Associate

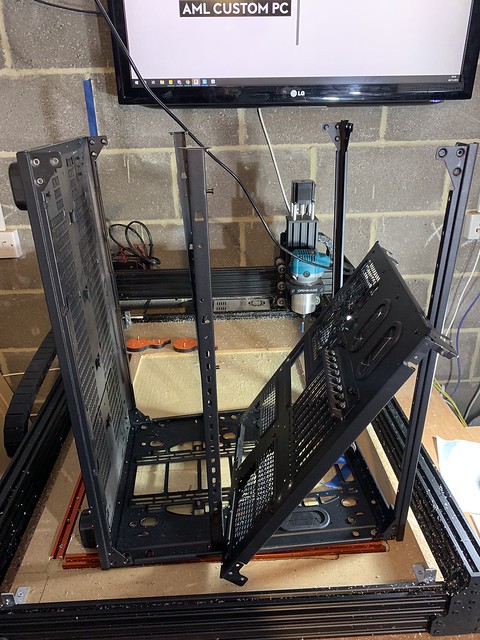

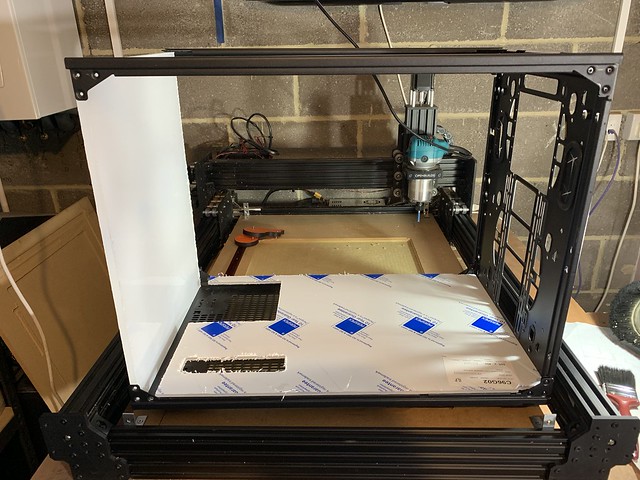

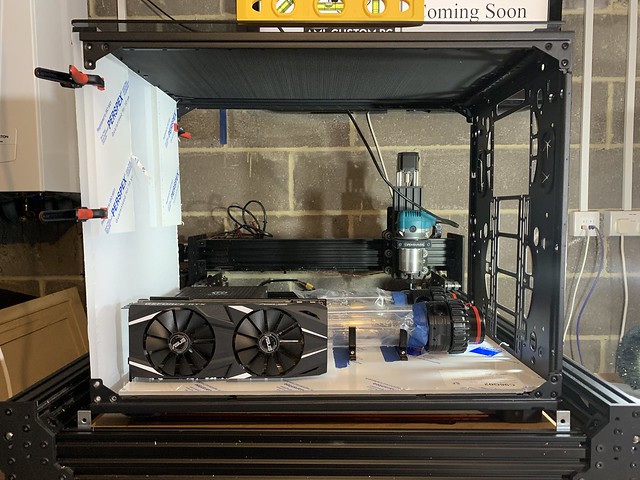

Thanks for checking out my build log, I have been lucky enough to have been picked (1 of 5) to be part of the Thermaltake UK Modding Trophy 2018, It’s been 2 years since the last one, I am very honored to have been chosen.

I just want to say a massive thank you to all the sponsors, Thermaltake, Asus, AMD, Adata, Bit-tech and Scan for their support in this competition.

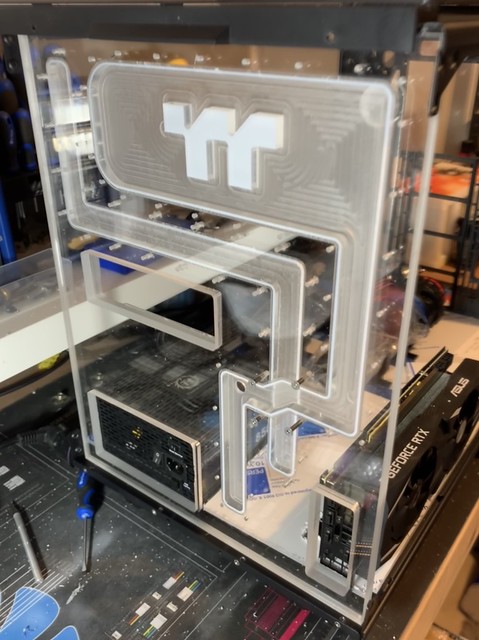

The name of my project is #TT20.

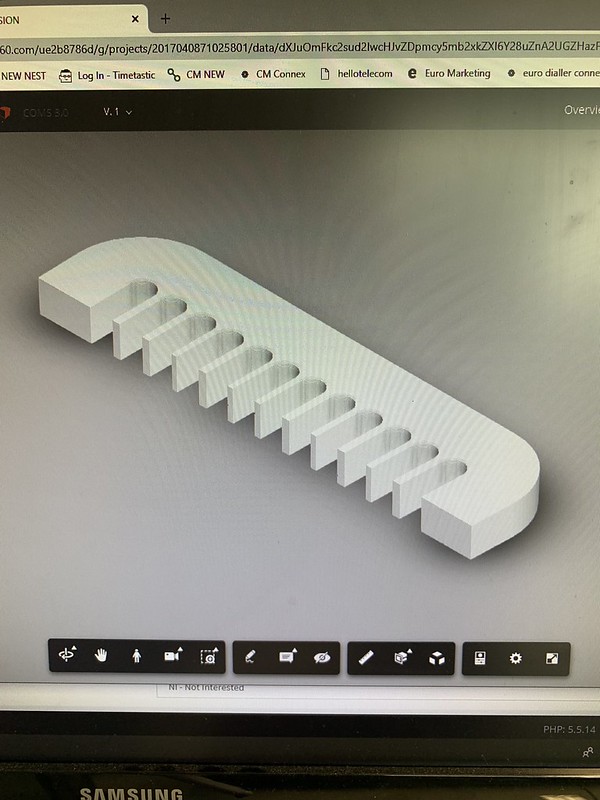

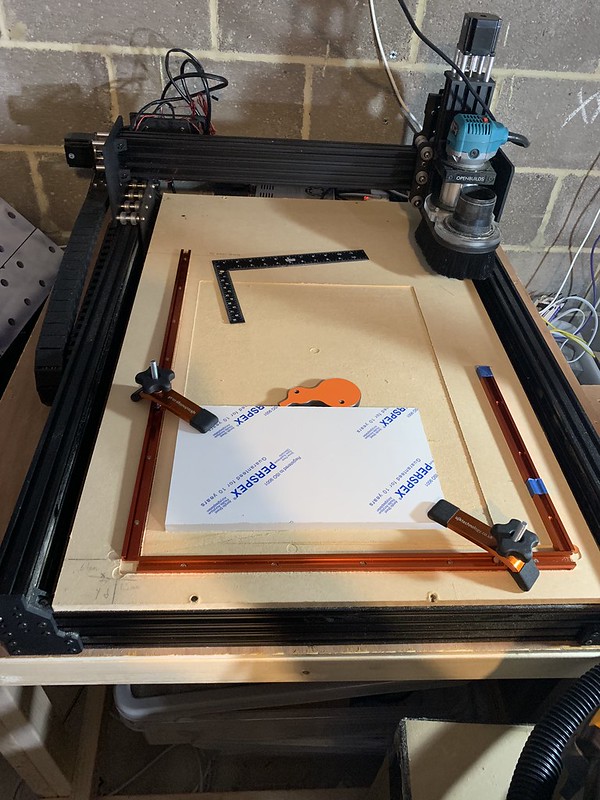

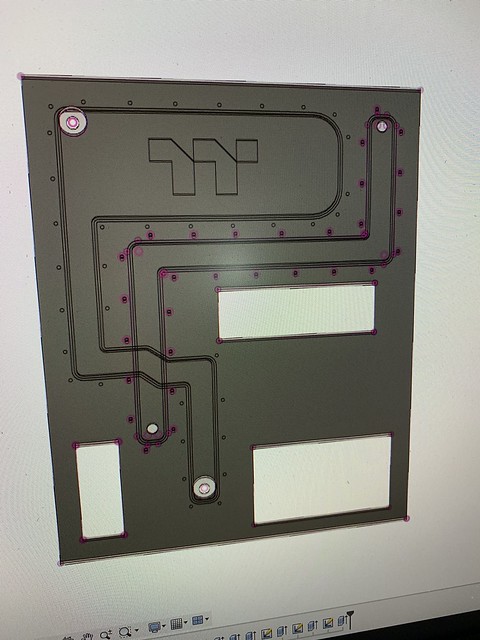

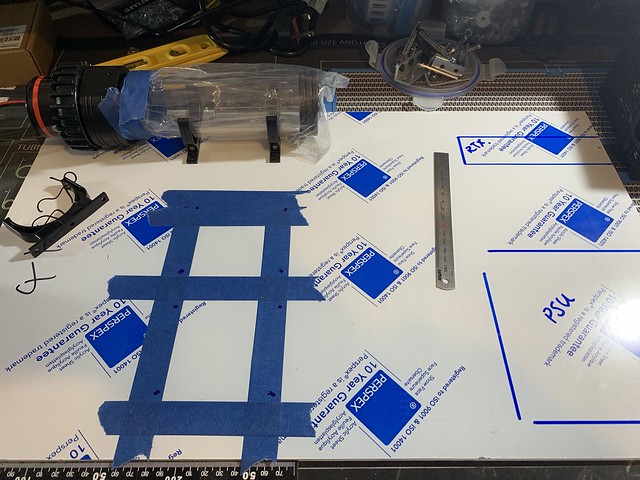

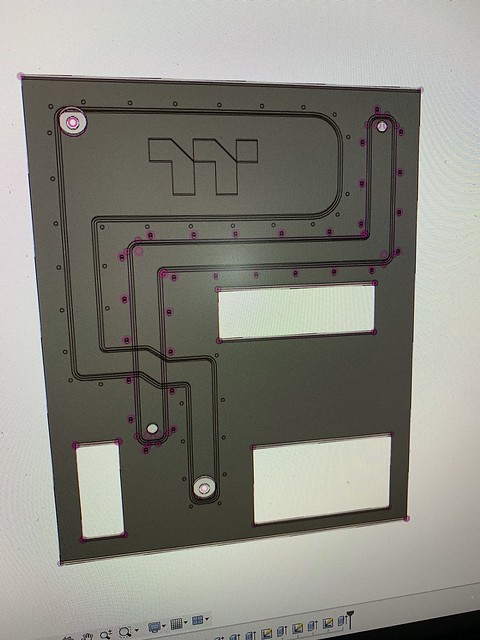

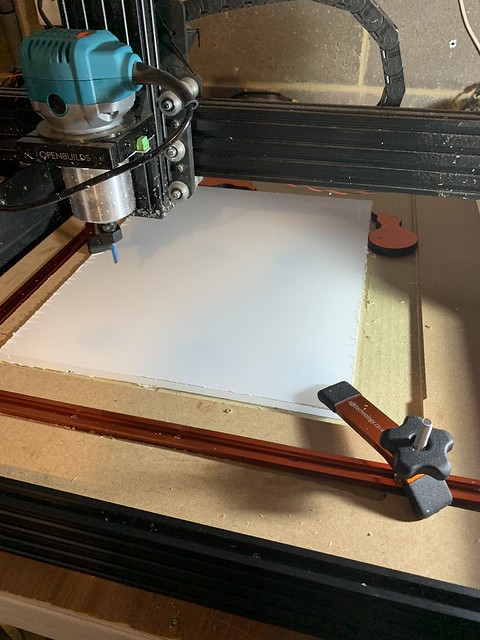

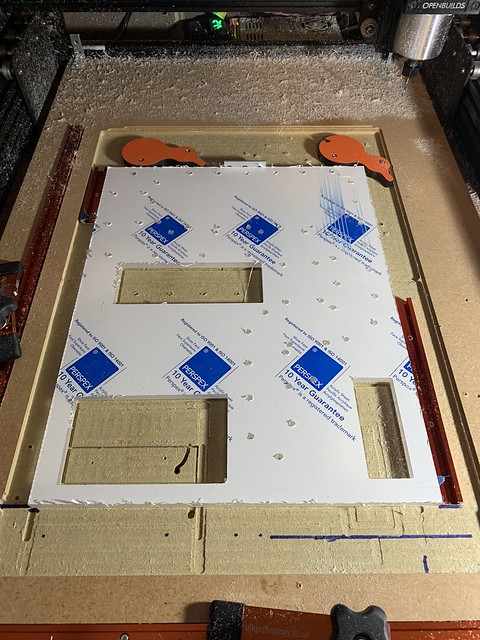

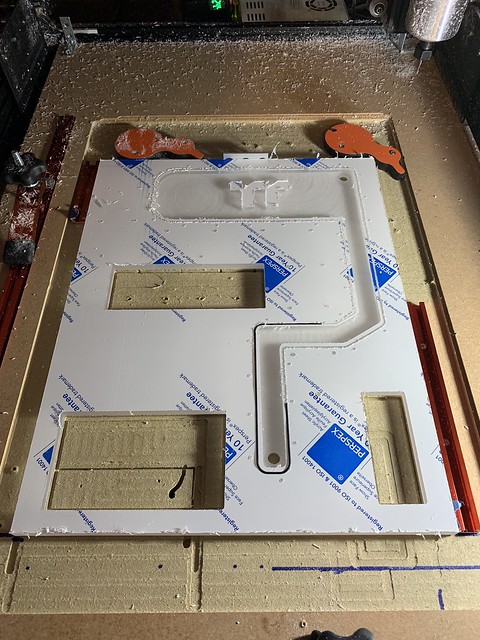

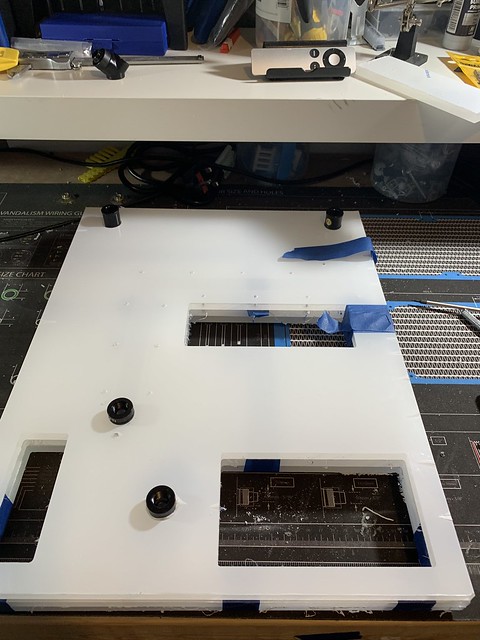

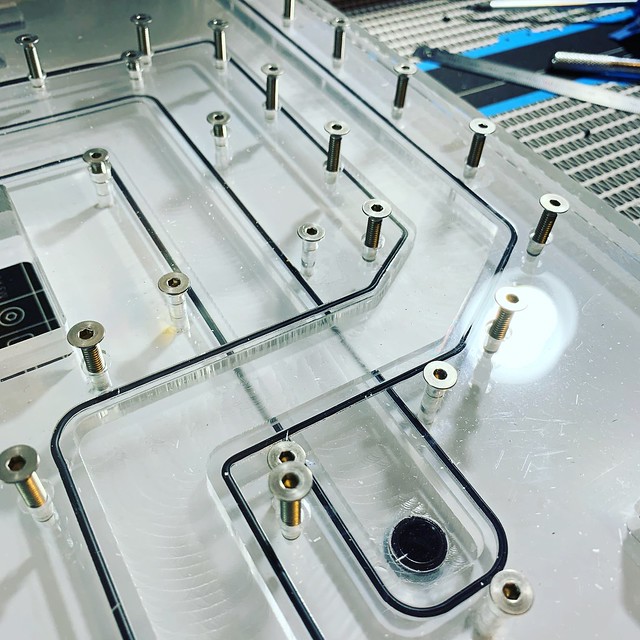

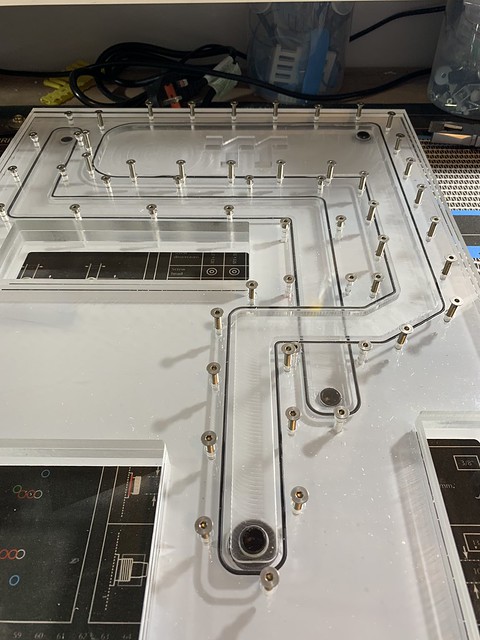

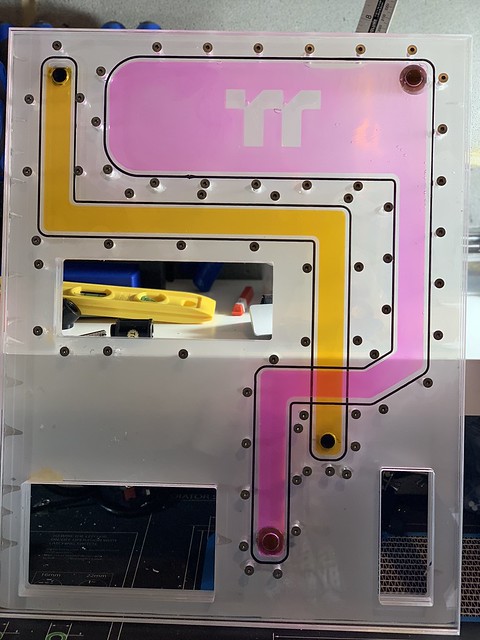

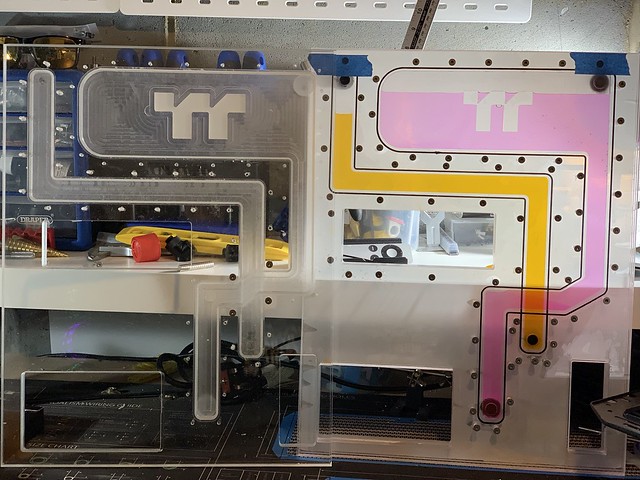

I have attached some drawing below that I submitted for the project, It will have a very clean look to the build. I always like to try new techniques or do something that I have not done in a build before and this build will be no different.

I will be keeping the front and the top of the case stock.

The back, side and the internal of the case will all be modded,

Back and Side

Front and side,

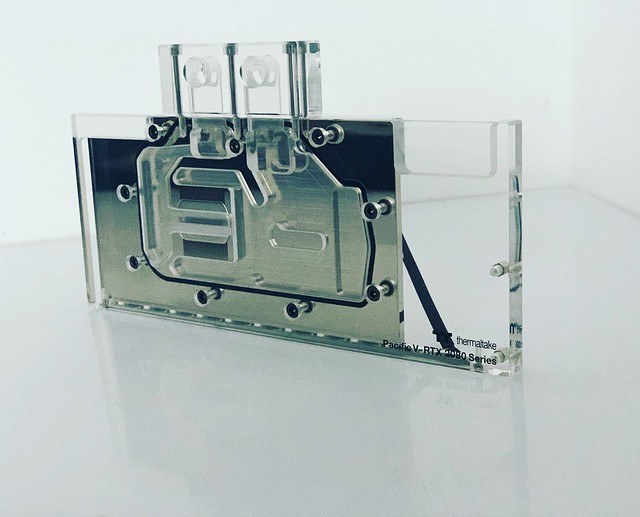

The Hardware,

https://flic.kr/p/MHYSxc

https://flic.kr/p/PBqQRb

I

I

https://flic.kr/p/2amQLag

https://flic.kr/p/PBr6mJ

https://flic.kr/p/PBr7yy

https://flic.kr/p/2amQMaH

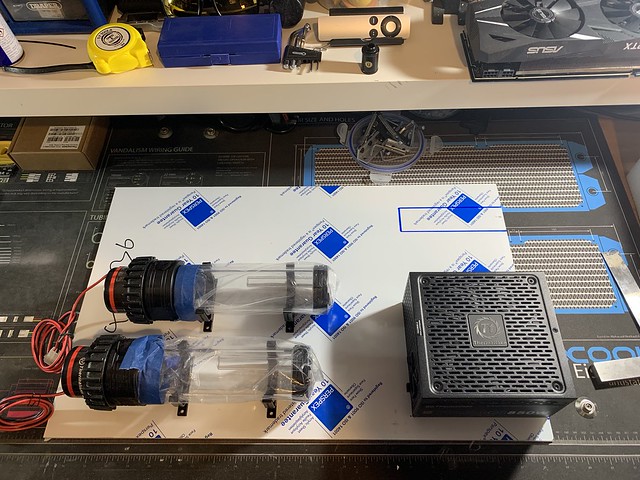

2x Riing Plus 20 fans RGB

6x Riing Plus 12 Fans RGB

TT Premium PCI-E 3.0 Extender

I

IThermaltake also gave us,

Thermaltake Dasher Gaming Mouse mat,

Thermaltake X1 RGB, think I am going to mod this.

TT esports Nemesis mouse RGB

I do have more stuff coming once I have them I will update the build log.

Feel free to comment below.

Thanks Richard.

Last edited:

(I've been looking at the one you have too and follow them on FB.)

(I've been looking at the one you have too and follow them on FB.)