Ok, so why am I constantly whining about how much of a pain it is to wire up these RGB LEDs? I'll try to explain....please leave your sanity by the door

First, you take a bag of 4-pin 5mm RGB LEDs. To work with the Farbwerk - which usually uses RGB LED strips (as opposed to singles) - you need common anode RGB LEDs. This means the 4th pin (or 2nd, if you want to be positional - they're wired R+GB) is a shared positive pin. ALL the RGB LEDs you can buy in this country (I searched quite a few places and found none) are common cathode - the shared pin is negative. So, from China with love, you eventually get a bag of 100....cos I anticipated mistakes

You need (for these particular spec LEDs) a 510 Ohm resistor for Red and 430 Ohm resistor for each of Green and Blue. I'd planned to wire them in series but because there is a common pin, you can't. So you need three resistors per LED - you can't share them with LEDs run in parallel off them because you end up with different brightness LEDs....also, that'd be far too easy *sigh*

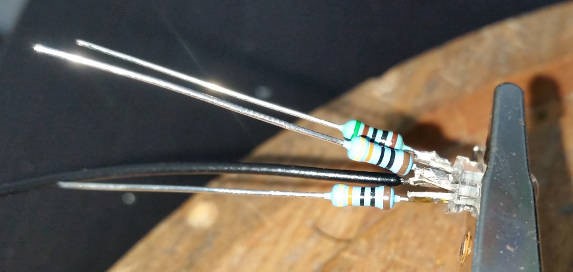

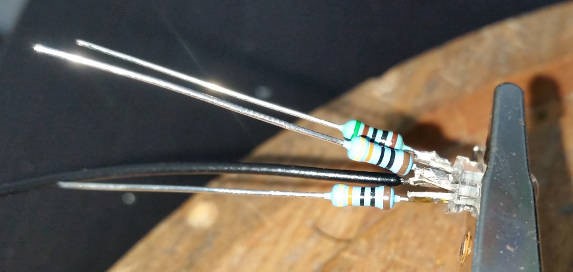

So, I've snipped down the pins to a more manageable length. I've left one longer because I need the whole package to fit down the conveniently deep holes in the bottom of the res so one resistor is going further back to make it slimmer. Pins are then bent alternately forward and back just to make it easier to solder onto them.

Resistors soldered directly onto the LED pins. From the top that's Red (bent up), + (bent down), Green (bent up), Blue (bent down). The resistor for the red is a different value as shown by the different bands - the entire body is actually a different colour but doesn't show up in these high quality pics

Next solder an excess of wire onto the other side of each resistor - trimming the lead short first. The shared positive had a wire directly onto it as it doesn't need its own resistor. Heatshrink over the top to cover both solder joints and the exposed pin - don't want these shorting out when they're next to impossible to get to. 1.5mm heatshrink from a blue highstreet component shop fits very nicely. 1.6mm from RS, does not

Next, you have to carefully arrange and join all three Red wires, +ve wires, Blue wires and Green wires....I would have made it easier for myself if I'd got wires in each those colours...but clearly I suffer from some form of advanced masochism! The left is before, the right is after.

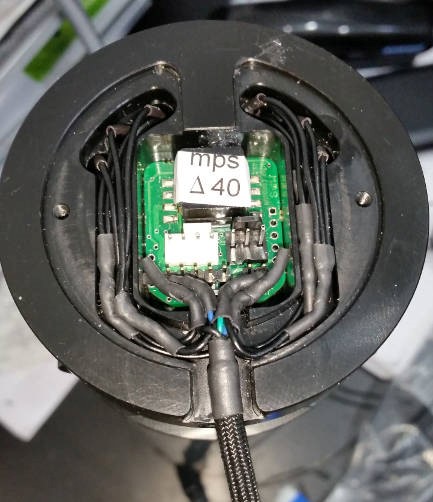

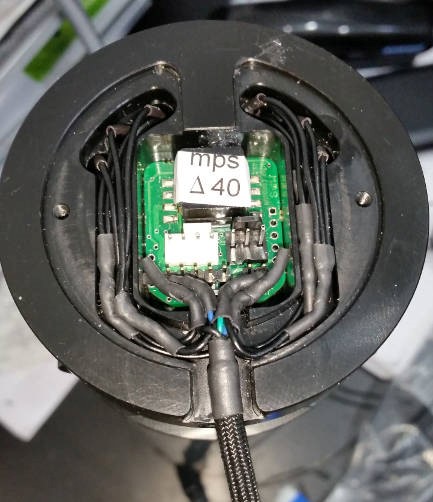

The two sides then had to be joined together and then soldered onto the cable that goes to the Farbwerk. THIS is what stuffed truly means

I did bend the ends more so they weren't in the way of the pins....just after I took the pic, naturally. There was a fair amount of swearing by this point anyway....especially as I'd found out half way through joining the second bank of three that I'd managed to swap the red and blue channels of one LED and had to carefully cut off the heatshrink and re-solder a longer wire back onto one pin.

And....finished. It's like having to sit on your suitcase to get it shut

Currently the res is on what's left of my pressure tester (it threw itself off the desk somehow and now reads 2psi before you start) because I had to open it up and clean off a ring of some sort of residue - like scale or something.

Will get action shots tomorrow once it's all filled

Now, you have some idea why my sanity is rapidly failing me

don't want aluminium powder in my house and I have no lights outside.

don't want aluminium powder in my house and I have no lights outside.