Washer Modded Lapped Result

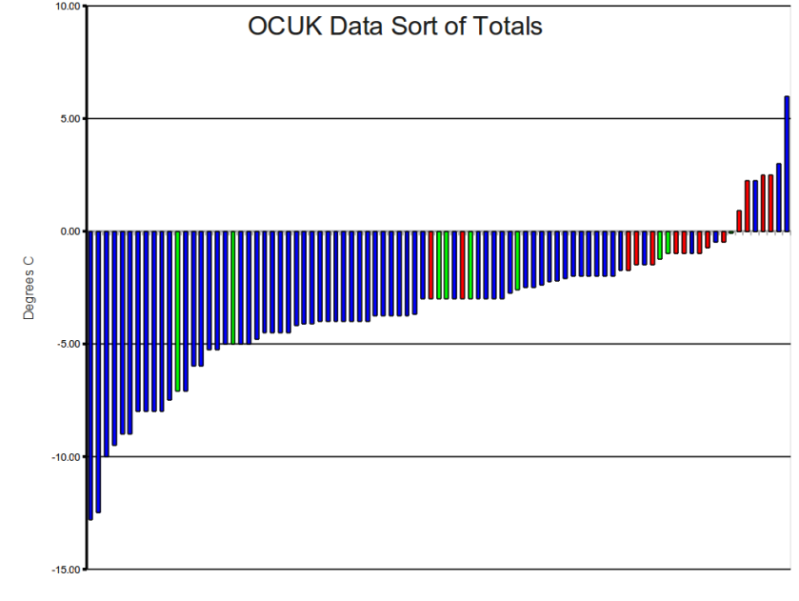

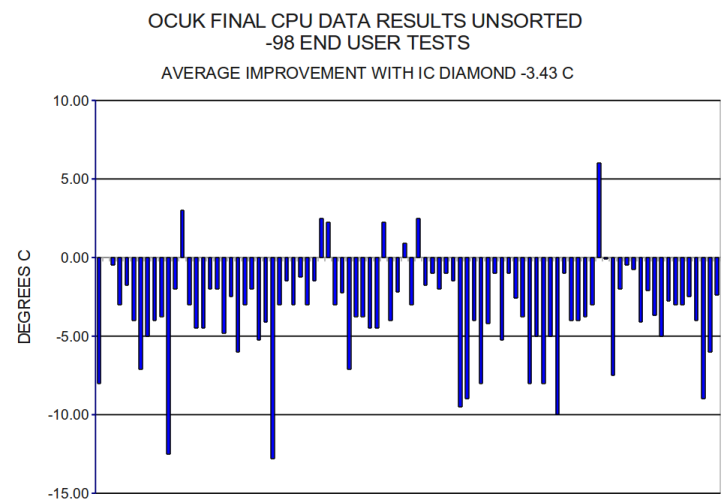

Thanks for emailing the results

. They are in my opinion very good results and huge improvement over previous contact/pressure results

I have rotated the image orientation based on previous results in which the upper and lower surface had more pressure. I think this would make sense as all the previous contact tests have given the same impression.

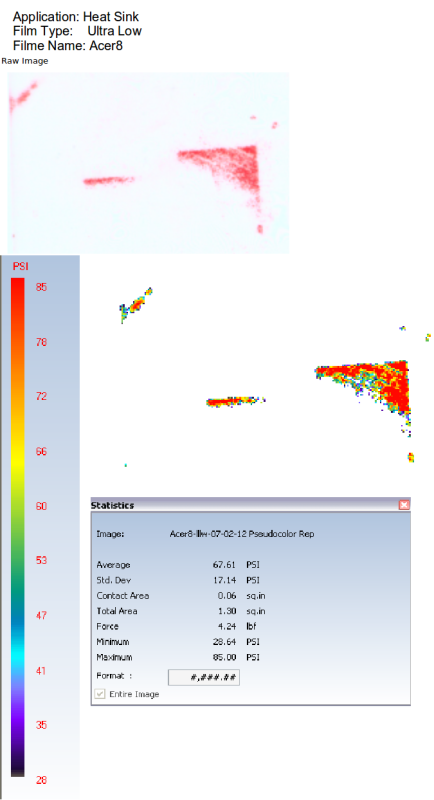

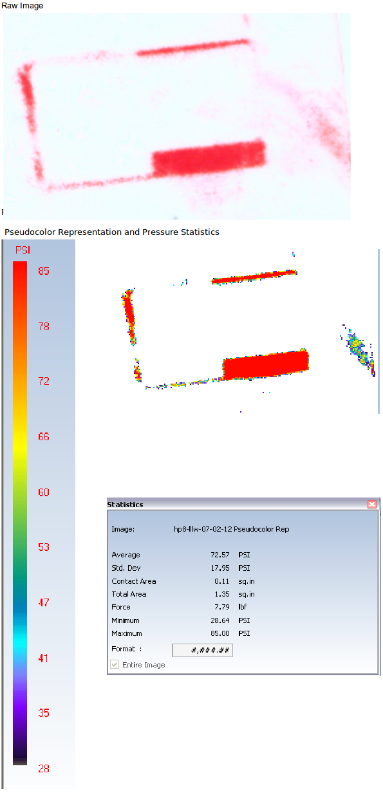

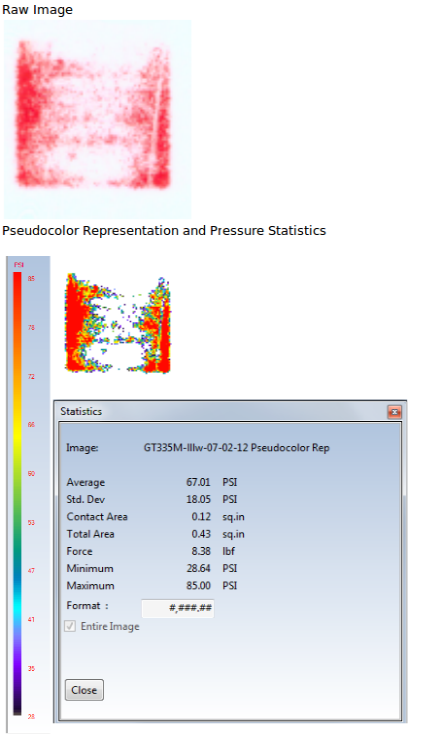

Raw Image

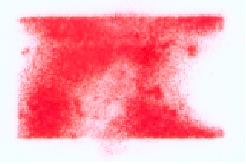

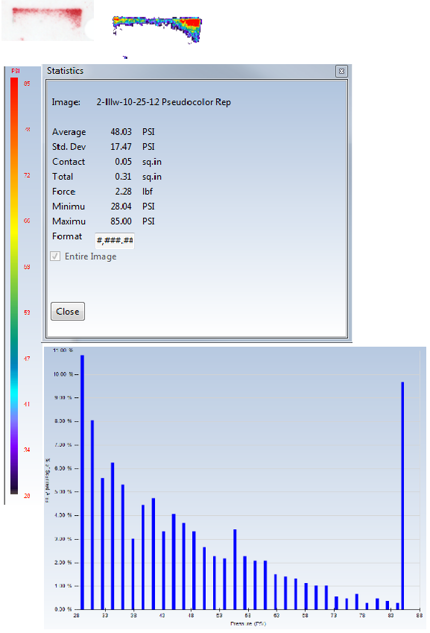

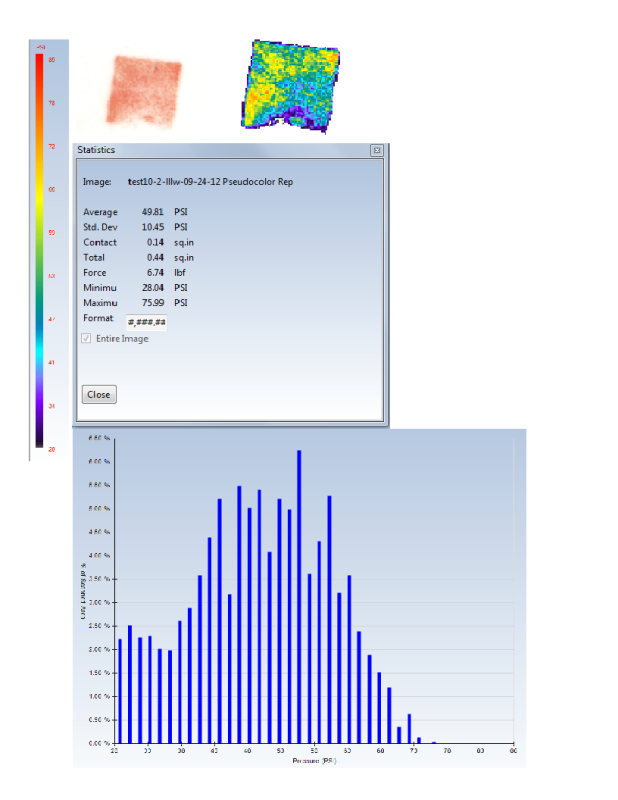

Pseudo Colour Representation and Pressure Statistics

Please resize image to a maximum 1024 pixels wide!

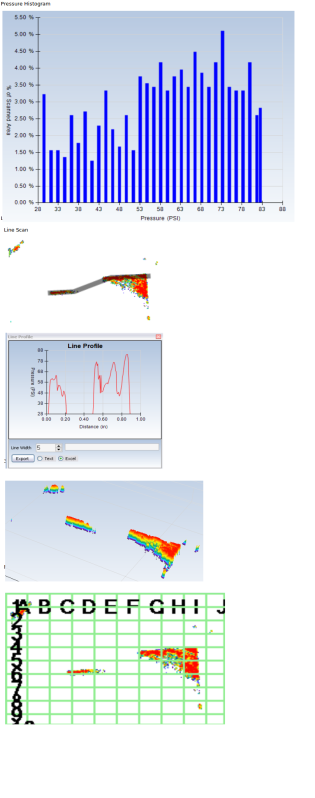

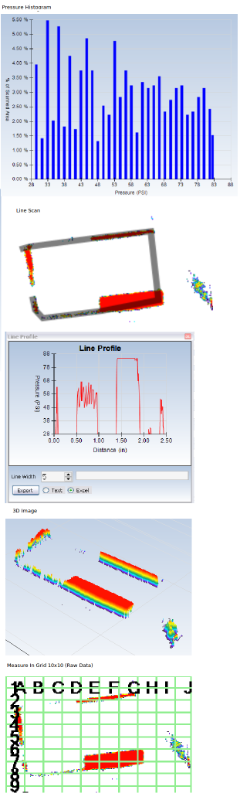

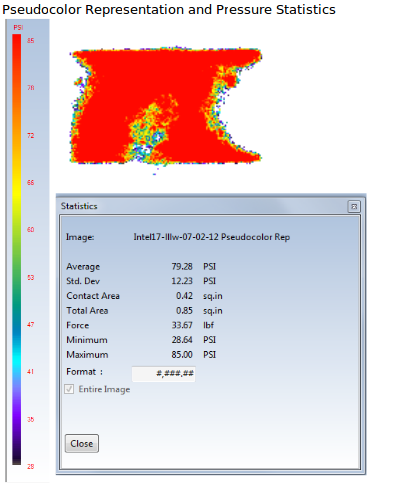

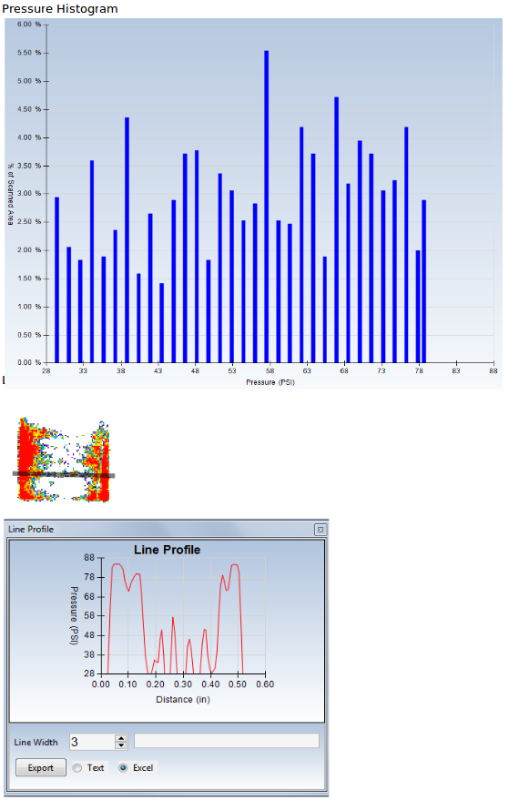

Pressure Histogram

Please resize image to a maximum 1024 pixels wide!

Line Scan

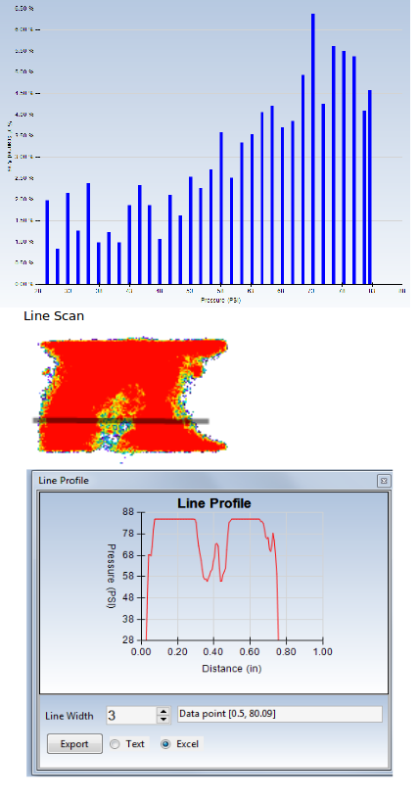

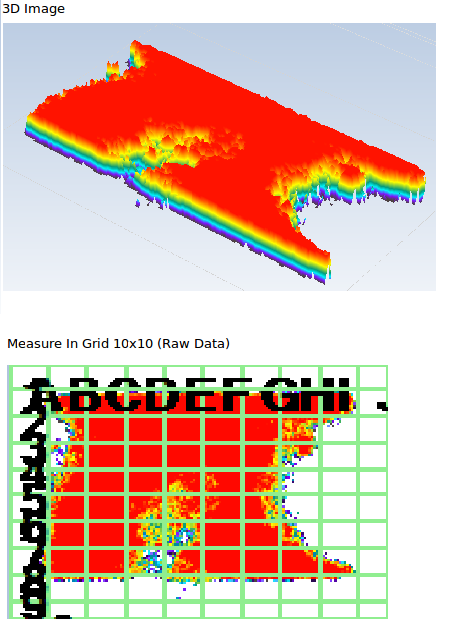

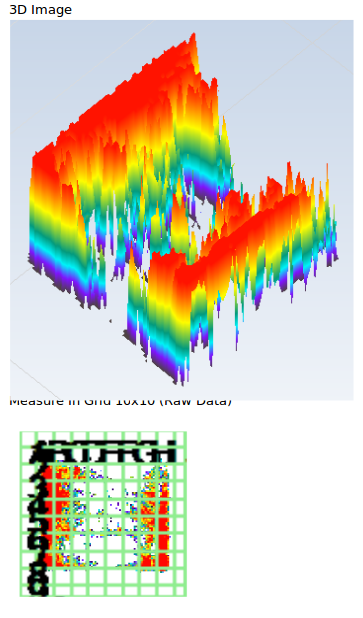

3D Image

Measure in Grid 10x10 (Raw Data)

First of all looking at pressure statistics I am very glad that my calculated estimate of contact area is very close to the

actual contact area of 0.97sq.in. Although there are anomaly contact impressions such as finger impressions, they shouldn't really affect the overall result as they are tiny and very few.

The rough measurement of the better pattern is 2.7cm x 2.3cm = 6.21cm^2 = 0.963 sq.in

Now in my case and as seen in earlier post, I found the total IHS area to be 1.215 sq.in:

I roughly measured Q6600 IHS (lapped square part that makes contact with heatsink) and it is 2.8cm x 2.8cm = 7.84cm^2 = 1.215 sq.in

In this regard overall contact is close to 80%.

However IC Diamond you stated the dims of 30mmx30mm. In that case overall IHS surface area will be 1.395sq.in.

So overall contact is close to 0.97/1.395 = 69.5% or 70% (round off)

So depending on the definition of IHS measurements, we are looking at the overall contact to be in the region of 70-80%. This I believe is excellent

Moving on, the

overall average mounting pressure of 71.92PSI is again an excellent news. I was hoping that with all the previous efforts, the mounting pressure would atleast increase to 70PSI. Such difference from previous raw lapped mounting pressure of 53.58PSI.

The

mounting force has also increased drastically to 69.56lbf (70 lbf round off) from previous results where for the raw lapped result, it was only 20.53lbf. So an increase of almost 50lbf!!

. I could definitely feel the resistive force of UNC spring screws.

From the pressure histogram it seems only about 27% of contact area is at 50PSI or below while the rest of contact area or 73% of it is at 50PSI and above.

The line scan, 3D image and grid pic all show that while the contact surface isn't perfectly smooth and hence some dips in pressure values across the surface, overall the pressure has increased significantly and in some regions reaching close to 80PSI+.

Again Contact/Pressure gets stronger as we move away from central position. As discussed previously I think the reasons why the pressure is weaker in central region is because:

1) The contact surface of both Cpu IHS and heatsink base is still not perfectly smooth. So we still have some areas of high and low regions. This suggests some further lapping preferably with belt sander.

2) As mounting force and pressure have increased drastically, this tends to warp the motherboard even though the bracket mounts and backplate movement has been 'fixed' or stopped. This was actually seen aswell once I fully tightened the IFX-14. However if this is good thing in increasing pressure, then so be it.

However looking at the 3D image, it is evident that mounting pressure in majority of central contact area is in the region of 66-85PSI. This is still very good.

To summarise:

Original Unlapped Pattern

-Average Mounting Pressure: 69.90PSI

-Contact Area: 0.55sq.in

-Mounting Force: 38.68lbf

Lapped Pattern

-Average Mounting Pressure: 53.58PSI

-Contact Area: 0.38sq.in

-Mounting Force: 20.53lbf

Washer Modded Lapped Pattern

-Average Mounting Pressure: 71.92PSI

-Contact Area: 0.97sq.in

-Mounting Force: 69.56lbf

All in all I am very glad with the latest results and with my PC system which has been able to facilitate improved contact/pressure/force. I think as an end-user it has been a magnificent experience learning about the whole process. Certainly as seen, to obtain the lapped pattern required several optimizations of the mounting system and this itself has been a challenging job. IFX-14 definitely has one of the least friendly mounting system and coupled with uneven Q6600 IHS, the cooling performce of my PC would have been severly restricted had I not learnt about improving the cooling further.

The thermal compounds can do rest of the job of filling in the uneven spaces. Of course with belt sander, results will improve certainly with regard to contact but that's for another day