Alright, some overdue updates. I did loosen the pump mounts but I also marked up the chamfered end of the tube with a red peranent marker - yeah, I know it should have been green!

Found that actually what I'd marked in the picture above was the edge of the groove the o-ring sits in and the glass was actually seated properly.

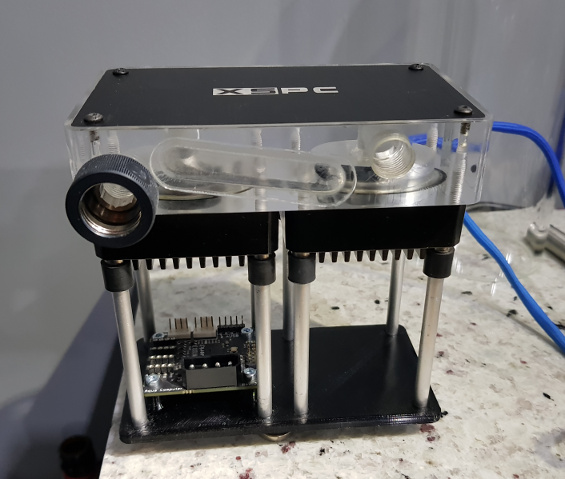

So, I pressure tested the half-loop (rad not connected) and it seemed good. A little drop of pressure (0.8 psi over night) but my res does seem to do that and not cause problems - I suspect the fill-level sensor is the culprit as that's effectively a hole in the bottom of the res with a pressure sensor bunged into it. Encouraged by that, I attached the rear door with its mounted rad, moved all the EPS cabling that I'd run through a convenient hole and been blissfully unaware that space would be fully taken up by the fitting on the top of the rad. Pressure tested again and all good so off we go.

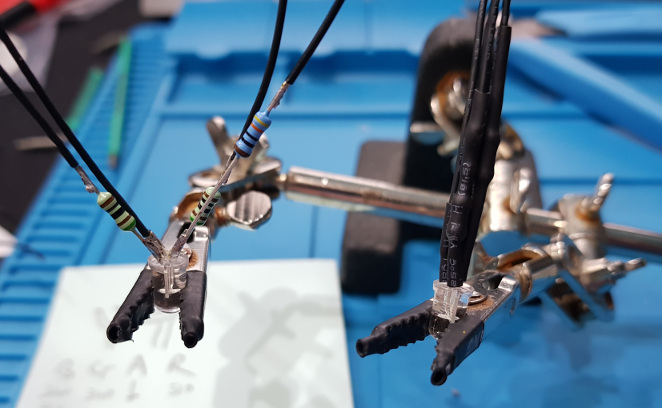

Filled her up with two litres of fresh EC6 Clear. I'd got some sealed containers from before but they'd gone first-wee-of-the-morning orange (available from all good paint stockists!) and I didn't fancy that. Two litres in and res only 1/3 full so I've got another on order. Aquaero alarmed fairly quickly that Pump1 was not spinning. It was, I could hear it. After ignoring it for a while (2nd pump did its job nicely - and this is why they are in series) I speculated that I'd snapped one of the wires at the pump when I'd trained it downwards and envisioned having to strip the entire loop to remove a pump and resolder - yes, a drain on the cards already; what fun!

Then I wondered if, when I shortened the wires, I could have been stupid enough to swap the blue and green (PWM and tacho) wires over - that would explain why it was running at full speed (by the sound) but reporting zero rpm. Yup, turns out I was that stupid.

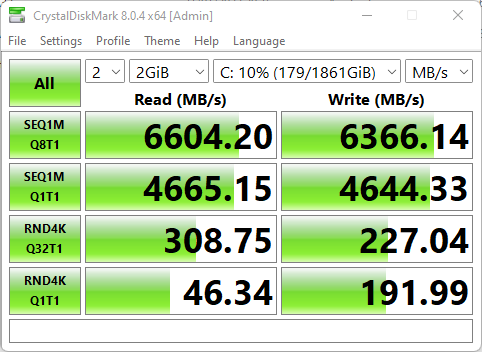

Updated the bios to support Windows 11 - got to bite the bullet sometime so while I have an empty disk seemed like a good time. CPU at stock as the RAM on XMWorked out the necessary hoops to get the Secure Boot, TPM and RAID0 for the two M.2 NVME drives. Got Windows 11 setup running and navigated the similar hoops to get it to recognise the RAID set (You need the right pair of drivers in the right order for AMD it seems). Updated Windows 11...and again...and again. You'd think it wasn't really finished yet! Ran Crystal Disk mark and got 6681 MB/s read and 6576 write. That’ll do very nicely

Pair of 1TB Samsung 970 Evo’s on Black Friday. Wasn’t any point in going for pricier PCI-E 4 sticks when I don’t have it!

Then Windows threw a BSOD, then Firefox crashed, the Aquasuite crashed repeatedly. Looks like my RAM that's spec'd for 3733MHz couldn't handle 3466MHz (I went with the lower of the two XMP profiles). I'd suspected this as I'd had stability issues running XMP on the last board but thought it might have been the board. I've dropped it to 3200 and it seems to be stable so far but I might see if OCUK will warranty them.

So crashing sorted (sort of) I changed the LEDs back to a blue-red temperature spectrum now that the blue channels aren't all blown and also dimmed them to 40% - which isn't as dim as it sounds but takes the edge off - in the hope of them lasting longer. Shut down and went to bed. This morning, I was going to write this post from the 'new' system....and then I noticed that sound that sounds disturbingly like someone taking a really long leak (res set for fountain and only 1/3 full), had stopped. Looked down and the res is empty. Turned her off, knelt down to check what was happening...and got a wet knee. Somehow the fitting for the pump inlet was noticibly loose - not wobbly but definitely a larger gap between the end of the fitting and the block than there should have been. So this morning has been wet-vac'ing the carpet, drying out the bottom of the case, doing that fitting back up with long nose pliers and then touching up the black paint where it had scuffed it - couldn't face dismantling half the loop to do it by hand. I can only assume that I hadn't fully tightened it when I was working out the complicated chain of fittings that go from the res to the pump. Passed a pressure test and a water test though.

So now I'm offline until the coolant arrives - probably tomorrow - as there's not enough in the res to run it. Once it passes another pressure test, of course

A long time ago when I was starting water-cooling and trying to decide on a coolant colour, a friend of mine wisely said (deadpan, too) "What colour stain would look best when you screw it up and it leaks all over your carpet?". The resulting clear, colourless coolant choice is one I've stuck to ever since. Cheers Fish!

Thoroughly hoovered out afterwards so lets hope that doesn't bite me in the arse later. So the result:

Thoroughly hoovered out afterwards so lets hope that doesn't bite me in the arse later. So the result:

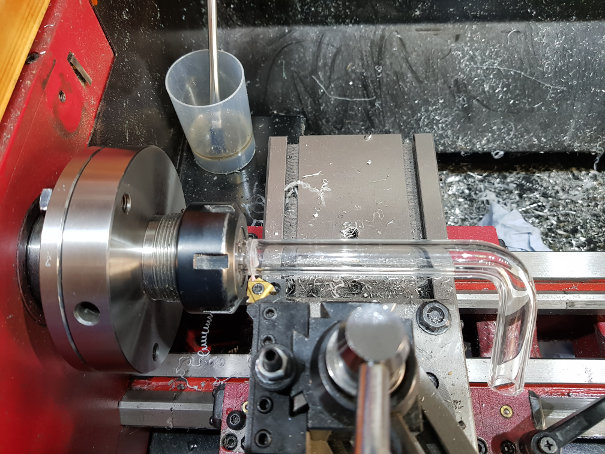

Those two sections will be replaced with one pre-bent piece similar to the GPU-CPU link so there will only be the one elbow in there. I didn't fancy trying to free-hand bend by blowtorch for my first go!

Those two sections will be replaced with one pre-bent piece similar to the GPU-CPU link so there will only be the one elbow in there. I didn't fancy trying to free-hand bend by blowtorch for my first go!

If you apply a drop of water to the diamond wheel as it's spinning, you can see glass dust (and presumably water mist) burst in all directions....so yeah, no mask would be a bad plan for long-term staying-alive!

If you apply a drop of water to the diamond wheel as it's spinning, you can see glass dust (and presumably water mist) burst in all directions....so yeah, no mask would be a bad plan for long-term staying-alive!

For a change, the coolant didn't leak anywhere, it all stayed put. The usual noise whilst the bubbles went through the pump....only it didn't stop when the bubbles had gone down. It did stop when I unplugged (only) pump 1. It didn't stop when I unplugged (only) pump 2. And it was a sharper, louder sort of ticking that it should be. Eventually I came to the conclusion that when the fitting on the pump inlet leaked, it must have broken part of the acrylic thread and that was what was trapped in the pump and making a hideous noise. I'll confess that I did contemplate running it just on the other pump to avoid the inevitable drain within an hour of filling it but no.

For a change, the coolant didn't leak anywhere, it all stayed put. The usual noise whilst the bubbles went through the pump....only it didn't stop when the bubbles had gone down. It did stop when I unplugged (only) pump 1. It didn't stop when I unplugged (only) pump 2. And it was a sharper, louder sort of ticking that it should be. Eventually I came to the conclusion that when the fitting on the pump inlet leaked, it must have broken part of the acrylic thread and that was what was trapped in the pump and making a hideous noise. I'll confess that I did contemplate running it just on the other pump to avoid the inevitable drain within an hour of filling it but no.