I need to plastic weld a 3mm piece to the 6mm and machine it down to the correct thickness

You can't mix additive and subtractive machining!.....the world might explode

I need to plastic weld a 3mm piece to the 6mm and machine it down to the correct thickness

I would need lessons in that.

Like, proper ones.

I just got in from work and looked through the updated on my media pc instead of my phone and spotted this. Love the badge and very on brandI had a media PC with the same board in it a while ago. This one.

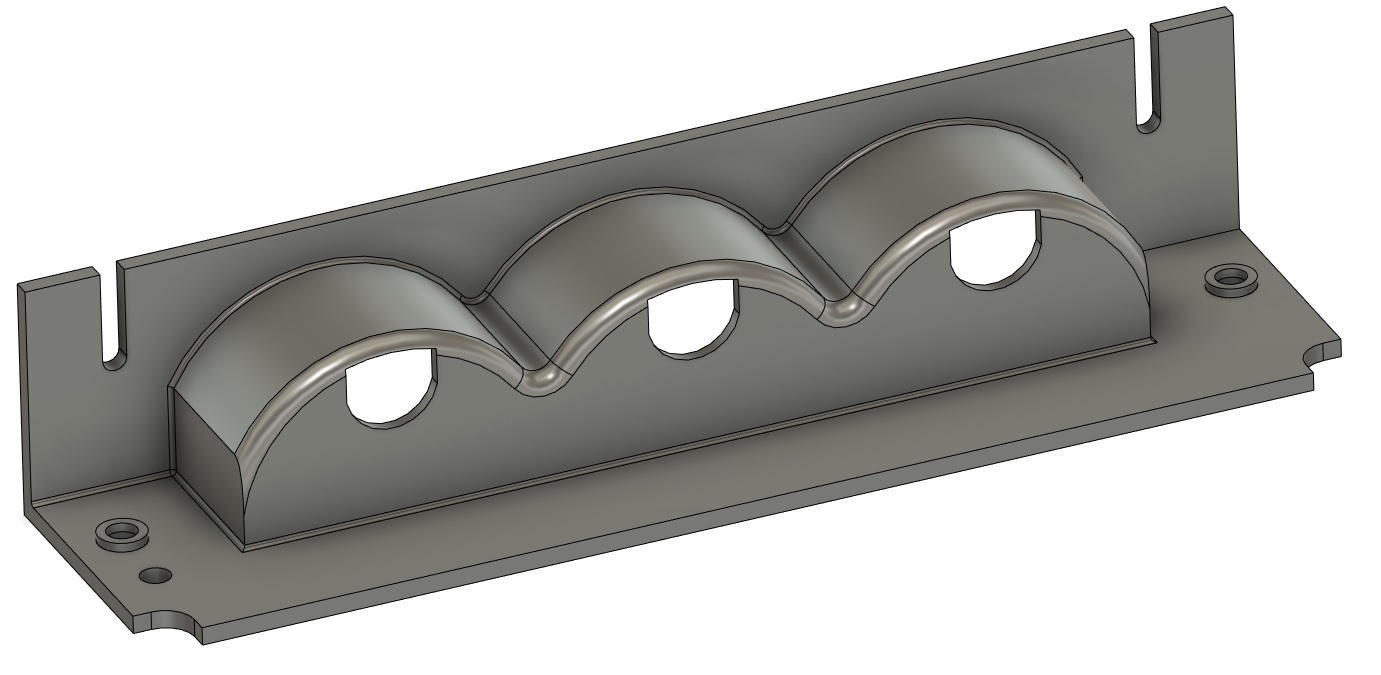

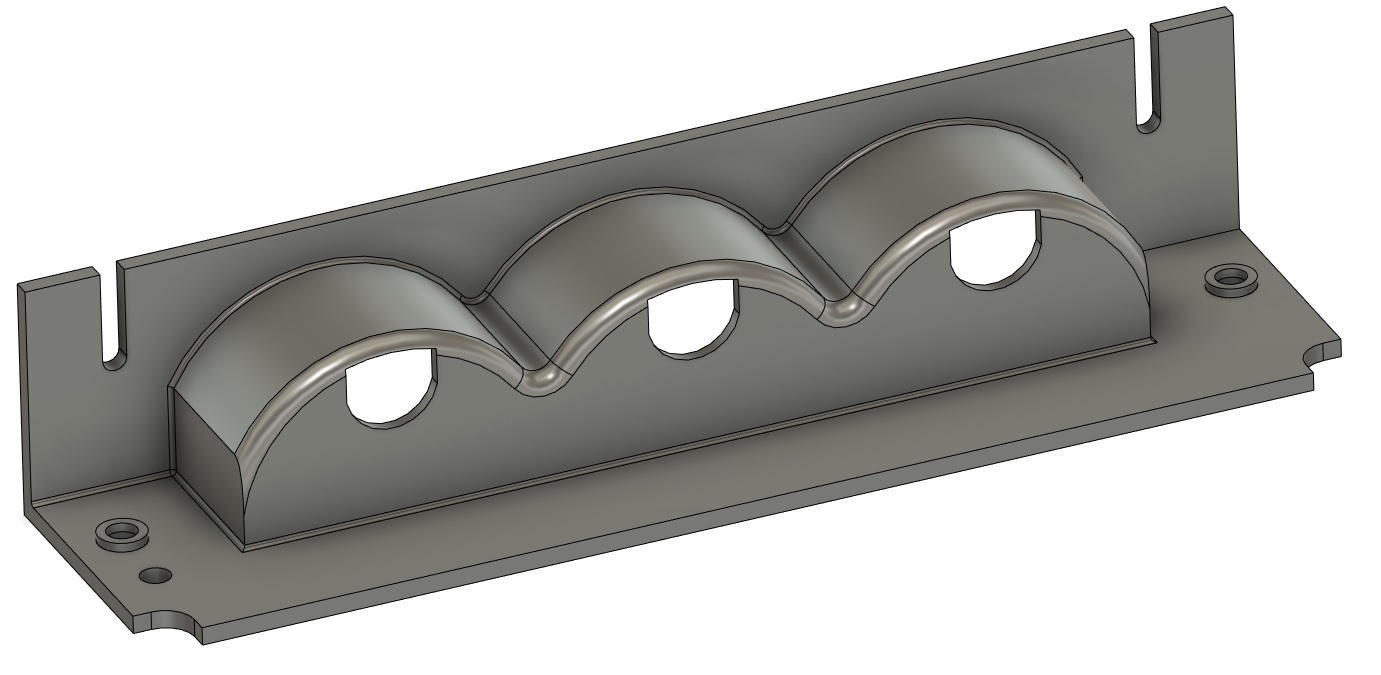

Very impressive how you knocked that up so quickly. Last time I did something like that was with autocad 14 and solid works.Yes. Damn useful skill to pick up though.

Nah, just some YouTube and practice (it's Netflix & Chill's poorer cousin!).

Here, I'll start you off (and email you the Fusion 360 file)

Maybe the badge goes on the NASYeah I am getting the badge back. I bought that for it. I forgot to remove it, and it has been in Dorset ever since lol.

My mate who has it is coming down soon. Like, within a couple of weeks. I have some gear here for the LAN night they do down there so we're going to sort it then.

Cheers. I should caveat that what I knocked up is exactly that. Some assumptions were made on symmetry and all the measurement are complete guesswork....but it looks about the right shape and could have those dimensions plugged in fairly easily.Very impressive how you knocked that up so quickly. Last time I did something like that was with autocad 14 and solid works.

Definitely need to spend less time on Netfix and learn another new skill

Thanks for the rundown. Will definitely look into this. As for sizing, its always a good idea to get your scales right and don't want to mix millimeters with meters otherwise you have something you cant get through the front doorCheers. I should caveat that what I knocked up is exactly that. Some assumptions were made on symmetry and all the measurement are complete guesswork....but it looks about the right shape and could have those dimensions plugged in fairly easily.

Fusion 360 (and others, I'm sure - this is just the one I went with) is great for this sort of thing. If you get yourself a 3D printer, you'll find so many things to use it for. The more you practice and pick up bits from YouTube (some of it maker stuff and some of it short Fusion technique lessons), you'll get better really fast. You just need a decent set of calipers (or a cheap pair, many spare batteries and patience to double-check every measurement) to pull the measurements off something.

Maybe the badge goes on the NAS

I have no idea what that is (but its very retro) and Mrs P would say the same about the washing machine

It kinda reminded me of an NES, so I just themed it on that.

It kinda reminded me of an NES, so I just themed it on that.