OJ46: Deliberately making something badly just doesn't sit right with me...even with the market economics behind it. Like you say, it'll be interesting if AMD can give them some competition again.

BornEvil: Good to know. I'd heard about 10C. My CPU max core temp hits the high 70's when playing a game that uses the CPU so a 10C drop would be nice. 8Pack commented in another thread that it's probably my board supplying too much voltage when the CPU is on turbo (4.4GHz all cores) so I probably need to sort that out but starting off by dropping the temp isn't going to be a bad thing!

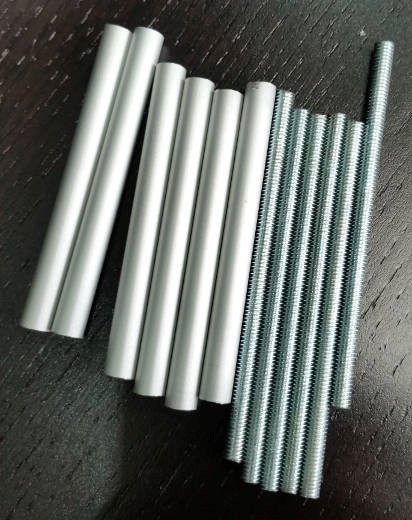

Progress pictures Cleaned up the existing gunk and applied some Cool Laboratories Liquid Ultra (CLU)

Cleaned up the existing gunk and applied some Cool Laboratories Liquid Ultra (CLU)

Spread it out with the supplied brush. Was a bit worried it seems a little lumpy but it seems to be the case in their instruction videos as far as I can work out. Assume it'll be fine when squashed and/or heated. Also applied a bit of clear nail varnish (who said wives weren't useful! ) over the uninsulated terminals in case the CLU spreads. Just because you're paranoid....

) over the uninsulated terminals in case the CLU spreads. Just because you're paranoid....

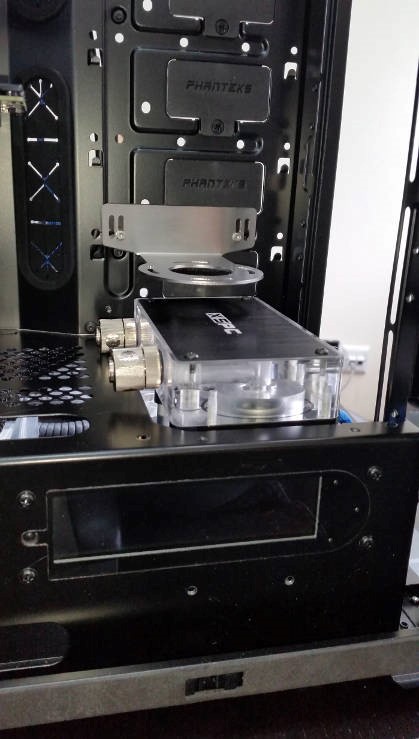

....and assembled. The black wires are temp sensors I stuck on the bottom of the M.2 SSDs to keep an eye on them. As far as I can tell, once you've stuck them in RAID 0, there's no way of accessing that data. Temp from the top of the chip would be more accurate than the bottom of the PCB but I wasn't going to be sandwiching the probe between the chip and the heatsink.

Hope to find out whether it lives later today

BornEvil: Good to know. I'd heard about 10C. My CPU max core temp hits the high 70's when playing a game that uses the CPU so a 10C drop would be nice. 8Pack commented in another thread that it's probably my board supplying too much voltage when the CPU is on turbo (4.4GHz all cores) so I probably need to sort that out but starting off by dropping the temp isn't going to be a bad thing!

Progress pictures

Cleaned up the existing gunk and applied some Cool Laboratories Liquid Ultra (CLU)

Cleaned up the existing gunk and applied some Cool Laboratories Liquid Ultra (CLU)

Spread it out with the supplied brush. Was a bit worried it seems a little lumpy but it seems to be the case in their instruction videos as far as I can work out. Assume it'll be fine when squashed and/or heated. Also applied a bit of clear nail varnish (who said wives weren't useful!

) over the uninsulated terminals in case the CLU spreads. Just because you're paranoid....

) over the uninsulated terminals in case the CLU spreads. Just because you're paranoid....

....and assembled. The black wires are temp sensors I stuck on the bottom of the M.2 SSDs to keep an eye on them. As far as I can tell, once you've stuck them in RAID 0, there's no way of accessing that data. Temp from the top of the chip would be more accurate than the bottom of the PCB but I wasn't going to be sandwiching the probe between the chip and the heatsink.

Hope to find out whether it lives later today

*blink* *blink*

*blink* *blink*

Will try to post some progress of mounting the bottom half of the Aquaero and the flow meter in the meantime.

Will try to post some progress of mounting the bottom half of the Aquaero and the flow meter in the meantime.