You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Which brand tubing do you use?

- Thread starter OptimaLnrg

- Start date

More options

Thread starter's postsupdate after working on loop at the weekend i can now definatly see sign of dicoloration one the masterkleer tubing, so ive ordered xspc to replace it all with lets hope that does the trick weird as the masterkleer seemd to hold up well originally i wonder if its because the system has beena little hotter over the last couple months and its reached its leach point ? anyway will see how the xspc goes and update again

I am currently running:

masterkleer - on the pump/res/rad assembly -> QDC fittings

ClearFlex60 - from the cpu block out of the case -> QDC fittings

The masterkleer has developed a very very faint yellow discolouration. this can't be seen with my coolant in it. I think this actually developed while I was running distilled only.

The masterkleer is much easier to route than the clearflex. By that I mean the clearflex kinks long before the masterkleer does.

The clearflex has stayed completely clear so far.

Downside to the clearflex is the blue writing on it, but as my coolant is blue you can barely see it

masterkleer - on the pump/res/rad assembly -> QDC fittings

ClearFlex60 - from the cpu block out of the case -> QDC fittings

The masterkleer has developed a very very faint yellow discolouration. this can't be seen with my coolant in it. I think this actually developed while I was running distilled only.

The masterkleer is much easier to route than the clearflex. By that I mean the clearflex kinks long before the masterkleer does.

The clearflex has stayed completely clear so far.

Downside to the clearflex is the blue writing on it, but as my coolant is blue you can barely see it

Associate

- Joined

- 10 Jan 2012

- Posts

- 2,375

Currently using alphacool HF

It has a much better bend radius than masterkleer but its harder to get it onto the barb and tighten the compression fittings.

It has a much better bend radius than masterkleer but its harder to get it onto the barb and tighten the compression fittings.

Soldato

Dont know if i should try Thermochill or just stick to Tygon for my build ??

Any advice mlwood37 ?

Any advice mlwood37 ?

Don

I always used to find Tygon would go cloudy, much the same as Masterkleer seems to be doing now. Think it's only about ClearFlex that left that still produces decent quality tubing?

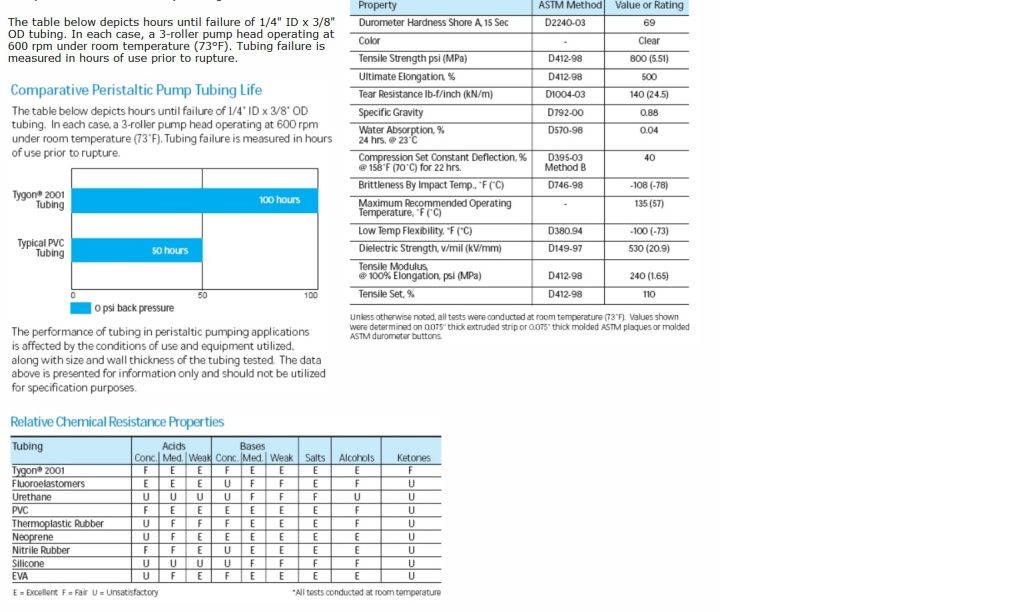

here just found this

TYGON® 2001 Plasticizer Free Tubing 1/2in. ID x 3/4in. OD AE300038

Product Description & Info

Superior Performance in a Broad Range of Applications

Tygon® Plasticizer Free Tubing is uniquely engineered to provide flexibility, chemical

resistance and extended pump life in a clear, plasticizer/oil free tubing product.

It is ideal for a broad range of demanding applications including peristaltic pump

systems, soap and detergent dispensing, ink transfer,water purification lines,

food and beverage and chemical transfer.

Outperforms PVC in Chemical Resistance

Tygon® Plasticizer Free Tubing is resistant to a wide range of fluids that typically

destroy PVC products. Its chemical resistance allows it to be used in applications with

aggressive chemicals such as polar solvents, benefiting the user with less downtime

and tubing changes. Tygon® Plasticizer Free Tubing yields a longer service life and does

not degrade over time, unlike other flexible tubing products (see “Relative Chemical

Resistance Chart” on back of sheet).

Additional Product Features

Upon incineration, many tubing products release hazardous by-products such as

hydrogen chloride gas, but when properly incinerated, Tygon® Plasticizer Free Tubing

does not. Since it contains no plasticizers or oils, Tygon® Plasticizer Free Tubing will

not yield any taste, which makes it an ideal choice for food and beverage applications with

strict taste requirements and will help ensure accurate results from analytical instrument

tests.Tygon® Plasticizer Free Tubing fully complies with FDA 21 CFR, 177.2600 criteria.

Features and Benefits

• Plasticizer and oil free—does not contaminate fluids

• Superior flex life in peristaltic pumps

• Chemically resistant to a wide range of fluids

• Temperature resistant from -108°F to 135°F

• Clear for easy visual flow monitoring

• Meets FDA criteria for food contact

Typical Applications

• Chemical transfer

• Peristaltic pumps

• Soap and detergent dispensing

• Ink transfer

• Water purification lines

• Food and beverage

• Analytical instruments

• Ideal for condensers, incubators, desiccators, gas and drain lines

TYGON® 2001 Plasticizer Free Tubing 1/2in. ID x 3/4in. OD AE300038

Product Description & Info

Superior Performance in a Broad Range of Applications

Tygon® Plasticizer Free Tubing is uniquely engineered to provide flexibility, chemical

resistance and extended pump life in a clear, plasticizer/oil free tubing product.

It is ideal for a broad range of demanding applications including peristaltic pump

systems, soap and detergent dispensing, ink transfer,water purification lines,

food and beverage and chemical transfer.

Outperforms PVC in Chemical Resistance

Tygon® Plasticizer Free Tubing is resistant to a wide range of fluids that typically

destroy PVC products. Its chemical resistance allows it to be used in applications with

aggressive chemicals such as polar solvents, benefiting the user with less downtime

and tubing changes. Tygon® Plasticizer Free Tubing yields a longer service life and does

not degrade over time, unlike other flexible tubing products (see “Relative Chemical

Resistance Chart” on back of sheet).

Additional Product Features

Upon incineration, many tubing products release hazardous by-products such as

hydrogen chloride gas, but when properly incinerated, Tygon® Plasticizer Free Tubing

does not. Since it contains no plasticizers or oils, Tygon® Plasticizer Free Tubing will

not yield any taste, which makes it an ideal choice for food and beverage applications with

strict taste requirements and will help ensure accurate results from analytical instrument

tests.Tygon® Plasticizer Free Tubing fully complies with FDA 21 CFR, 177.2600 criteria.

Features and Benefits

• Plasticizer and oil free—does not contaminate fluids

• Superior flex life in peristaltic pumps

• Chemically resistant to a wide range of fluids

• Temperature resistant from -108°F to 135°F

• Clear for easy visual flow monitoring

• Meets FDA criteria for food contact

Typical Applications

• Chemical transfer

• Peristaltic pumps

• Soap and detergent dispensing

• Ink transfer

• Water purification lines

• Food and beverage

• Analytical instruments

• Ideal for condensers, incubators, desiccators, gas and drain lines

Don

Ooo, that stuff could be interesting.

Associate

Does any1 know if Clearflex 60 is available in 1/2" ID and 3/4" OD suitable for compression fittings?

Any benefit of going 3/4" OD anyway?

Any benefit of going 3/4" OD anyway?

Associate

How come OD ads to flow and volume of water?more flow and volume

Soldato

- Joined

- 30 Nov 2011

- Posts

- 11,381

How come OD ads to flow and volume of water?

ID adds volume to the system purely by containing more water, it won't add flow if you already have adequately sized tubing for your system - e.g. if you go from 10mm ID to 13mm ID you shouldn't notice a difference... if you go from 6mm ID to 13mm ID you might

OD is mostly down to looks and bend radius / kinking

some people like big fat sausage tubing

thinner walled tubing will bend easier but also risks kinking, big tubing will be more resistant to tight bends but also won't kink as easy

Last edited:

Associate

Sorry, I'm still confused.

We have 1/2" ID and either 3/4" or 5/8" OD... so we only change tuning thickness... how there would be more water if ID hasn't changed?

We have 1/2" ID and either 3/4" or 5/8" OD... so we only change tuning thickness... how there would be more water if ID hasn't changed?

Soldato

- Joined

- 30 Nov 2011

- Posts

- 11,381

Sorry, I'm still confused.

We have 1/2" ID and either 3/4" or 5/8" OD... so we only change tuning thickness... how there would be more water if ID hasn't changed?

ah, no, craarc went from tiny tubing to 13mm ID... if you only change OD there's no change in volume or flow

by od being bigger i meant going from small bore to larger bore maybe i should have said id but 13/19 is better than 11/16 or what ever as andybird123 said

just increasing the wall thickness wont increase flow ofc....

ive gone from 10mm od and 6mm id to 19 and 13 so a huge diference in flow and volume ability id try 19mm id or more if there were fittings and blocks that would take it

just increasing the wall thickness wont increase flow ofc....

ive gone from 10mm od and 6mm id to 19 and 13 so a huge diference in flow and volume ability id try 19mm id or more if there were fittings and blocks that would take it

for those having this plastersizer problem check you water temp i bet it has gone over 35c at some point.....

Mine will have with the primochill as I was running passive