You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Left Handed Build

- Thread starter piggin

- Start date

More options

View all postsUnfortunately I have not had a lot of time to play with 'The Left Handed Build' recently.

I have been bizzy @ work with outages & away on holiday.

I have also been learning the art of 'Detailing'

Even with all this going on, I have still had some time to play around with my build.

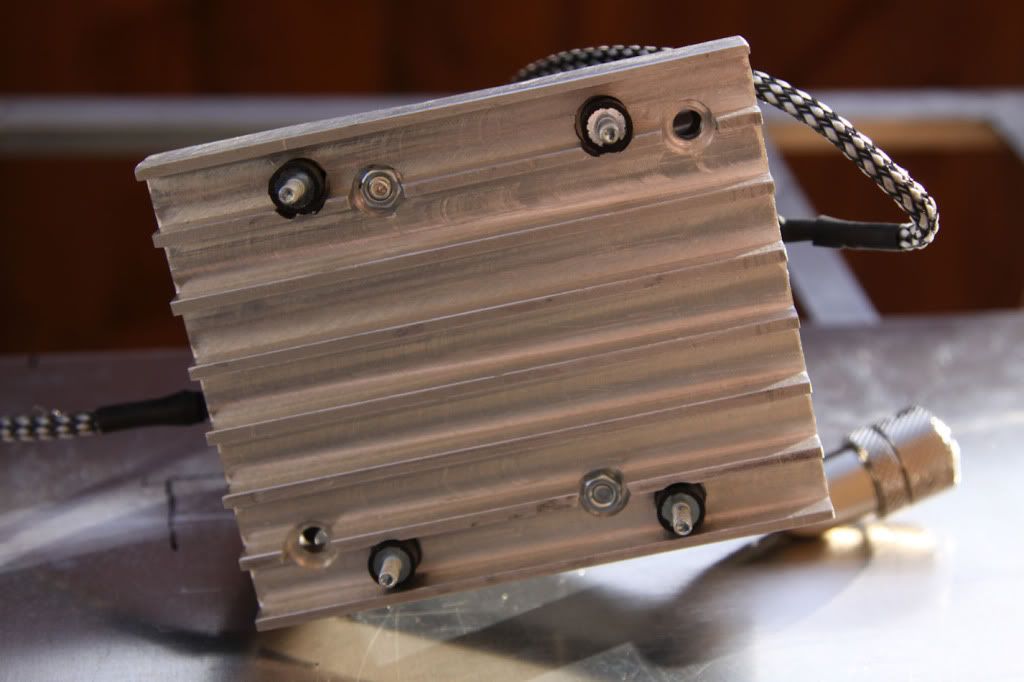

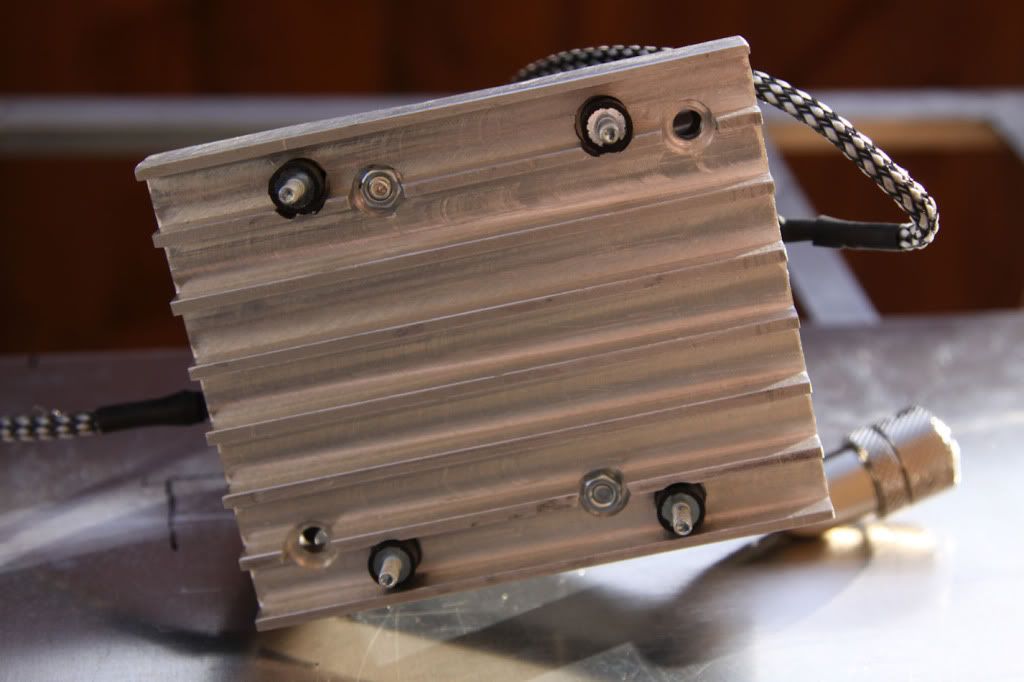

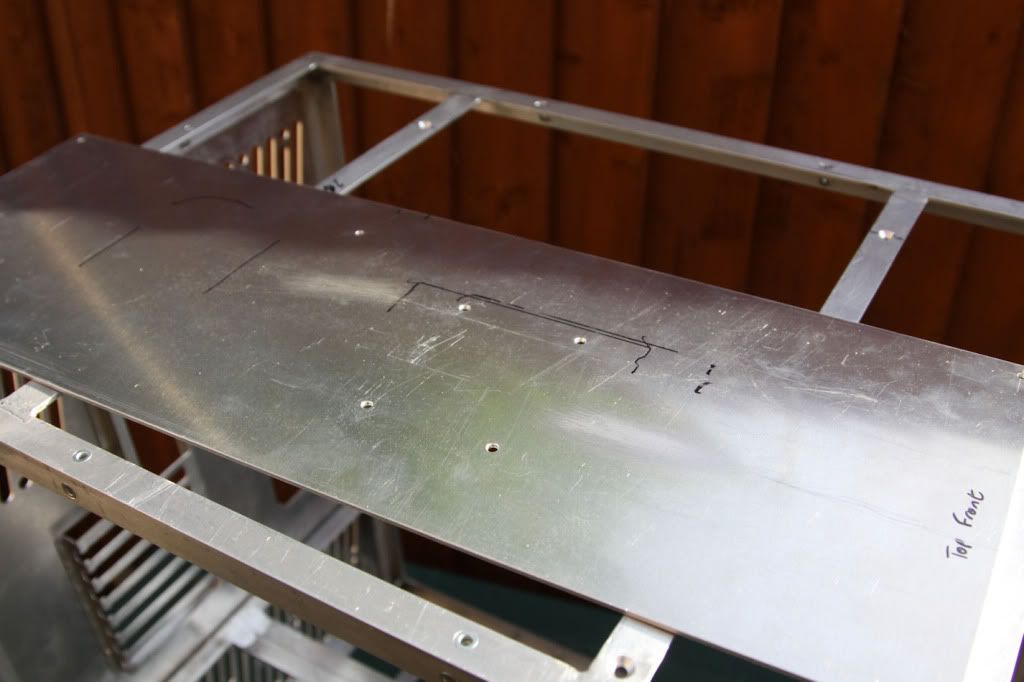

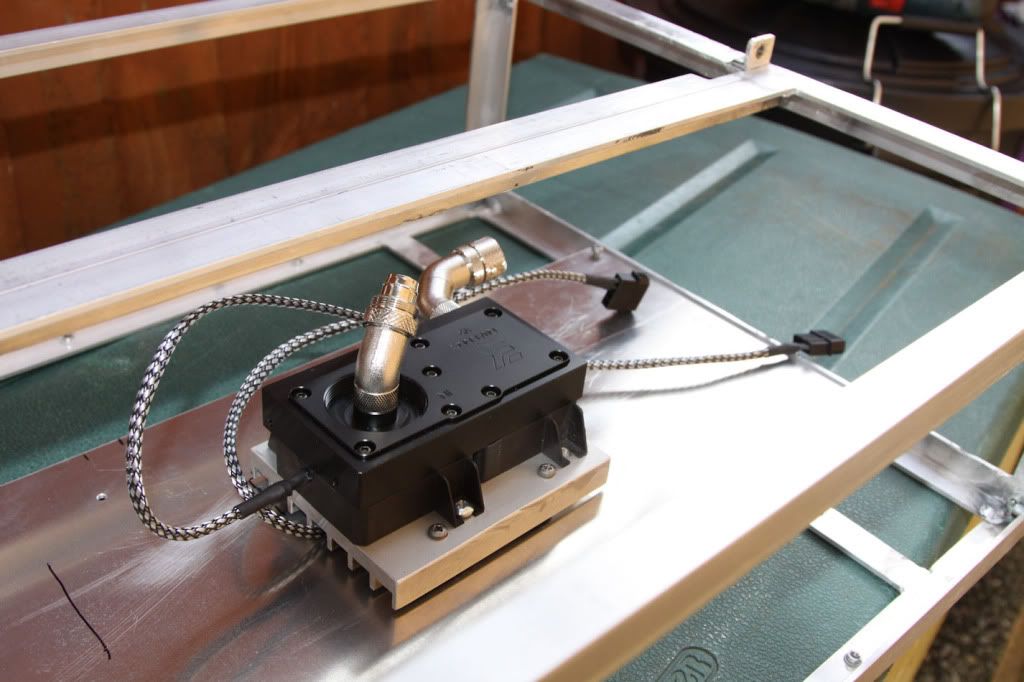

On my previous build, I mounted my DDC pump on blocks of aluminium.

As I am going to use a duel DDC top on my pumps, I needed a larger mount.

As these do not exist, I started a little bit of DIY

Purchased a block of aluminium from 'the bay'

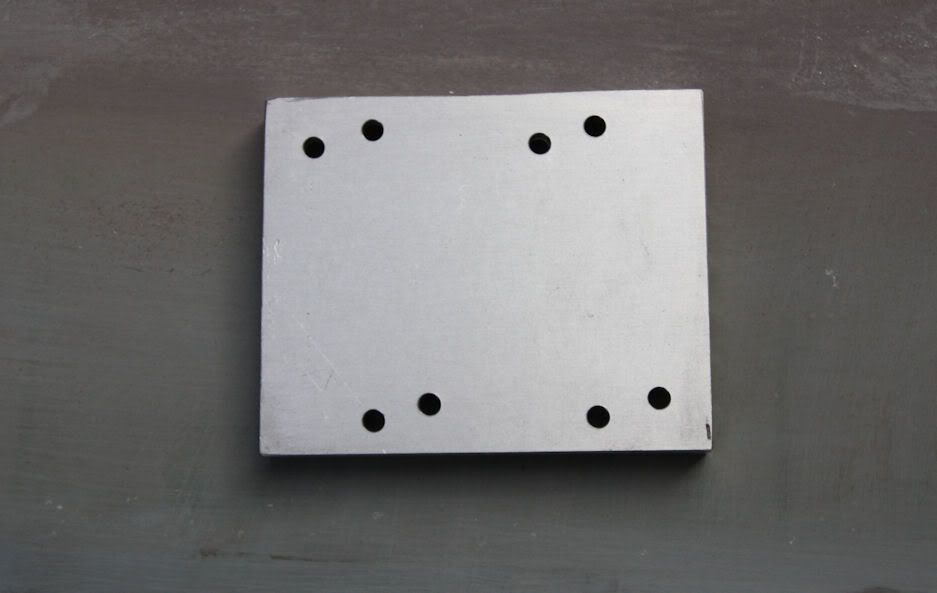

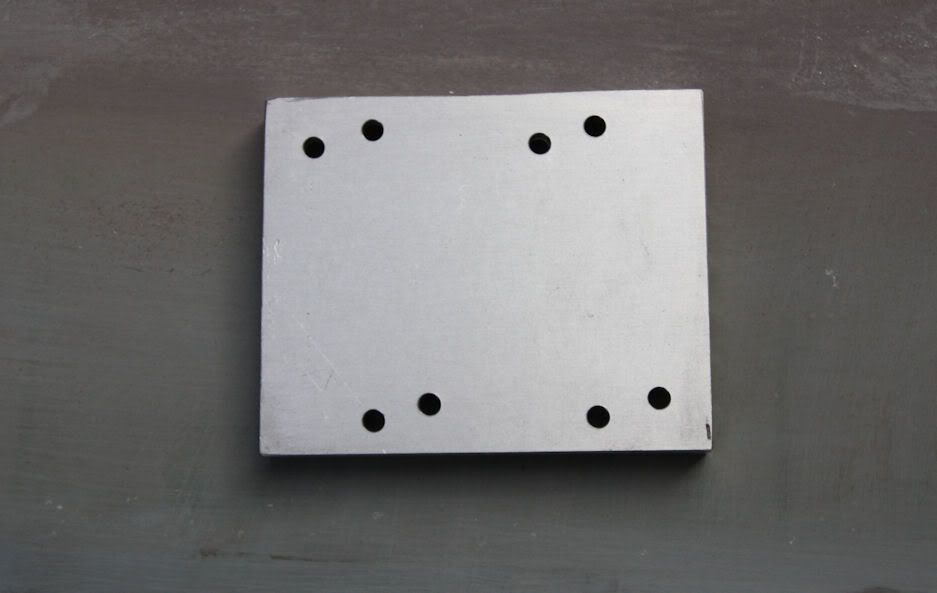

The block was then drilled to fit two pumps & anti vibration stand offs

A slotted along the bottom to give extra cooling with a milling machine

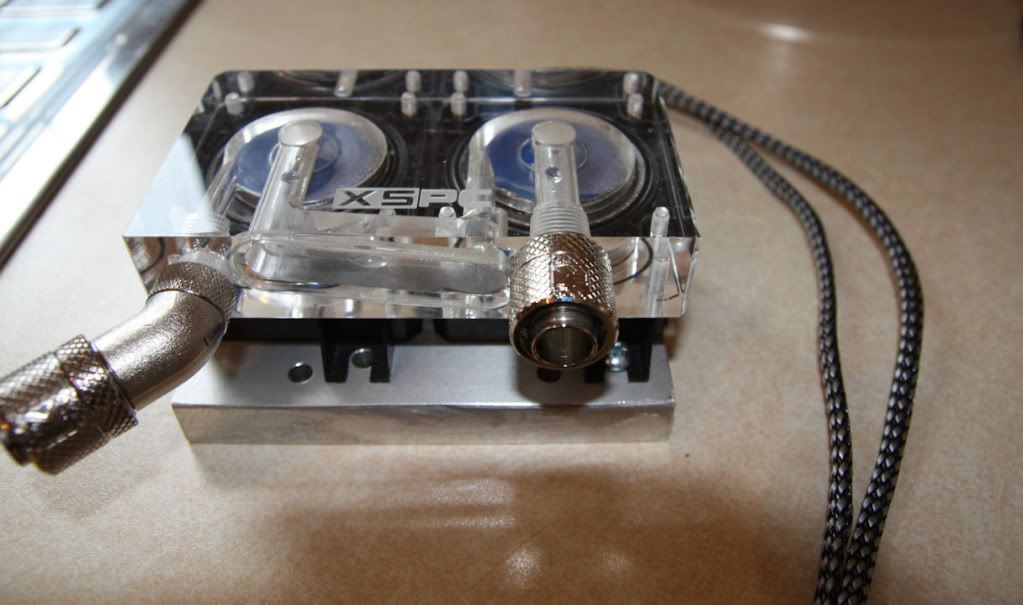

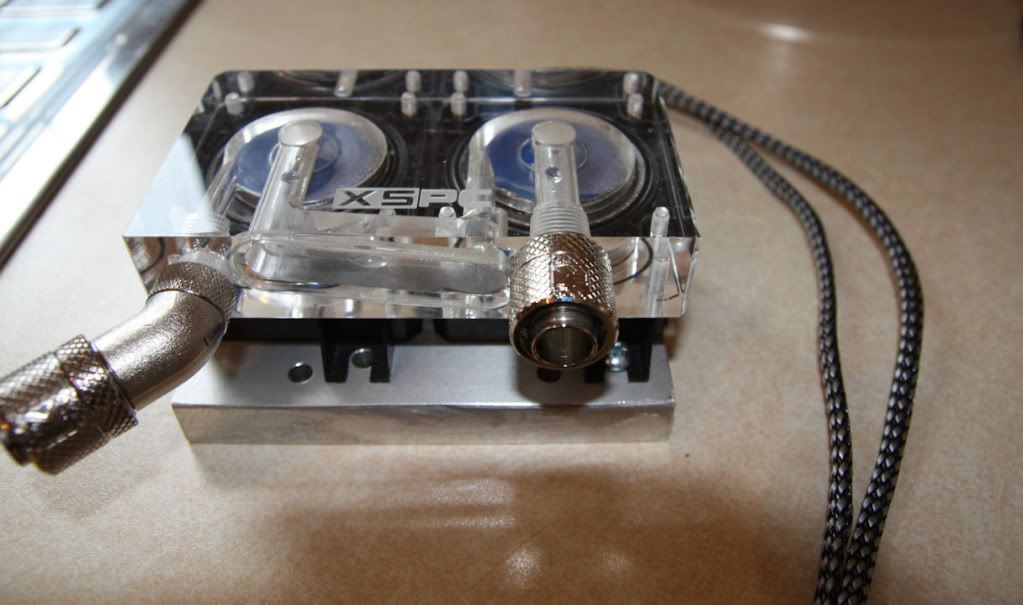

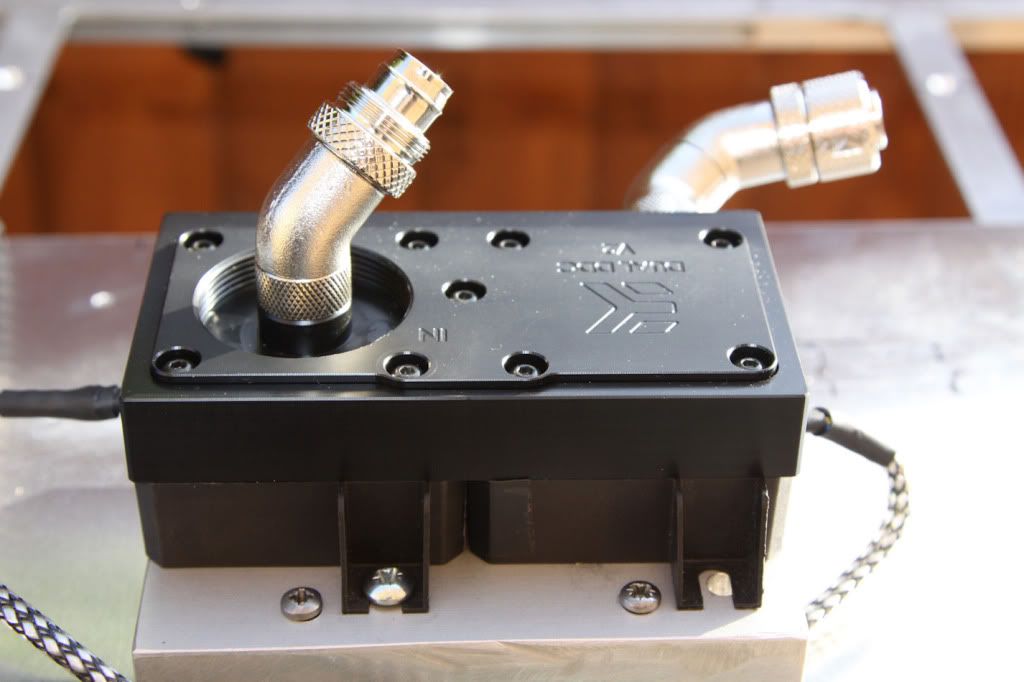

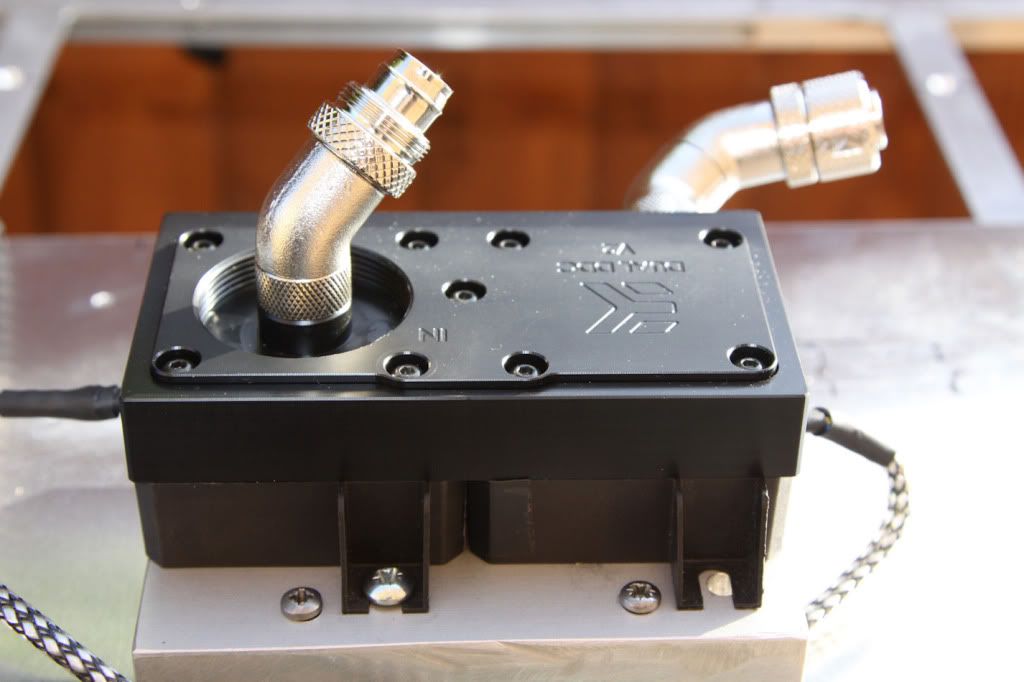

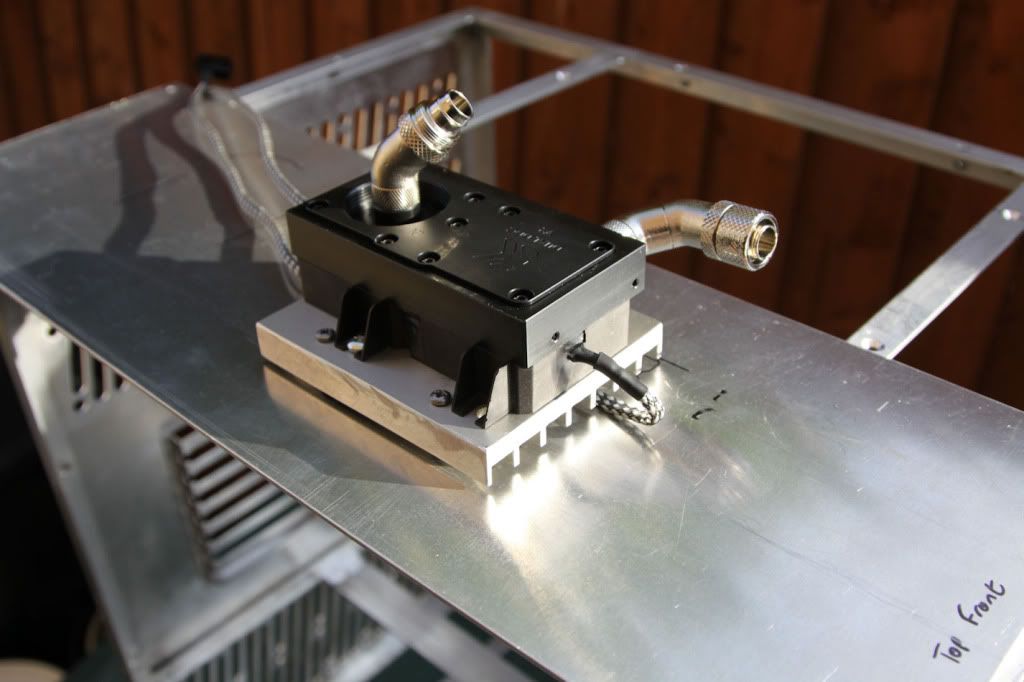

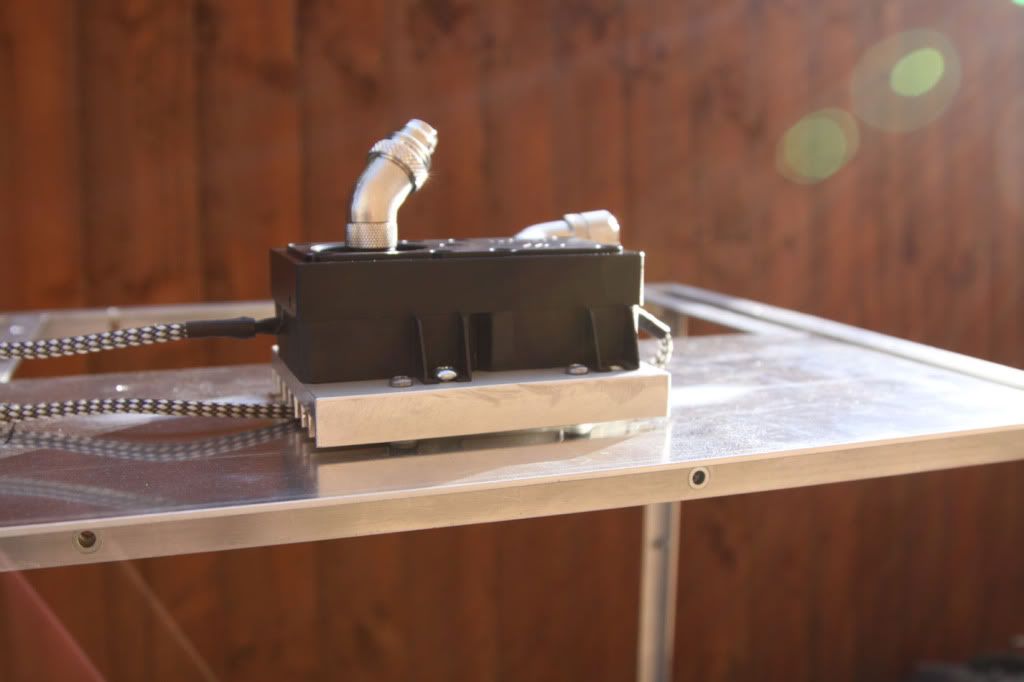

The DDC pumps were then fitted to the duel XSPC pump top

I then decided the pumps did not look correct. So changed them around & re-braided the cables

After all that work, I decided the XSPC top did not have the pump inlet in the correct place.

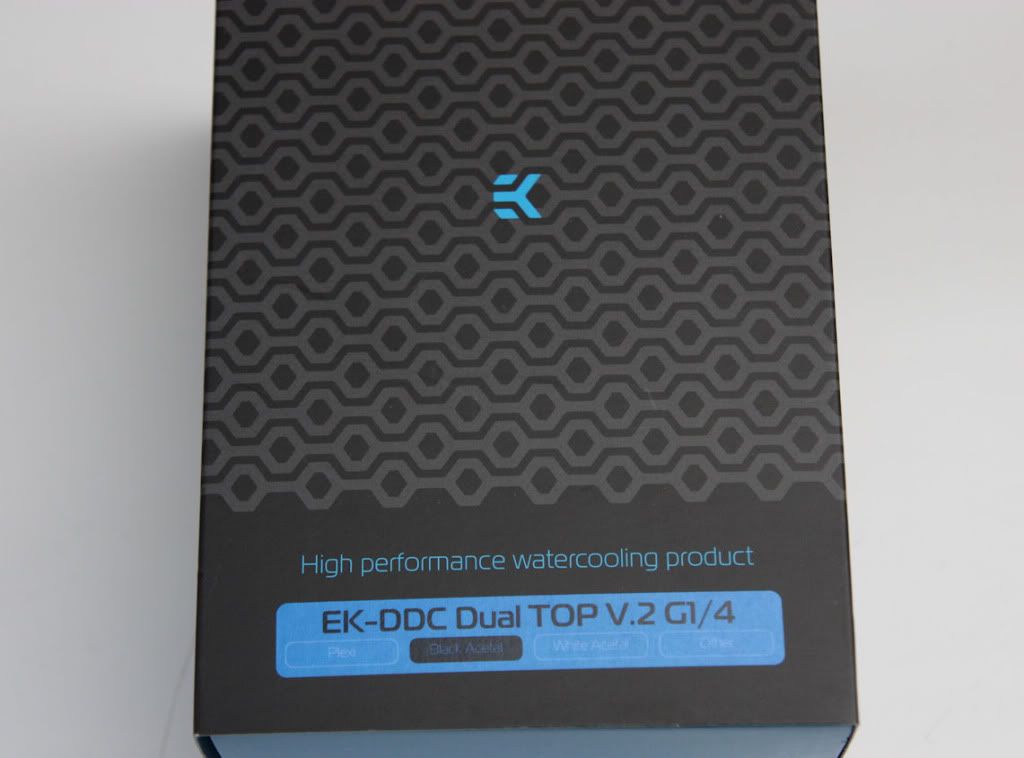

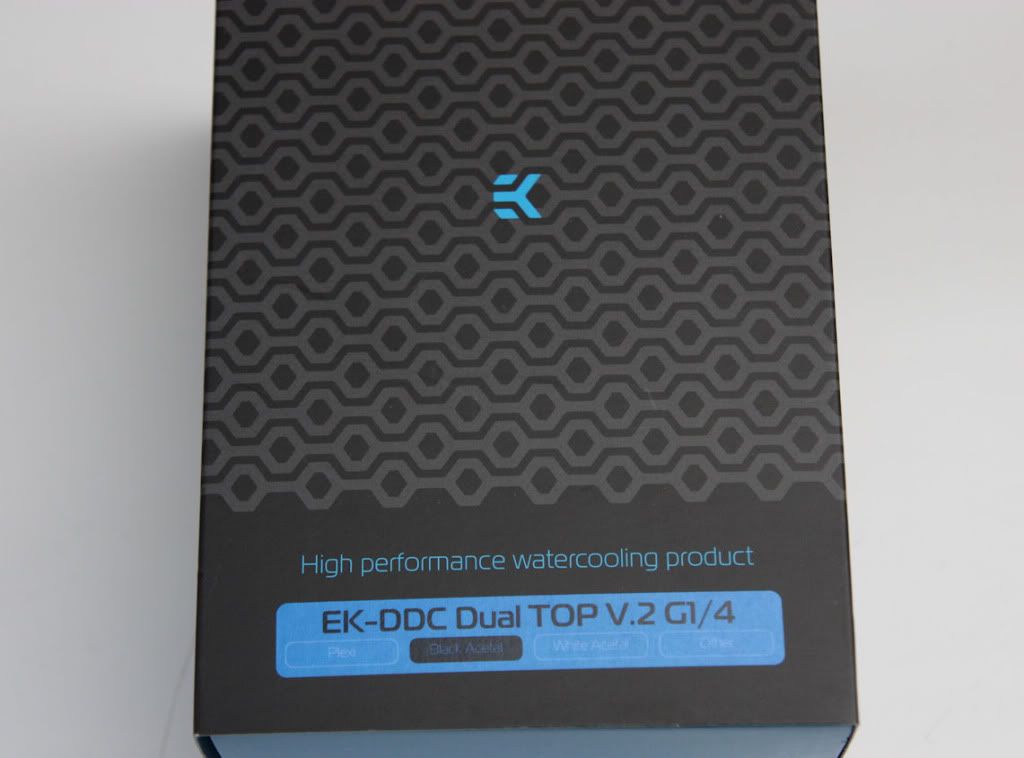

So out came the credit card once more & I purchased this

In the box there was the pump top in sexy black to match the rest of the build

And a set of mounting brackets, screws etc.

Due to the change of tops, the pumps were touching in the middle so the cabling had to be changed once again

Now I am happy with the finished item

I have been bizzy @ work with outages & away on holiday.

I have also been learning the art of 'Detailing'

Even with all this going on, I have still had some time to play around with my build.

On my previous build, I mounted my DDC pump on blocks of aluminium.

As I am going to use a duel DDC top on my pumps, I needed a larger mount.

As these do not exist, I started a little bit of DIY

Purchased a block of aluminium from 'the bay'

The block was then drilled to fit two pumps & anti vibration stand offs

A slotted along the bottom to give extra cooling with a milling machine

The DDC pumps were then fitted to the duel XSPC pump top

I then decided the pumps did not look correct. So changed them around & re-braided the cables

After all that work, I decided the XSPC top did not have the pump inlet in the correct place.

So out came the credit card once more & I purchased this

In the box there was the pump top in sexy black to match the rest of the build

And a set of mounting brackets, screws etc.

Due to the change of tops, the pumps were touching in the middle so the cabling had to be changed once again

Now I am happy with the finished item

I like the new pump top. I agree that it matches the rest of the build, but I have got to say that the work you did with the XSPC pump tops looked great in isolation.

I agree, I like the way the cabling turned out on the XSPC top.

The problem was the EK top has different hole centers (closer together).

This means that the pumps had to be turned around & the cables could not stay as they were.

Overall this is not that big a problem as you will see very little cable in the finished build.

Just read all of this... very enjoyable, look forward to the next installment

Thanks TFC, its nice to know that new people are still find my build log & are enjoying it.

Hopefully it will have a happy ending

We haven't seen any updates on here for quite some time now.

Hopefully you haven't lost interest... or have you just been spending too much of your 'free' time with that lovely car you showed us earlier?

Hi Montala, apologies for not replying to you until now but I have not been keeping up with this build log.

In post No.149 I wrote about the problems I was having with my back

Also had my own problems recently having a trapped nerve in my back stopping me from using my right arm

Unfortunately it was not my back but my neck.

On Sunday 18th September my neck went once again.

This time I felt it go (felt like some one put a knife in & twisted).

Since that time I have had an MRI scan & I have been told I have a prolapsed disc @ C6-C7 (lower part of your neck).

This again has put me out of action for many months (no work, driving etc etc) due to the problems with my right arm & the pain medication.

As for the build, the shelf is still going strong with very little change but once things settle down again with my neck I will crack on. (had lots of time to plan

)

)All I can say is WOW!!!

Looks great, not seen this thread before but after reading this please do not stop!

This thread is great, I'm looking forward to more updates!

Thank you both.

Its nice to see that people are still finding my build interesting & enjoyable.

Hopefully there will be more updates soon.

Hi Mr Piggin, I am really sorry to hear that you are having further back and neck problems.

They really are a pain (no pun intended!) and being a sufferer myself, albeit nothing to the extent of your current problems, you have my sympathies.

Although the current 'trend' seems to be to encourage the 'patient' to continue moving and walking around as much as possible, rather than just lying on a hard flat bed, that is often easier said than done!

I hope you start to feel better soon though, and feel able to continue with a more 'normal' life again... I am sure that Mrs. Piggin is looking after you well though!

Do keep us updated on progress... both on your health, and to a lesser extend on your build, which I am sure you will eventually finish... one day!

Edit: I have just realised that Post No. 149 is over a year old now, so let's hope that 2012 is a better year for you than 2011 was!

Thanks Montala for your concern.

It looks like 2012 is going to be a better year.

The swelling of the disk in my neck has gone down & my right arm has improved a lot.

So much so, that I have started back to work again.

Hoping to start work on the case again very soon & I have been given the green light by Mrs Piggin for further upgrades to the hardware.

So 2012 is a good year, health improving & looking forward to new Ivy bridge rig + new graphics cards.

So watch this space, as the story of 'The Left Handed Build' continues

As you can see, my build log has not been updated for some time now.

This has mainly been due to me having a prolapsed disc @ C6-C7 (lower part of your neck).

Now things are getting better, so the build goes on.

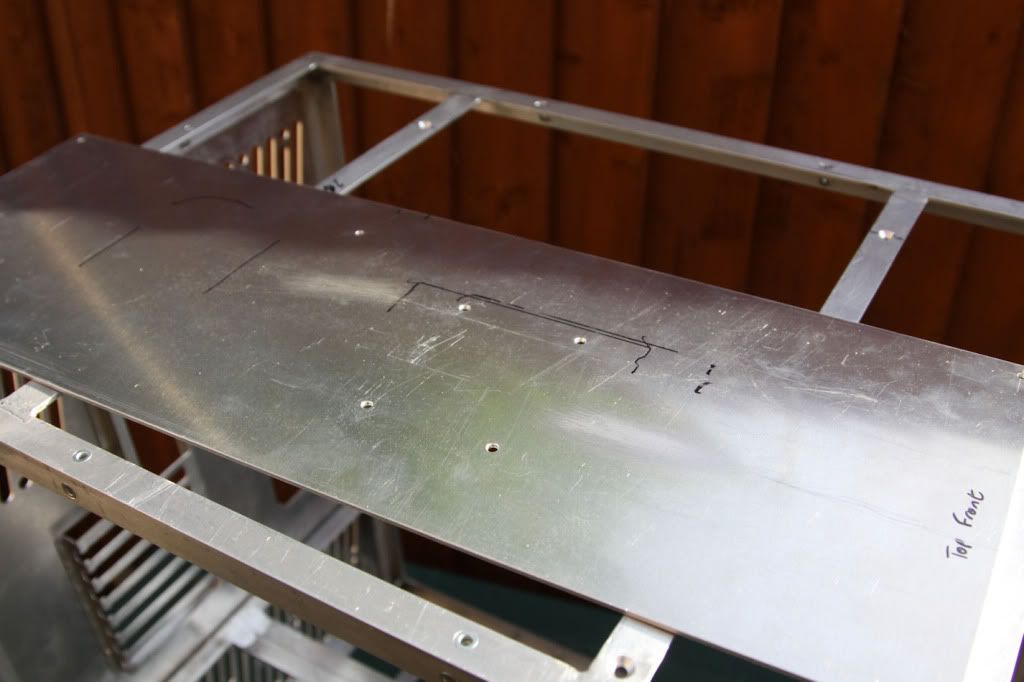

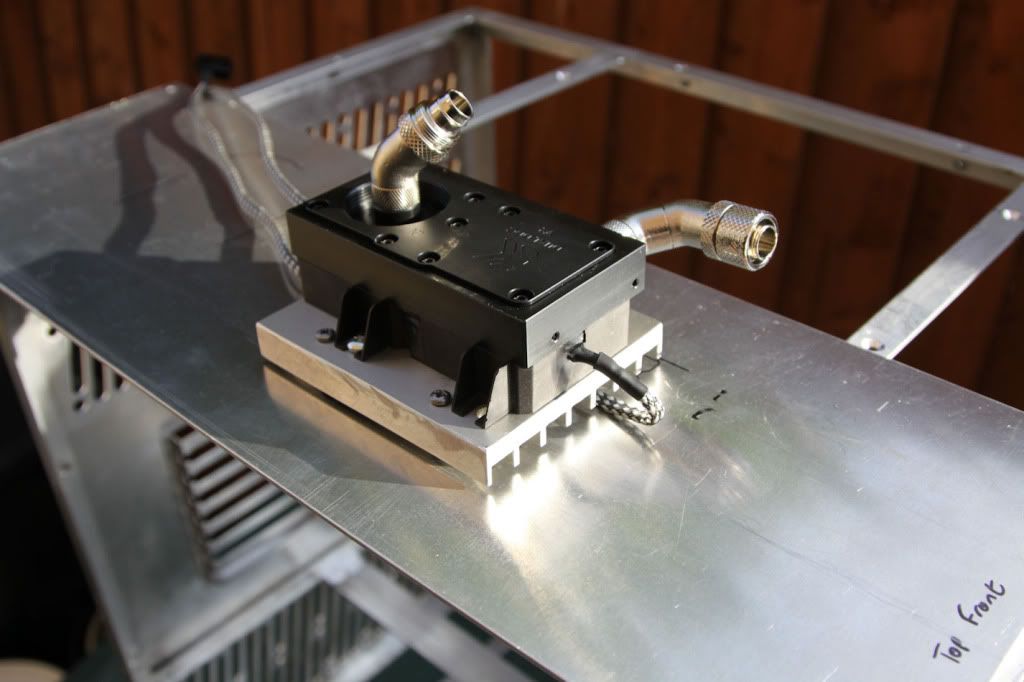

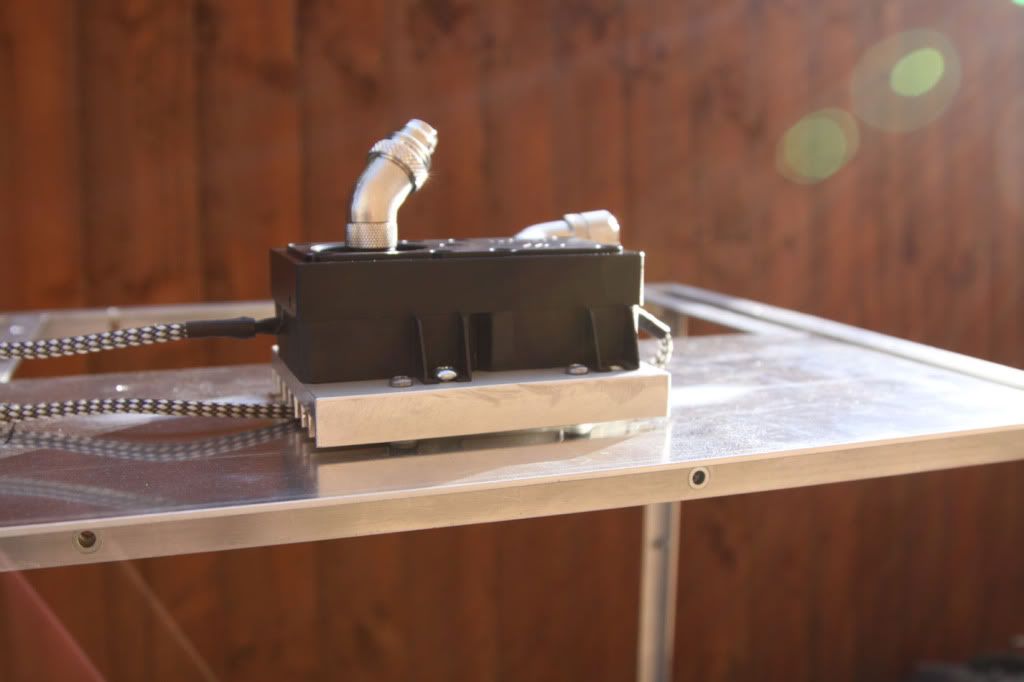

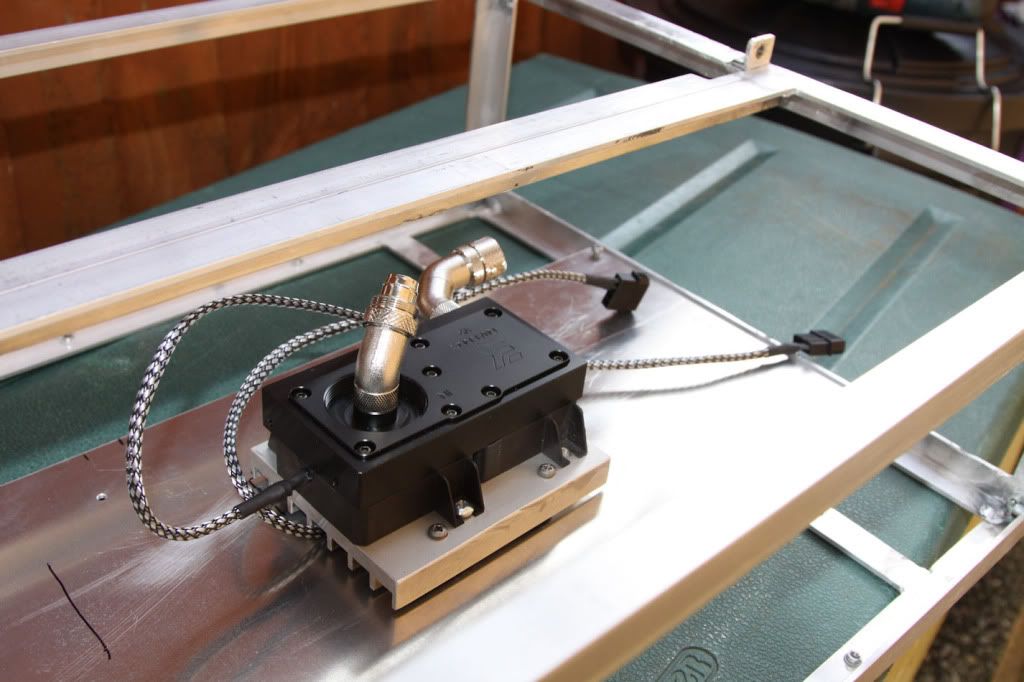

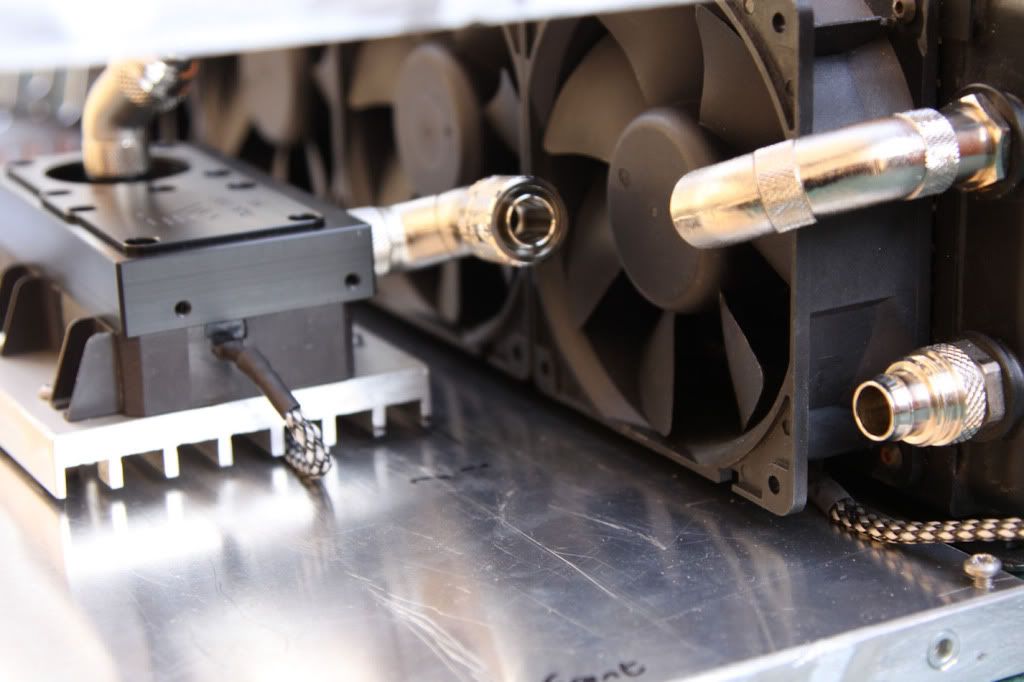

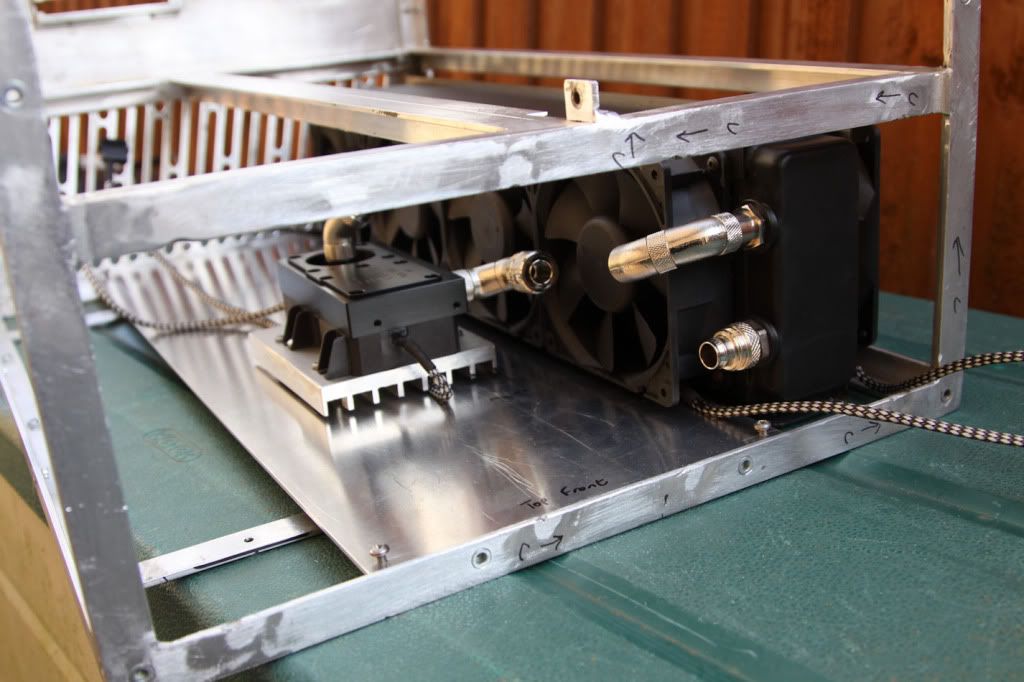

Having built a custom cooling block for my twin DDC pumps. I wanted to make sure that vibration was at a minimum.

I started by mounting the block on rubber isolation pads.

The pumps can then be mounted onto the block with its fittings.

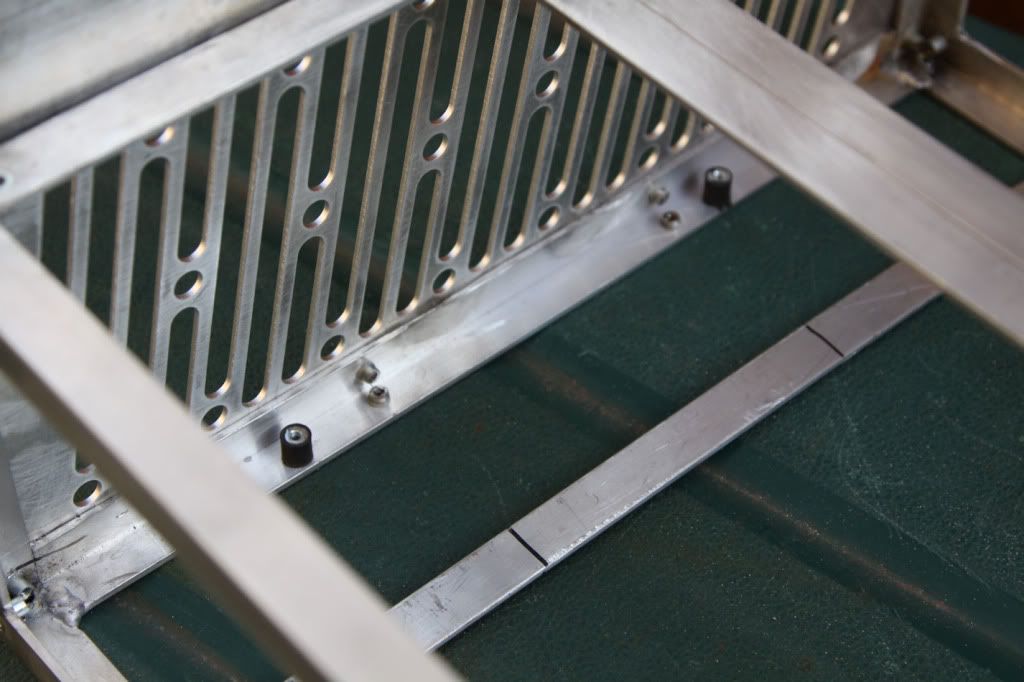

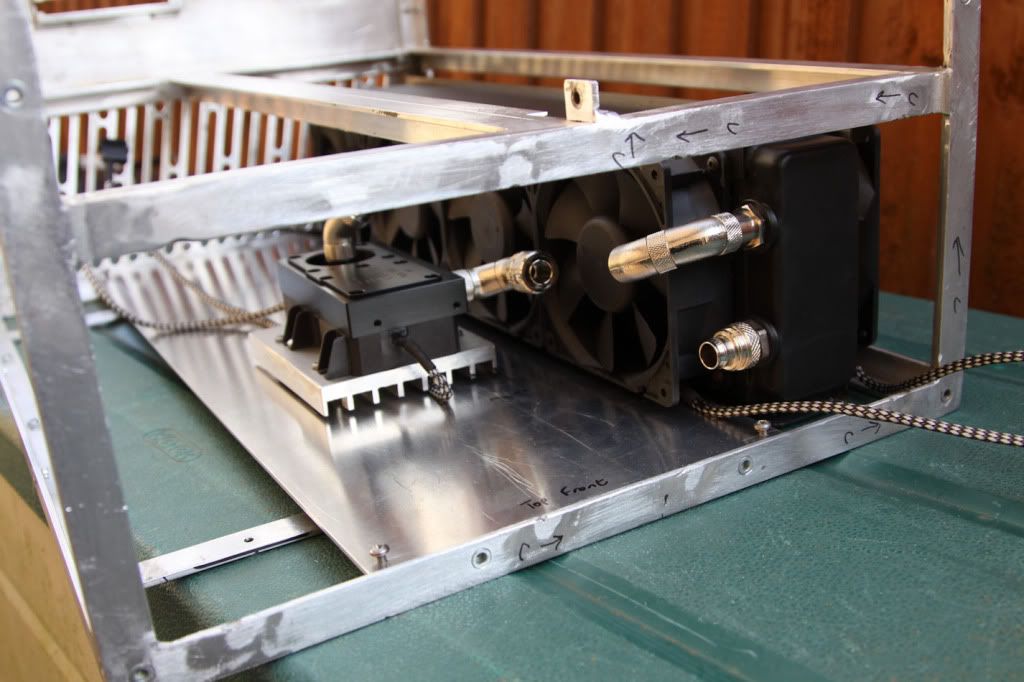

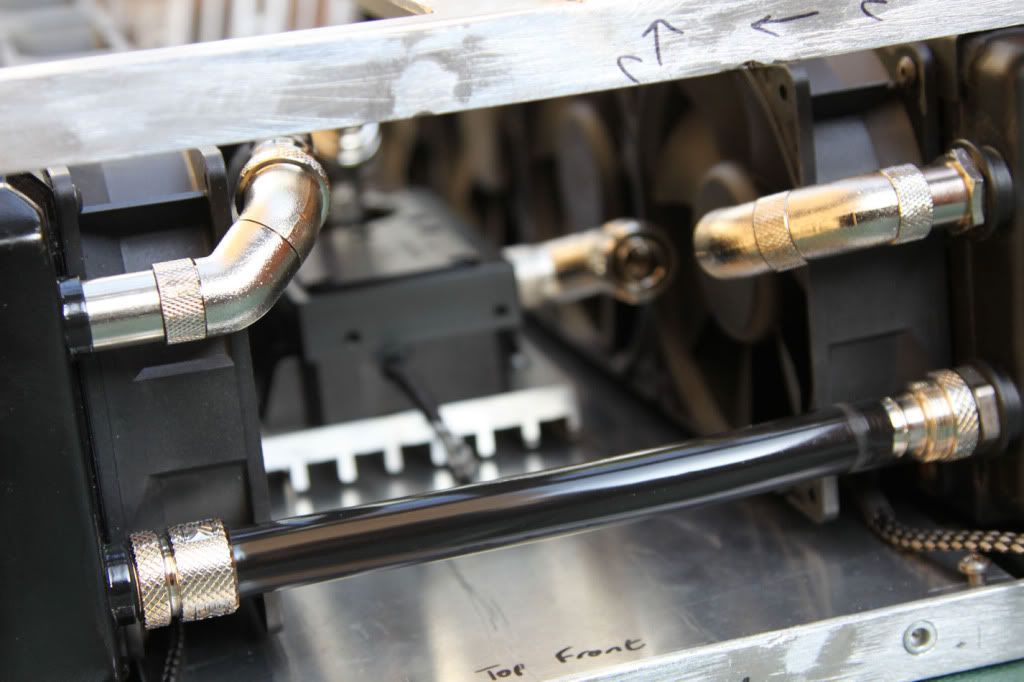

The pump if then going to be mounted in the bottom of the case on a centre divider between the rads.

The pump was positioned & screws were used to mount the rubber isolation pads from underneath.

Mounting the block in this way, will minimise vibration and create a small air gap.

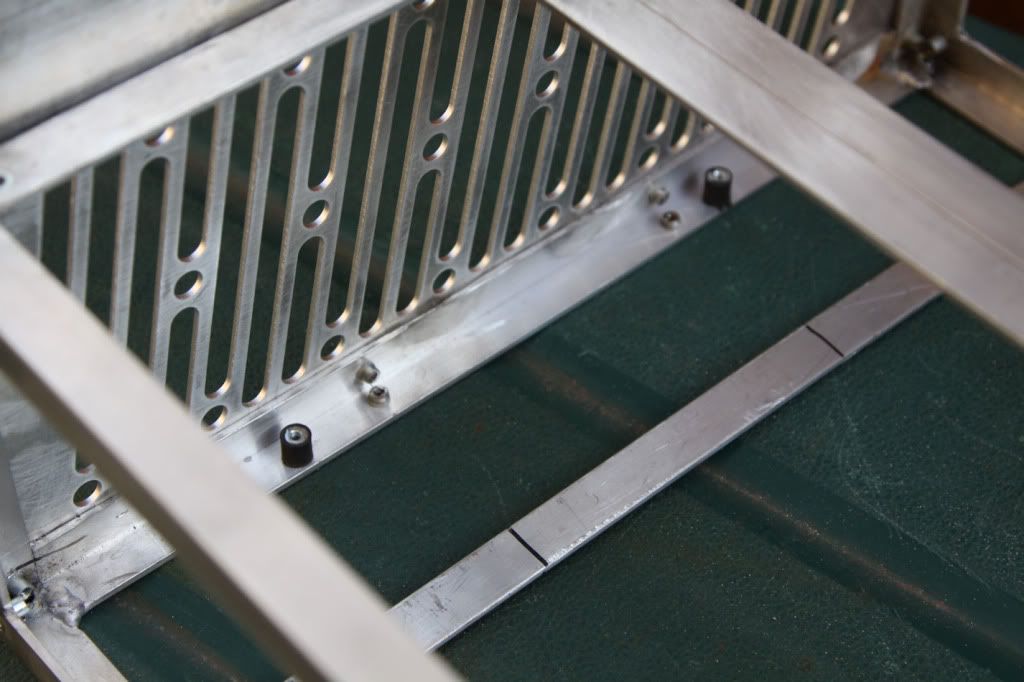

More rubber isolation blocks were fitted into the lower section of the case.

The frame was drilled & holes tapped for the blocks to screw into

The centre divider was then mounted in the lower section of the case on more rubber isolation blocks.

This in turn creates a small gap between the floor & the centre divider.

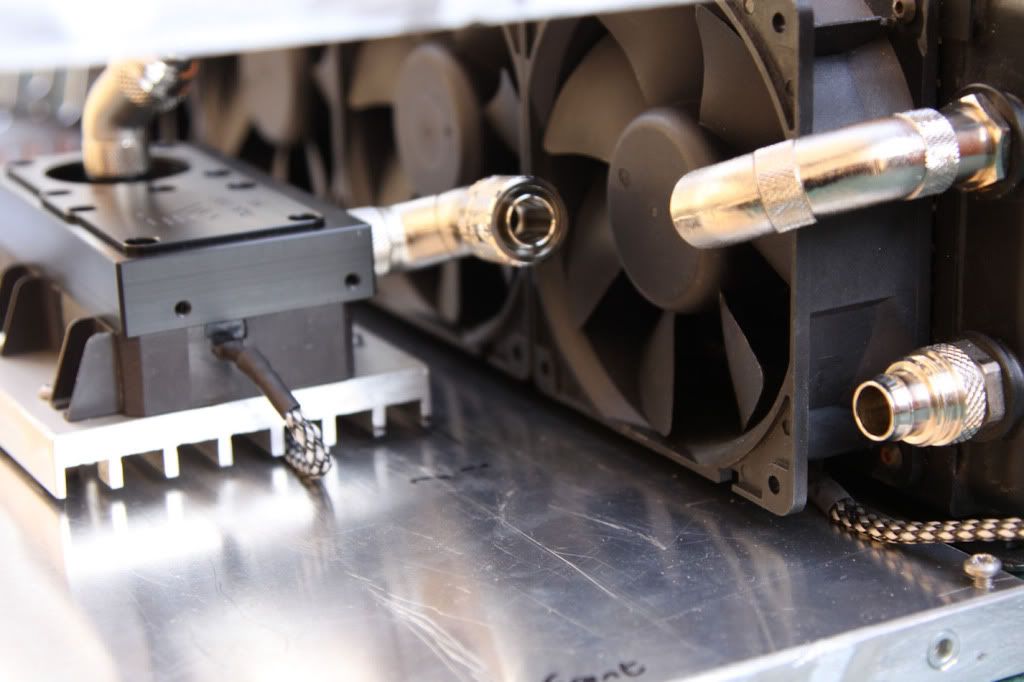

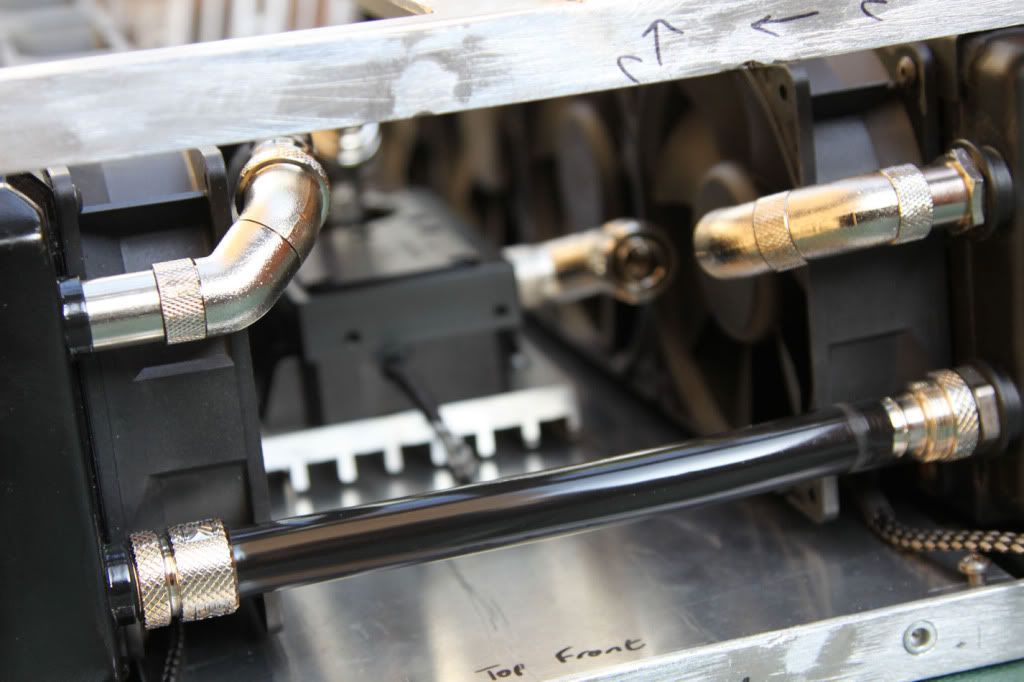

One of the rads was then put into position & a selection of fittings used to keep the pipe runs neat.

The spacer on the top right rad was a little long. This problem was overcome by a little machining

More fittings were used to link up the second rad

This has mainly been due to me having a prolapsed disc @ C6-C7 (lower part of your neck).

Now things are getting better, so the build goes on.

Having built a custom cooling block for my twin DDC pumps. I wanted to make sure that vibration was at a minimum.

I started by mounting the block on rubber isolation pads.

The pumps can then be mounted onto the block with its fittings.

The pump if then going to be mounted in the bottom of the case on a centre divider between the rads.

The pump was positioned & screws were used to mount the rubber isolation pads from underneath.

Mounting the block in this way, will minimise vibration and create a small air gap.

More rubber isolation blocks were fitted into the lower section of the case.

The frame was drilled & holes tapped for the blocks to screw into

The centre divider was then mounted in the lower section of the case on more rubber isolation blocks.

This in turn creates a small gap between the floor & the centre divider.

One of the rads was then put into position & a selection of fittings used to keep the pipe runs neat.

The spacer on the top right rad was a little long. This problem was overcome by a little machining

More fittings were used to link up the second rad

Wow mate. Subscribed!

Thanks very much and goodluck with yours

looking good, glad to see this back in action

Thanks m8, Nice to be back in action.

The metal work is incredible! Subscribing

Thanks very much. Hope to get more updates very soon.

Agreed... that's not just a computer case... it is a masterpiece of engineering!

I take my hat off to you Mr. Piggin... you are a very clever man indeed!

P.S. Pleased to hear that things are getting somewhat better, health wise... it has been a long haul for you.

Thank you very much for your very kind words.

My health has been a very big problem over the last year & this build should have been finished a long time ago.

At least the weather is getting better, so I can get out & play with my toys

I recently received as set of custom aluminium feet from Pulse Modding

The bolts for the feet have to go through the bottom strengtheners & bottom panel.

The bottom strengtheners were marked out

And pilot holes drilled with a centre drill to ensure they were in the correct place.

The bottom panel was then fitted

The hole were then drilled through the bottom panel.

All the cables that sit in the bottom of the case will need to be brought up to the PSU.

This will be achieved by having a small section cut out of the cases frame

The frame was marked out

Due to its position, a fine toothed junior hacksaw was used to cut out the section

The finish was not very good due to the awkward position

This issue was overcome with a quick session with a file

The covering panel was also cut the same size as the frame

The bolts for the feet have to go through the bottom strengtheners & bottom panel.

The bottom strengtheners were marked out

And pilot holes drilled with a centre drill to ensure they were in the correct place.

The bottom panel was then fitted

The hole were then drilled through the bottom panel.

All the cables that sit in the bottom of the case will need to be brought up to the PSU.

This will be achieved by having a small section cut out of the cases frame

The frame was marked out

Due to its position, a fine toothed junior hacksaw was used to cut out the section

The finish was not very good due to the awkward position

This issue was overcome with a quick session with a file

The covering panel was also cut the same size as the frame

I hope they were left handed feet!Perhaps that's why they had to be customised?

It looks as it is coming along well... I do admire your constructional skills though!

Keep up the good work.

Thanks, I am trying to move this build along but I don't have the time to make good progress.

Regarding the feet, I was looking for custom trotters but was unable to get any

I ended up just having to have standard feet

Build looks like its going to be awesome.

I love the detail of your pictures and explanations, really helps people understand the way you are achiving what you have. In this respect I think it's one of the best build logs I have read.

I have read lots of build logs & found them very informative but there are pieces of information missing.

I thought I would do my log slightly differently by taking the reader through every aspect of what was going on in the build.

Basically show them my thought process (not a good place to be, inside my head)

I hope that people will read this & find that it's not that hard do modify their own builds.

Also lovely detailing job on the Audi was going to do mine at the weekend but as soon as I got the snow foam out it started to rain.

lol, another man with snow foam

Got my power washer out on the weekend & it started to rain.

The car was so dirty, I just carried on (helped washing the snow foam off & the Mrs already know I am mental, so washing cars in the rain is nothing new)

The problem is, they have gritted the roads again & the car has gone white

The position of the two reservoirs have been finalised & the holes have been cut for the cables to go through the motherboard tray

The four mounting brackets were then attached to the motherboard tray for the reservoirs

The position of where the tubes would go through the centre plate was worked out.

This was marked on a piece of masking tape

Holes were then drilled into the plate

Bulk head fittings are then attached to the plate

The reservoirs were then lined up again

Tubing was used to ensure that everything will fit together in the final build.

The position of the GPU’s supply was also cut out in the centre plate

Further pipework runs have also been worked out

The ‘dry build’ is now almost completed & some of the pieces have been sent away for powder coating.

I am now in the middle of ‘wet flatting’ the panels ready for spraying.

The four mounting brackets were then attached to the motherboard tray for the reservoirs

The position of where the tubes would go through the centre plate was worked out.

This was marked on a piece of masking tape

Holes were then drilled into the plate

Bulk head fittings are then attached to the plate

The reservoirs were then lined up again

Tubing was used to ensure that everything will fit together in the final build.

The position of the GPU’s supply was also cut out in the centre plate

Further pipework runs have also been worked out

The ‘dry build’ is now almost completed & some of the pieces have been sent away for powder coating.

I am now in the middle of ‘wet flatting’ the panels ready for spraying.

Subbed

Great Build log

Thanks, glad you like it.

This is not just a computer 'case'... it is an engineering masterpiece!

Everything looks so neat and tidy, and very professionally finished indeed.

Here's looking forward to the next update!

Thank you.

When I set out to do this case, it was my intention to make it as neat & tidy as possible.

I wanted everything to look like it belonged & that it had not just been throne together.

I should have more updates soon, as things are being powder coated at this time.

As mentioned in my last update, some of the pieces have been away to the powder coaters.

This means I can get to work on some of the sub assemblies that will make up the finished build.

Fitted the feet to the hard drive caddy

As this part will not be taken out again for some time, I thought I should increase my storage capacity.

So purchased a new 2TB Seagate drive

As the prices of hard drives are now coming down & these were on special offer, I purchased two

Set the drives up in the hard drive caddy

Manufactured a new SATA power cable

Fitted the cable to the drives

Fitted the SATA cables to the drives (the drives & cables are numbered to make it easier to connect/disconnect in the future)

Everything neatened up with a few cable ties

Also had the pump heat sink back. So fitted the pumps

Unfortunately, I am becoming more anal than normal & fitted all matching bolts

This means I can get to work on some of the sub assemblies that will make up the finished build.

Fitted the feet to the hard drive caddy

As this part will not be taken out again for some time, I thought I should increase my storage capacity.

So purchased a new 2TB Seagate drive

As the prices of hard drives are now coming down & these were on special offer, I purchased two

Set the drives up in the hard drive caddy

Manufactured a new SATA power cable

Fitted the cable to the drives

Fitted the SATA cables to the drives (the drives & cables are numbered to make it easier to connect/disconnect in the future)

Everything neatened up with a few cable ties

Also had the pump heat sink back. So fitted the pumps

Unfortunately, I am becoming more anal than normal & fitted all matching bolts

Wow, this is incredible, I so can't wait to see how this ends up

Great work mannn

Thanks very much. Happy to know you are enjoying it.

I have never seen such a neat, tidy and precise build before... when it is finally finished it should look truly amazing!

It WILL be finished one day, won't it?

lol, yes (fingers crossed)

All the panels have now been wet sanded & are with the sprayer.

That should be completed within the next few weeks.

All the powder coating has been completed & I have more work to do on sub assemblies.

I have a few more pictures to take & then I can do another update (end of the week or the start of next week)

I'm sure I've seen this over on Hexus - great to see that you've resumed the build, because it is a fabulous piece of work. Can't wait to see how it concludes....

Thanks very much.

Yes, its on Hexus also on a few others but OcUK has been the most in-depth

There are lots of people wanting to see how this turns out (me included)

The way things are going, this should be finished shortly

I wanted to have my DVD drive powder coated again & thought I would do a little ‘guide’

Started with a standard Pioneer DVD drive

Use a straightened paper clip to open the door

Pull the tray out fully

There are four retaining screws on the underside

Remove the screws

Ignore the manufacturer’s warranty

Depress the side clip to remove the front cover

Remove the front cover over the front tray

Lift the top cover off

You now have a drive that is stripped down

You now have to clean the top & bottom covers of the drive

The disk centraliser is plastic & has to be removed from the top cover

Push on the centre & pop out the disk

Remove the thermal pad from the bottom cover

Clean off any stickers etc from the covers

Refit the screws back into the holes of the drive. This stops the holes from filling with powder coat

You can now get the covers powder coated.

Now rebuild the drive in the reverse of the above (did not refit the front cover on mine)

All fitted with both the fan controllers

Started with a standard Pioneer DVD drive

Use a straightened paper clip to open the door

Pull the tray out fully

There are four retaining screws on the underside

Remove the screws

Ignore the manufacturer’s warranty

Depress the side clip to remove the front cover

Remove the front cover over the front tray

Lift the top cover off

You now have a drive that is stripped down

You now have to clean the top & bottom covers of the drive

The disk centraliser is plastic & has to be removed from the top cover

Push on the centre & pop out the disk

Remove the thermal pad from the bottom cover

Clean off any stickers etc from the covers

Refit the screws back into the holes of the drive. This stops the holes from filling with powder coat

You can now get the covers powder coated.

Now rebuild the drive in the reverse of the above (did not refit the front cover on mine)

All fitted with both the fan controllers

A lovely job, as always!

Now that is what I call attention to detail!

Sometimes being anally retentive pays off

Nice job matey.

When I did my sata drive I just masked up the front panel and sata connector and went at it with black paint

Came out suprisingly OK

lol, done the same myself m8.

The powder coater did everything as a 'job lot', so it worked out cheaper to get it powder coated than spray it

I am going to place perforated plate over all the fan air intakes on this build.

This will stop any unwanted objects from being sucked into the fans

The perforated plate was powder coated black

I then covered the perforated plate with a very fine mesh to act as a air filter

The perforated plate was laid out on top of the mesh

The mesh was then cut down to size

And cut to fit each piece

The mesh will be held on with 6mm double sided tape

The tape was placed on all four sides

The mesh was then pulled tight & held in position with masking tape

The double sided tape has a protective coating on one side that has to be removed

This is not easy as its very thin

The perforated plate was then placed on top of the mesh

Once the mesh was fully stuck to the plate, the double sided tape was removed

The excess mesh was then trimmed off

The mesh was very neat on the reverse side of the plate

And looked good from the other side

This will stop any unwanted objects from being sucked into the fans

The perforated plate was powder coated black

I then covered the perforated plate with a very fine mesh to act as a air filter

The perforated plate was laid out on top of the mesh

The mesh was then cut down to size

And cut to fit each piece

The mesh will be held on with 6mm double sided tape

The tape was placed on all four sides

The mesh was then pulled tight & held in position with masking tape

The double sided tape has a protective coating on one side that has to be removed

This is not easy as its very thin

The perforated plate was then placed on top of the mesh

Once the mesh was fully stuck to the plate, the double sided tape was removed

The excess mesh was then trimmed off

The mesh was very neat on the reverse side of the plate

And looked good from the other side