You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Left Handed Build

- Thread starter piggin

- Start date

More options

View all postsI would be very interested (you may have seen my attempts in my project log) particularly in how to braid and make up cables from scratch without splashing out on loads of tools.

Yes m8, I have seen your braiding. Nice job.

I will see if MrsP will do some camera work (or soldering) on the weekend.

I will see what I can put together & post it in the build log

A 'mini' how to braid guide would be nice

Looks like the build is coming along nicely

And yeah I think it is a universal thing you know... My girlfriend's favourite few are 'that costs HOW MUCH?'

and

'Yes, but do you really need it?'

kd

lol, yes I have had the HOW MUCH one a few times now.

I had another big box delivered the other day (more disapproving looks from MrsP)

Unfortunately, she had to sign for it as I was in work. So no hiding that one.

I did have a very cunning plan, both of us in work, miss the delivery man & I pick up the box on the way home.

Unfortunately the delivery driver missed us both in the morning but called back in the afternoon as MrsP was getting home from work. BUSTED

This is why i get all my stuff delivered to work. Granted people at work look at me funny be the misses never finds out so thats all good. Imagine if i put this much thought into my work i would probs be getting paid more and the misses wouldnt care what i spent o well lol.

Unfortunately I can't get my stuff delivered to work.

Even if I did come up with some cunning plan, I would be found out.

Then I would be in even deeper trouble.

Hmmmmm I don't believe it is possible for a wife to think that you earn enough (and therefore not care what you are spending)

I agree, the more you earn, the more they spend.

Been keeping a eye out on this thread, liking the work

Thanks m8.

I have taken a few photos over the week end to do a mini cable braiding/ manufacturing guide.

I will put some words with it & post later in the week (hopefully).

As requested by a few people, this is how I produced my cable extensions.

Firstly I purchased some AWG18 copper wire for the cables

I then cut all the cables to the correct length with my side cutters from the pound shop

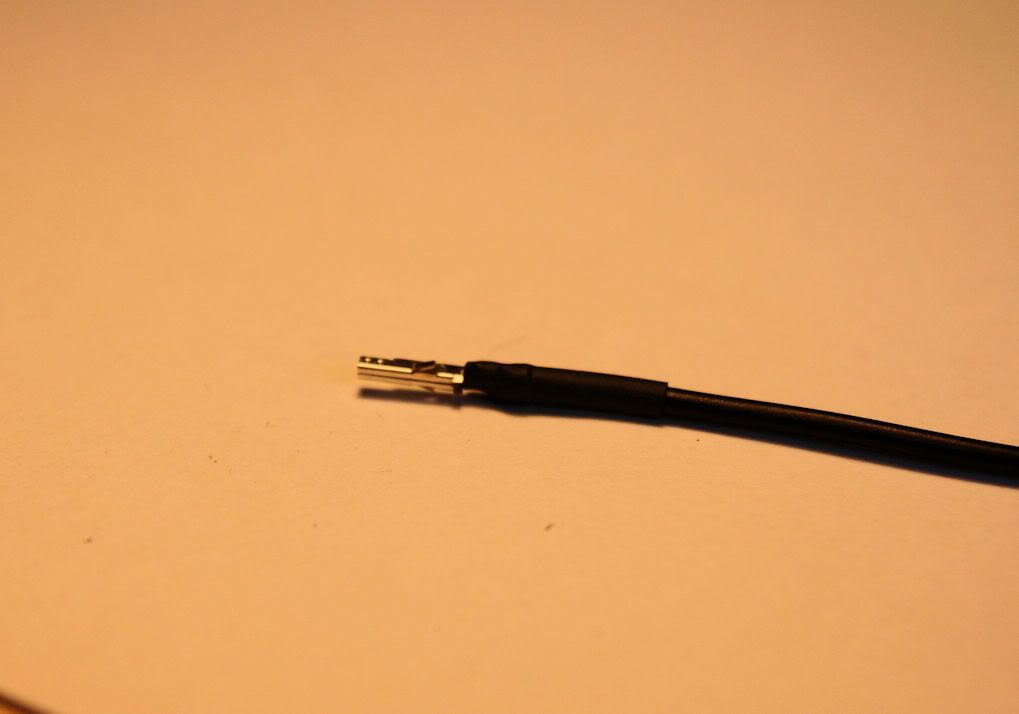

Each end of the cable had its insulation stripped back (8mm from the end)

(I borrowed a cable stripper for this job)

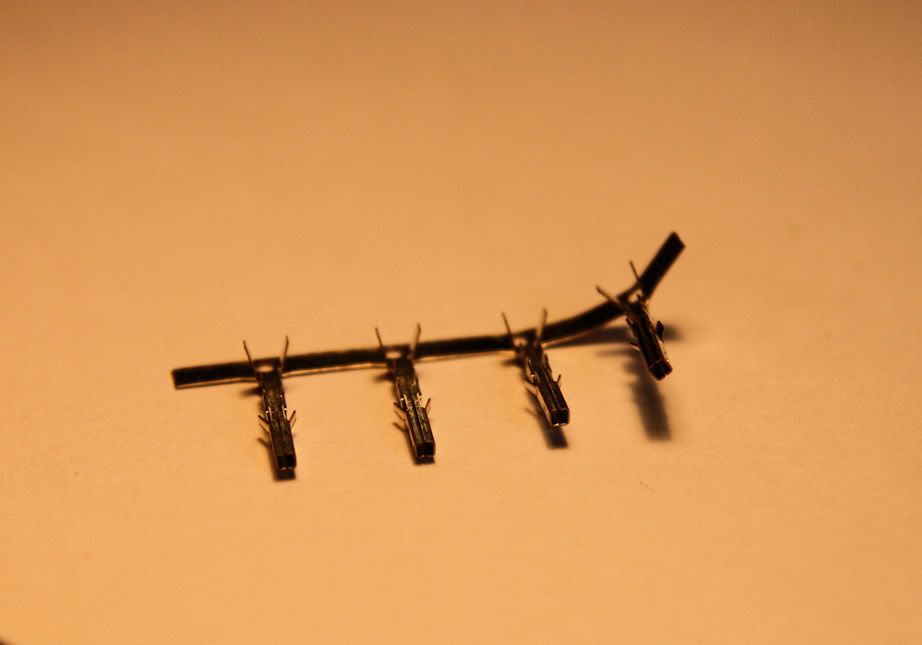

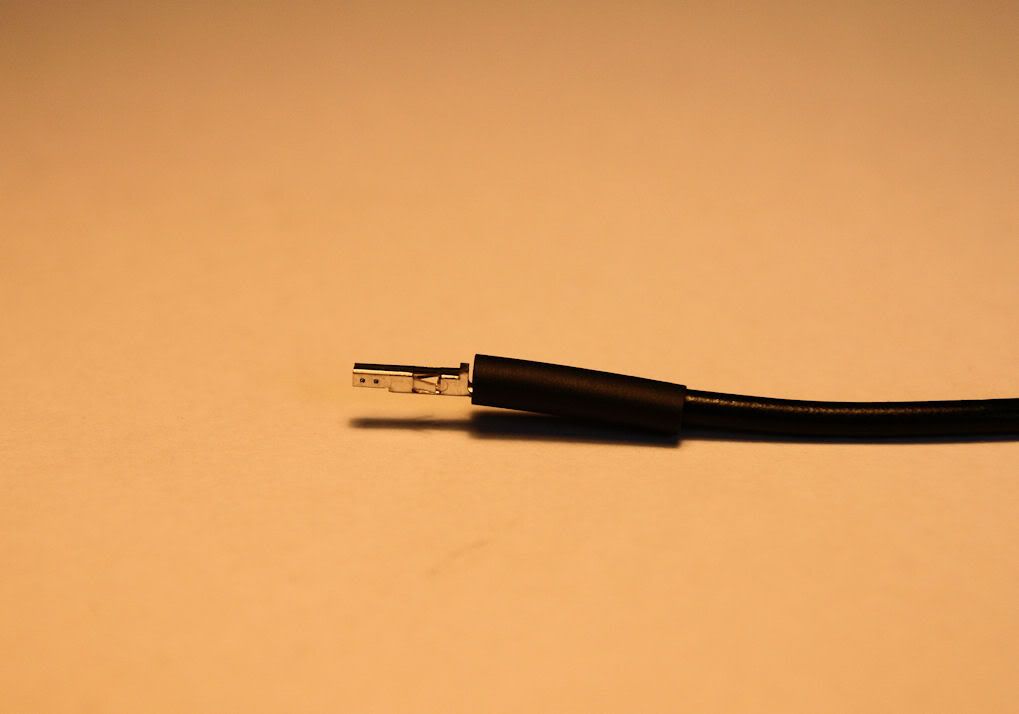

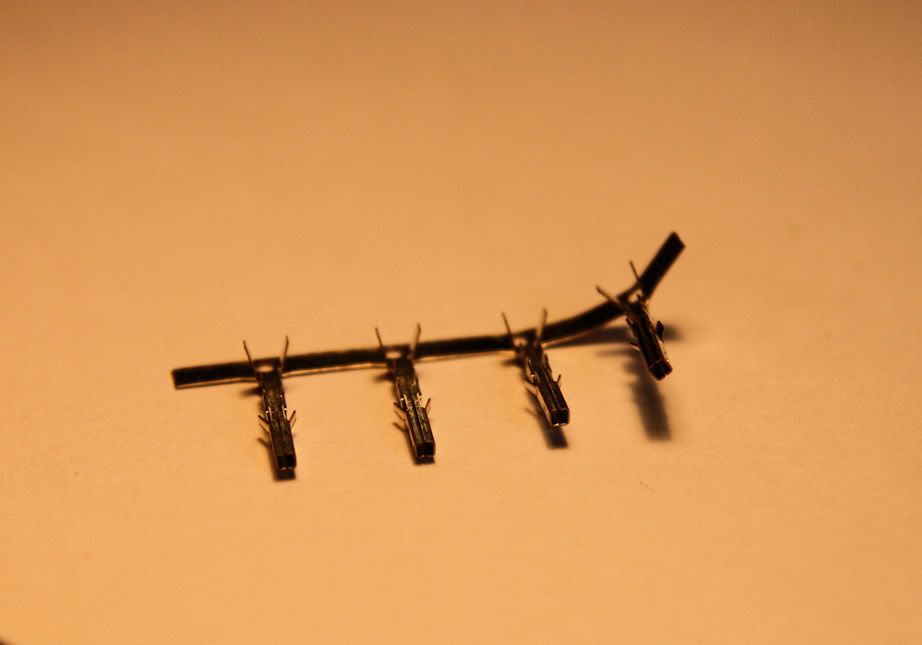

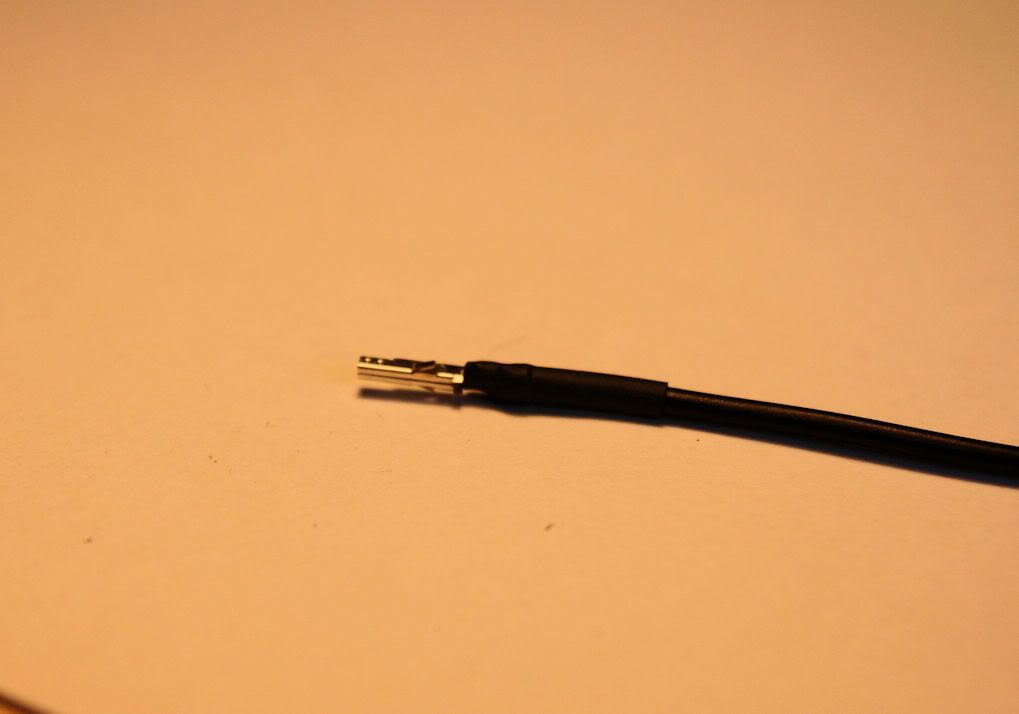

I purchased male & female atx pins

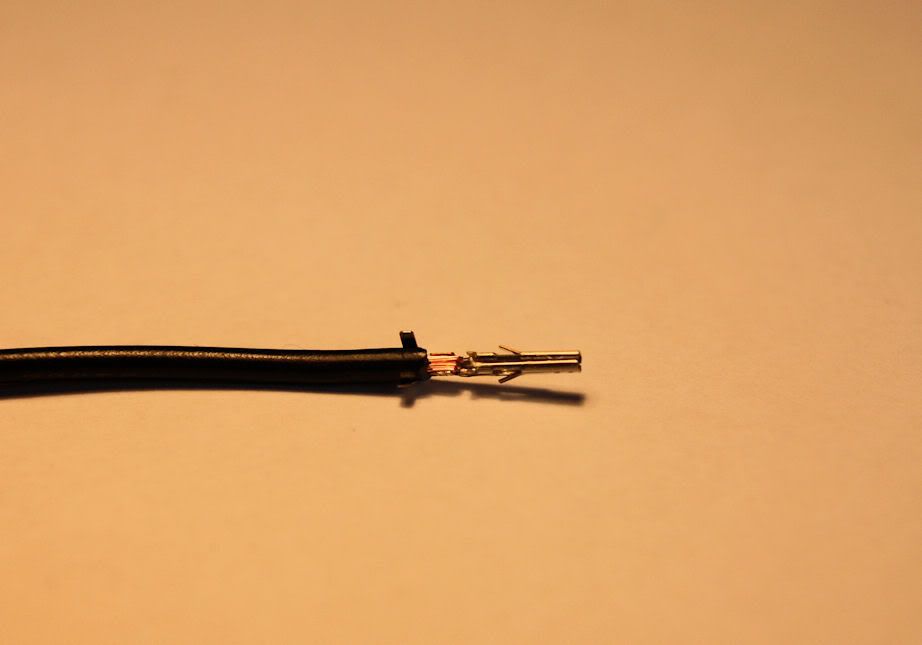

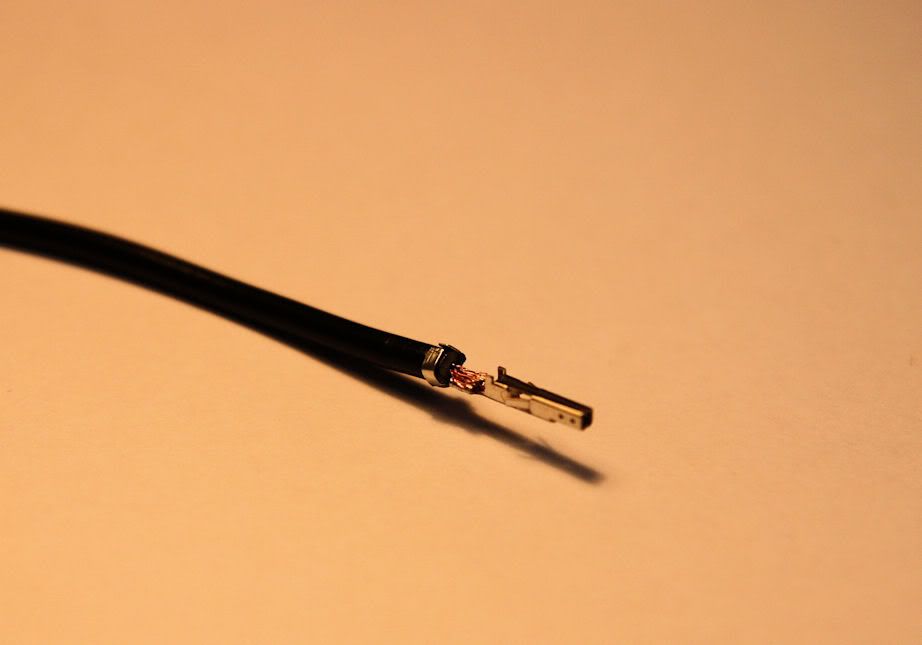

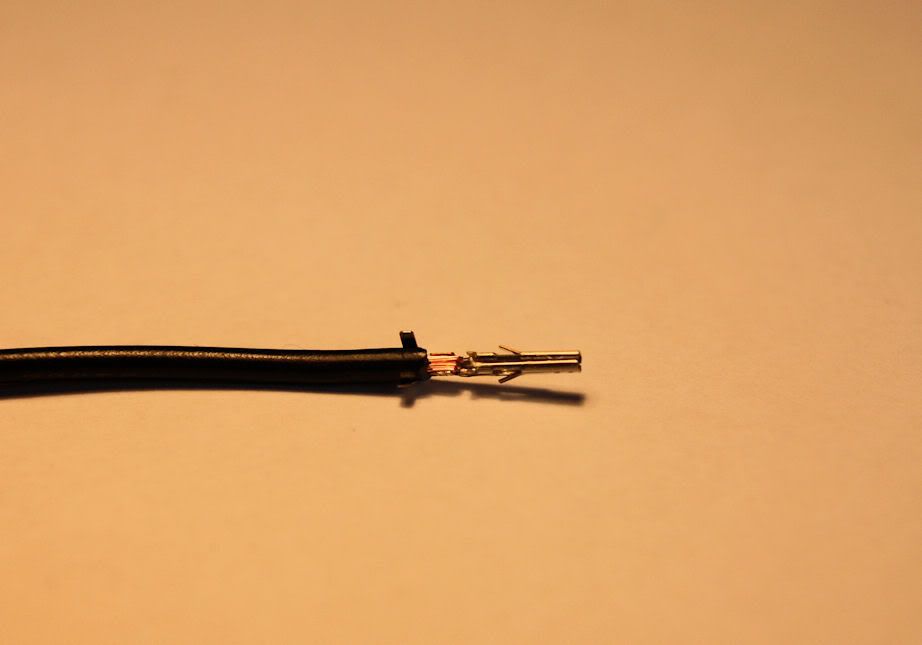

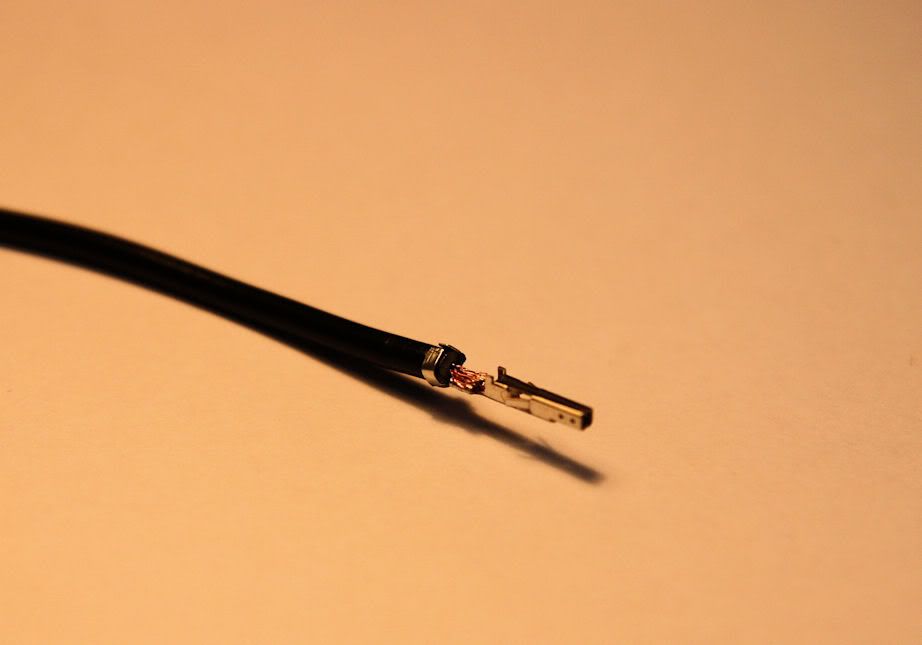

Place the pin on the end of the cable

Bend the inner tabs of the pin over the exposed copper core

This was achieved by using a small set of long nose pliers (from the pound shop)

Then fold the outer tabs over the insulation of the cable

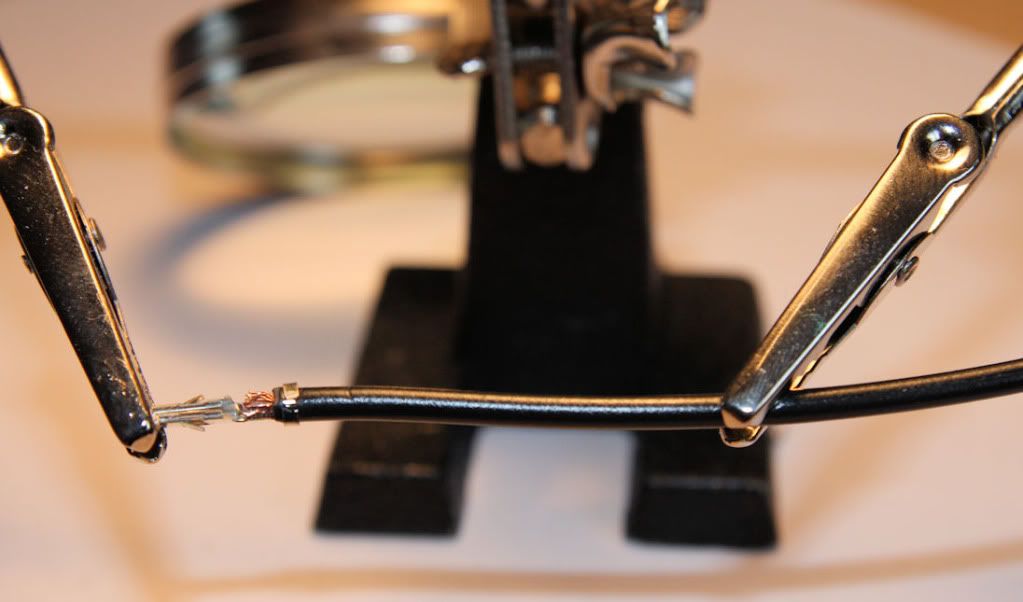

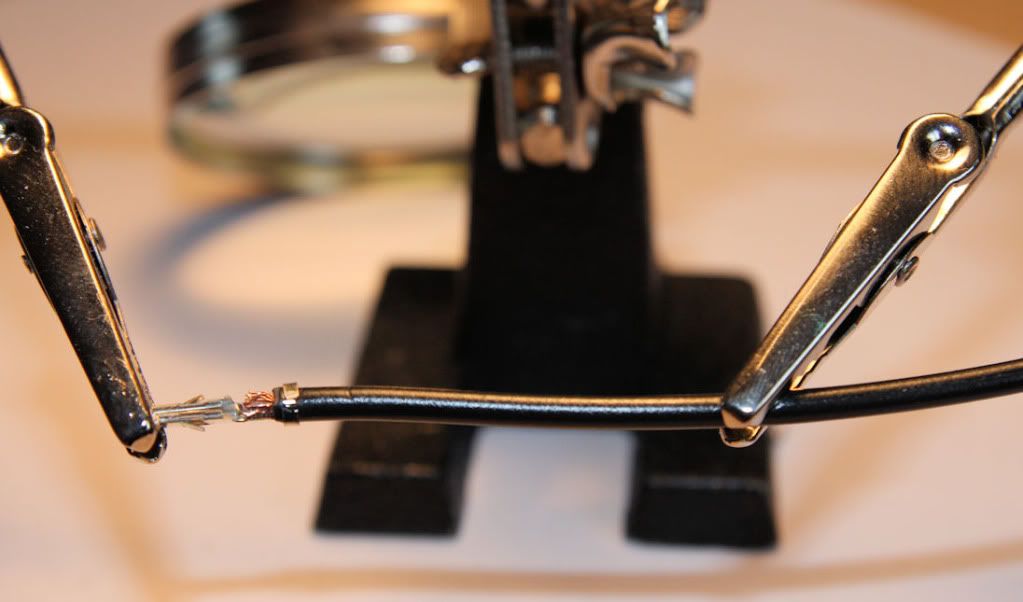

I decided that I required a little help with the soldering. As Mrs P was not that keen, I purchased a set of helping hands

A quick blob of solder on the wire/inner tab section.

The next stage is braiding the wires.

First cut up some heat shrink (Mrs P was very helpful with this but she did get carried away)

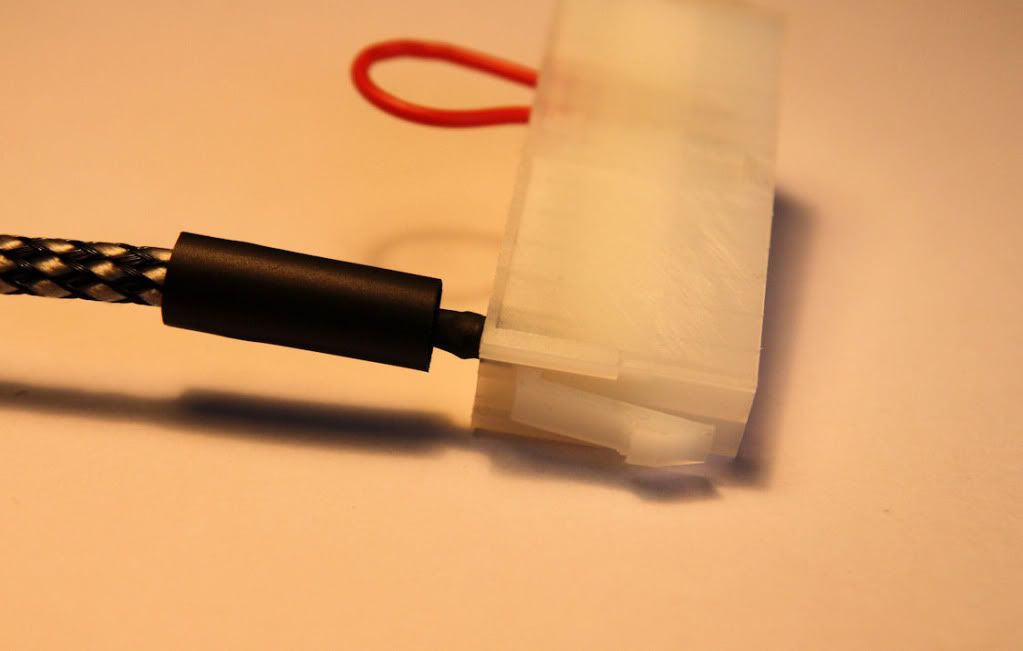

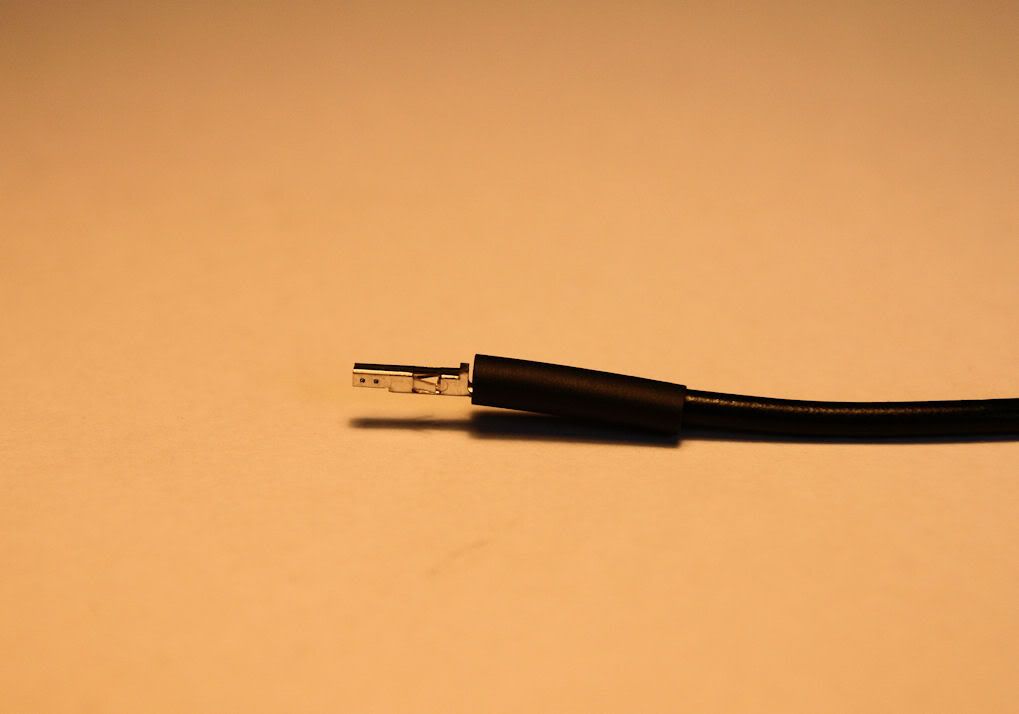

Place a piece of 3mm (3:1 shrink ratio) heat shrink on the end of the pin/wire.

Then apply heat (Mrs P's hairdryer did the job)

Repeat this on the other side

I purchased a few mts of braid to do this project

Cut the braid to length & slightly melt the ends to stop them fraying. (Used a cigarette lighter for this, pound shop again)

Place the cable up the inside of the braid

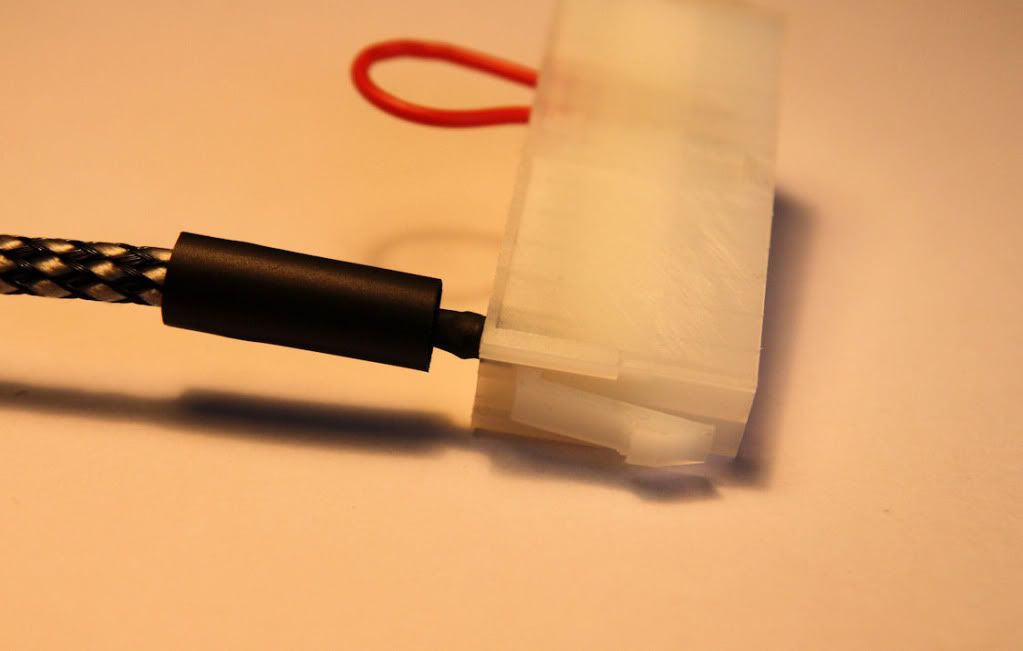

Put a piece of 7.9mm heat shrink over the top of the braid.

Now fit the ATX plugs (these are directionalised & will only fit one way)

Shrink the end in the correct position.

After a little time, you will have this

Firstly I purchased some AWG18 copper wire for the cables

I then cut all the cables to the correct length with my side cutters from the pound shop

Each end of the cable had its insulation stripped back (8mm from the end)

(I borrowed a cable stripper for this job)

I purchased male & female atx pins

Place the pin on the end of the cable

Bend the inner tabs of the pin over the exposed copper core

This was achieved by using a small set of long nose pliers (from the pound shop)

Then fold the outer tabs over the insulation of the cable

I decided that I required a little help with the soldering. As Mrs P was not that keen, I purchased a set of helping hands

A quick blob of solder on the wire/inner tab section.

The next stage is braiding the wires.

First cut up some heat shrink (Mrs P was very helpful with this but she did get carried away)

Place a piece of 3mm (3:1 shrink ratio) heat shrink on the end of the pin/wire.

Then apply heat (Mrs P's hairdryer did the job)

Repeat this on the other side

I purchased a few mts of braid to do this project

Cut the braid to length & slightly melt the ends to stop them fraying. (Used a cigarette lighter for this, pound shop again)

Place the cable up the inside of the braid

Put a piece of 7.9mm heat shrink over the top of the braid.

Now fit the ATX plugs (these are directionalised & will only fit one way)

Shrink the end in the correct position.

After a little time, you will have this

Last edited:

I really appreciate the mini guide, along with details of where you got your tools.

We've got a 99p shop near us - perhaps they have those tools and I could save even more money

No problem m8, I would stick with the £1 shop as the quality is a little bit better.

Good guide, and the braiding is great, but the only thing I am not keen on is there is an awful lot of heatshrink used. Was that deliberate?

Thanks Diggsy, I put an extra few mm of heat shrink on the ends of the cables, as I have had problems with braid pulling out of the ends in the past.

I have pulled & bent these cables extensively with no problems.

Typo? You're using AWG18 (standard size for PSUs judging from the two I have in front of me) wire from the photo. AWG24 would be far too thin surely.

Turambar, thanks for pointing that out, it is AWG18 or 1mm.

The confusion arouse when I was going to use AWG24 for the 24 pin extension but decided on standardizing everything with AWG18.

This also meant, I only had to purchase one coil of cable instead of two.

Therefore keeping the cost down

lol, I don't think Mrs P sees it that way.

Especially when things like this turn up on the door step.

Just like christmas all over again.

Only purchased a few items this time.

I required a few 140mm fans

Also a few 120mm fans

Also needed a few cold cathodes

SATA power connections

Pipe fittings

3 pin fan fittings & pins

Anti vandal switches

Some good old MX3

Had to get the MX3, as I purchased this

Normal high standard of fittings in the box

Quick look at the contents of the box

And finally the block

Especially when things like this turn up on the door step.

Just like christmas all over again.

Only purchased a few items this time.

I required a few 140mm fans

Also a few 120mm fans

Also needed a few cold cathodes

SATA power connections

Pipe fittings

3 pin fan fittings & pins

Anti vandal switches

Some good old MX3

Had to get the MX3, as I purchased this

Normal high standard of fittings in the box

Quick look at the contents of the box

And finally the block

Wow that is a lot of kit. I can see Mrs. P glued to the shoe catalogues now...

Can't wait to see it all in place.

I thought that would be the last box but more have come this week.

I think the shoe bill is going to be massive

These aren't to protect against Mrs. P are they?

I am more concerned about the case itself. As it will sit on the floor, I will have to place armco around it to stop Mrs P with the hover.

Now those are some proper fans! Any idea how loud they are going to be?

They will not be very loud, as they will all be run through fan controllers.

The 38mm fans shift a lot of air at low speeds.

Those 120mm fans look rediculously small next to the 140's

I remember when everything was cooled by 60 and 80mm fans... having a 120mm fan was 'extreme cooling' LOL

lol, I remember when 80mm fans were classed as extreme

That looks like some awesome kit there m8 keep the pictures coming please I for one can not wait to see the finished result it is going to be EPIC!

Stoner81.

The story continues, so there is a lot more pictures to come.

Let me know how they are! I will be looking for some silent fans that move a good amount of air- I know YL's are very good performers but I thought they would be too loud.

I like the 38mm yates.

They give very good performance with very little noise.

(I have 8 running on 'the shelf' this minute.

Thankfully, photo bucket is now working so I can do my next update.

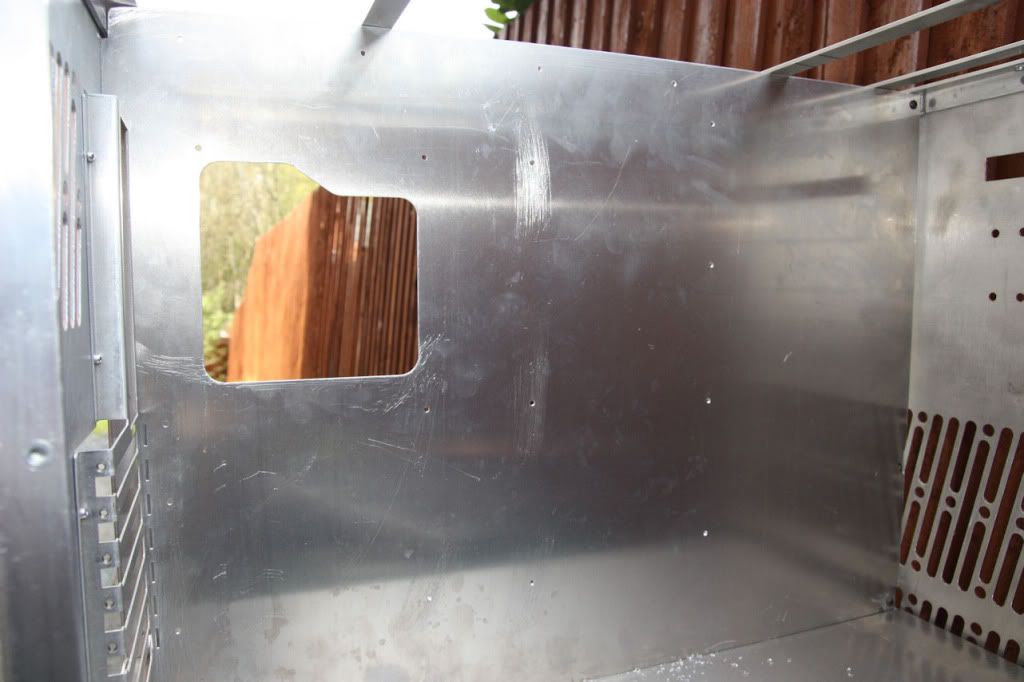

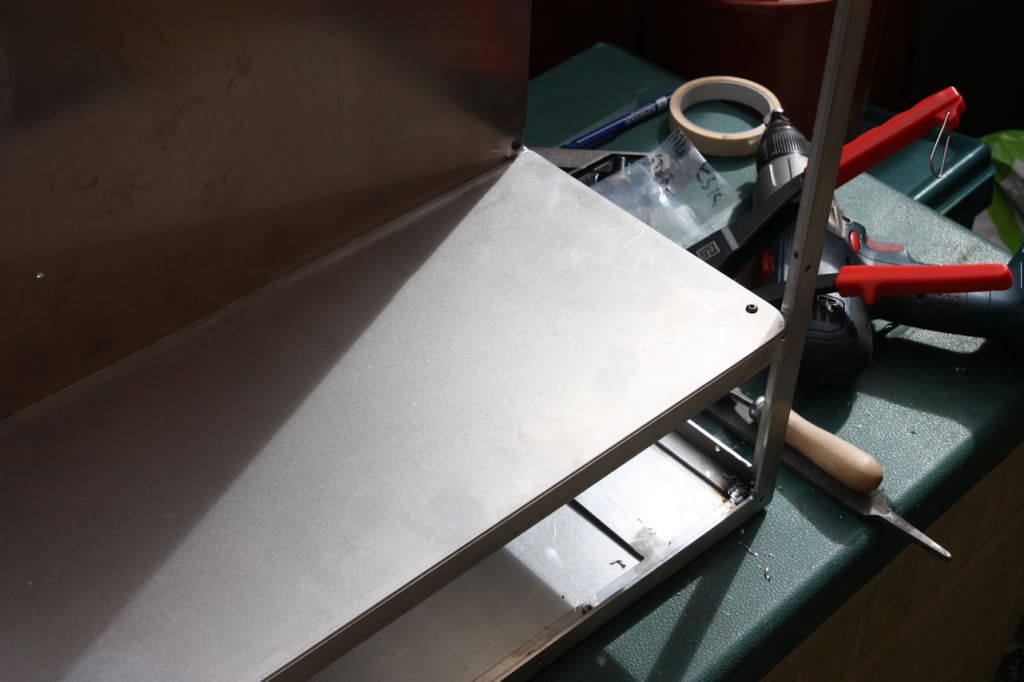

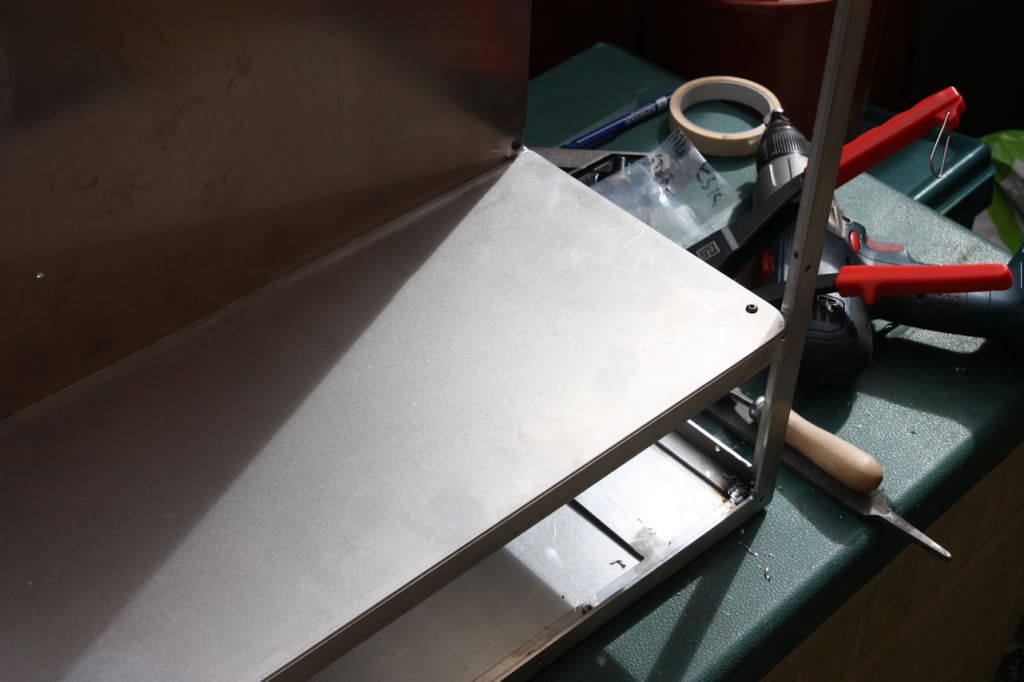

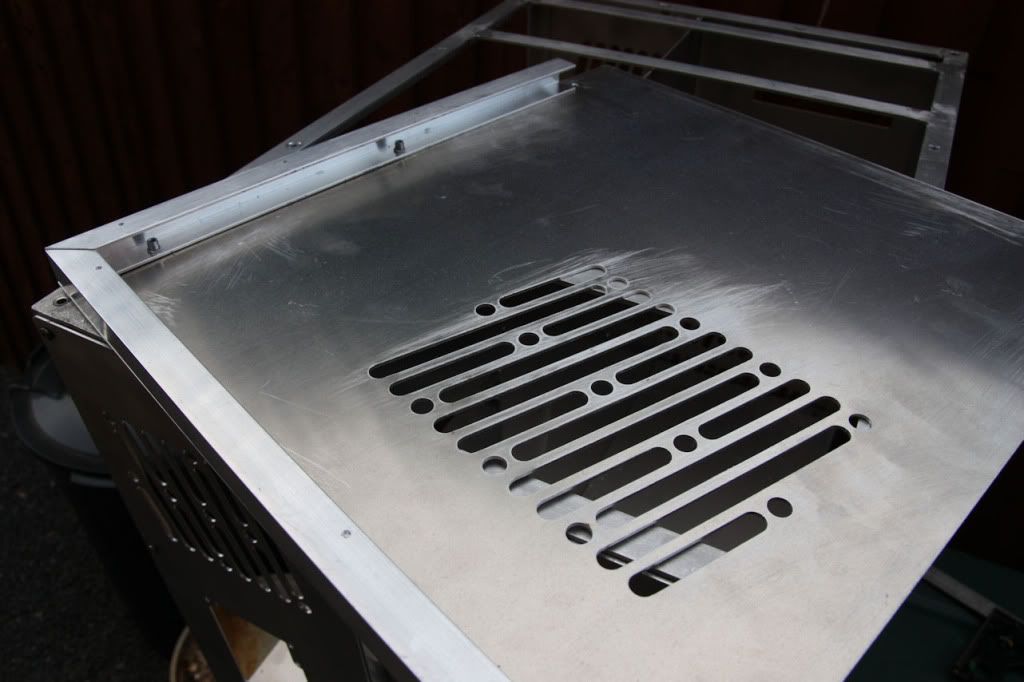

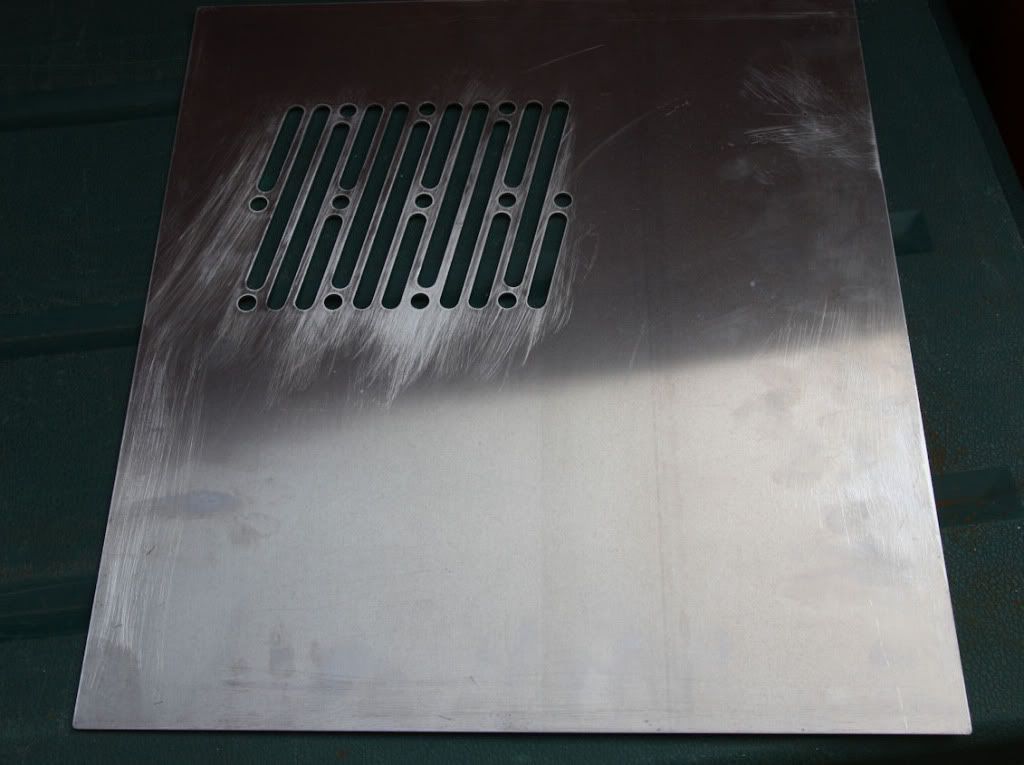

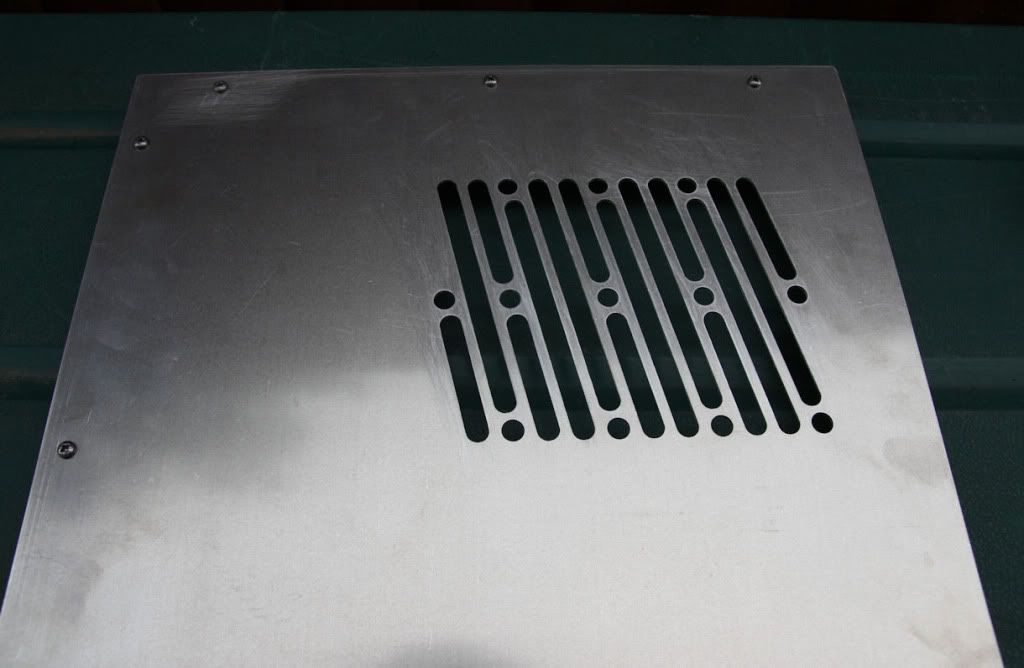

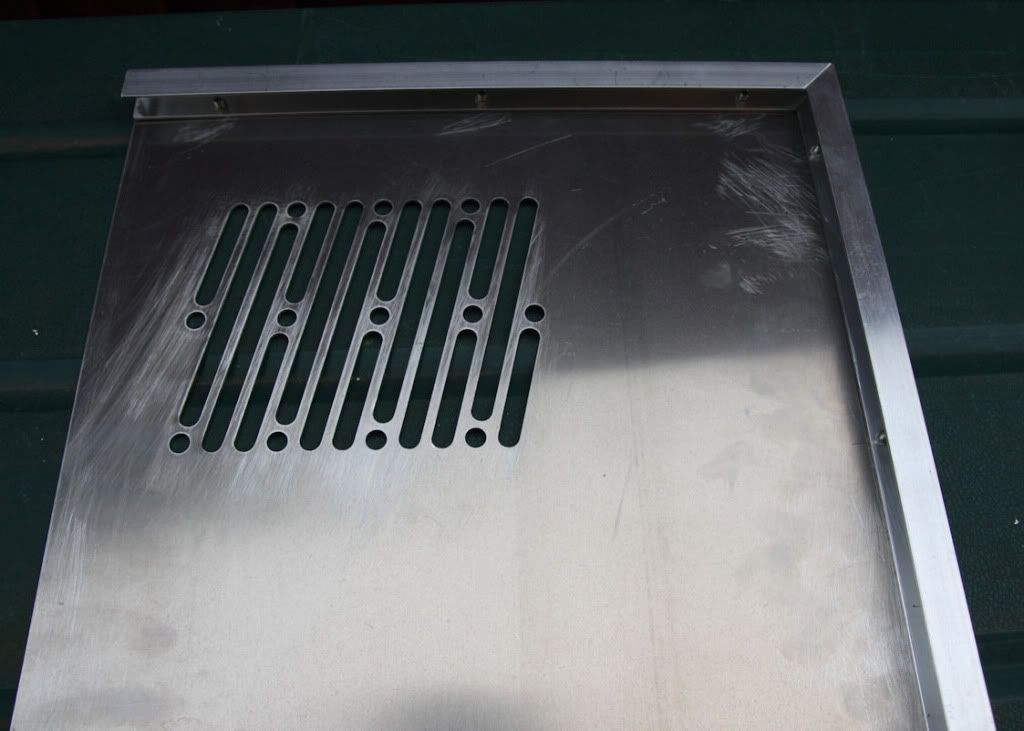

Motherboard back plate cut & fitted.

(Held in place by tags that have been welded onto frame)

A lot of further work required on this with regards cable management etc.

Cut & fitted bottom sectionalising panels for both sides.

Panels marked & drilled

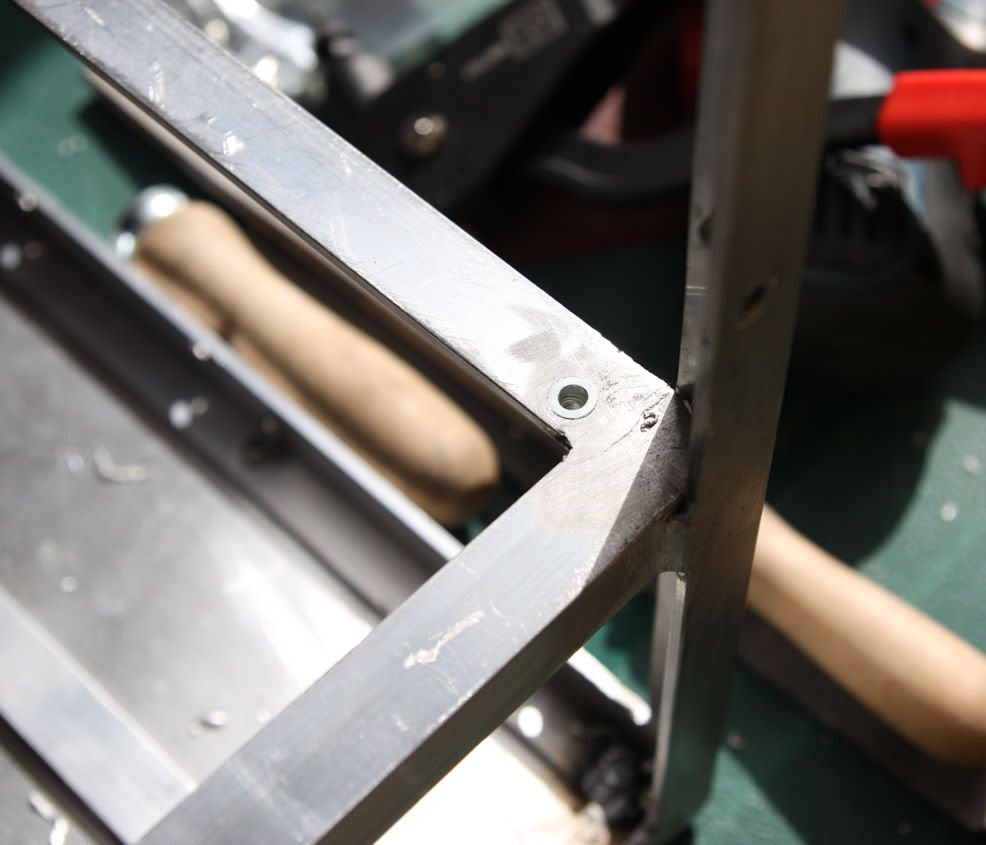

Frame drilled & nut rivets used

Panel firmly attached to frame

Repeated on all four corners

Motherboard back plate cut & fitted.

(Held in place by tags that have been welded onto frame)

A lot of further work required on this with regards cable management etc.

Cut & fitted bottom sectionalising panels for both sides.

Panels marked & drilled

Frame drilled & nut rivets used

Panel firmly attached to frame

Repeated on all four corners

Last edited:

Nice Job mate

Thanks Br4d

looking good. There's a fair amount of space under the motherboard tray. Is that for cable management or something else?

I agree, there is a lot of space under the motherboard.

I designed it this way, as motherboards are getting longer (just look @ the EVGA Classified).

I want to make this case future proof (lol)

(I don't think Mrs Piggin will ever let me do this again)

If I get a longer motherboard, I only have to change the PCEI backing plate.

As for cable management, that will be my next update.

you mean the hole?

its for mounting backplates for custom coolers without having to remove the motherboard first.

Yes, the hole in the motherboard tray is for easy access to the rear of the CPU (but John alrady knows this

)

)No I meant the part of the case that's behind the motherboard (that you can see through the hole for the CPU cooler):

I can make out what I think it a hole for the PSU, but there's going to be tons of room there so I figured it was for running cables, but I thought it would be good to check...

Yes m8, you can see the cut out for the PSU but as you said there is a lot of room.

Some of the room will be taken up with cable management (that will be my next update) & the rest will be taken up with other pieces from 'the shelf'

I would assume that's where all the water cooling parts are going - rads/pump etc

Not a bad assumption Diggsy but what will I put in the bottom chamber

Slap her face and then ask her if she still wants the back bedroom back as it was*

*This advice may lead her to beating the crap out of you

I am not sure domestic violence is the way forward.

Not sure I will be a battered husband, as I am 1.9 mts tall & she is only 1.65 mts.

(I think she would have to play dirty)

That doesn't sound very nice... I am sure she is a lovely lady... as well as being a very understanding one!

Yes Montala, Mrs Piggin is a wonderful woman, who I love very much (even though she does nags a little)

lovely! Is it going to be one color or is there going to be a custom paint job?

Thanks marc

Its going to be very custom

I am in talks with different sprayers @ this time

I'm 165 cm too. Me v Mrs P would be a fairer fight then

Your build is going to be awesome mate, can't wait

I think you will have age on your side & Mrs P has the experience.

Could be a close fight.

But you must always remember girls fight dirty & know how to hurt a man (in the wallet)

This is amazing! And to think i'm only just about to put together my first build and there are people building from scratch properly! Love it!

Can't wait to see more and love the tales of Mrs Piggin!

David

Thanks David, I have lots of tales about Mrs Piggin (could right a book but would not be about relationship advice

)

)I don't know if it would be a best seller but it would be interesting.

You really missed a trick with the "shelf" computer then - you could have placed it out of reach, thereby avoiding fried Mrs. P and keeping your computing going.

Very good point m8.

I should have put it on the top shelf of the desk completely out of her reach.

That would have cut the credit card bill down on ebay.

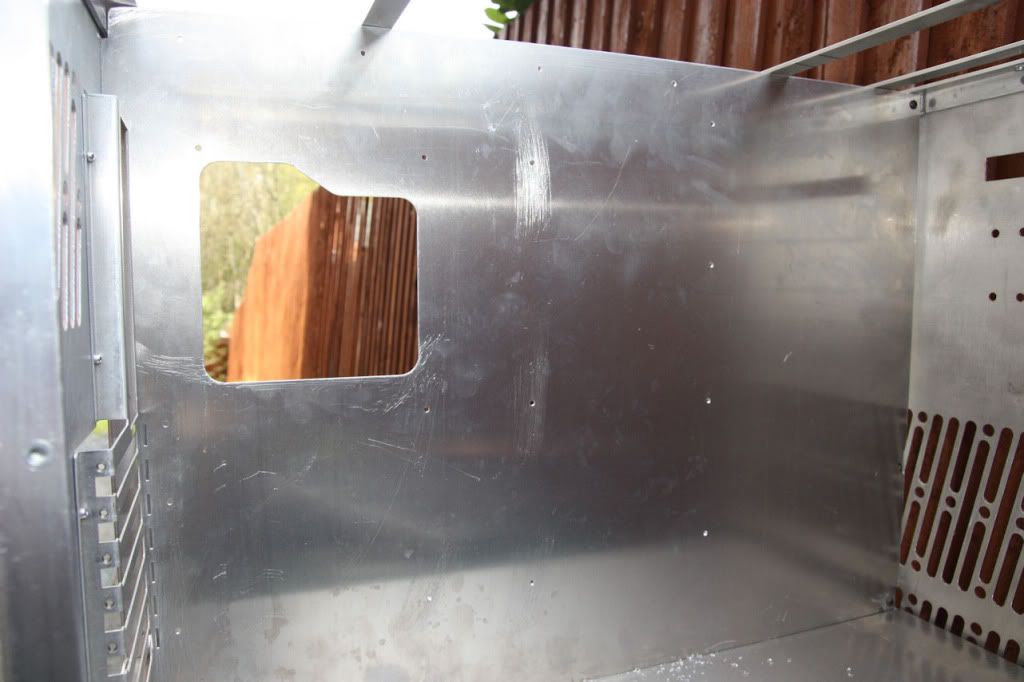

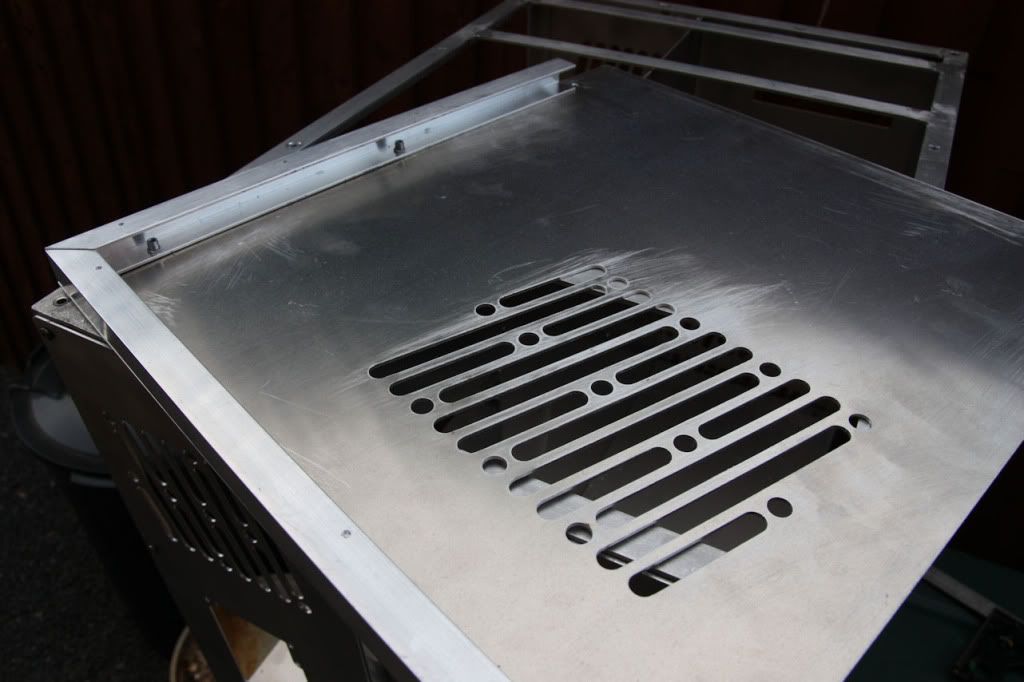

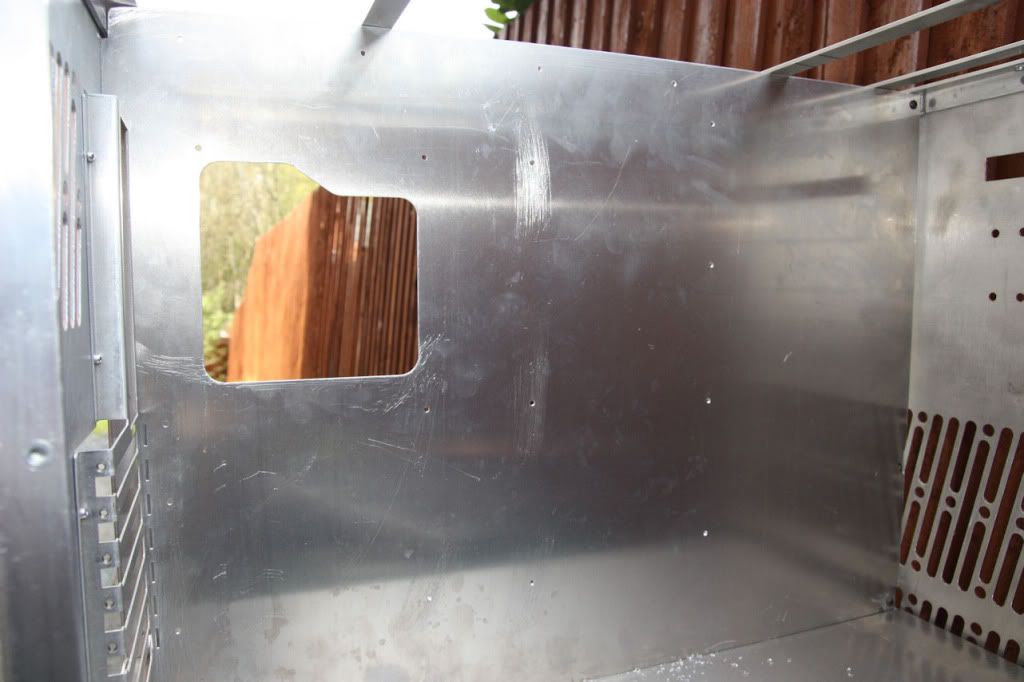

As I have previously owned a Mountain Mods case, I know how hard it is to do cable management correctly.

As this case is based on a MM design (very loosely) I realised that I had to put something in place to rectify this problem.

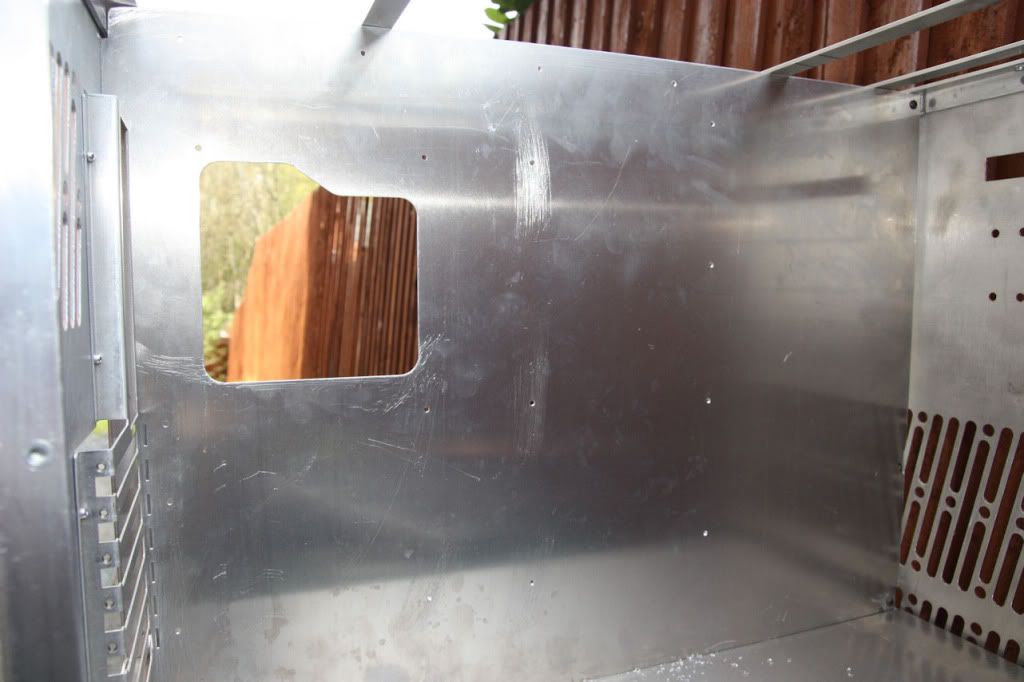

After some thought, I decided to put a false panel behind the motherboard tray.

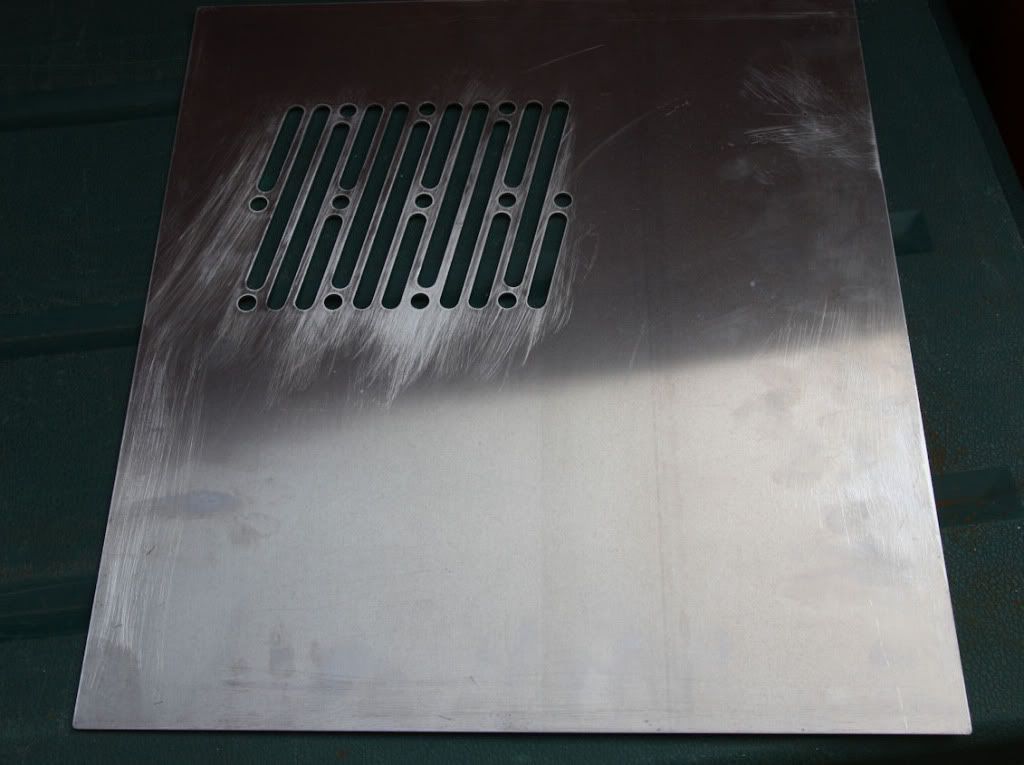

Panel cut to size with an area cut out, to keep the rear of the CPU cool

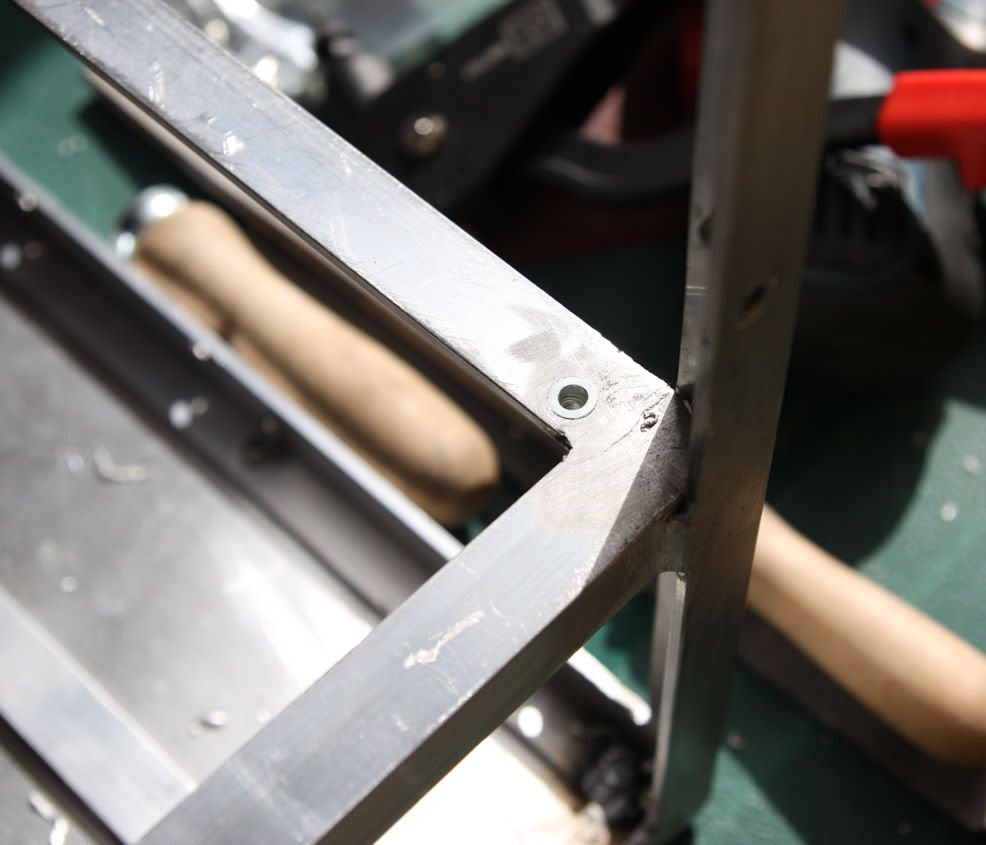

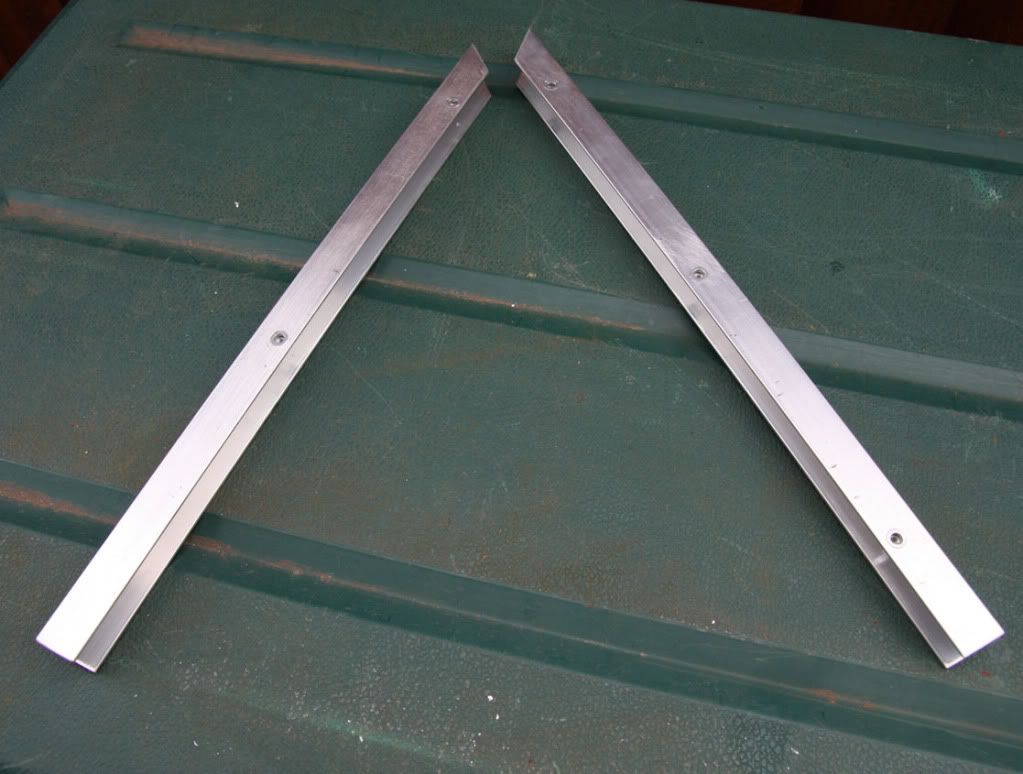

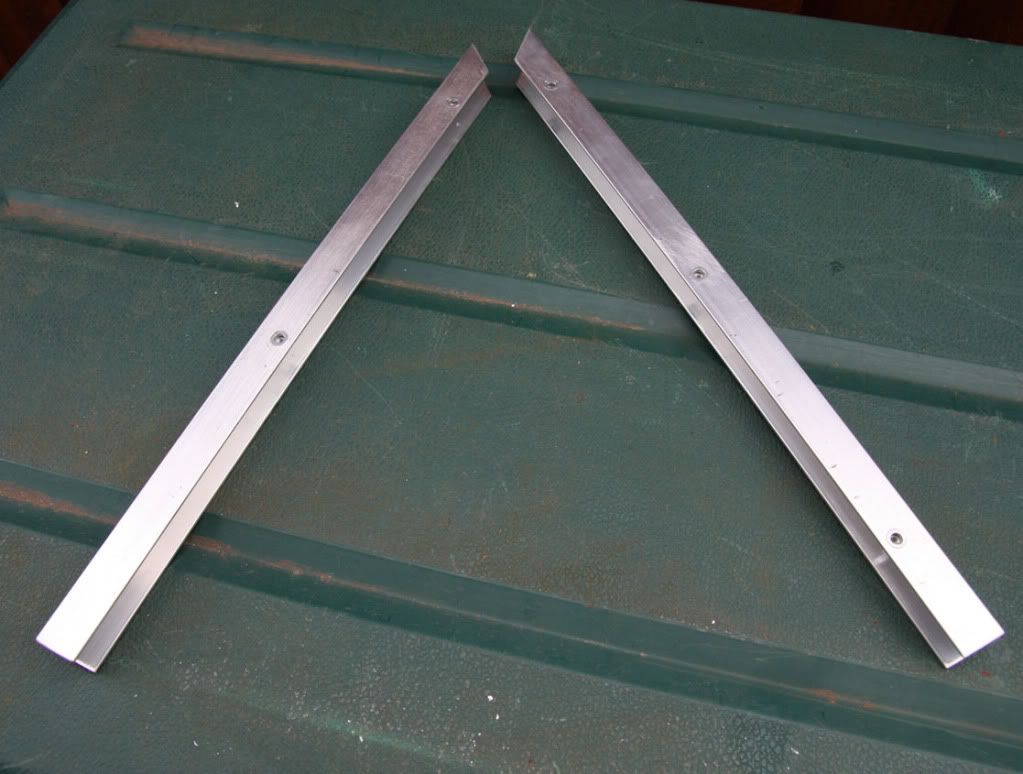

To hold it in position, I used some 20mm U section aluminium

U section drilled & fitted with the good old rivet nuts

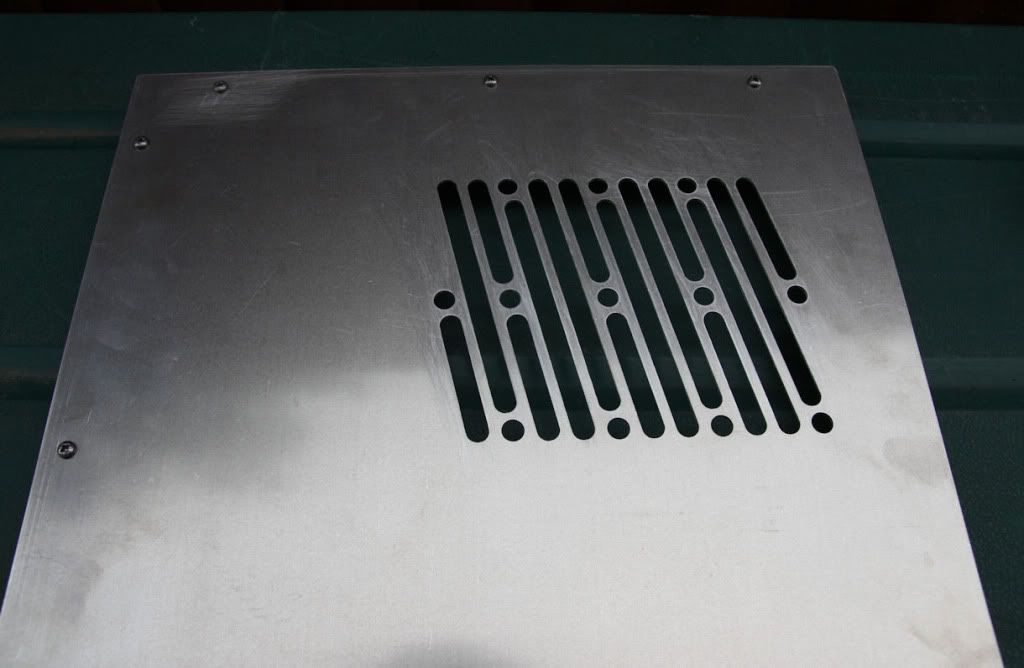

False panel marked out & drilled to match the U sections.

False panel bolted to U sections

The rear of the U section was then marked out

U section drilled

Motherboard panel drilled to attach U sections

U sections attached to motherboard tray with countersunk pop rivets

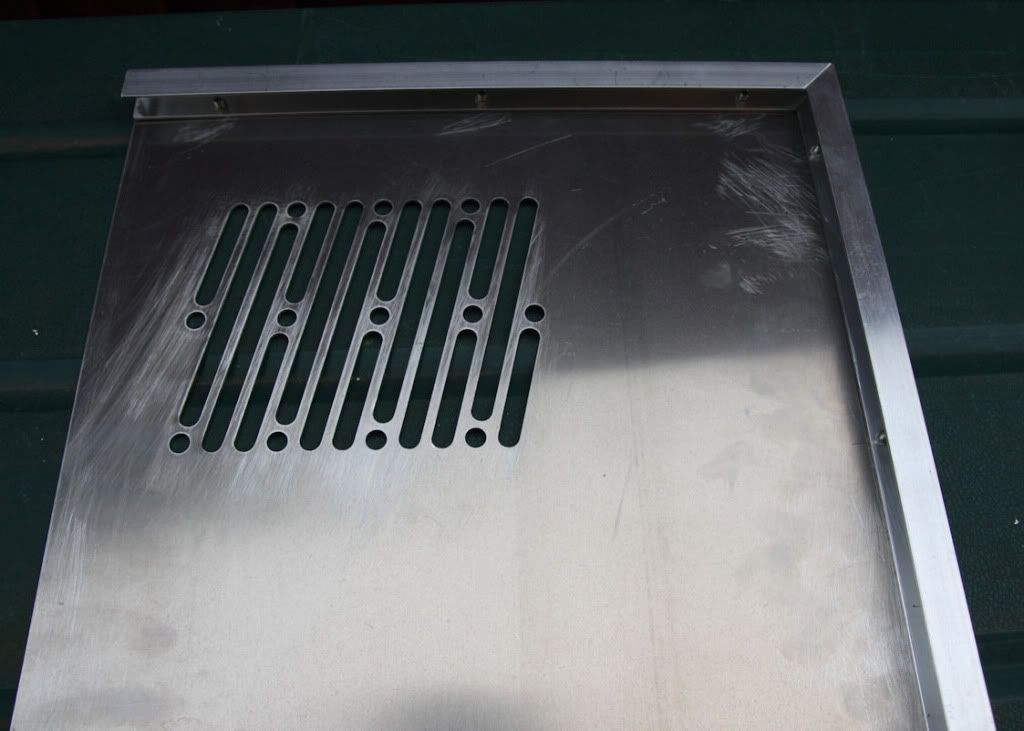

False panel fitted in place

Now I have a 25mm gap between the rear of the motherboard tray & the false panel to hide all my cables.

As this case is based on a MM design (very loosely) I realised that I had to put something in place to rectify this problem.

After some thought, I decided to put a false panel behind the motherboard tray.

Panel cut to size with an area cut out, to keep the rear of the CPU cool

To hold it in position, I used some 20mm U section aluminium

U section drilled & fitted with the good old rivet nuts

False panel marked out & drilled to match the U sections.

False panel bolted to U sections

The rear of the U section was then marked out

U section drilled

Motherboard panel drilled to attach U sections

U sections attached to motherboard tray with countersunk pop rivets

False panel fitted in place

Now I have a 25mm gap between the rear of the motherboard tray & the false panel to hide all my cables.