Afternoon all. Some progress, some to go and some issues.

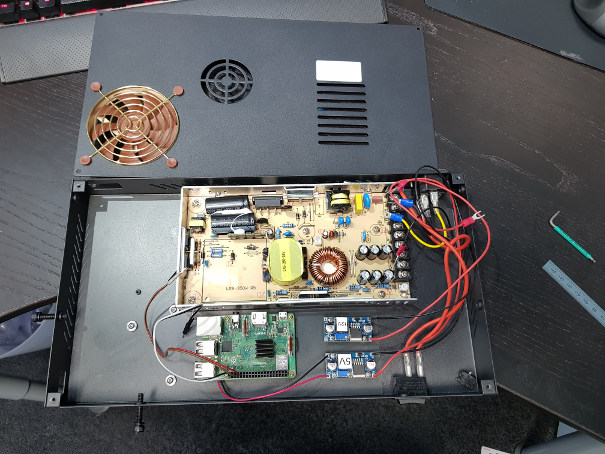

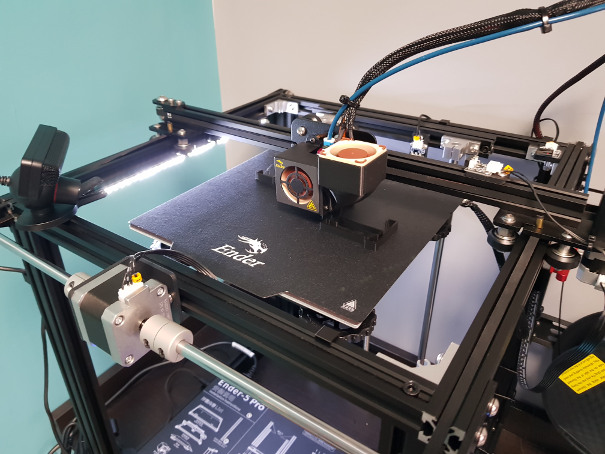

I needed things to be quieter or I wasn't going to be able to use the printer much - wife shares the same office and is now full time. So far we have a Noctua 40x20 as the hotend fan. That's currently got just a couple of M3 standoff nuts holding the cowl further out since it's twice as thick as the stock fan. Went with the thicker one as it was quieter and had higher static pressure. PSU fan (60mm) and control board fan (40mm) are now gone and replaced by a 92x14 Noctua. Went 92mm simply because that was the only one thinner than the 25mm standard....and I was pushed for space as it was! Some of the factory vent holes at the sides have been blocked with Kapton tape and the 60mm fan hole in the lid has been block with some lovely black duct tape - classy! This should mean that the 92mm fan blows air over everything though. I fitted the low-noise adapter (you can see the inline resistor that's left after I stripped it down) and that does mean it's pretty much silent. I can feel an outdraft of air from the vents that are open so hopefully it's all good.

I still need to sort out the layer fan as that's horrible. The bearing is.....bad and the PWM done by the control board is noisy. Can't do much about that until I'm able to print a duct to allow an axial fan to replace the existing radial blower.

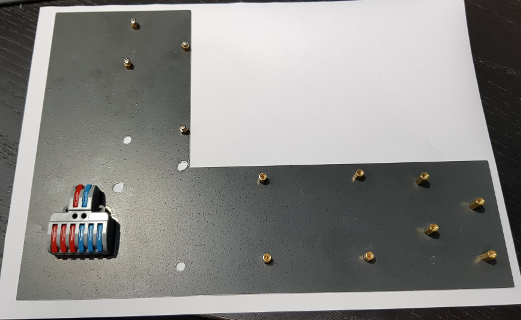

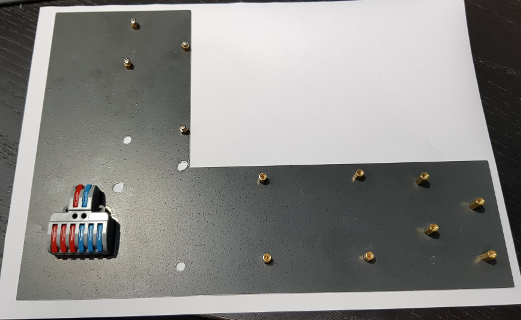

So, a mounting board for all the stuff so that I wasn't making ugly holes in the top of the case - mainly gave me the ability for a do-over if necessary. The new base plate used to be the side panel for an aluminium Cooler Master case and it's 1mm thick. Modelled out the insides to make sure everything would fit. Used transfer punches to mark out and then drilled 2.3mm holes in it. Then tapped those with an M2.5 roll tap. These form the threads by displacing the metal rather than cutting it. Apart from the bonus they don't make any chips (not so relevant in this but very useful in blind holes) they also seem to do a better job in very thin sheet materials like this. M2.5 simply because that's what the Pi is pre-drilled for - in hindsight it probably would have been more sensible to just enlarge those holes as the hex of the standoffs is the same size anyway. Ah, you live and learn....well, hopefully.

The lever block (SPL-62 Wago-style) is for distribution of 12V. The convertors are LM2596S buck convertors at five for £9 online. One for 12V for the fans and one at 5V to power the Pi. I soldered wires to the points on the bottom for this because I wanted the protection of the polyfuse on the microUSB port (which is bypassed if you feed the header pins directly) but didn't have room for an actual microUSB plug. The Pi is connected to the USB of the control board so I can load prints via OctoPrint.

The USB on the right is for the webcam. I went with a Playstation 3 EyeToy because it was a tenner all-in (and on the supported list)....but mainly 'cos it was cheap

The green LED you can see on the front is an illuminated tactile switch. Using

GPIO Shutdown to light up when Octoprint is ready and a press of it shuts the Pi down before power-off. I found some copper-clad PCB, drilled the through-holes for the switch's 6 pins and milled the copper off to leave pads to solder to as well as a track to the resistor. The whole thing is friction fit into the 8.2mm hole drilled in the case - step drill essential here or it'll end up triangular and followed up with the 8.2mm after getting to 8mm.

So it's all good now, right? Yeah, you'd think. I wiped down the bed with IPA and levelled it. Started printing a 20mm calibration cube. Got 4mm up it and it left the bed. Good news is that

The Spaghetti Detective worked and stopped the print. I was there but left it failing for a bit to test whether TSD worked. I suspect if you pay for the premium version it'll spot the fail earlier as it samples more frames than the freebie.

Re-levelled and had a few goes at printing a hollow cube and got problems. Those turned out to be Cura settings issues with thin walls and I eventually got that printed. It does look like I have adhesion issues though. The nozzle prime down the right hand edge sticks very nicely but the actual print right in the middle, does not. I checked all the corners were level - a sheet of A4 drags - and then checked the middle of the bed. It took three sheets stacked to get a light drag. Is this the infamous Creality bowed bed issue?

Looks good though. Hefty linear rail on the back there. Is it limited to Aluminium by the spindle or can it handle steel? I'd have guessed by the size of the rail that with the right spindle it could handle something tougher.

Looks good though. Hefty linear rail on the back there. Is it limited to Aluminium by the spindle or can it handle steel? I'd have guessed by the size of the rail that with the right spindle it could handle something tougher.