This is my first project on OCuK. I've built myself a sandybridge system and am now about to stuff it full of watercooling kit.

Kit

This kit has been running now for a week or two and performs fine apart from the gfx card sounding like a hairdrier as soon as a game is fired up.

Did some research, and decided I was going to need more than one radiator, especially as I may go Crossfire in the future. So worked out I wanted to do this.

Cooling

Additional

So the puzzle is to fit this lot

into this

Unpacked all the kit, visual inspection etc.

Test fitted a radiator. Looks like the barbs have to go to the back of the case. Was concerned there wouldnt be enough room to mount a rear fan, but its fine.

Gap between the radiator and the 5.25" drive bays is only enough to fit a single sheet of paper.

Gap between the motherboard and the radiator is huge.

Checked the height of the drivebay areas for the 2nd radiator, then drilled out the rivets.

Note: Swarf from drilled out rivets is sharp. Use a brush or a vacuum cleaner.

Removed the CPU and test fitted the CPU backplate and block.

I am loving these XSPC fittings. My last build used barbs and hoseclips, clear hose and started out with coloured coolant. These look so much classier.

Dismantled the pump, fitted the reservoir / pump-top.

The planned placement of all the bits is like this.

Flushed the radiators with a mix of hot water and vinegar. These are drying in the kitchen. Will flush again with distilled later.

Connected up some hose to the pump, put some water in and fired it up for a test. (I have one of those PSU jumper adaptors for leaktesting). That hasnt gone well.

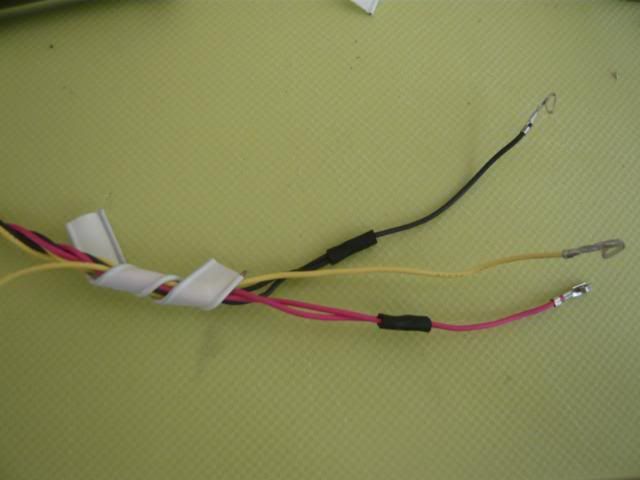

Going to move onto the PSU and motherboard cable braiding now.

Kit

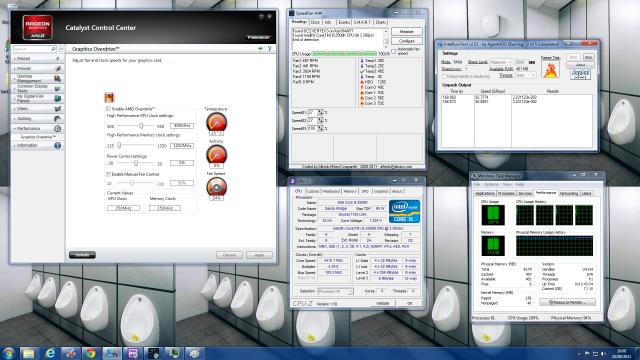

Gigabyte Z68X-UD4-B3

Core i5 2500K

VT3D 6950 2GB

Fractal Arc Midi case

Antec semi-modular PSU

Core i5 2500K

VT3D 6950 2GB

Fractal Arc Midi case

Antec semi-modular PSU

This kit has been running now for a week or two and performs fine apart from the gfx card sounding like a hairdrier as soon as a game is fired up.

Did some research, and decided I was going to need more than one radiator, especially as I may go Crossfire in the future. So worked out I wanted to do this.

Cooling

2x XSPC RX240 radiators

4x Scythe Gentle Typhoon fans

Laing DDC Pro pump

XSPC res/pump-top

XSPC white hose

XSPC Rasa CPU block

XSPC Rasa universal GPU block

(I quite like XSPC kit having bought various bits from them for my last PC)4x Scythe Gentle Typhoon fans

Laing DDC Pro pump

XSPC res/pump-top

XSPC white hose

XSPC Rasa CPU block

XSPC Rasa universal GPU block

Additional

Grey para-cord for braiding cables

Heatshrink in a couple of sizes

PSU and Fan pin removal tool

XSPC 120mm Radiator stand

Heatshrink in a couple of sizes

PSU and Fan pin removal tool

XSPC 120mm Radiator stand

So the puzzle is to fit this lot

into this

Unpacked all the kit, visual inspection etc.

Test fitted a radiator. Looks like the barbs have to go to the back of the case. Was concerned there wouldnt be enough room to mount a rear fan, but its fine.

Gap between the radiator and the 5.25" drive bays is only enough to fit a single sheet of paper.

Gap between the motherboard and the radiator is huge.

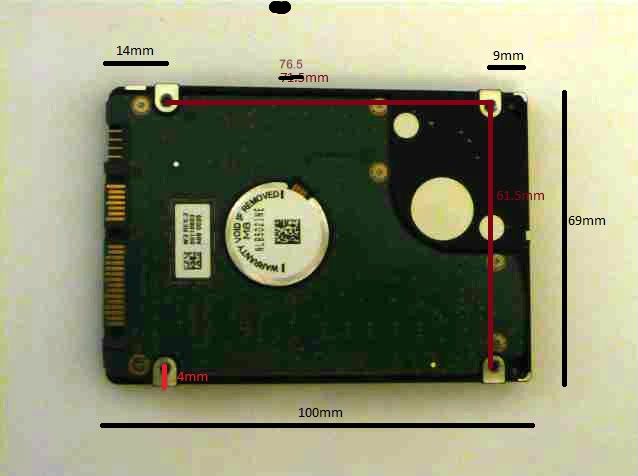

Checked the height of the drivebay areas for the 2nd radiator, then drilled out the rivets.

Note: Swarf from drilled out rivets is sharp. Use a brush or a vacuum cleaner.

Removed the CPU and test fitted the CPU backplate and block.

I am loving these XSPC fittings. My last build used barbs and hoseclips, clear hose and started out with coloured coolant. These look so much classier.

Dismantled the pump, fitted the reservoir / pump-top.

The planned placement of all the bits is like this.

Flushed the radiators with a mix of hot water and vinegar. These are drying in the kitchen. Will flush again with distilled later.

Connected up some hose to the pump, put some water in and fired it up for a test. (I have one of those PSU jumper adaptors for leaktesting). That hasnt gone well.

Going to move onto the PSU and motherboard cable braiding now.

Last edited: