Ok, some semblance of sanity has returned and I've actually got a *spoilers* functioning PC again. eSATAp ports fitted and working. Even found the long eSATAp cable I was convinced I had but couldn't find.....after I'd ordered a replacement, obviously!

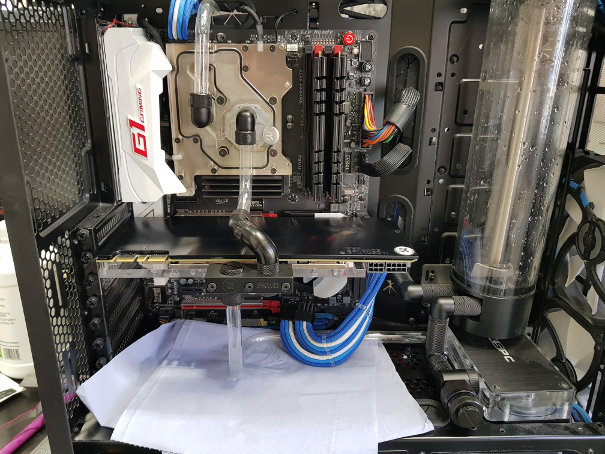

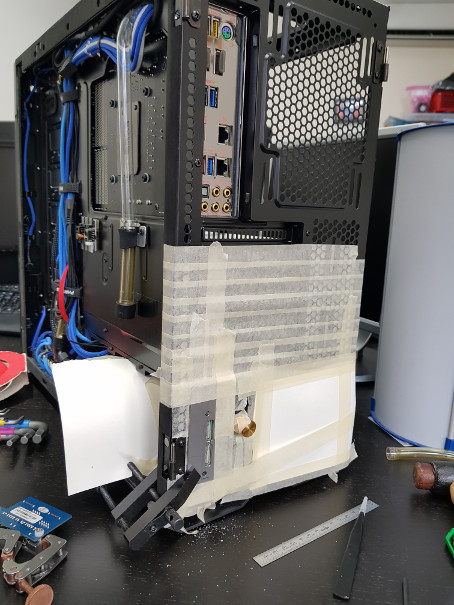

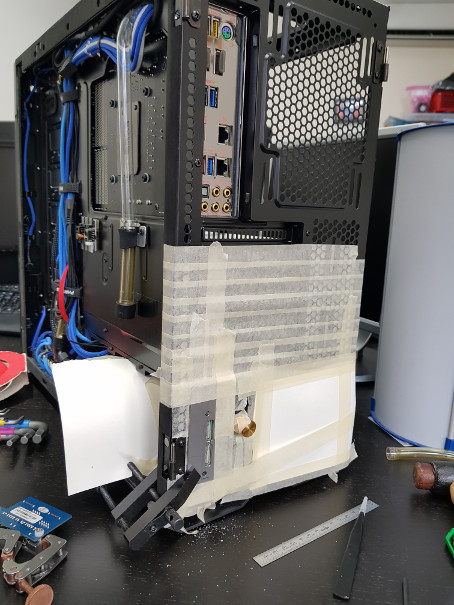

So, to cut chunks out of your case, you should obviously first remove all electronics because the swarf (metal filings) will conduct and short circuit things that could be expensive. So, with that in mind, I masked everything up, cut it, hoovered out well and prayed! Do as I say, not as I do does seem to be the mantra of the times, no?!

New filing template was made out of 2mm stainless steel. Did it need to be stainless? Nope, but that's what I had. Clamped and taped it on in an insufficient fashion, drilled out the two holes and then bolted it on properly!

Drilled out the bulk of the rectangles, joined the holes with a Dremel and a carbide burr and then filed until I'd got this:

Painted the edges and screwed in the module:

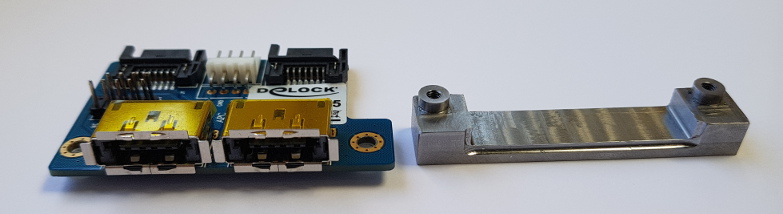

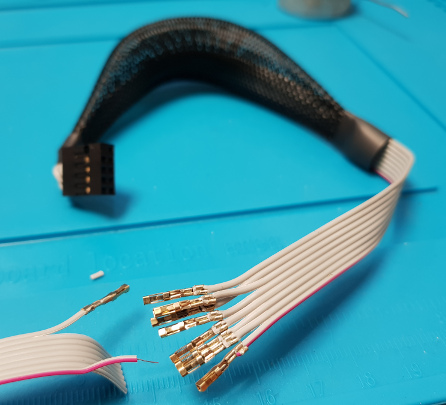

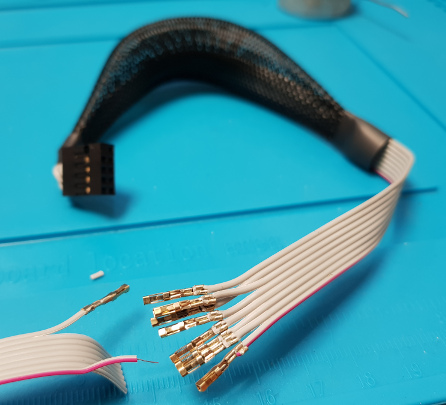

Module came with an internal USB header (eSATAp ports also carry USB - you can plug a USB device or eSATA device) but it was too long and ugly. Cut it down and then found out just how thin the wire is! It's 0.2mm but at least it's solid not stranded....or you could argue that it is stranded, but just one of 'em! So these crimps were a joy to do. Used the Engineer (brand) crimps again that do just one pair of wings at a time....fiddly but they do get a decent connection.

And here we are. That's two SATA, one floppy power (which needed making up) and one cable carrying a pair of USB channels. You can see why I didn't want this slung in the bottom PCIE slot, right?

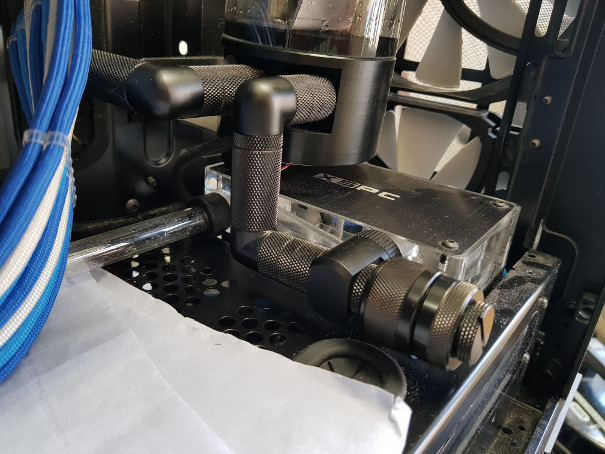

Next was to find out whether the door still shut....since the right-angle bend that returns from the rad sits in that cut-out at the back of the lower edge of the case. It did....but there wasn't much in the way of clearance!

About as soon as this was back together, my wife declared that the office needed to be a different layout. It all looks lovely now but because of the layout changes, the window of the PC is now pretty much obscured by her PC (shared home office) so you've got to question whether it was worth the time to do it without making it look ugly. Ah well.

Might get round to sleeving an ATX extension so that you might call things "finished"....as much as they ever are!

Well done for getting away with it!

Well done for getting away with it!