While i'm here some snaps from my tinkering while I wait/move house yet again... So after much looking at this kit while I can't actually build it in decided I wanted to lose the sort of cheapy feel and make it look a bit different. Part of that was to remove the funny stickers and go for a more stealthy 'EVGA' board look.

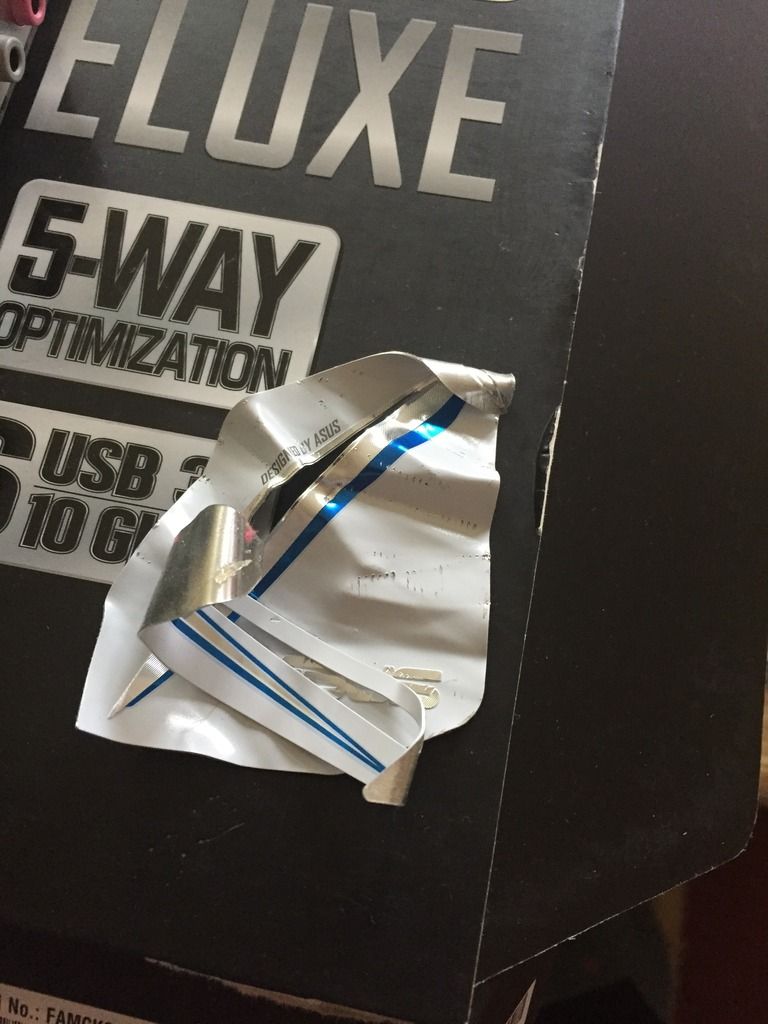

Step 1, remove kiddy stickers (I was pleasantly surprised at how easily these metal stickers peel off).

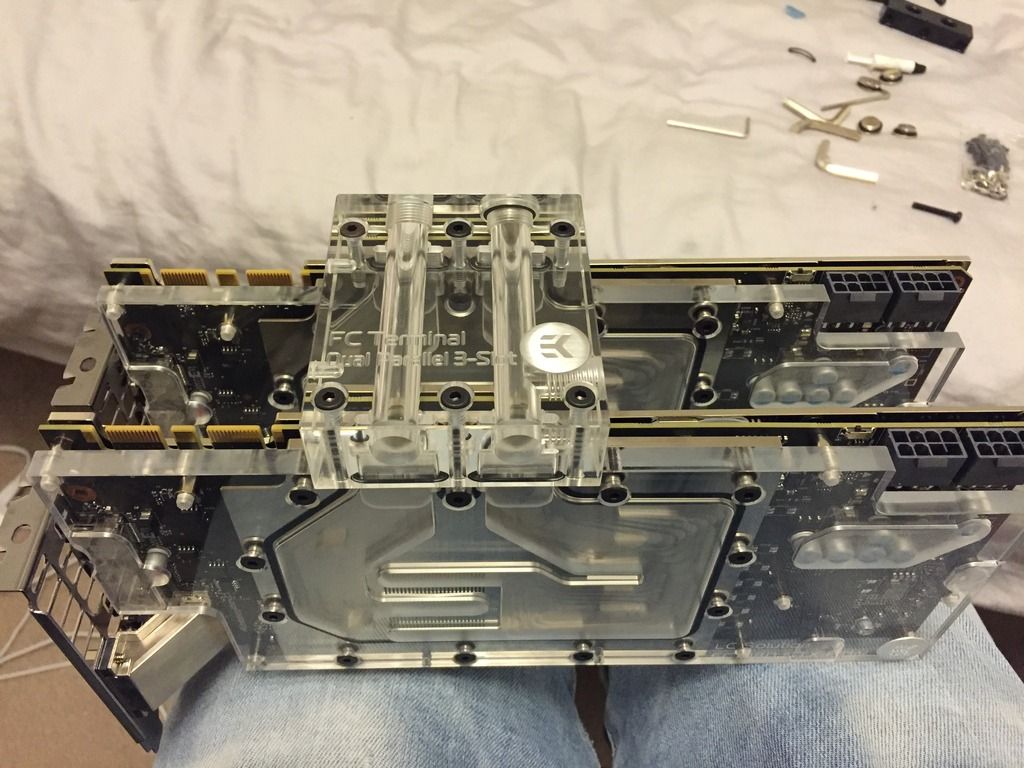

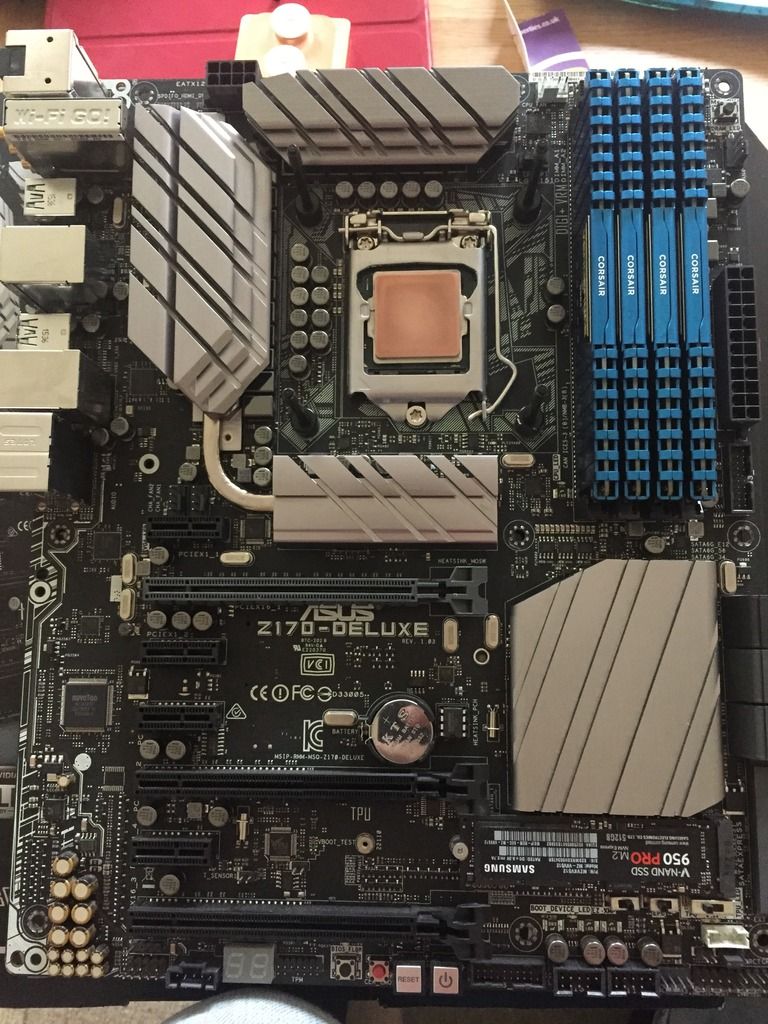

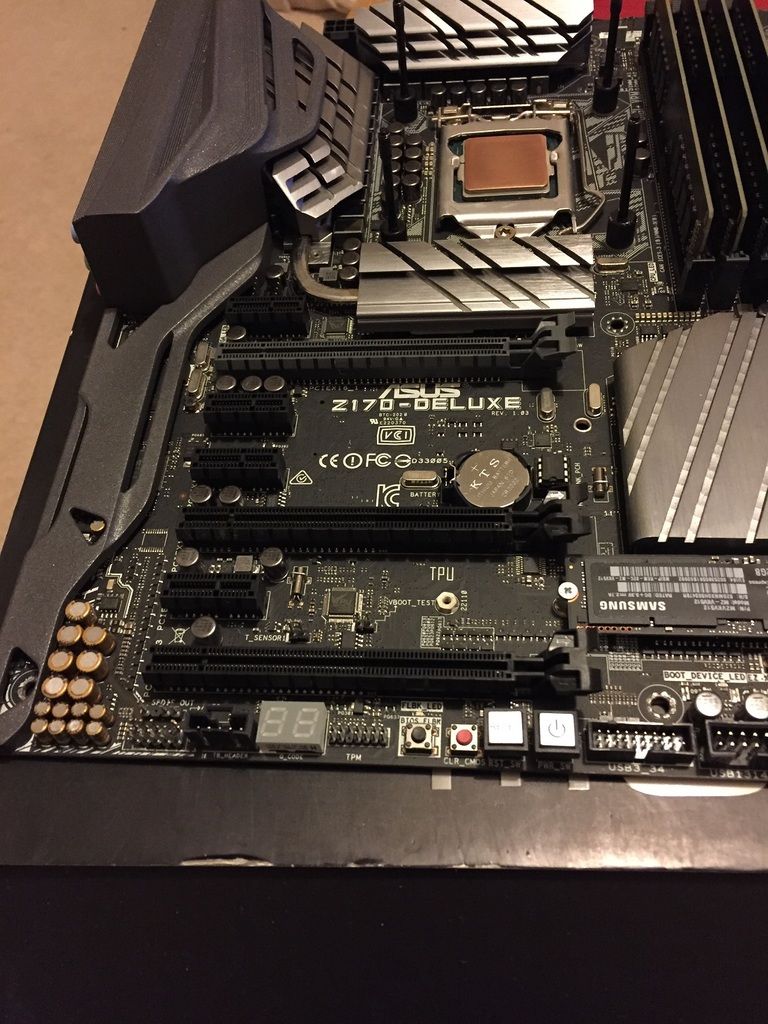

Reminder of how it looked:

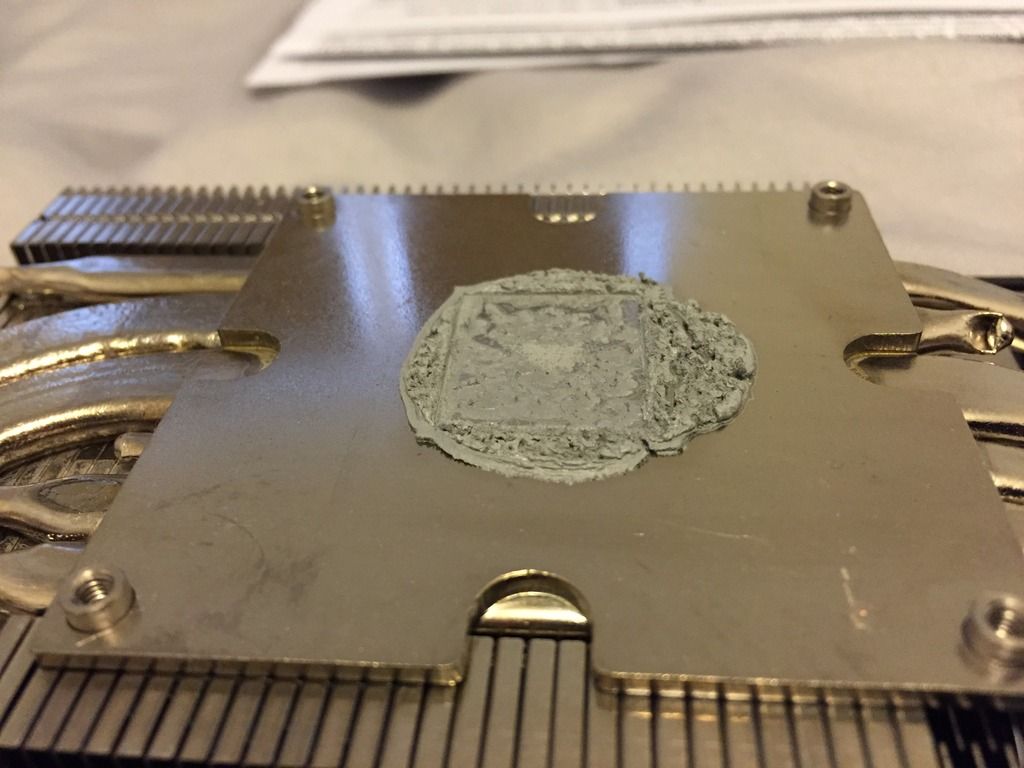

Unscrew the various metal heatsinks from the rear of the board and they just fall off. The stickers are stiff as hell but peel an edge up then I pulled them off with pliers...

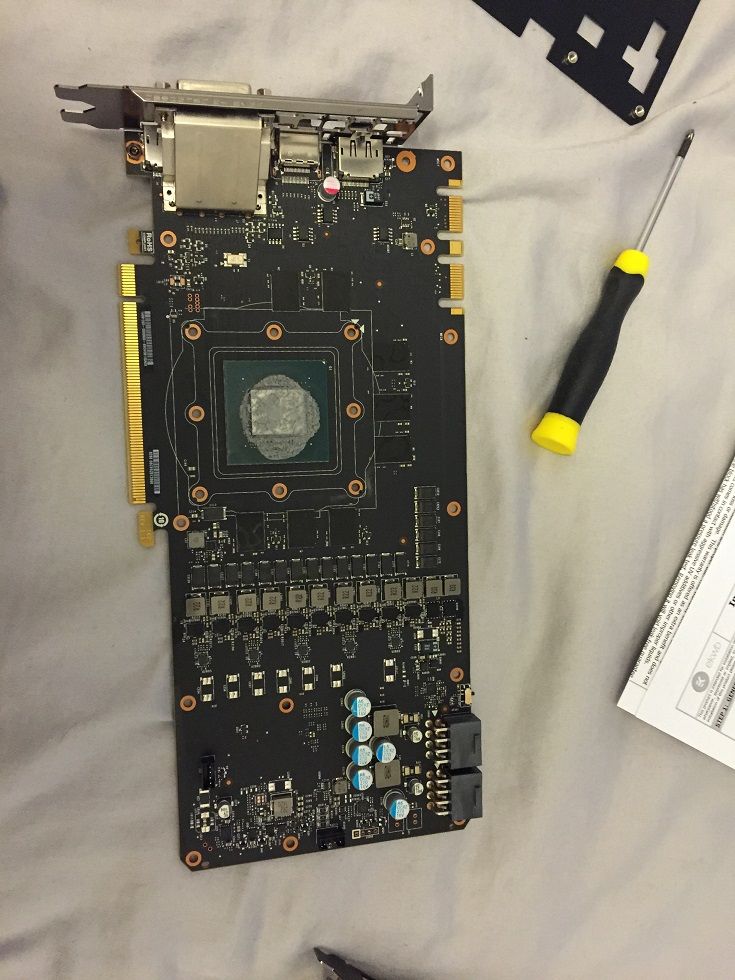

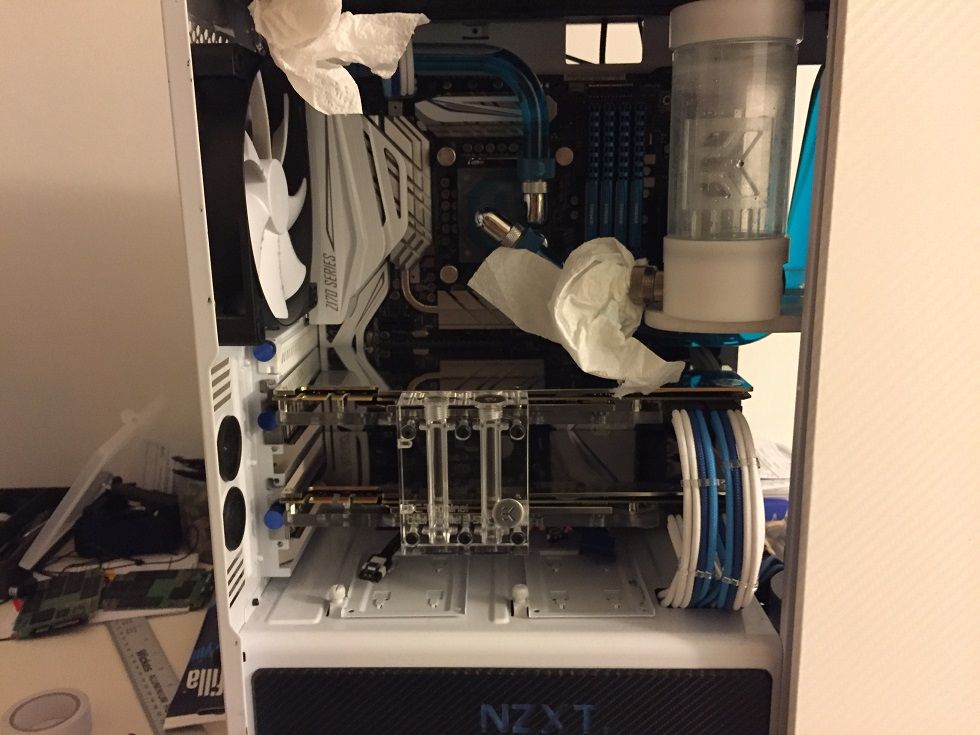

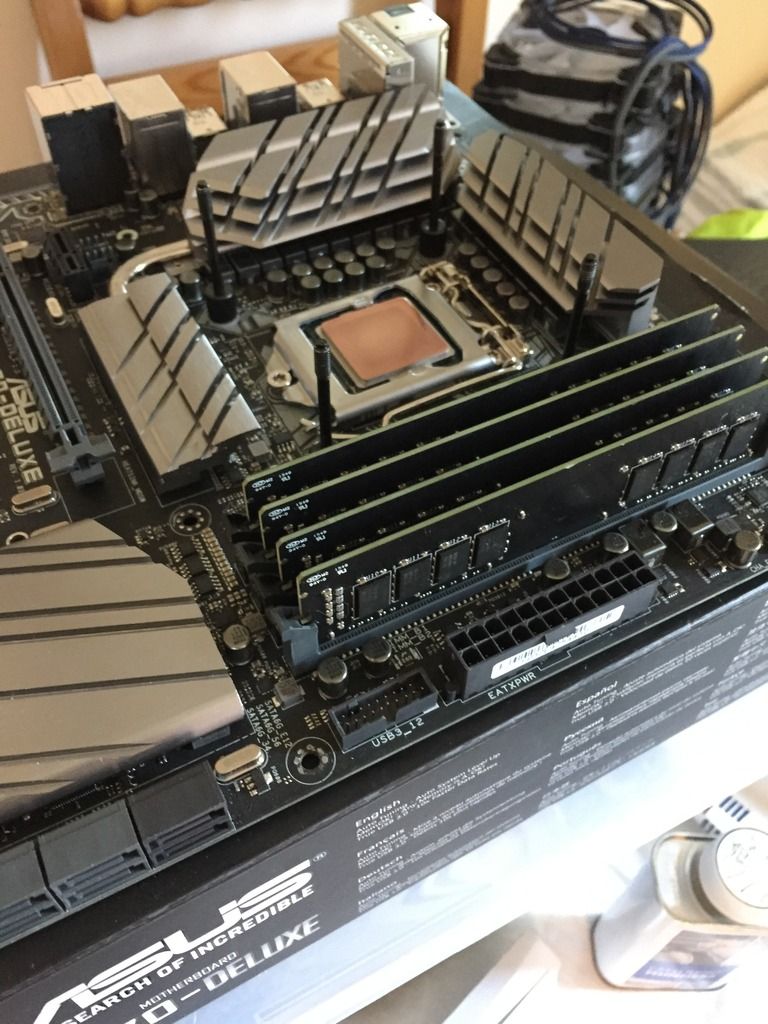

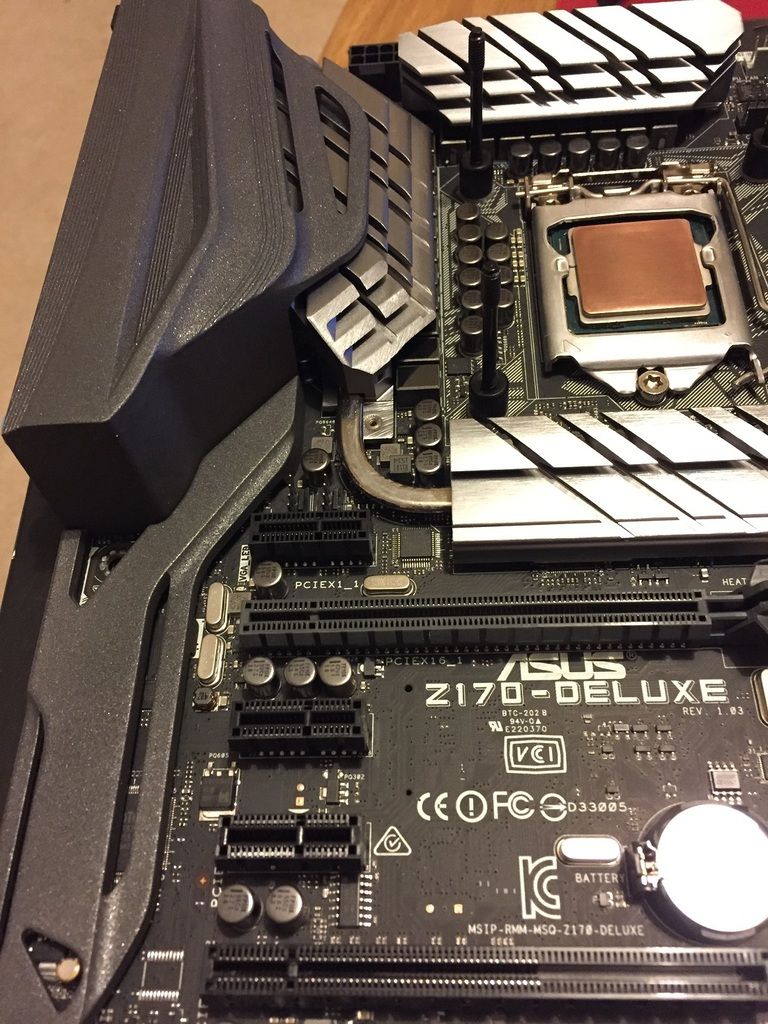

Back on the board with the white shrouds (plastic aesthetic only) removed:

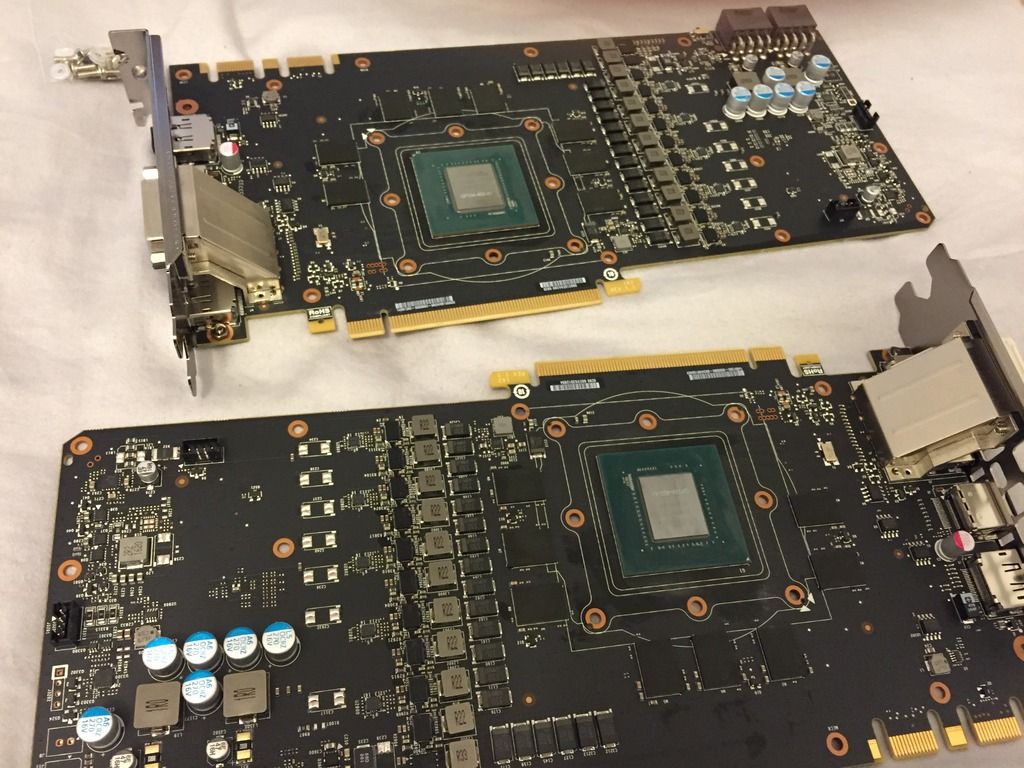

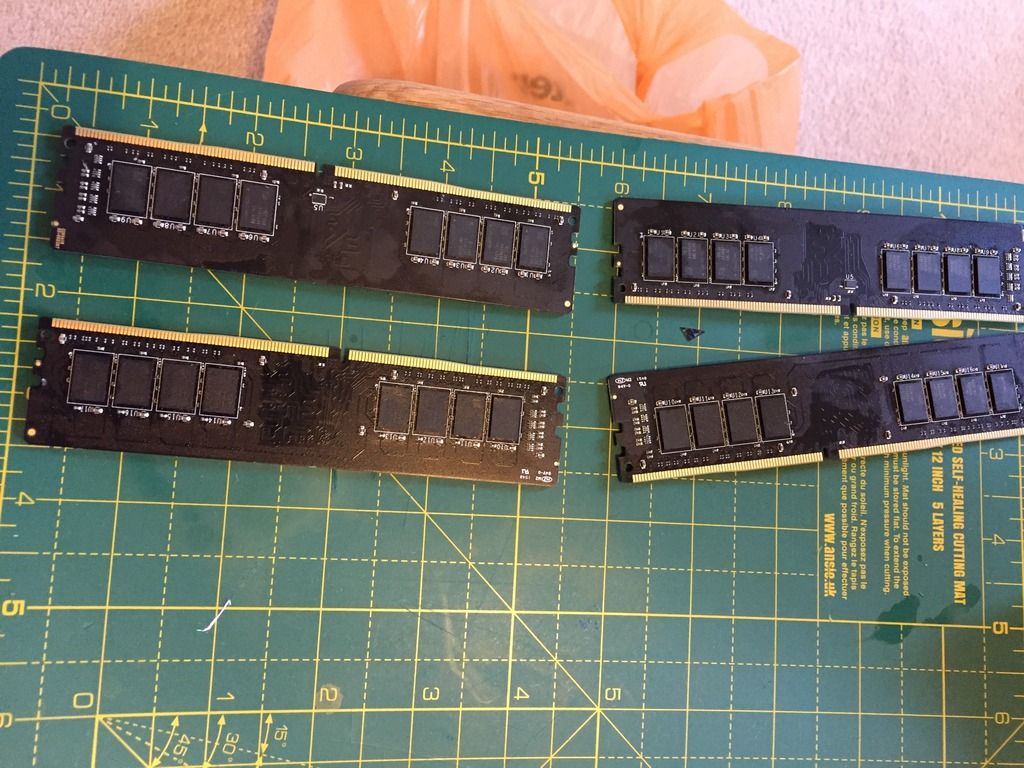

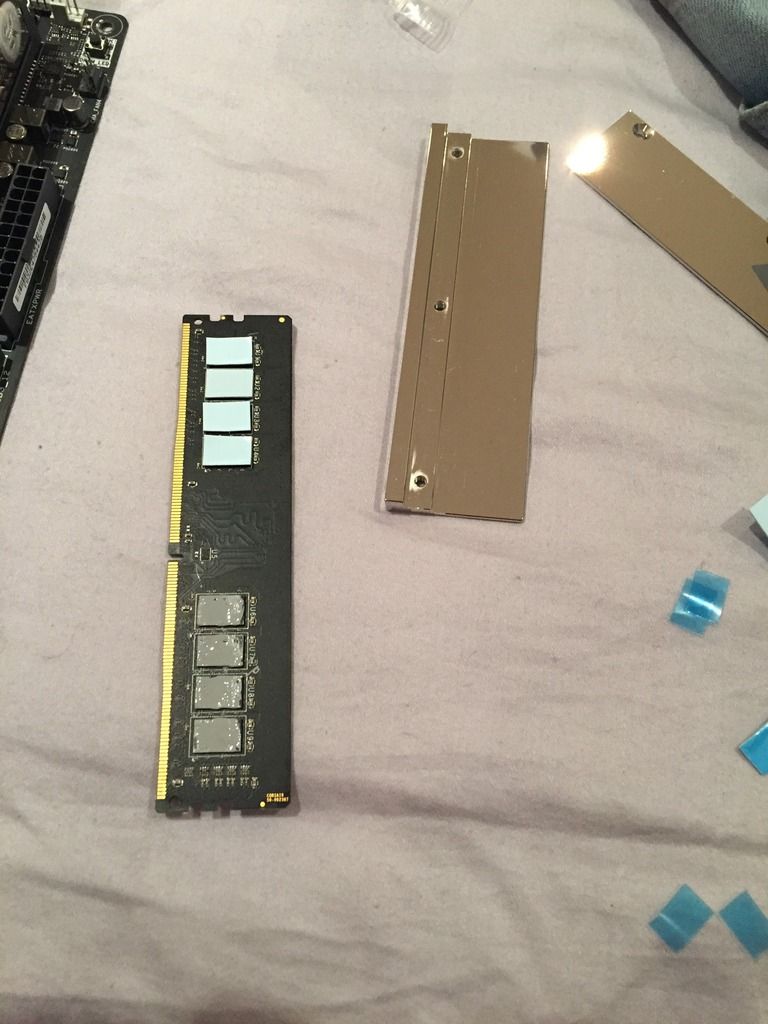

Step 2, decide I don't like the RAM anymore... remove the heat spreaders carefully - this was tricky but ease it open and give a squirt of contact cleaner/isopropl and it should start to ease off. It was tedious though I won't lie.

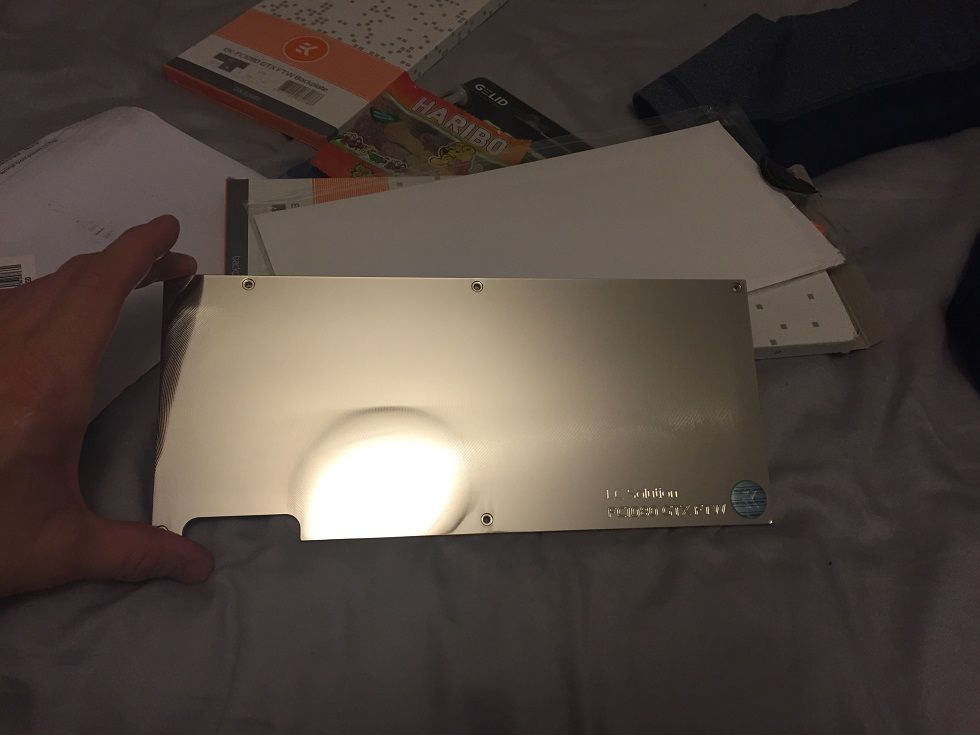

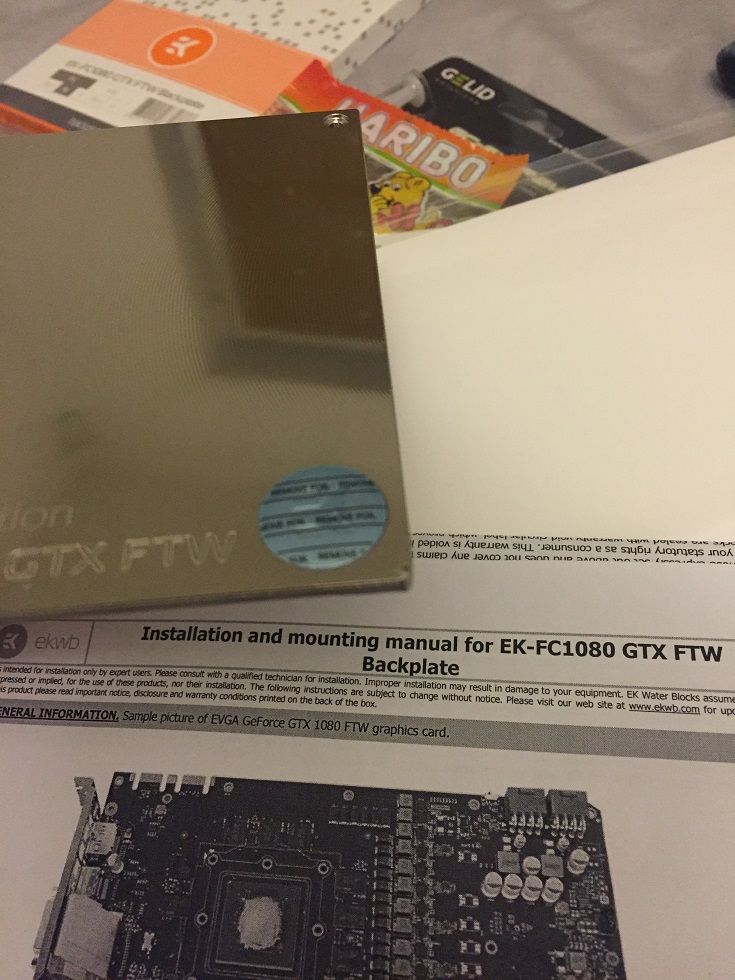

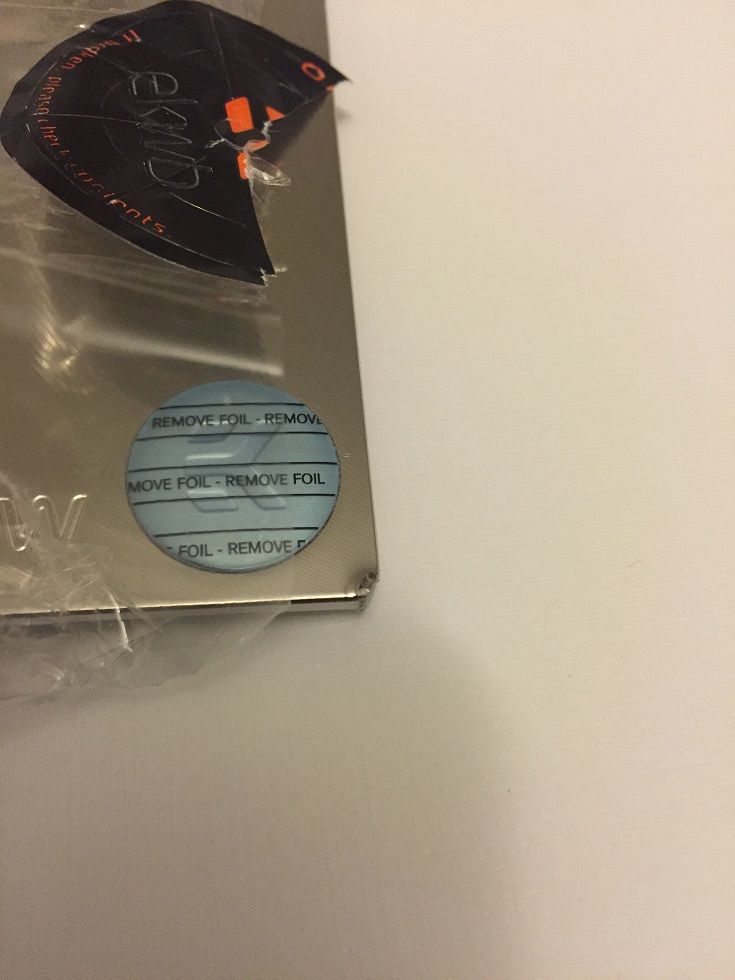

Back in the board while I wait on my new EK Monarch Nickel bad boys to arrive - two are here now (nobody had stock of more than 1 pair) so pics of that later:

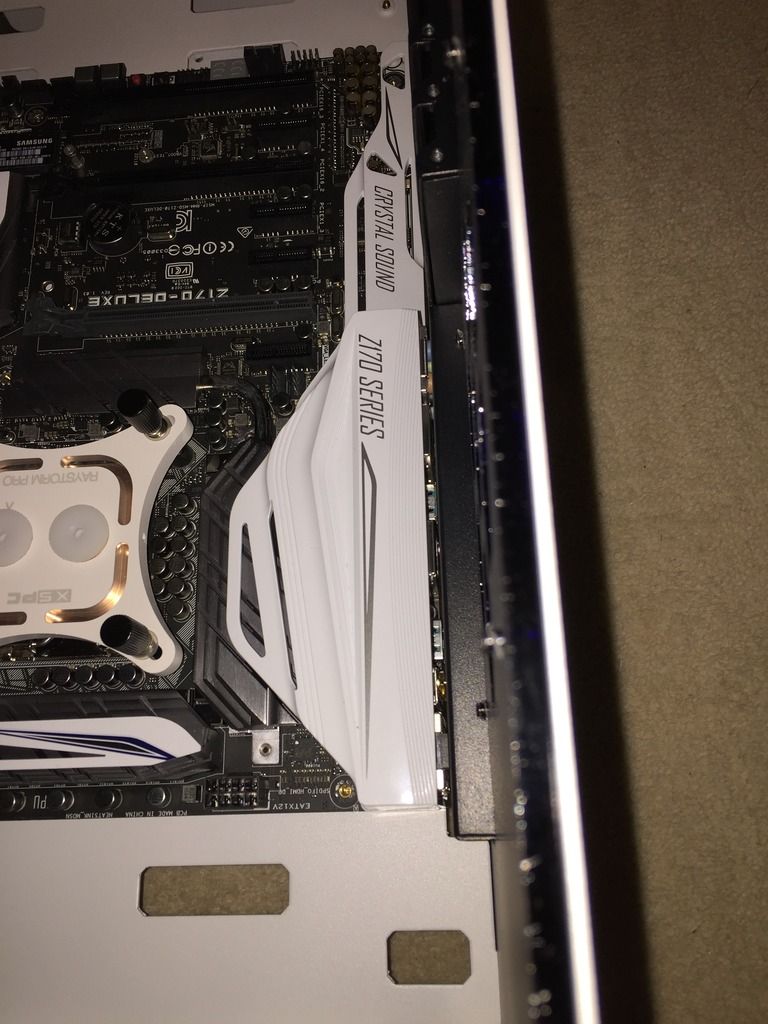

Stage 3, making my board look a bit more stealthy... Decided to spray the shroud with this lovely looking metallic grey/black:

I think its come out really well, love the paint...

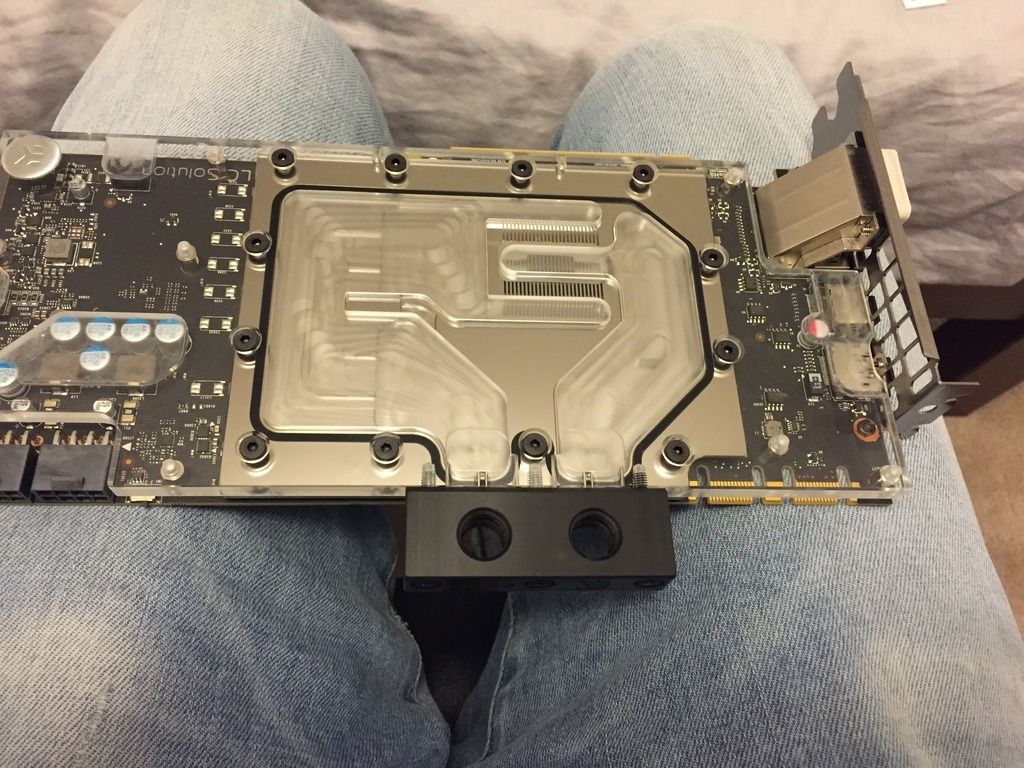

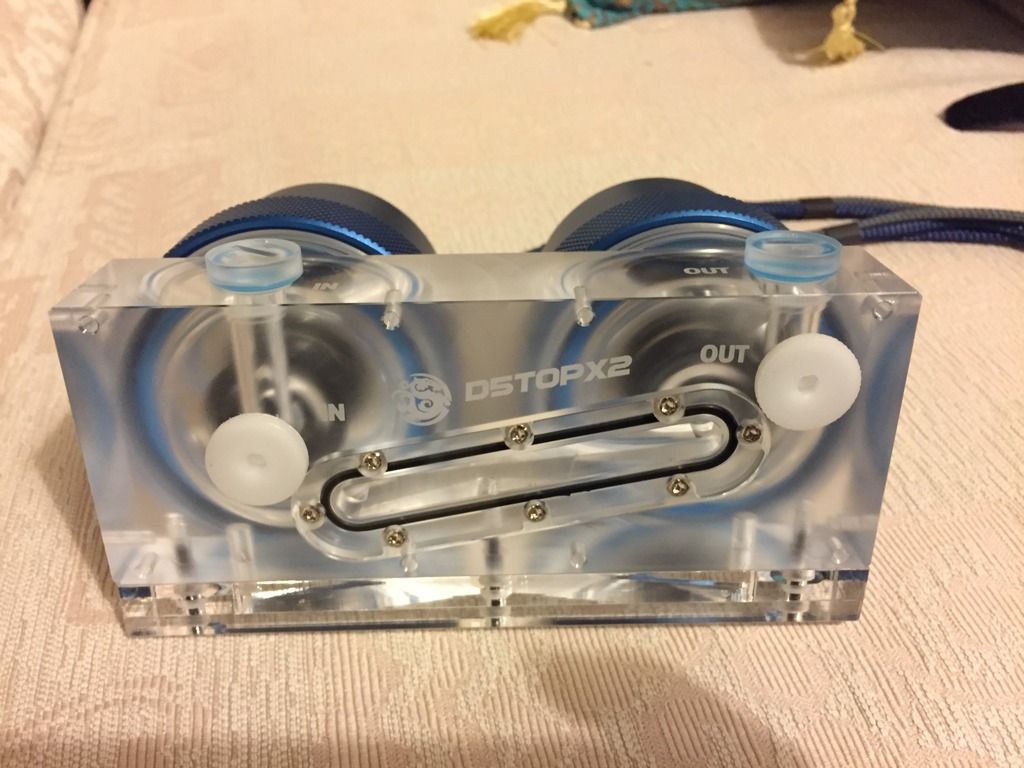

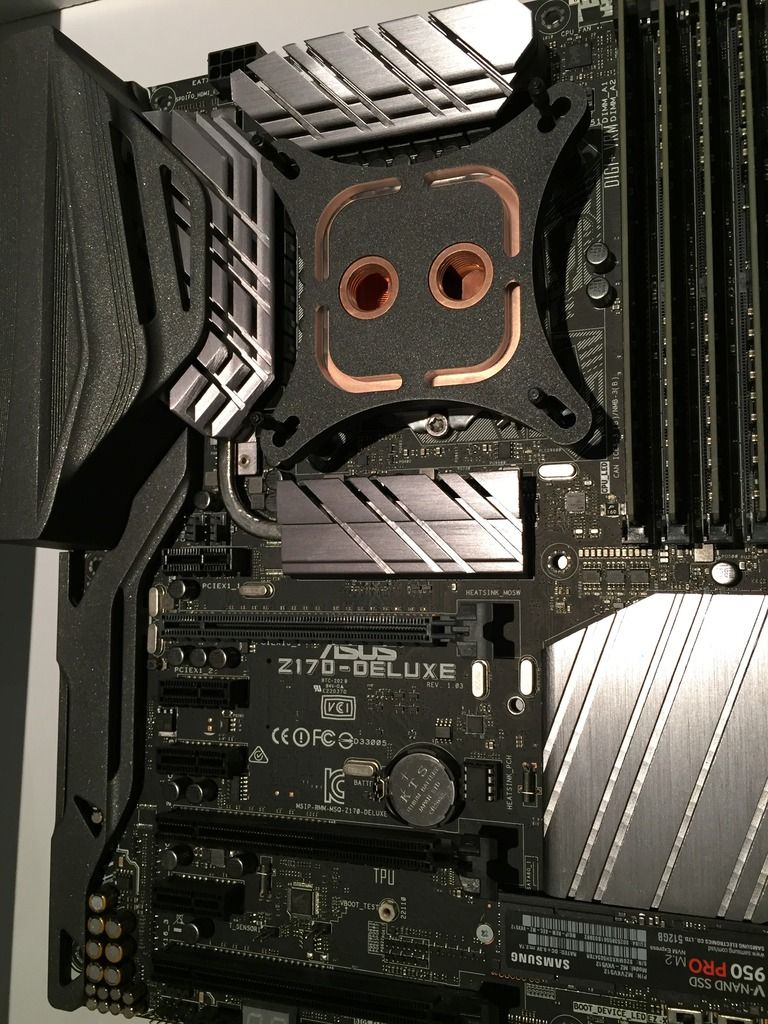

Step 4, decide again you don't like your brand new XSPC Raystorm block... Debate about returning it... Decide to attack it. Stripped off all the pain on the surround, its solid aluminium so wanted to see how the finish was naked:

Looked a little off being quite bright so opted for the same metallic paint job as with the board shrouds which I think looks really nice... Also thinking I might copper pipe the liquid cooling instead of PETG...

They better hurry up and sort my case before I obsessively mod anything else! My plan for the RAM is just to leave the Nickel casings on as heat spreaders, at this point I don't plan to actually loop in the RAM and water cool it.

What do you think to my new EVGA ASUS board?