- Joined

- 13 Mar 2006

- Posts

- 6,712

Sorry to be the bearer of very sad news for you matey.

R.I.P. Waynio

Hi guys, this is Wayne’s brother, Mark. Wayne regrettable passed away surrounded by his family on the 2nd of Feb from a rare, aggressive and...forums.bit-tech.net

Thanks for letting me know - that's terrible news, and I wish he were here to see the project get finished as he was really enthusiastic when it was started many years ago and wanted to see it completed! Whenever I spoke to him he came across as a really decent guy - helpful, friendly and passionate about modding (and very talented to boot!). Very sad to hear that, he passed far too soon.

Last edited:

YouCut_20221225_222010169

YouCut_20221225_222010169

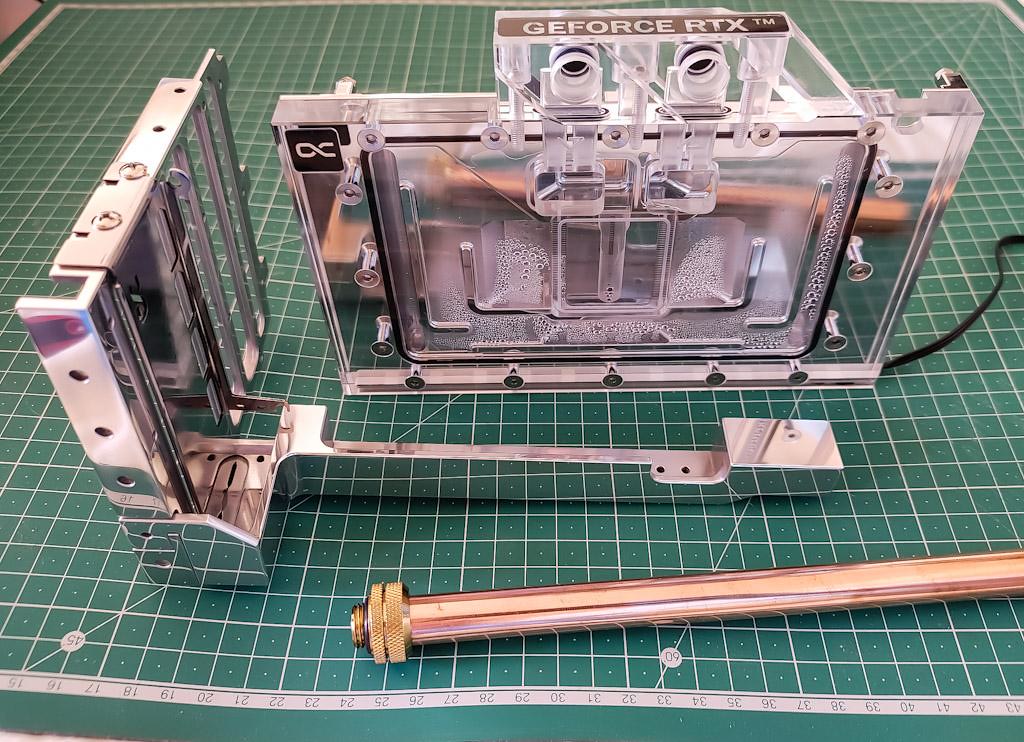

20230102_224607_HDR

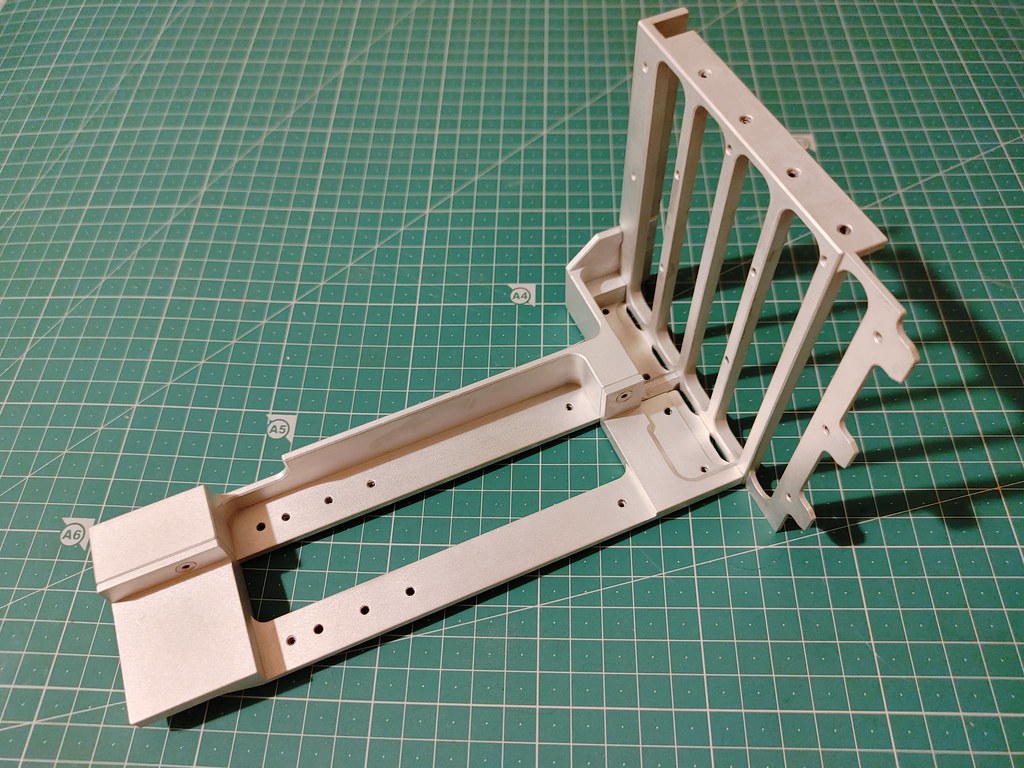

20230102_224607_HDR 20230105_154119_HDR

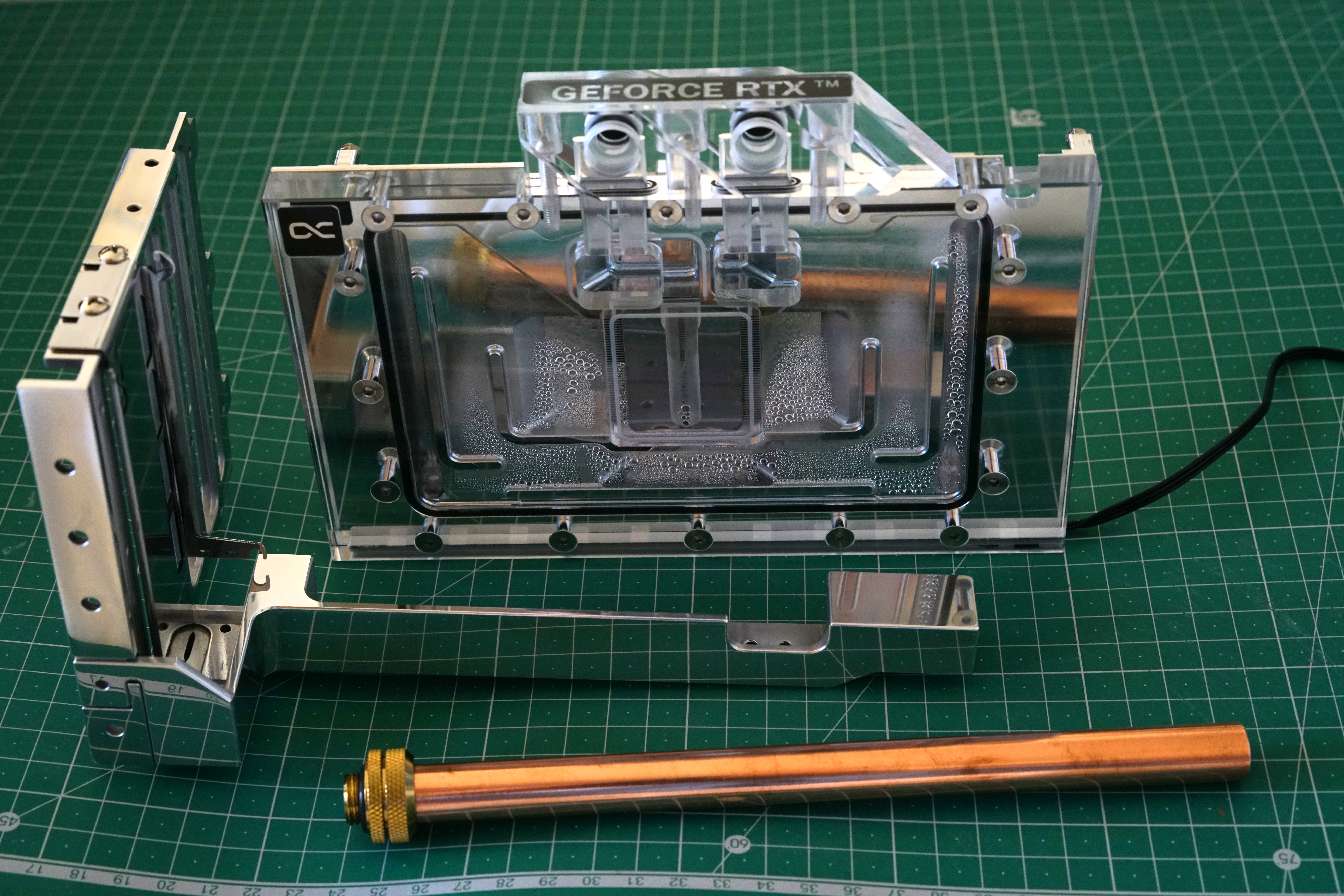

20230105_154119_HDR 20230105_154148_HDR

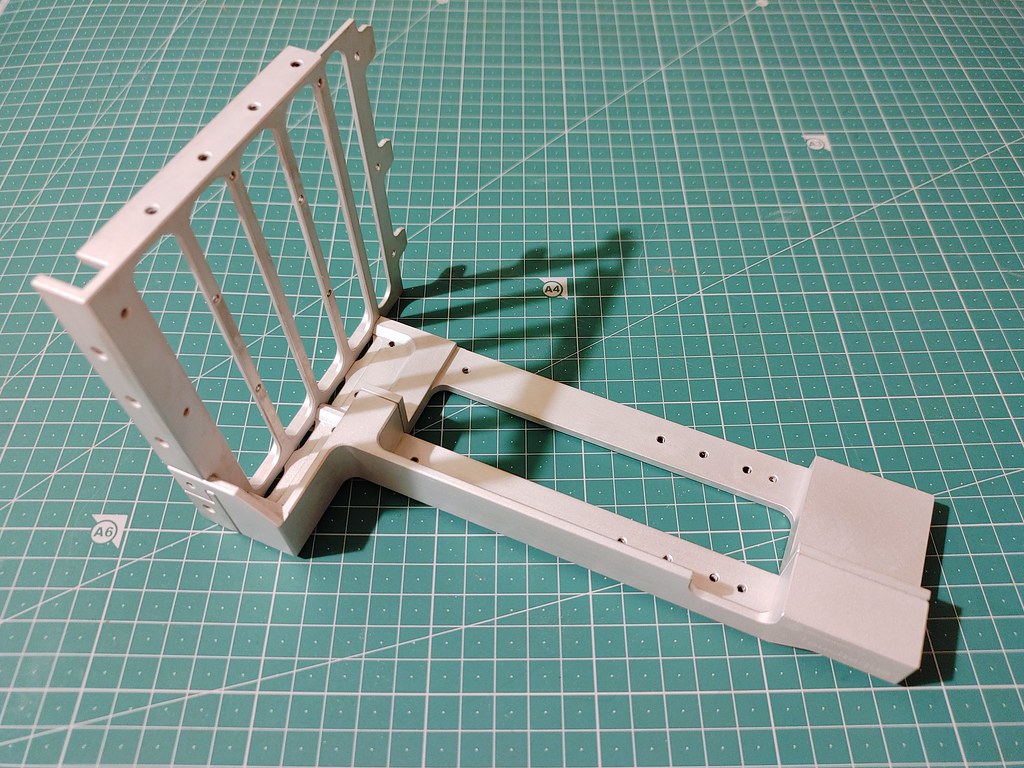

20230105_154148_HDR 20230105_200749_HDR

20230105_200749_HDR 20230105_200727_HDR

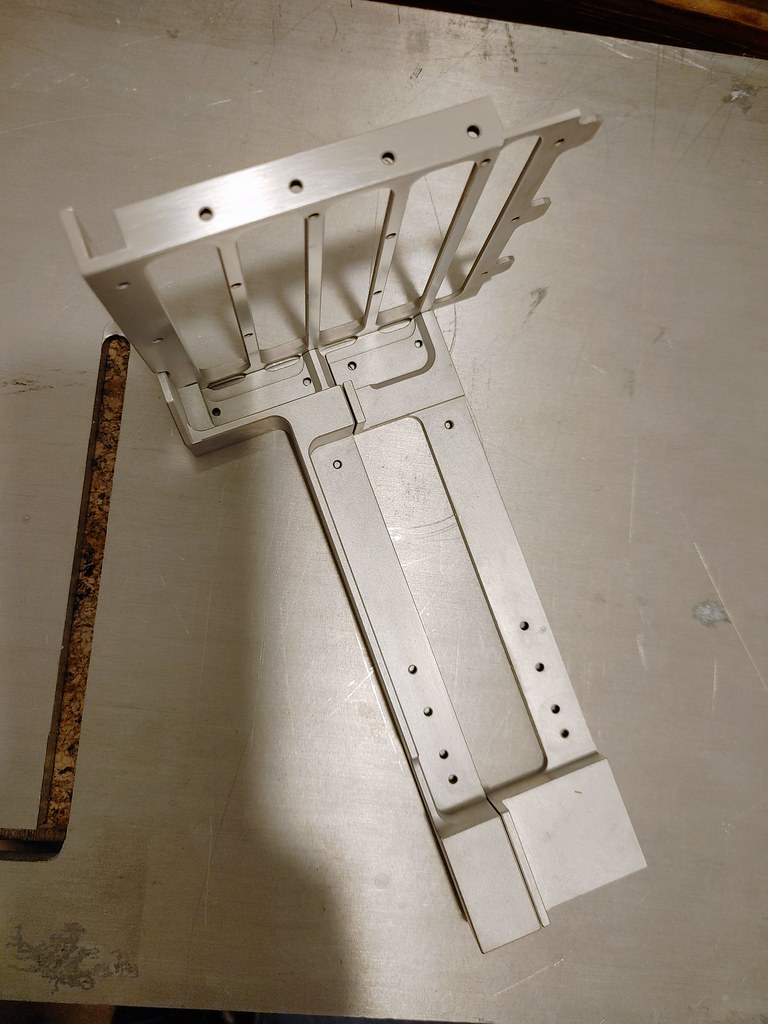

20230105_200727_HDR 20230213_232438_HDR

20230213_232438_HDR 20230213_215105_HDR

20230213_215105_HDR 20230213_232417_HDR

20230213_232417_HDR 20230213_215048_HDR

20230213_215048_HDR 20230226_165447_HDR

20230226_165447_HDR 20230225_163211_HDR

20230225_163211_HDR 20230225_163149_HDR

20230225_163149_HDR 20230326_123800

20230326_123800 PSX_20230407_182333

PSX_20230407_182333 20230407_173335~2

20230407_173335~2 PSX_20230407_182857

PSX_20230407_182857

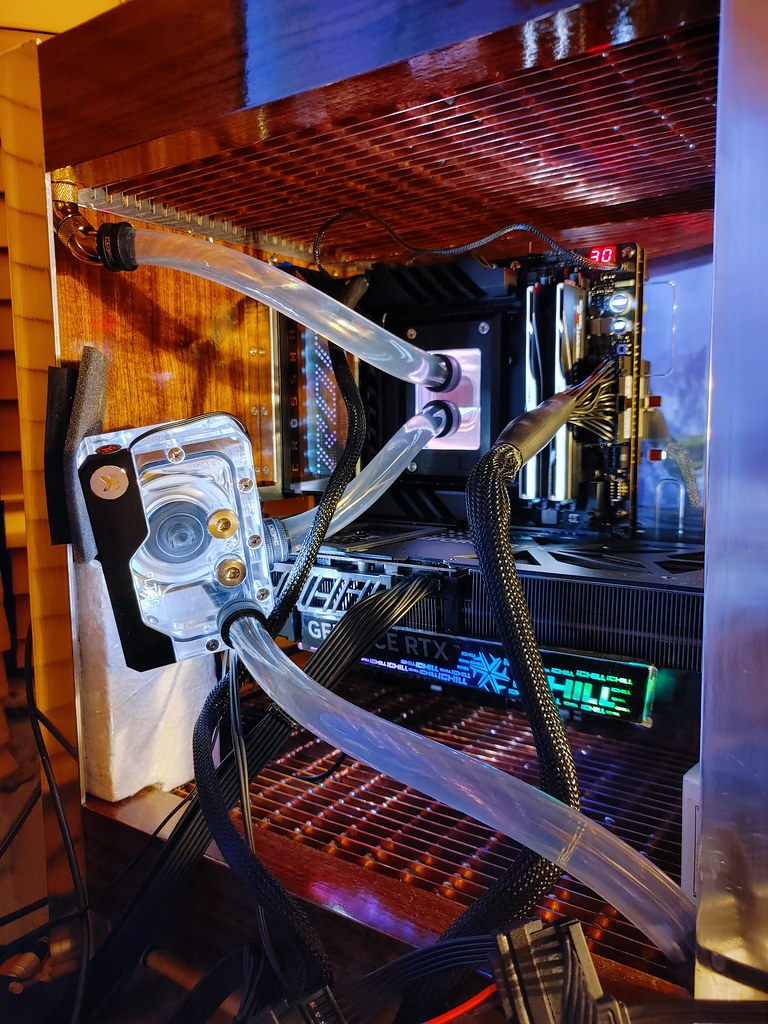

20230410_194342_Edited

20230410_194342_Edited