Associate

- Joined

- 1 May 2017

- Posts

- 16

Hello Overclockers UK Community and welcome to my project "Baby Blue".

Those who know and follow me already might think, "hey, i know this project" and you're right. This is my second attempt on this project since i lost my motivation and needed to start it new. The main reason for this is that i messed up a few things because i lacked experience with the tools i used. I then tried to fix all these problems but never was really happy with the results which was a bit depressing. So after a long time i decided to draw the line and begin new. I'm already pretty good with this tools right now but i will choose another way this time.

Idea:

I will keep the idea for this project. For everyone who sees this project for the first time: I want to build a "Breaking Bad" themed ITX system. The name of this build origins from the song played in the last scene of this amazing show (Badfinger - Baby Blue (Breaking Bad Soundtrack) (HQ) 1080p - YouTube). This means i'm going to use different elements from this show in my build. I want the inside of the case look like a lab using metal, a stainless steel Reservoir like the big reaction vessels in the superlab, soft tubing with crystal blue coolant and more. All in all, it will look pretty industrial. On the outside there will be symbols and stuff, things you know when you watched the show, but not made of simple decals or stickers. I want to make it look really cool.

Case:

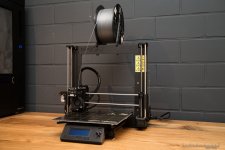

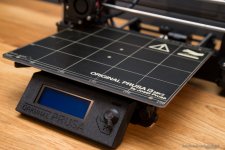

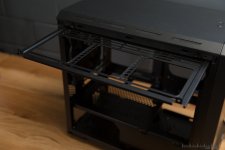

What really annoyed me on my first attempt was the case. It was the Jonsbo U2, it's a cool case but not for this mod. All the time i thought i had to fit everything inside this little case and eventually forget that this wasn't the goal for this project. Of course i don't want to use external cooling on an ITX build but the U2 was just too tiny. So i decided to get a new one and chose the Phanteks Enthoo Evolv ITX since i really enjoyed working with the ATX version. I just love the design and the features it offers.

For an ITX Case it's really spacious without being to big.

One of the features i really love, the removable radiator mount. I'm going to put the fans for the top radiator inside the top. Saw this a few times now and it seems to work.

Will be really tight but it fits. On the back i used an 140mm case fan from the ATX version. I love the simple look and it does its job.

Hardware:

The hardware i'm using isn't the newest but it is more than enough for 1080p gaming.

CPU: Intel Core i5-6600k

MB: ASUS Z170i Pro Gaming

GPU: ASUS RX480 8GB

RAM: 2x8GB G.Skill Ripjaws V

SSD: Crucial MX300 525GB M.2

PSU: Silverstone Strider Gold 550W

I got the board last year from ASUS and going to mod this one to fit the rest, no red allowed in here.

I already installed the RAM modules but i'll take these off again. The black doesn't really fit.

Cooling:

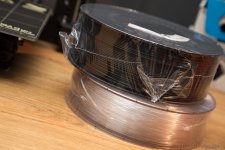

Since the whole build will be watercooled Aquatuning Germany / Alphacool sent me a big package full of stuff.

Unbelievable what's going inside this little build.

Really love the look of the Eiszapfen series, simple and shiny.

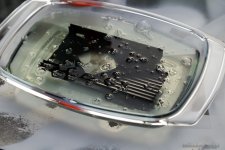

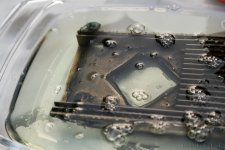

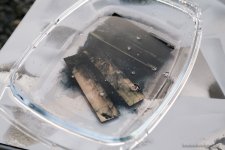

Let's head over to the reservoir. This one is from my first attempt and it was custom made. I did the drawing and went to a metalworker. It is made of stainless steel like the big reaction vessels in the superlab. To keep it waterproof i used sealing compund (i hope this is the correct word) and a flange to keep it together.

For the CPU i'll be using the Eisblock XPX and for GPU the GPX from Alphacool.

I chose 2 240mm ST30 full copper radiators, enough to keep it quiet and cool without having a fat radiator blocking the view on the rest of the inside. The fans are NB-eLoops from Alphacool, the color doesn't matter cause you won't see them later.

I will make the cables myself and use the new Eiskamm cable combs.

CAD:

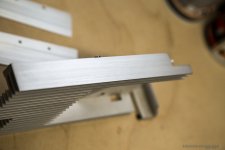

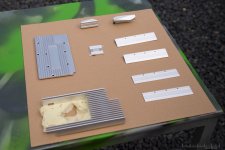

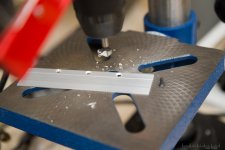

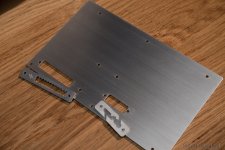

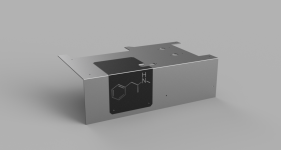

This time i don't want to mess up again so i'm using other methods, methods with which I am more familiar. Since i use CAD for my studies and know some people with a CNC milling machine, why not use this to my advantage. Some people say this has nothing to do with modding, but as long as these ideas and drawings are made by me i think it's still modding, just another kind of it. Of course i'm going to do more than just this but i had to start somewhere. I can guarantee you i have to use my dremel for this project more than once. The pieces will be milled and edged by Gosumodz.

Let's stop talking and take a look at the first pieces i planned. The inside will get a new PSU Cover made of aluminium, this will not replace but only cover the original PSU Cover and will make the inside look way cleaner. The small darker piece is a standalone piece of aluminium, i made it darker for the rendering to make it more visible but i really like it this way, maybe powdercoat it black? We'll see. The chemical formula of Methamphetamine will be backlit later.

The next part is a tray for the reservoir and functions as passthrough for the 24Pin ATX und the front panel connectors. There are also a few combs for tubing and cables which will be mounted to the tray and PSU Cover.

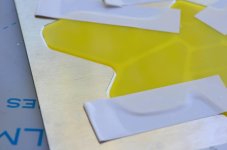

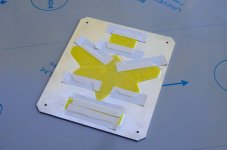

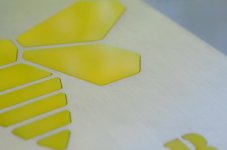

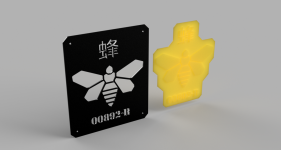

On the front of the case i want to have the "Golden Moth Chemical" Logo, the "yellow bee" that is printed on the Methylamine barrels. As i told you i won't use decals for this, so i designed an inlay consisting of a powder coated aluminium cover and yellow acrylic. This will also be backlit.

I really hope you like my idea and please let me know if you have tips or suggestions for improvement.

A big thanks to my sponsors for trusting in me and supporting this project!