Ba-ba-bump. It's been a while since I've felt like doing anything but today I went out fully prepared to get dirty. Still only a few degrees here and it's wet, damp and muddy but it can't be helped and it certainly isn't going to finish itself.

First on the agenda was fixing the indicators which had mysteriously stopped working long before I started doing any of this. There are two flashers, one for hazards and one for the indicators and as the hazards still worked fine, it was clearly a fault with the indicator flasher.

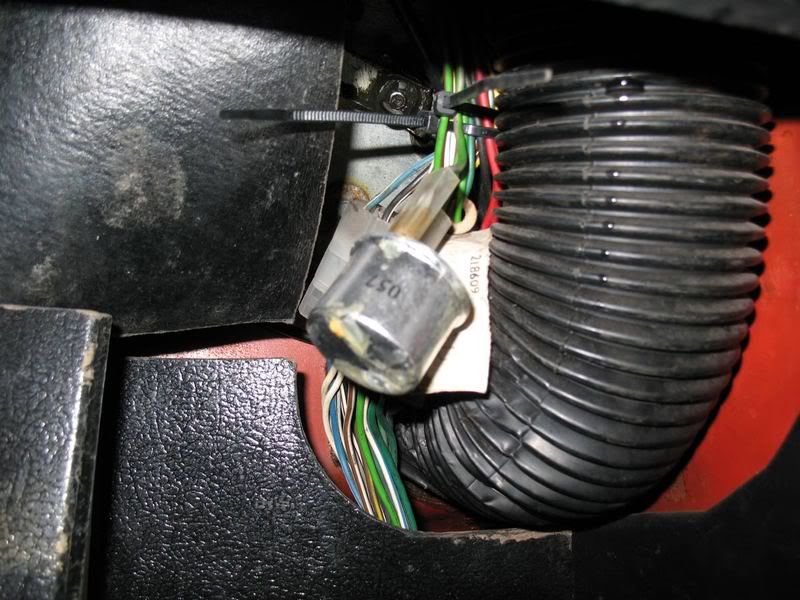

It's hidden under the dash, although most of the time they end up dangling around, like so:

That little cylinder is it. I knew I'd found the problem when I turned it upside down and water poured out of it! Seems like when the windscreen had been leaking the water had made it's way into the cabin, down the wiring and straight into the flasher.

I think it's had it:

It sloshes lots if you shake it, which is remarkably entertaining. Fortunately I found a spare unit and hooked it up (as it's only two push on connectors). It works OK but the indicators are a little slow - the flasher's been in the shed in freezing temperatures for months so it may take a little time to wake up properly. Nonetheless, I now have functioning indicators:

Next on the list was refitting the front windscreen trim. I've also got near rear trim but I'm considering replacing the rear window seal so am leaving it for the meantime:

This went in quite easily (it just pushes in) but very irritatingly the company who supplied it packaged it in a coil, so it was all twisted. Consequently it's not very happy sitting where it is, as it wants to ping itself out - but I'm hoping that once it's been in the sun for a bit and held in place it'll settle down.

I also reattached all the rear chrome, the desired 1500 trim as originally intended:

......as well as several of the badges:

I used a little waterproof sealant just to retain the badges a little more securely (they're push-fit as standard), as well as preventing any water ingress through the trim holes.

The interior had all got a bit hodge-podge what with the sanding, painting and tools being shuffled around so I spent the morning pulling all the tools out of the boot, sorting through everything, cleaning the toolboxes and binning all the rubbish, as well as hoovering and wiping down the interior.

This led to another task - something I'd discovered whilst cleaning out the interior. What I found in the rear map pocket was this:

The correct carburettor needles to use with the K&Ns. The tapered needle regulates the quantity of fuel delivered to the engine at any given point, as it moves up and down in response to changes in engine vacuum, varying the size of the orifice that fuel is supplied through as required.

Now K&N filters deliver considerably more air (in this application) than the standard paper filter, which can cause the engine to run lean, as not enough fuel is supplied to match the increase in air supplied. Consequently this requires reprofiled needles, those which I'd found in the map pocket.

So, seizing the opportunity to give the dashpots a quick overhaul and change the damping fluid, I started to disassemble the carburettors:

Here's the dashpot exposed - the spring is what makes sure that the dashpot doesn't osscilate and also returns it to the 'zero' position if you let off the throttle.

You can see the hole the fuel is delivered through at the bottom (in bronze) here:

....and the dashpot itself:

It's upside down to drain the damping fluid and also to stop it potentially bending the relatively flexible the needle in the bottom:

At this point I removed the needles to find that they are the correct profiles, anyway - for some reason there's a spare set floating around. Nevertheless it was better to check and also gave me a good reason to swab everything down with WD40 and make sure it all moved freely.

Now, the dashpots are damped, with oil, controlling the rate at which they rise under acceleration, preventing the engine from running too lean or too rich when you squeeze the throttle.

Various sources recommend that you use engine oil but I've always found that automatic transmission fluid gives a slightly sharper, crisper response and in theory will make the engine less likely to go lean under hard acceleration (as the damper is freely able to rise in response to the additional vacuum developed by hard acceleration).

I refilled the dampers, checked all the screws for tightness and fired it up. Runs a treat and certainly seems a bit quicker off the mark when you rev it - I don't know what was in it before but it was quite viscous. It also doesn't fluff or falter now, whereas previously it'd think for a moment before picking up, so result in this instance

Hey - another bonus - the paint's still all attatched to it

......and as you can see, the headlamp surrounds are now back in place. Grilles next

The only dilemma I have at the moment is what to do about the irritating Webasto sunroof. Mine's not very watertight and is also quite heavy. I do have an alternative one in the garage, in good condition, which could be fitted but it'd entail making the apature slightly larger.

Alternatively, I could put a bit of alloy plate over it (just remove the whole thing and rivit plate on through the existing holes used for the Webasto with some sealant for the interim). This'd make it watertight and 'complete' but also mean I could go back to the Webasto later if I saved to get mine recovered, or find an alternative.

Any suggestions welcome

Hard to get around to it any other way

Hard to get around to it any other way