What's this? Well, I was whinging at @LePhuronn for selfishly having a 3D printer. Why? Well, I'd been watching a YouTube series and after a while the incessant "I needed a <thing> so I just printed this and it's perfect!" gets seriously irritating. So, in other words I think this comes down to basic jealousy

LePhuronn said he would recommend the Ender he has and suggested that @Vince would enjoy a natter too. So rather than clutter up his build thread (which you should probably check out here) I started this one. The intention is for it to be less specific than the other threads. It's not specifically about 'Which one should I buy?' but mainly to get a little less clueless and also make sure that if I do buy a lemon, it's by informed choice with the intention of upgrading it.

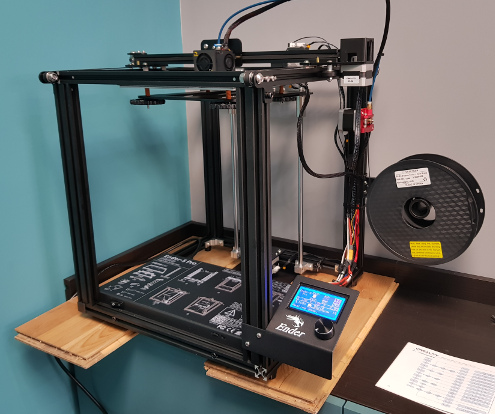

So, what am I looking at? LePhuronn has an Ender 3 Pro but suggested that the Ender 5 is superior. As far as I can tell, there is an Ender 5 Pro that seems to be what you'd probably mod the 5 into but supplied that way out the box. I'm sort of thinking along the lines of if I'm going to spend a couple of hundred quid, I may as well spend a little more and do it properly.....but I'm not yet clued up enough to know where that line is yet and I'm hoping to bypass the buying a lemon and learning this by regretting it stage. Well, if I'm honest, I'm hoping someone will just hand me all the knowledge on a plate.....but I'm interested enough that the laziness will go away eventually

What do I want to print? Well, I'm trying to work through Clough42's Electronic Lead Screw and build one for my lathe. If you get to part 17 (no, seriously!) he's starting to 3D print parts for the control panel. There are buttons printed in Ninjaflex and spacers etc. That's the sort of thing I have in mind. General prototyping, brackets, fixtures etc. To be honest, I suspect that this will be a new hammer along the lines of "When all you have is a hammer, everything looks like a nail".

If people want to chip in with anything else, feel free - that's sort of the point of this thread.

LePhuronn said he would recommend the Ender he has and suggested that @Vince would enjoy a natter too. So rather than clutter up his build thread (which you should probably check out here) I started this one. The intention is for it to be less specific than the other threads. It's not specifically about 'Which one should I buy?' but mainly to get a little less clueless and also make sure that if I do buy a lemon, it's by informed choice with the intention of upgrading it.

So, what am I looking at? LePhuronn has an Ender 3 Pro but suggested that the Ender 5 is superior. As far as I can tell, there is an Ender 5 Pro that seems to be what you'd probably mod the 5 into but supplied that way out the box. I'm sort of thinking along the lines of if I'm going to spend a couple of hundred quid, I may as well spend a little more and do it properly.....but I'm not yet clued up enough to know where that line is yet and I'm hoping to bypass the buying a lemon and learning this by regretting it stage. Well, if I'm honest, I'm hoping someone will just hand me all the knowledge on a plate.....but I'm interested enough that the laziness will go away eventually

What do I want to print? Well, I'm trying to work through Clough42's Electronic Lead Screw and build one for my lathe. If you get to part 17 (no, seriously!) he's starting to 3D print parts for the control panel. There are buttons printed in Ninjaflex and spacers etc. That's the sort of thing I have in mind. General prototyping, brackets, fixtures etc. To be honest, I suspect that this will be a new hammer along the lines of "When all you have is a hammer, everything looks like a nail".

If people want to chip in with anything else, feel free - that's sort of the point of this thread.

Although I am trying to use at least some of the beer tokens for something less ephemeral!

Although I am trying to use at least some of the beer tokens for something less ephemeral!

Mainly because I'm browsing Thingiverse going "Ooh, I may have to print one of those" rather than browsing the rainforest and dropping hard-earned cash on things I probably** don't need!

Mainly because I'm browsing Thingiverse going "Ooh, I may have to print one of those" rather than browsing the rainforest and dropping hard-earned cash on things I probably** don't need!