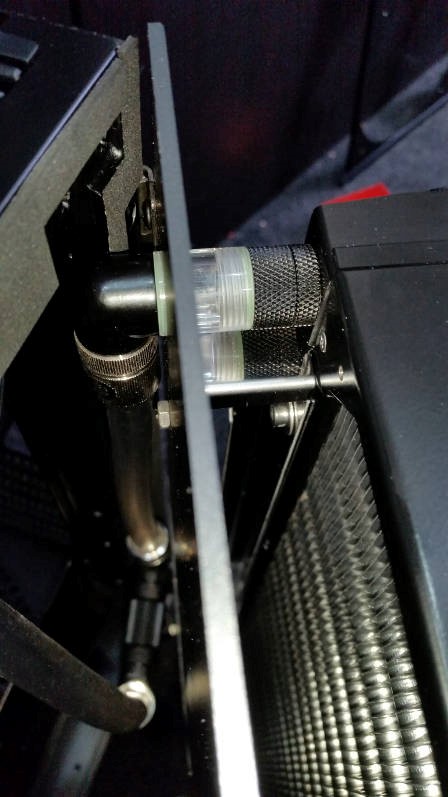

So what's worse than flushing a rad? Flushing a MONSTER rad! I foolishly assumed the design was like most with atria at each end. Found out the hard way when I poured water in one top port with another top port open to let the air out. Turns out they're directly connected

Actual design seems to be 3 or 4 tubes going from top ports to the right, then 3 or 4 tubes back and zig-zagging all the way down. It makes it a real pain to fill with a funnel in order to flush it out and I was fearful that flow would be naff.

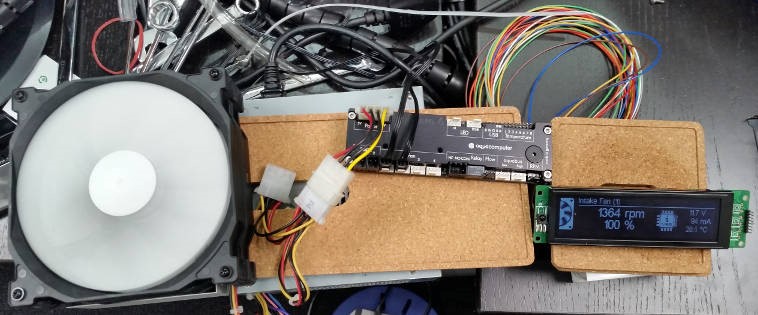

A while ago someone posted the genius idea of siphoning water through the rad to flush it. I gave this a go for the last rad and was dead smug with myself but the results were disappointing when I gave it a final shake with some DI and flakes came out. In the spirit of Overkill, I took it to the next level. I present to you the Dual DDC PowerFlush! Fun for all the family...clearly.

I was careful to keep water and mains (and son!) separated

Looks like I need not have worried about flow rate! It does seem to increase with the 2nd pump running - at least the jet goes further - but I won't have figures until I get everything finished and have the Aquaero and flow meter in the loop. So with massive flow gushing through the rad, it's all clean now and my laziness has been rewarded, right? Nope. A shake with tap water still has it coming out cloudy - like difficult to see through white cloudiness. Seems like there isn't really a good shortcut to this. Very disappointed.

Actual design seems to be 3 or 4 tubes going from top ports to the right, then 3 or 4 tubes back and zig-zagging all the way down. It makes it a real pain to fill with a funnel in order to flush it out and I was fearful that flow would be naff.

Actual design seems to be 3 or 4 tubes going from top ports to the right, then 3 or 4 tubes back and zig-zagging all the way down. It makes it a real pain to fill with a funnel in order to flush it out and I was fearful that flow would be naff.