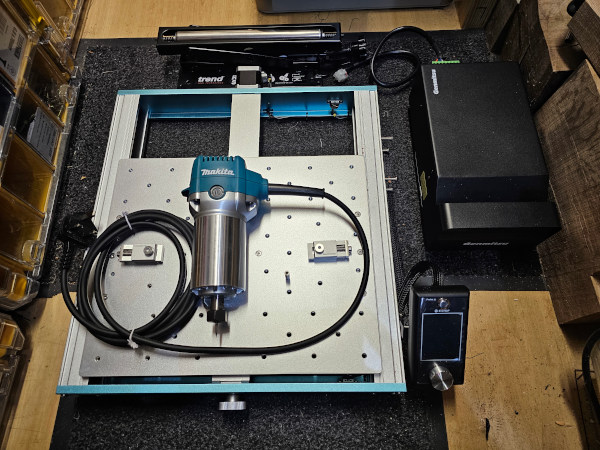

On the bed there's obviously the router that will be the spindle. The little cylinder to the right of it is a 1/4" to 1/8" collet reducer so I can chuck up the supplied engraving bits (one mounted to test it and the runout looks good) and potentially anything else that comes with a 1/8" shank.

Either side are a pair of Genmitsu toe clamps that fell in my basket at the same time - might be quite good for clamping acrylic sheet without sticking up over the sides much.

Black box to the right is the control box and the Trend thing at the back is the height-adjustable roller that might let me hang the material over the back....or might just not reach and be useless.

Gantry, 300w spindle and an air-blast nozzle. I'm set up for compressed air in the workshop but it's a silent compressor so you sacrifice speed for retaining your hearing. Will have to see if it can keep up without horribly exceeding the compressor's duty-cycle.

Edit: thanks very much autocorrect but my CNC has a gantry, not a gentry.... it's not that posh!

Yeah, I know; I hear it too.

Yeah, I know; I hear it too.