That a wheel builder spends more time building a wheel certainly could be where there is value added. Whether it adds any value I'm not sure but that in itself doesn't necessarily make it a better wheel.

A decent factory wheel manufacturer would have invested money on R&D, using computational fluid dynamics software to optimise aero profiles, use different resins and lay ups on brake tracks to improve braking performance, have test rigs for life testing etc. Of course a wheel builder could have all these things but it costs a lot of money and not something I expect a wheel builder to invest in. A wheel manufacturer yes, a builder no.

A decent wheel manufacturer after spending money on R&D trying to sell a product that differentiates itself from the mass market, I doubt then sells its IP on the open market to wheel builders. Do zipp, reynolds, lightweight or mavic sell their hoops on the open market to wheel builders? They may do I don't know.

There is a huge amount of snobbery in cycling and perhaps I misread it but the part you wrote about "what enthusiast buys a wheel without wanting a particular hub and spokes" smacked of snobbery.

A wheel builder just puts components that are avilable on the mass market together, there is little to no innovation / R&D. It offers customisation for sure and it offers a potentially longer build time whether that yields a better product I'm not convinced.

Hi Bear,

thanks for following my train of thought although some of what you posted does go above my head.

I'm not a wheel guru but a geeky enthusiast who really enjoys time spent out on the open road, I graduated from the life academy of bang-for-buck so the fact you see my posts coming off as snobbish is quite amusing as I spend very little on my cycling "hobby" and always push for the best value. I've been on the saddle for over 40 years and its only the past three years that I've actually become geeky and immersed myself in the "tech" and reasoning behind the cycle.

As I have been mostly happy most of my riding career with the bog standard value factory wheels that come with the bike I have no understanding or interest in the upper end of the market, I don't really even browse any hardware that costs more than £100 so up until making this post I was unaware that the big brands offered wheels for sale that used protected I.P, all the wheels I have ever looked at personally equal the sum of their parts and all the parts can be picked up individually hence why I was questioning the difference between factory built vs hand built.

As mentioned in the O.P the only reason I now have had built wheels is because I wanted silver 700c disk hub wheels. To my amazement I couldn't find the required wheel in Silver? The Cycle industry only provided black wheels (or multicoloured). Am I am snob because I want some control of my steeds colour scheme? Am I a snob because I'm enthusiastic about the hardware that I use in my machine? I don't think so? . . . Is it snobbish to put a nice coloured bar-tape on your bike, to clip on a solar powered radio or to swap out your black tyres for blue ones? I don't think it is but if you want to make a case that any customisation of a machine = snobbery I will indulge you because I am only hear to listen to what other people think as I'm interested to learn.

I've heard of Zipp wheels but from what I have seen the prices are not reasonable to me therefore I didn't scrutinize them or any other high end wheels, up until this thread I was unaware some of the parts of these factory built wheels were not for sale separately, that's interesting and adds something to this topic.

When you state "A wheel builder just puts components that are available on the mass market together, there is little to no innovation/R&D" I'm not sure if I agree, my thinking is that the wheel-builder has so much choice of components at their disposal that it's possible to both "innovate" and perform R&D . . . keeping it simple look at the possibilities below:

- Rims: material, construction, width, size, weight, spoke holes, colour

- Spokes: material, construction, width, size, weight, colour

- Hubs: material, construction, width, size, weight spoke holes, colour, bearings, axel, dynamo

If I'm understanding your viewpoint correctly then we are meant to trust the big wheel companies with their large R&D budgets to mix and match all the possible combinations above and deliver what is just right for you and I? . . .

If this is right I don't agree because its based on the "assumption" that the big companies know better than you or I what our needs our and what is best for us. Have you ever taken part in an extensive MAVIC customer feedback consensus, have you spoke your mind about the wheel with anyone from MAVIC? I'm guessing not but who knows? . . My point is if MAVIC or another large wheel factory don't know what you think is best how can they make a product which fits an individual's needs.

You could argue that they employ hardcore boffins with masters in Classical Mechanics but I wouldn't pay much attention to that line of reasoning as I'm only influenced by actual facts i.e this wheel is better because it was designed by a professor vs this wheel is better because the professor who designed it realised that [xyz technical innovation] improved the [xyz technical barrier].

I am taking the position that MAVIC/ZIPP don't know more about wheels then you or I and that what they are releasing in mainly based on random market research, test results and probably quite a bit of feedback from racing pros but all of this combined does not mean a dedicated wheel-builder cannot "innovate" or perform "R&D"

I remember 16 years ago working with a bunch of fellow computer enthusiasts on this very forum, we were taking products from HUGE corporations like INTEL and modding them, squeezing more power from the product. As a group of unpaid enthusiast overclockers worldwide we were performing R&D, we were innovating and sometimes producing clouds of thick black smoke coming from our machines when it didn't come right but we were cutting edge and were ahead of the "mainstream" by many years

Personally, I don't see any difference between INTEL and MAVIC, although their markets are different in essence they are both technology companies. So if simple but passionate enthusiasts can outperform a tech giant in the world of computing doesn't it stand to reason that a similar bunch of simple but passionate enthusiasts can outperform a tech giant in the world of Cycle-wheel?

My conclusion so far is that the cycle industry is still in the dark ages, innovation is slow and plodding and from my personal viewpoint doesn't offer me the products I want or would like.

When I look at a computer I see both a tool that serves a purpose and also a machine containing a dozen different bits of technology that I can select myself, according to my needs and "wants", conversely when I look at a cycle I see both a tool that serves a purpose and also a machine containing a dozen different bits of technology that I can select myself, according to my needs and "wants" (Ok I could live without silver wheels but I really "wanted" them, they look nicer to my eyes).

I can even say the same principle applies to just the wheel, there is so much customisation possible by mixing the variety of spokes, rim, hubs that I am genuinely surprised that the same smart tech savvy gentlemen who spec'ed, built and overclocked their own personal computers are not just as enthusiastic about "over clocking" their cycles, spending time to understand the hardware and the basic principles of classical mechanics to experiment, innovate and just eek the extra performance.

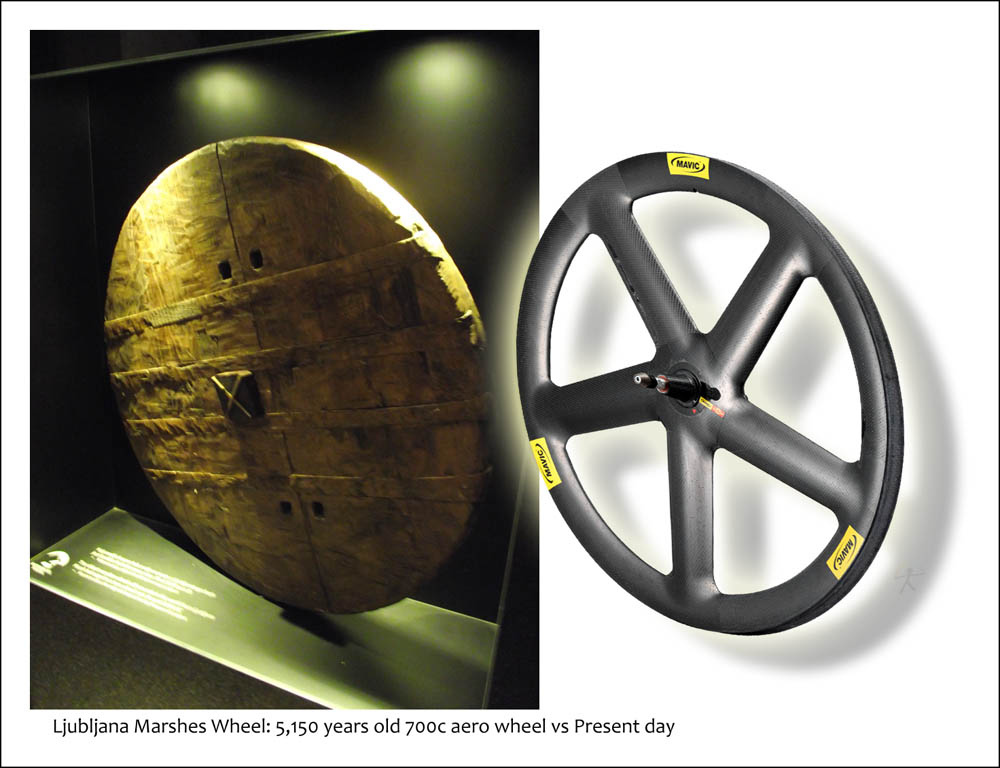

The wheel is the principle technology in cycling so it's an obvious target for innovation but innovation is so damn slow in the world of cycling, look at how far the mainstream wheel has evolved in over 5,000 years

I think personally the wheel is very interesting and I've learnt enough basics to actually physically alter my machine so am able to cycle faster and further. The same curiosity that made me tinker with my computer, get under the hood, changes voltages etc is exactly the same curiosity that makes me pull my hubs apart to service the cones, experiment with different bearings, spokes, spoke count (and colour!), rim width, construction, material, all the while the main focus is actually using the cycle for the beautiful hobby we all enjoy while trying to keep my money in my pocket.

From the limited feedback I have received so far it seems a number of you are just plain not interested, or have your consumer needs met just fine by the factory wheel manufacturers.

I want all of you who haven't already done so to consider having a hand-built wheel next time you're in the mood for an upgrade, after you look at the bog standard wheels on offer from the factories I want you to think about your perfect wheel and look at the price of the parts. If anyone intends to spend more than £300 on a wheel I would be grateful if you could explain your reasoning behind this.

If any of you have useful feedback about stock factory wheels that you have owned I'd be interested to learn from your insights (good or bad) . . . If any of you have useful feedback about wheel technology I'd be interested to hear about it.

So in summary, this is my current position:

- Some people think owning or talking about a hand built wheel is snobbish

- Some people just buy factory wheels because they "like the brand and that's all there is to it"

- Some people assume a hand-built wheel equals expensive ££££

- Some people assume the product being released is the best possible product

- Some people assume a hand-built wheel gets more craftsmanship time

- Some people assume a wheel warranty is useful when a spoke breaks in the wilderness

- Some people assume the factory hand-check and finish is equal/better than a good wheel builders hand-check and finish

If you are asking me my own question I would say a hand built wheel would likely get a little more workmanship time, assuming both ho-lee-sheet in the mavic factory is the same skill level as bob-the-wheel-builder

If you are asking me my own question I would say a hand built wheel would likely get a little more workmanship time, assuming both ho-lee-sheet in the mavic factory is the same skill level as bob-the-wheel-builder